Automatic production equipment for power module

A power module and production equipment technology, applied in the field of power module automatic production equipment, to achieve the effects of improving uniformity and consistency, conveniently fixing positioning nails, and reducing the probability of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

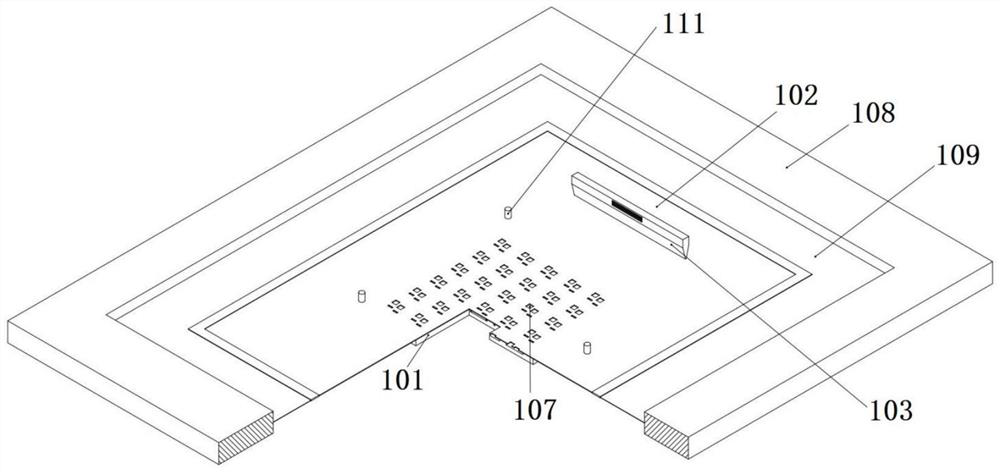

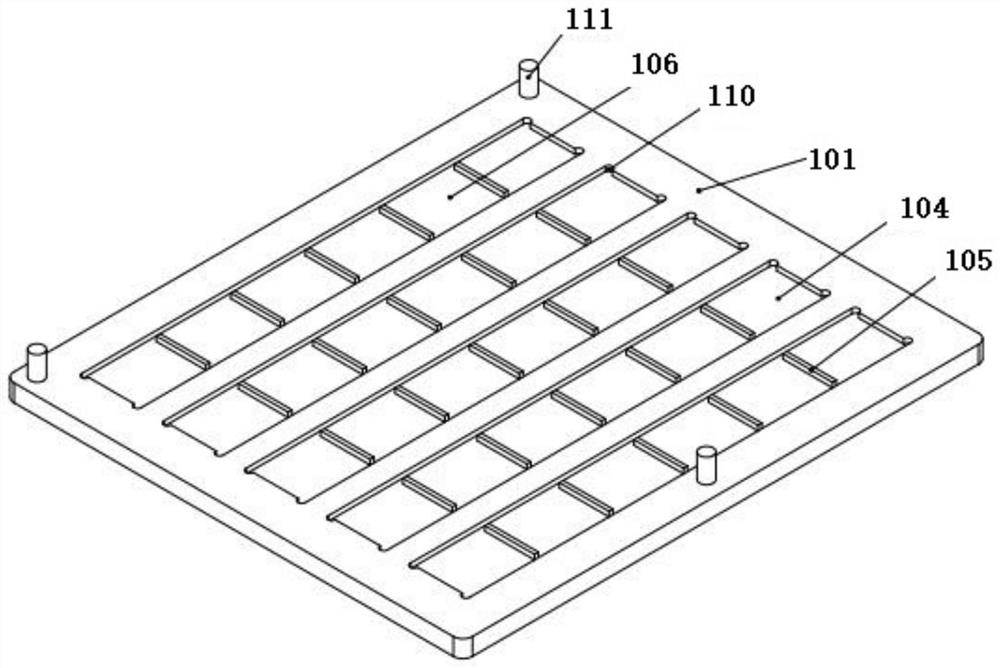

[0038] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

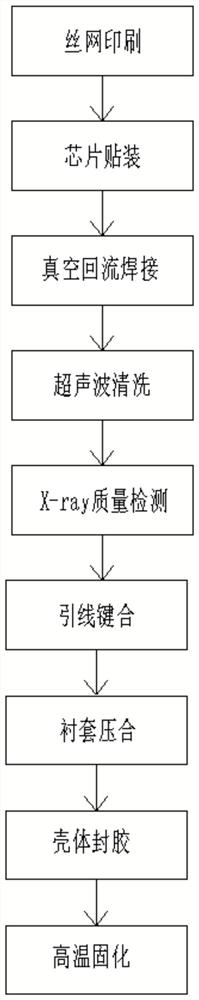

[0039] Such as Figure 1-14 As shown, an automatic production equipment for power modules, including a screen printing machine, an automatic placement machine, a vacuum reflow welding machine, an ultrasonic cleaning machine, an X-ray testing machine, an automatic wire bonding machine, and a laser marking machine connected in sequence , bushing pressing machine, shell filling machine, and high-temperature curing machine; among them, the screen printing machine uses the solder paste setting graphics to print on the surface of the DBC copper plate, making preliminary preparations for the subsequent automatic placement, in order to improve the tin For the efficiency of past

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap