Method for preparing adhesive solution in wet granulation process

A binder solution, wet granulation technology, applied in the field of pharmacy, can solve the problems of complex binder components, difficult realization of clear solution, poor water solubility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

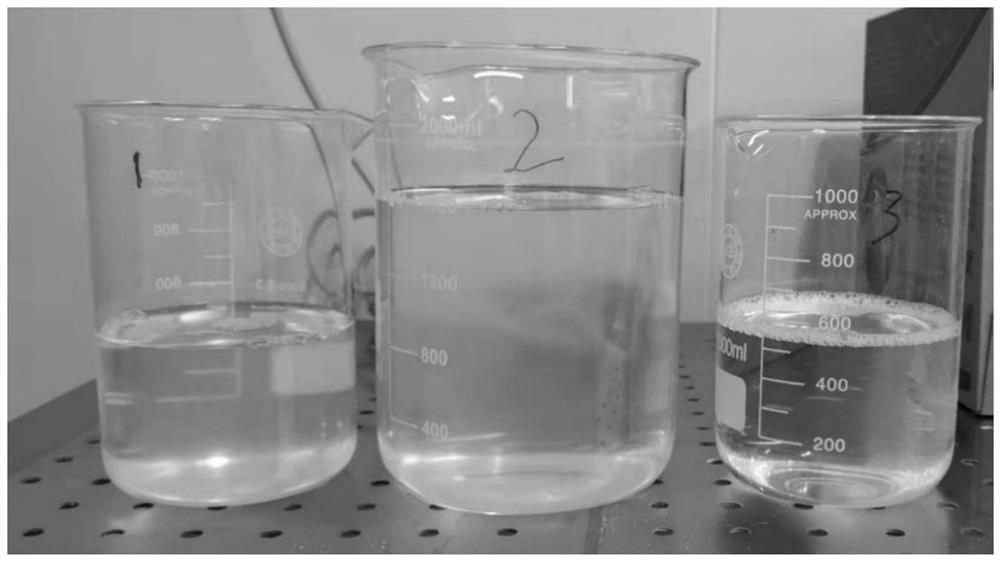

[0036] It is weighted 450 g of purified water, and the purified water is stirred to form a vortex, weigh 25.4 g of the poloxham P407, and the stirred water is slowly added, stirred to form a uniform transparent solution. The purified water of 25 g was added, 0.7 g NaOH was added, stirred until dissolved. The aqueous sodium hydroxide solution was slowly added to a container containing a water solution of a water, and a beaker of the NaOH solution was dissolved with 25 g of water, and 17.4 g of glucamine was added, then 17.4 g of glucamine, continued to stir up and finally obtained a clear clear clarification. Solution (see figure 1 3 cups).

Embodiment 2

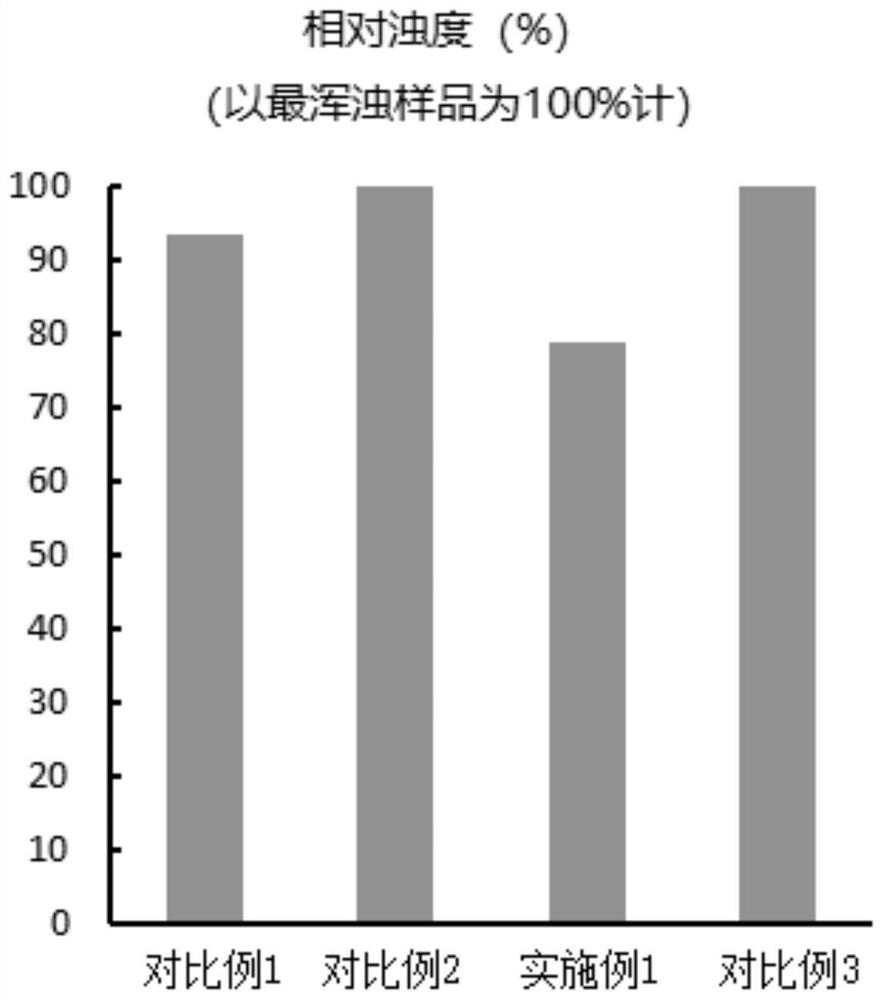

[0039] Example 2 Comparison of clarity

[0040] The solution obtained from the Solution 1, 2, 3 and Example 1 was placed in the absorbent tank of the spectrophotometer, and the absorbance was determined at 550 nm, and the results were shown in Table 1 and image 3 .

[0041] Table 1, 4 samples of ultraviolet visible light absorbance and relative turbidity at 550 nm

[0042]

[0043] The test results indicate that the solution obtained in Example 1 was crystal clear, and the difference was significant.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap