Apparatus for uniform flow distribution of gas in processing equipment

a technology of processing equipment and apparatus, which is applied in the direction of lighting and heating apparatus, muffle furnaces, furnaces, etc., can solve the problems of insufficient heating or cooling of the entire workpiece, insufficient use of gas at a uniform temperature in order to maintain the same temperature in all areas of the furnace, and increase in furnace operating expenses. , to achieve the effect of simple and economical manufacture and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

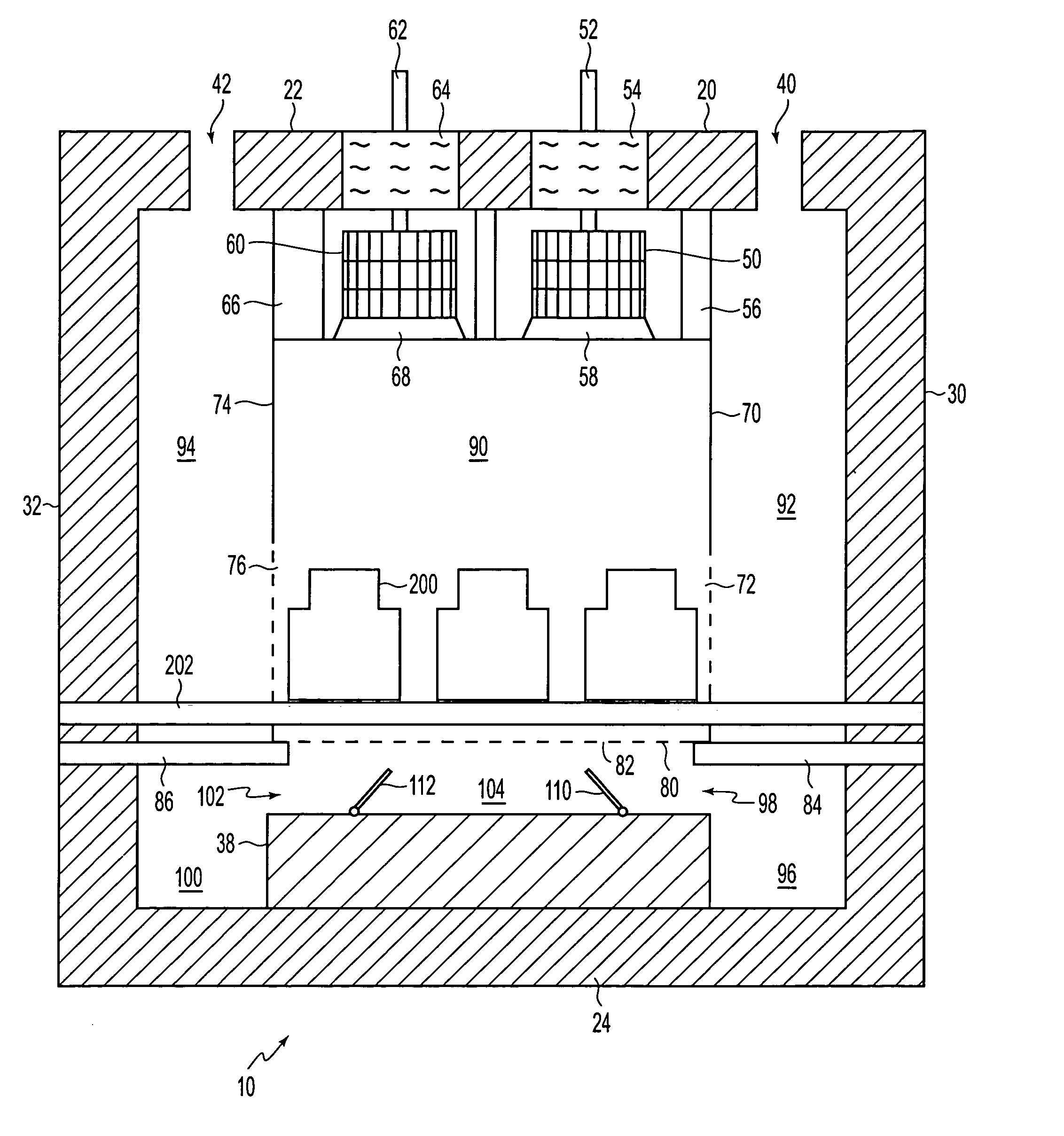

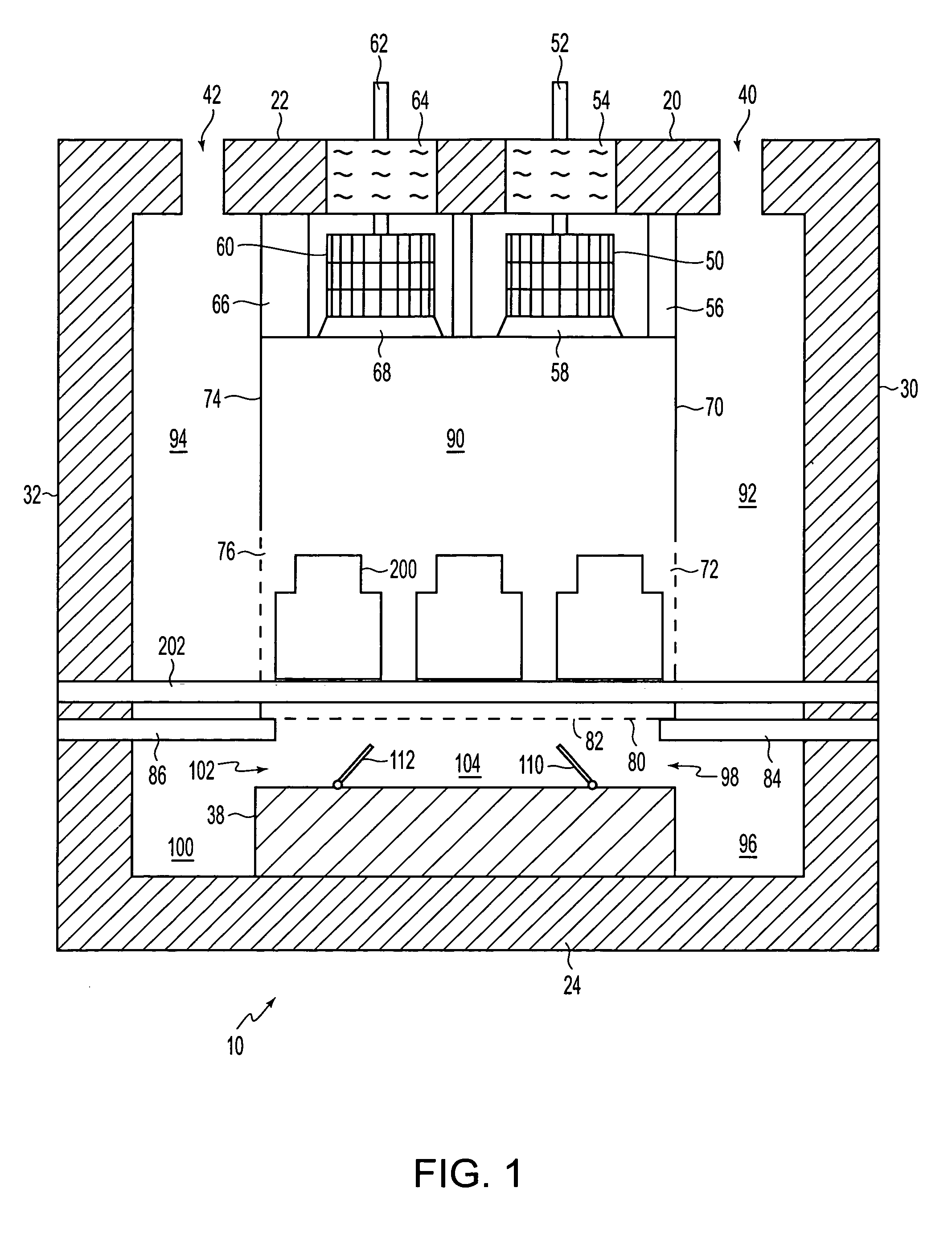

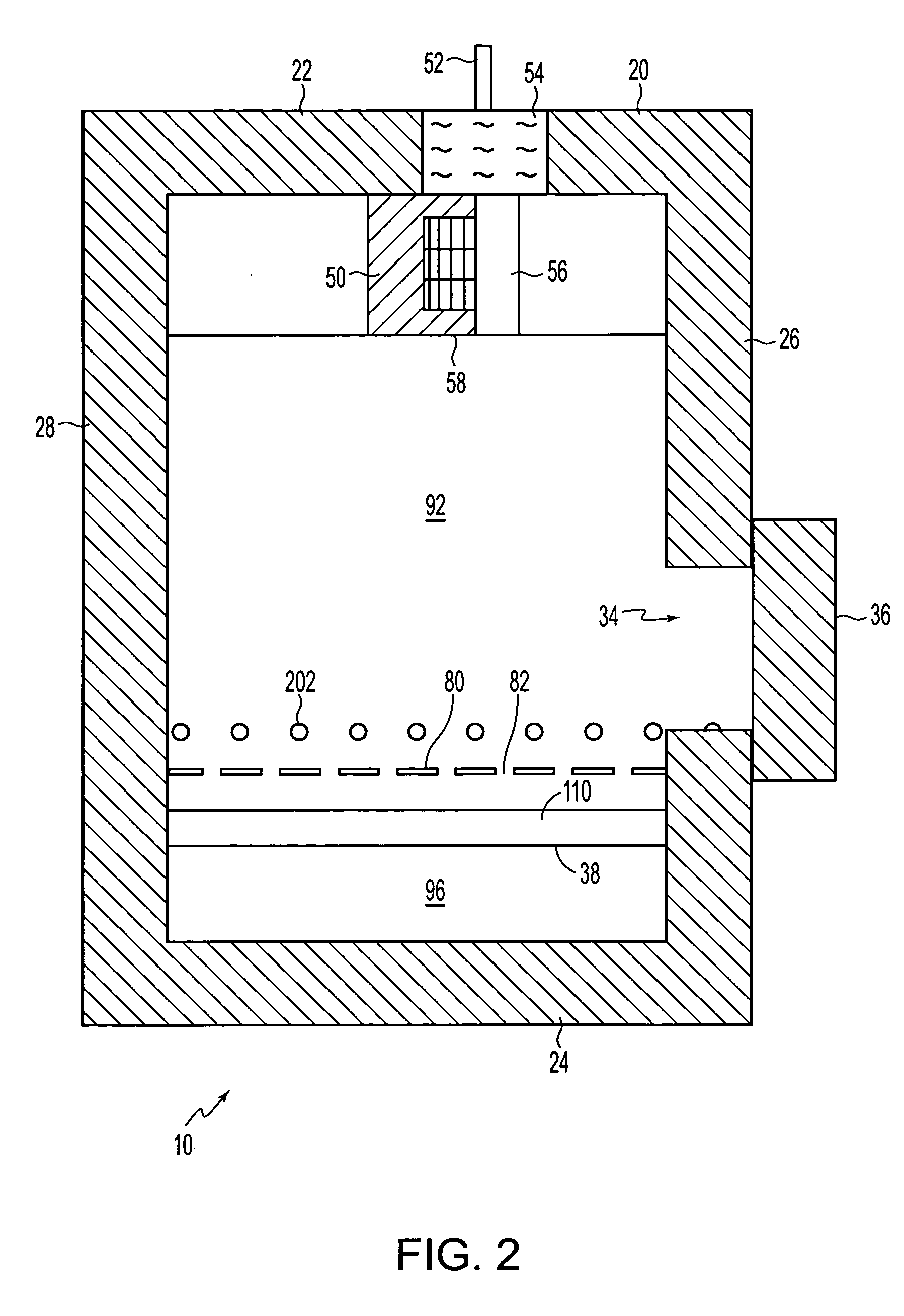

[0024] Referring now in detail to the drawings, there is illustrated in FIGS. 1-3, a furnace as an example of processing equipment. For simplicity and clarification, the operating principles and design factors of the invention are explained with reference to an embodiment of a furnace according to the invention, as shown in FIGS. 1-3. The basic explanation of the operation of the furnace shown in FIGS. 1-3 is applicable for the understanding and design of any processing equipment that incorporates the uniform flow systems and methods according to the invention.

[0025]FIGS. 1-3 show a batch type furnace 10, preferably of metal construction, with a layer of insulating refractory material on the interior to form an insulated enclosure 20. The enclosure 20 has a generally horizontal top wall 22 and bottom wall 24, a generally vertical front wall 26 and rear wall 28, and generally vertical side walls 30, 32. The front wall 26 is formed with a large entrance opening 34 which is adapted to be

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap