Unconstrained hydraulic amplification electrostatic self-driven rolling type robot

A hydraulic amplification and robot technology, which is applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of huge mass and volume, difficult to achieve efficient operation, low driving force, driving efficiency and driving power, and achieve low manufacturing cost. , high power density, easy to manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A hydraulically amplified electrostatic self-propelled rolling robot of the present invention will be described in detail below with reference to the embodiments and accompanying drawings.

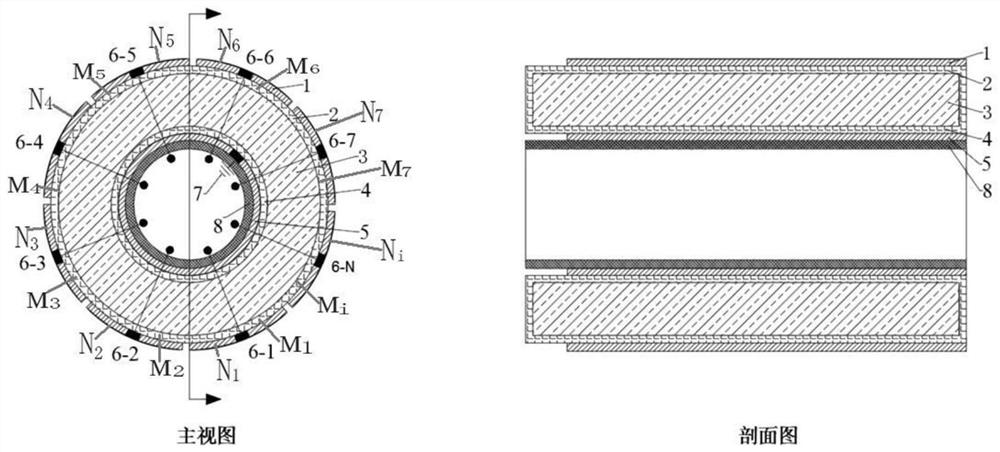

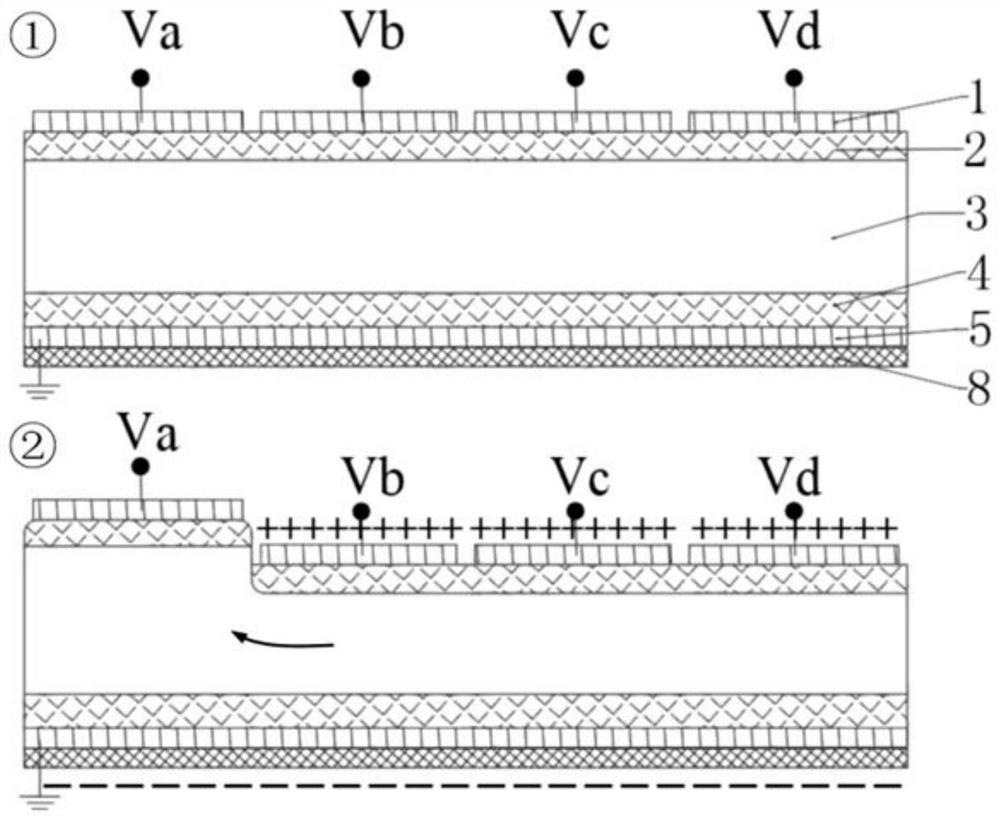

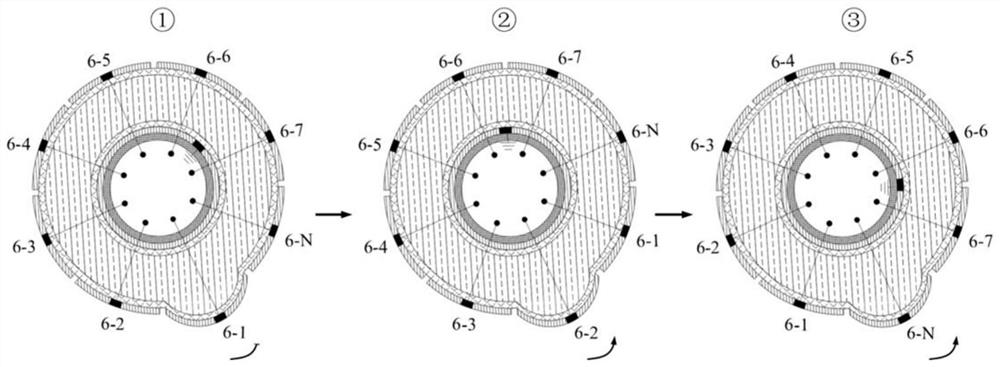

[0018] Such as Figure 1 to Figure 3 As shown, an unconstrained hydraulic amplified electrostatic self-propelled rolling robot, including N outer flexible electrode layer 1, inner flexible electrode layer 5, outer elastic layer 2, inner elastic layer 4, inner liquid dielectric layer 3 and rigid inner Frame 8, the inner flexible electrode layer 5 is arranged outside the rigid inner frame 8, the inner elastic layer 4 is arranged outside the inner flexible electrode layer 5, the inner liquid dielectric layer 3 is arranged outside the inner elastic layer 4, and the outer elastic layer 2 is arranged on the inner liquid dielectric Outside the layer 3, N outer flexible electrode layers 1 are evenly attached to the outer surface of the outer elastic layer 2 with a gap distance l; the inner fle

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap