Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11 results about "Aero engine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

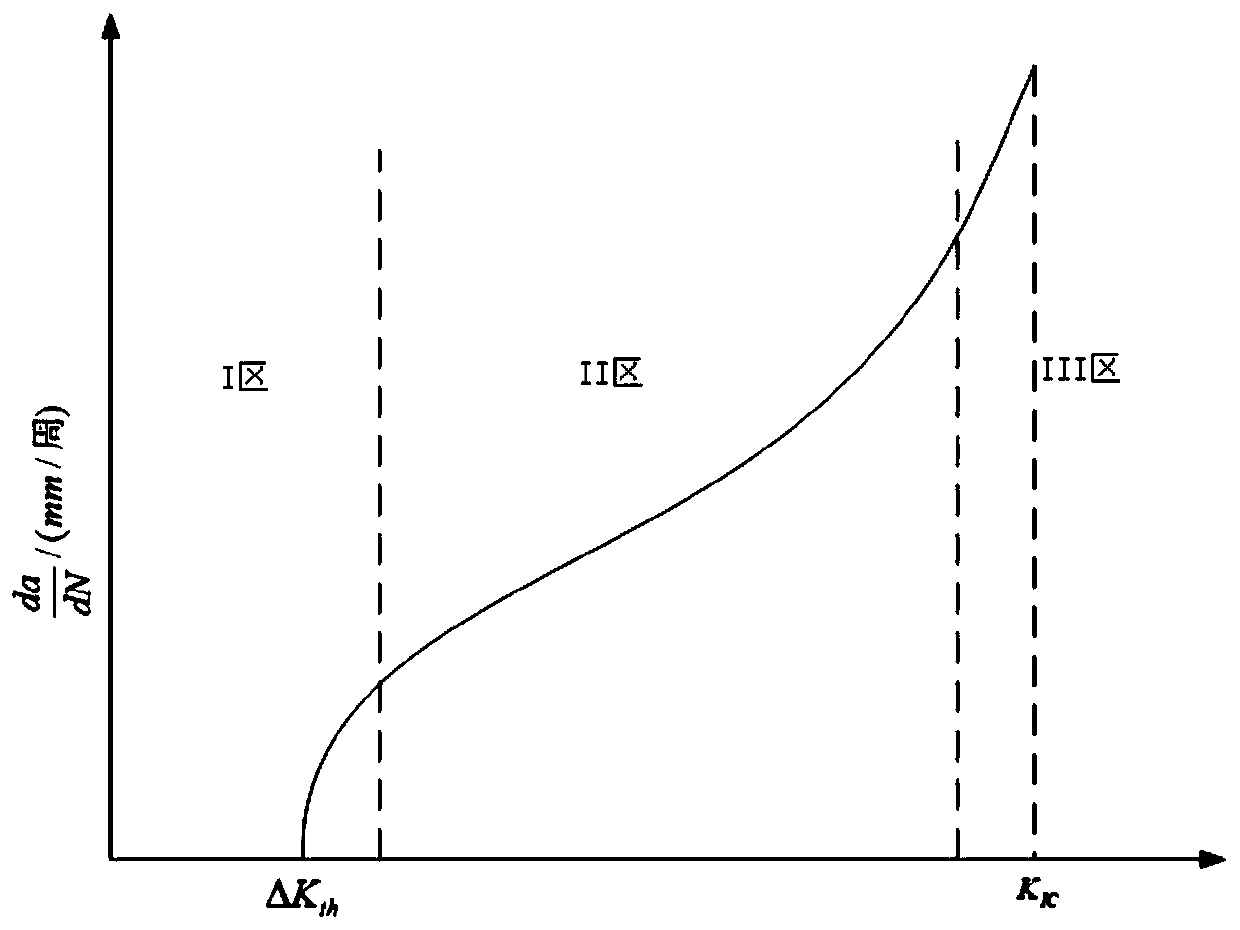

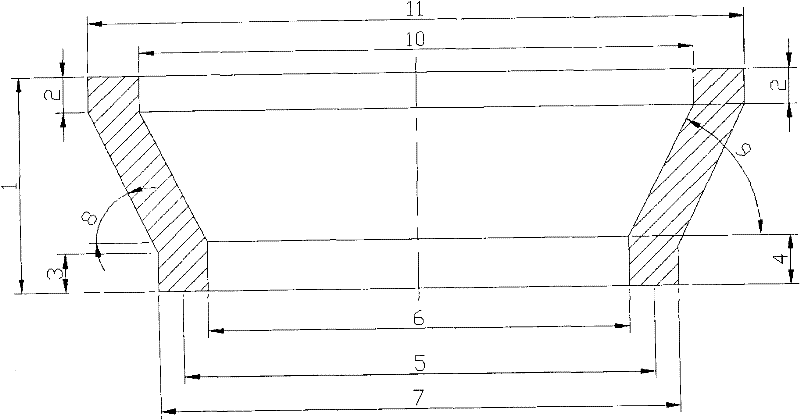

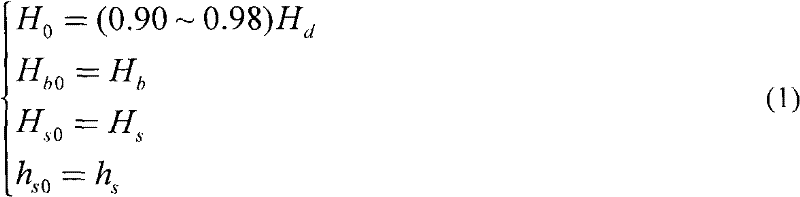

Aero-engine turbine blade reliability evaluation method based on fracture mechanics

InactiveCN110147618AAccurate lifeAccurate and reliableGeometric CADDesign optimisation/simulationReduced modelAviation

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Reverse flow combustor and double-wall elbow structure thereof

ActiveCN109974033AReduce peak wall temperatureHigh strengthContinuous combustion chamberCombustorCombustion chamber

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

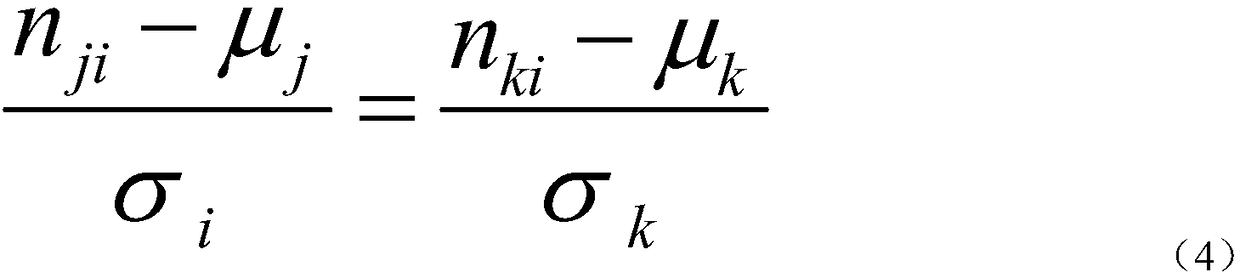

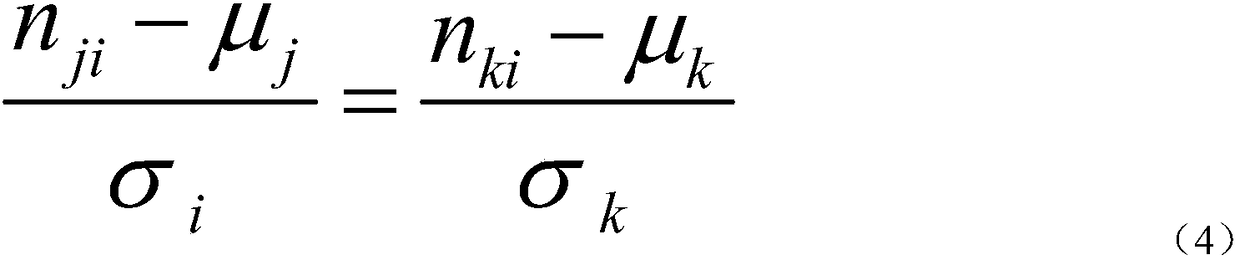

Test method for testing P-S-N curve of high-cycle fatigue of aero-engine material by small sample amount

Owner:上海航空材料结构检测股份有限公司

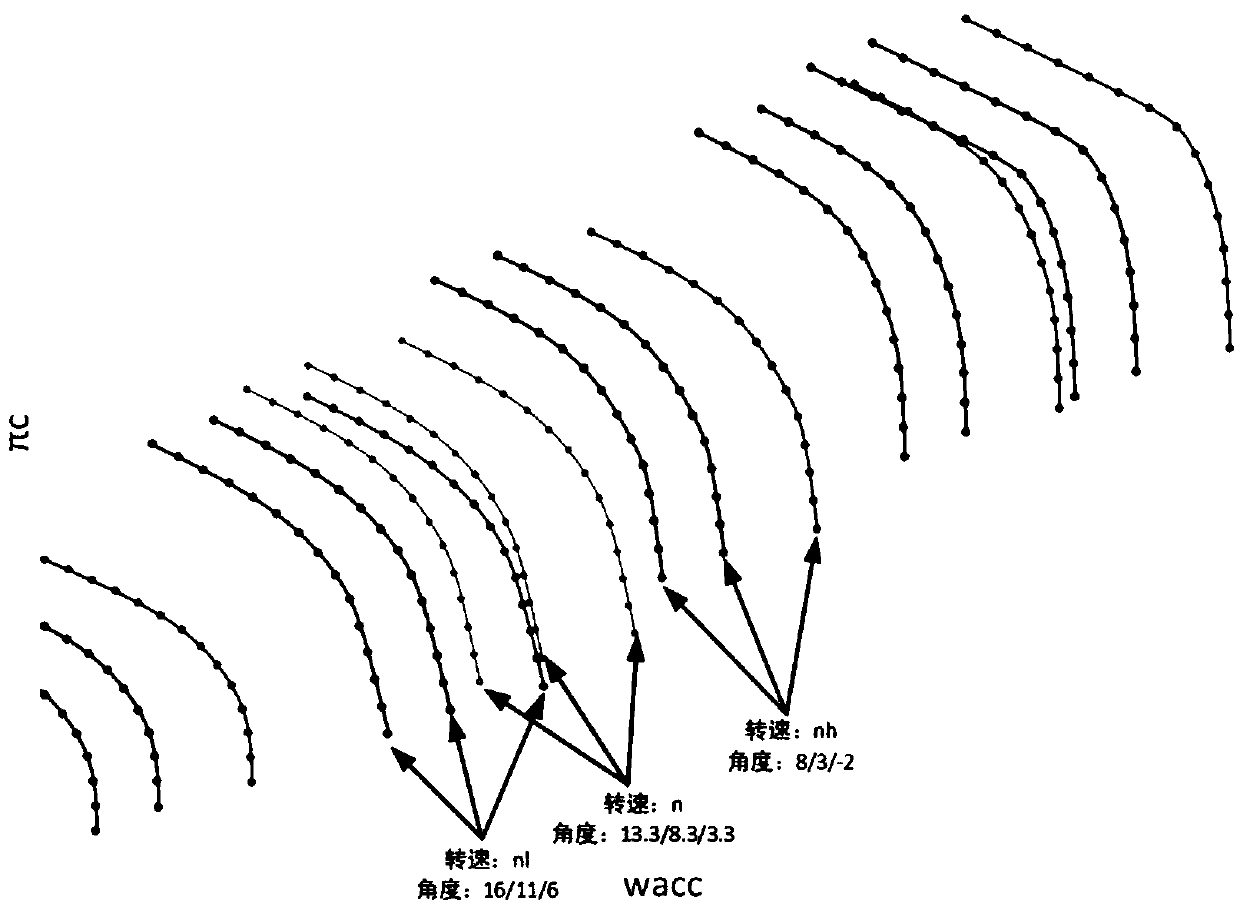

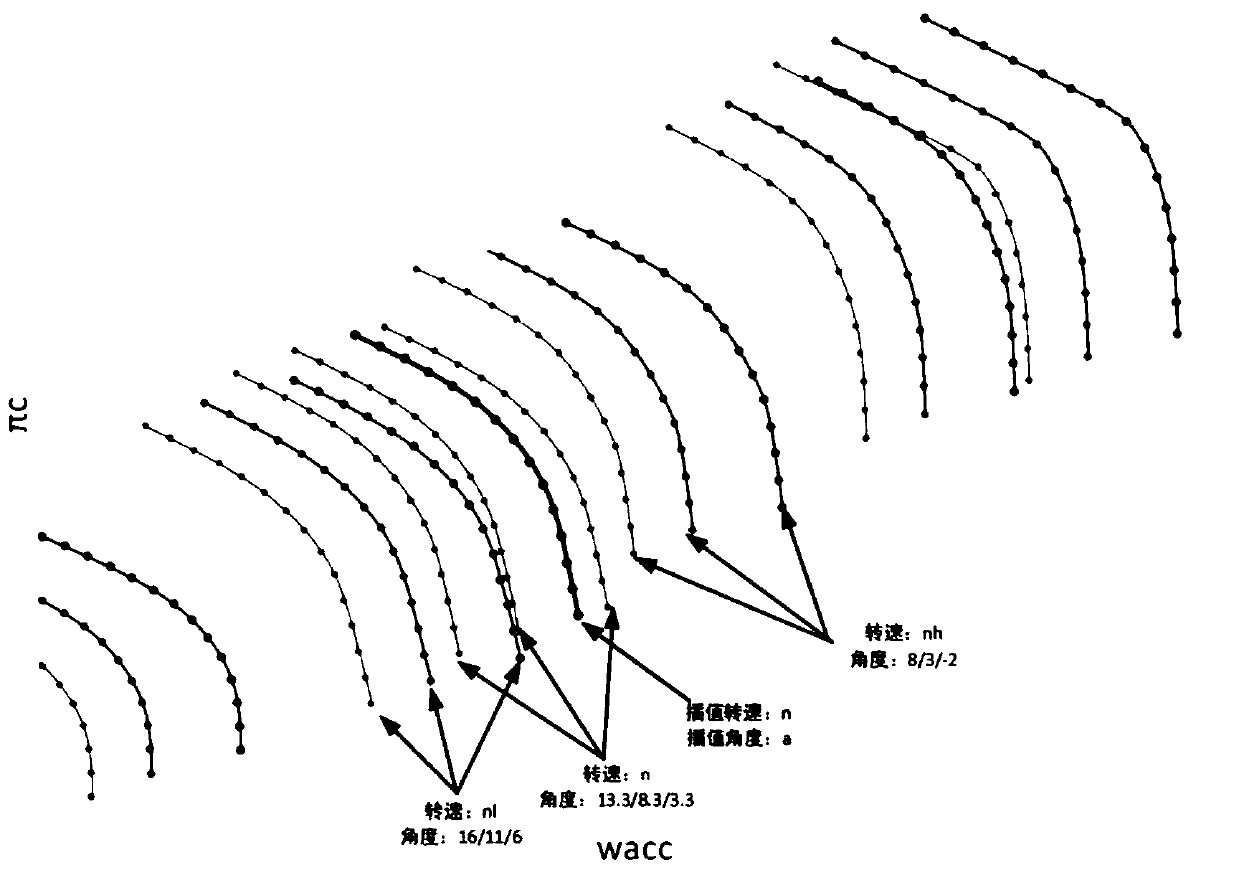

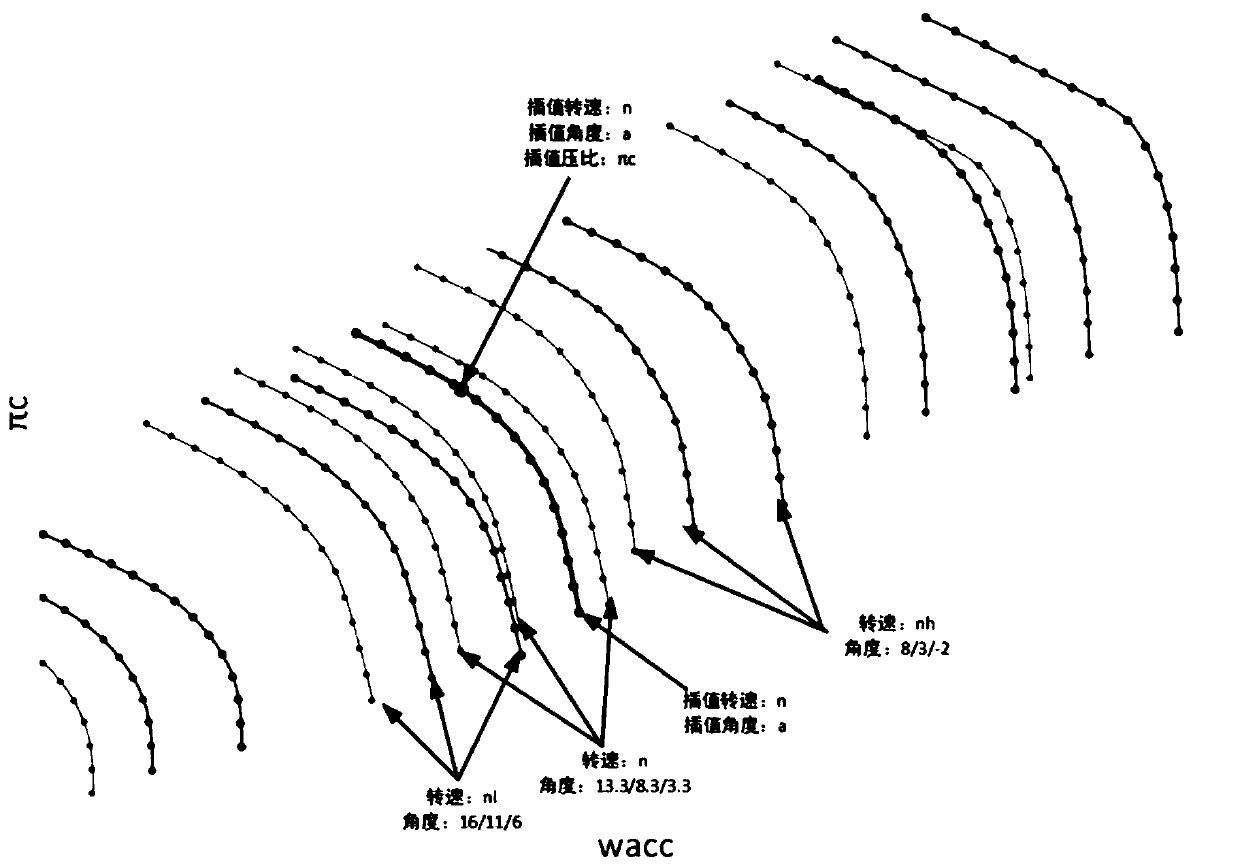

Interpolation method suitable for aero-engine real-time model

ActiveCN110489877AReduce computing timeSustainable transportationSpecial data processing applicationsAviationCurrent voltage

Owner:AECC SHENYANG ENGINE RES INST

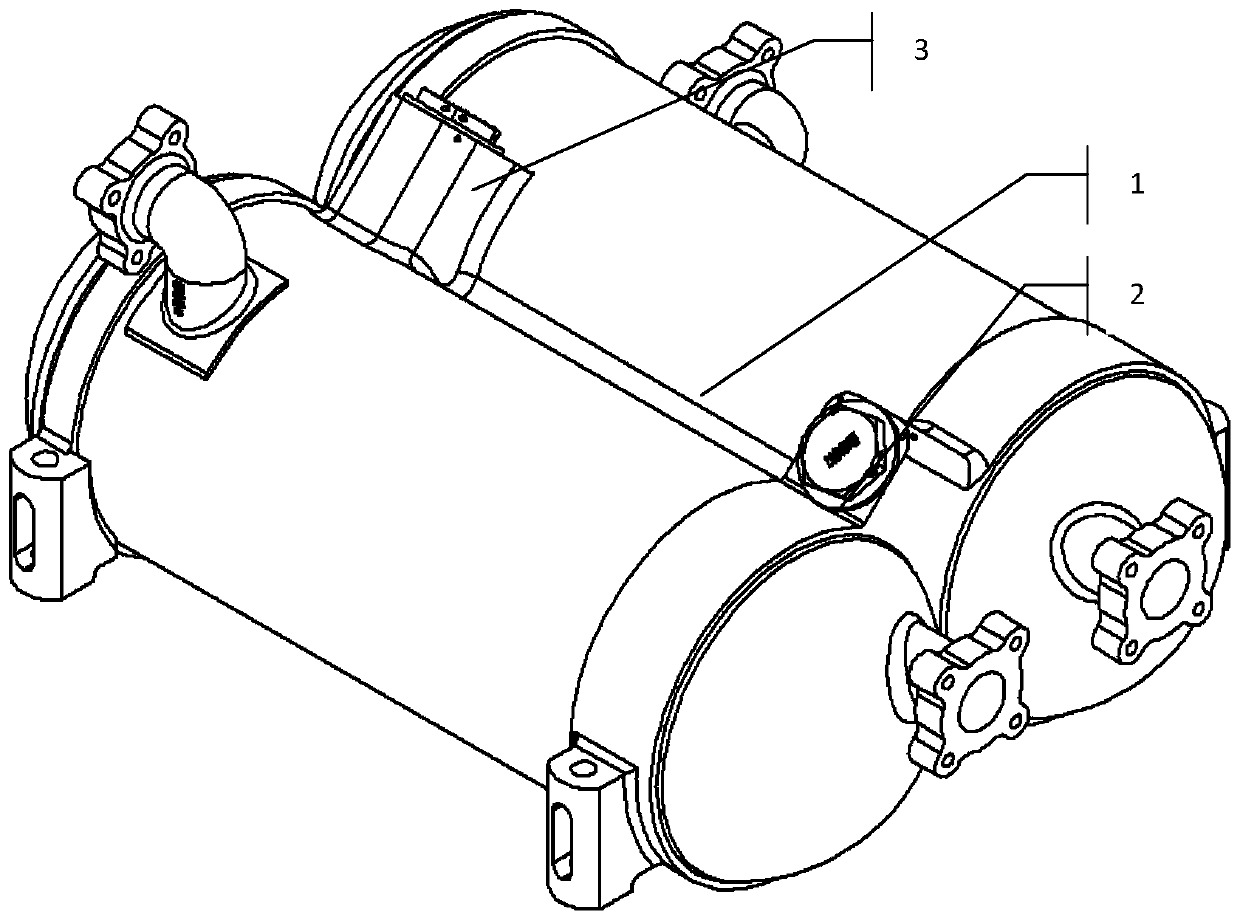

Aero-engine high-pressure fuel and grease heat radiator

InactiveCN110043342AGuarantee the safety of useReduce weightMachines/enginesThermal treatment of fuelModel engineHigh pressure

Owner:GUIZHOU YONGHONG AVIATION MACHINERY

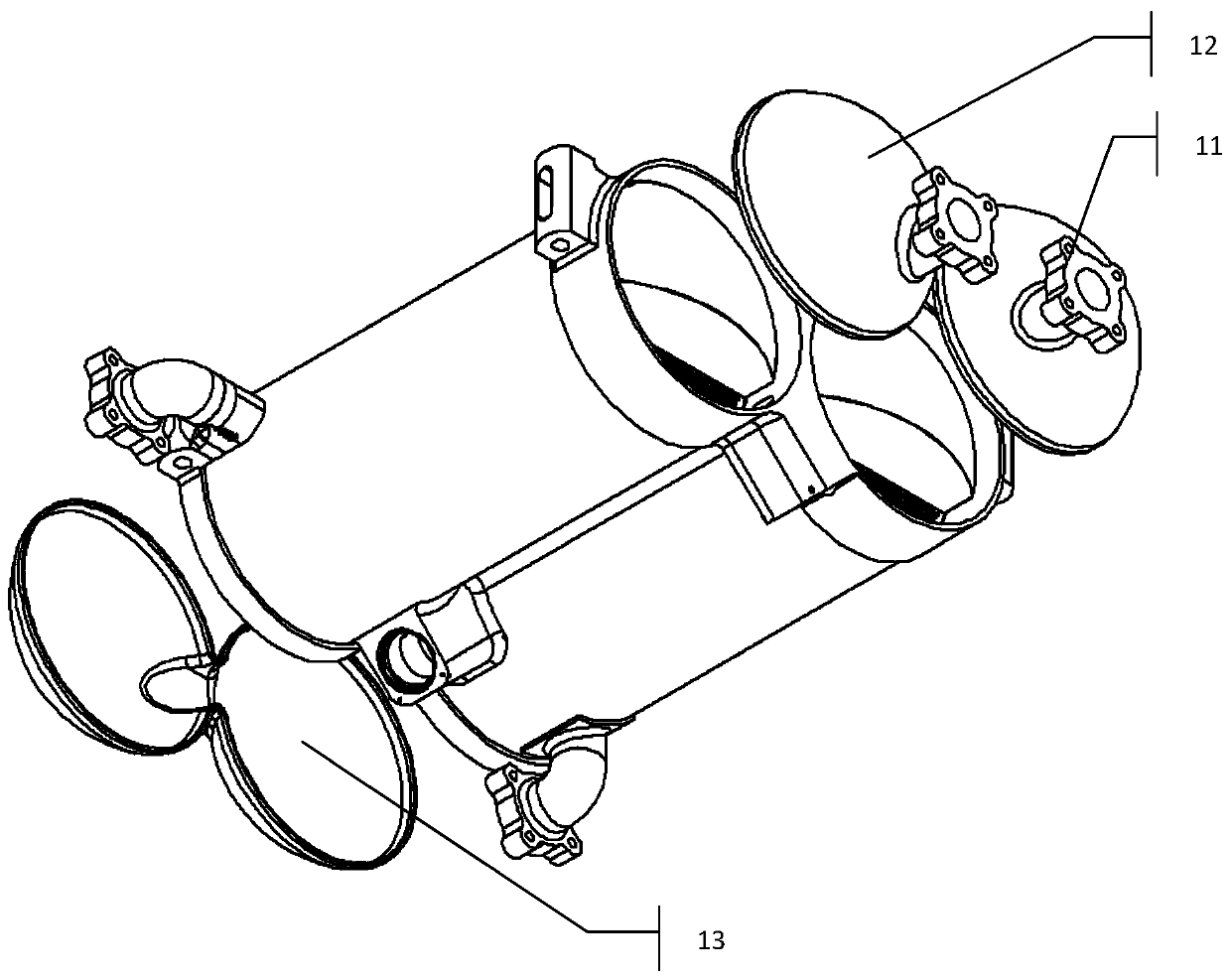

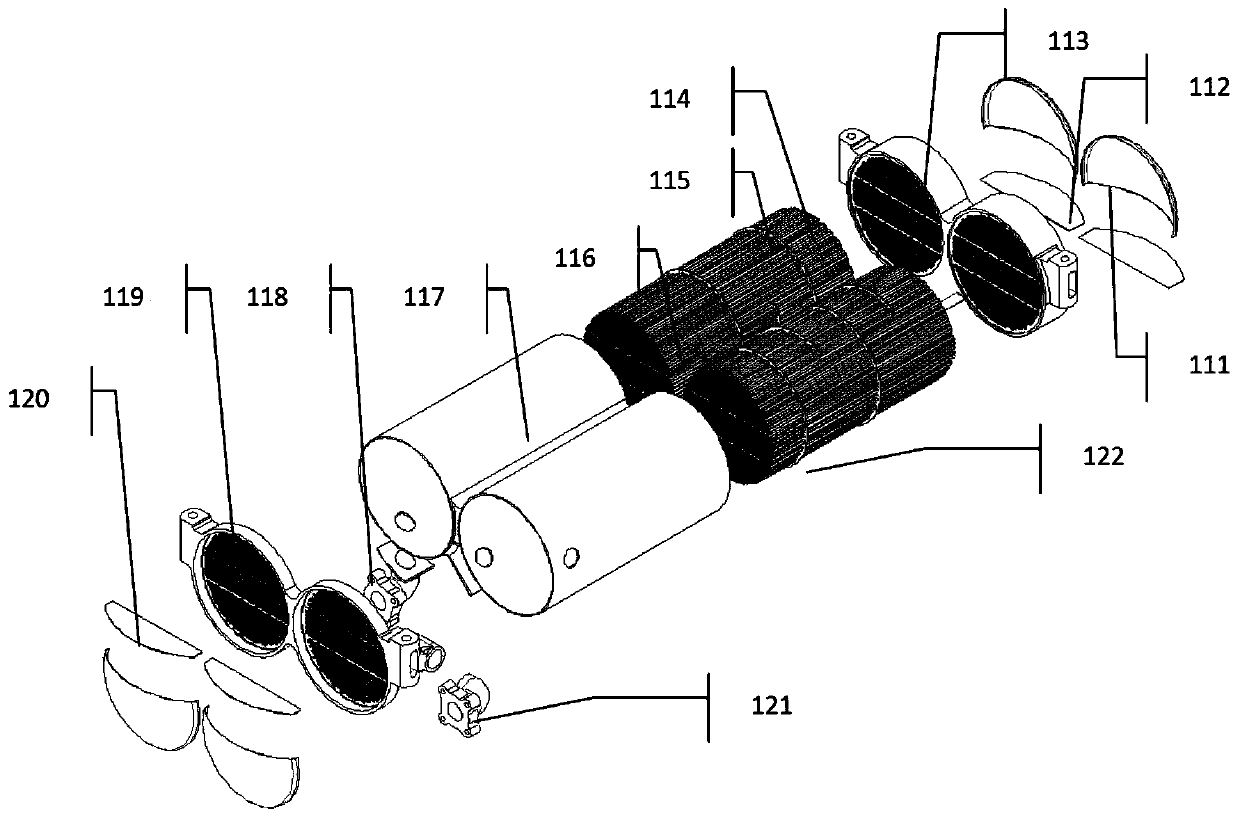

Manufacturing method for high-speed permanent magnetic rotor

Owner:HARBIN DONGAN ENGINE GRP

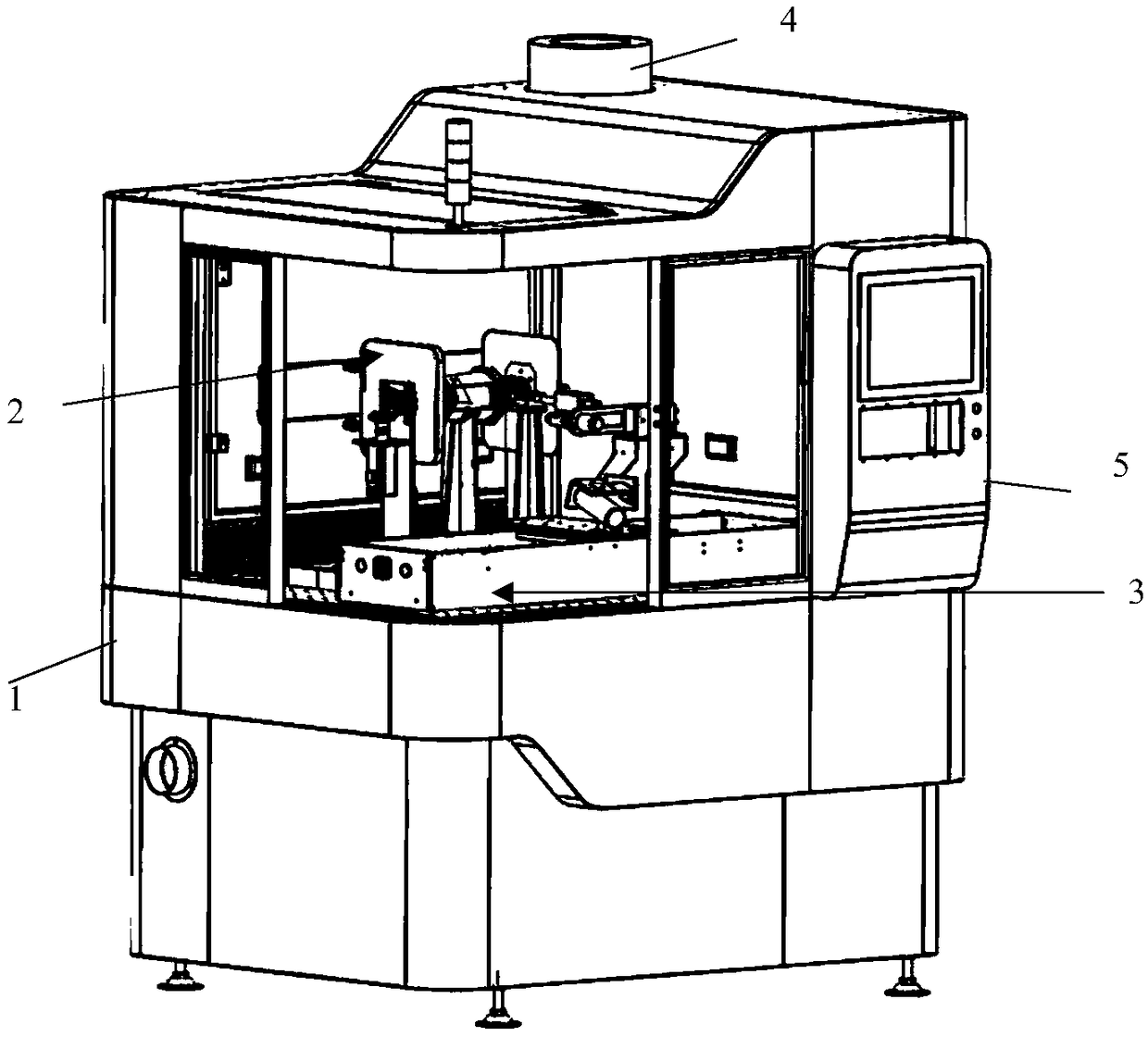

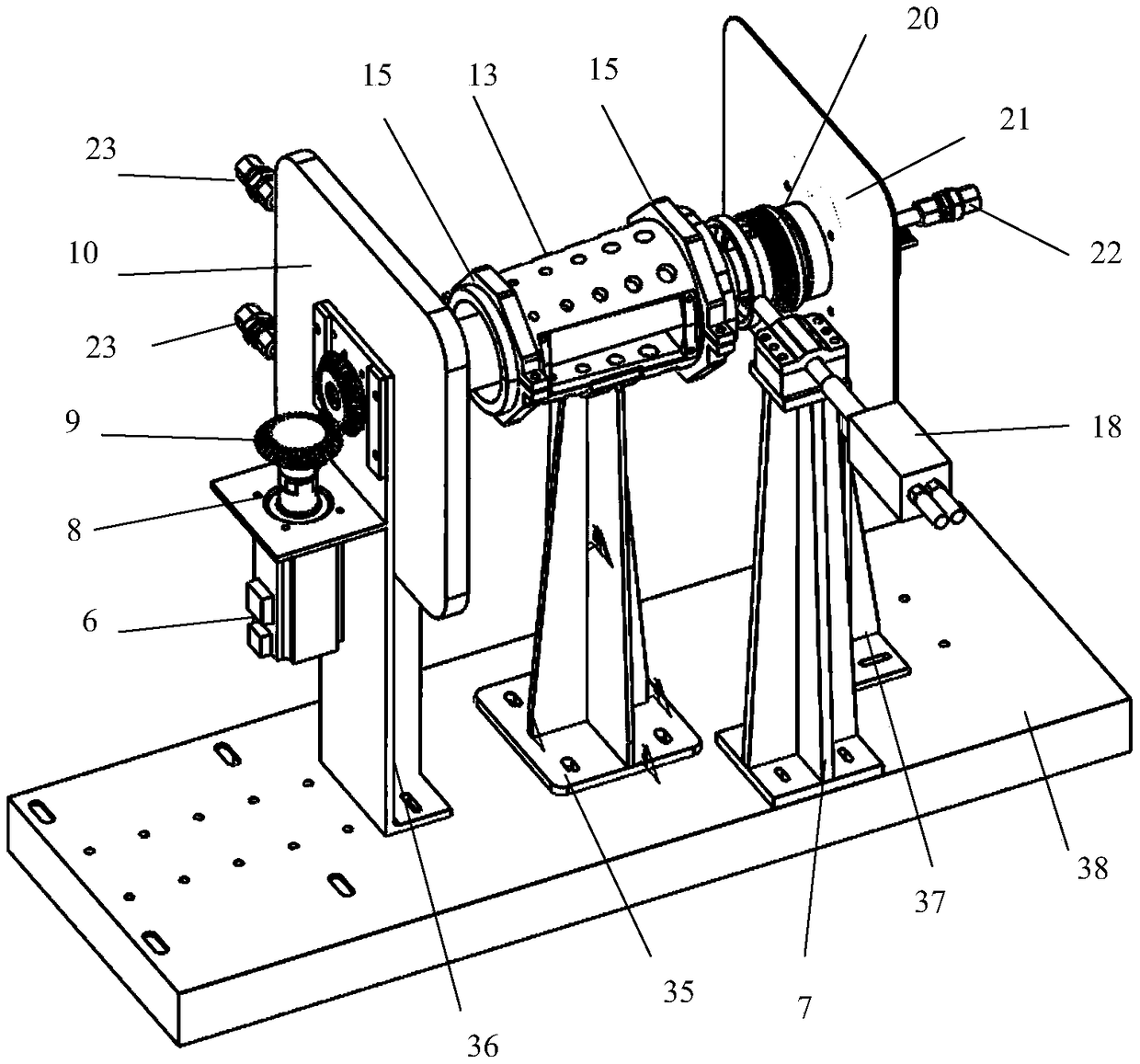

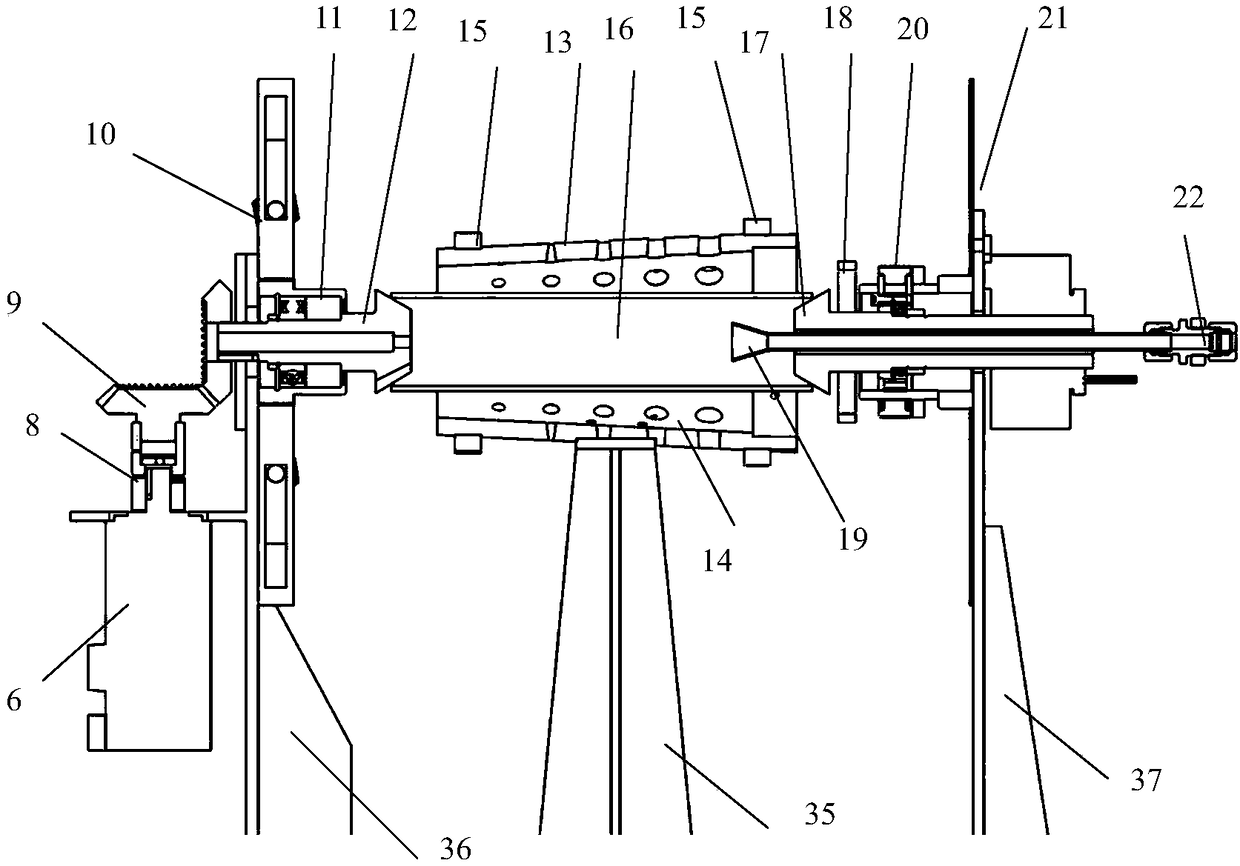

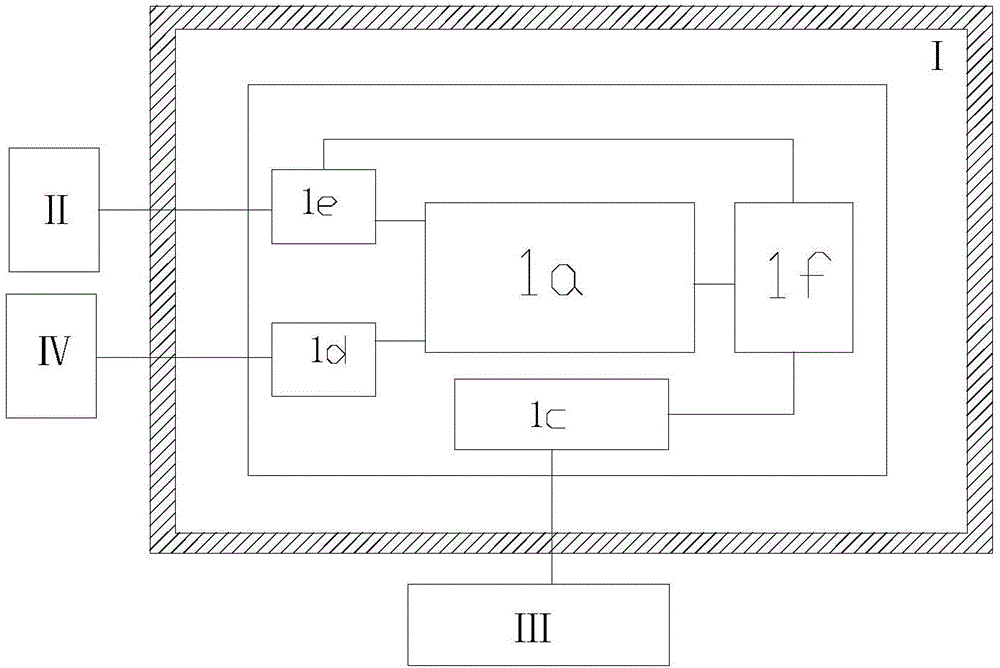

Steady-state-temperature-field-included simulation test bench of aero-engine combustor

InactiveCN109374308ALow costShort cycleGas-turbine engine testingJet-propulsion engine testingAviationSteady state temperature

Owner:CIVIL AVIATION UNIV OF CHINA

Aircraft engine test site digital bus control device

InactiveCN104568452AOvercome functional deficienciesGuaranteed uptimeEngine testingProgramme control in sequence/logic controllersAviationCommunication interface

Owner:HARBIN DONGAN ENGINE GRP

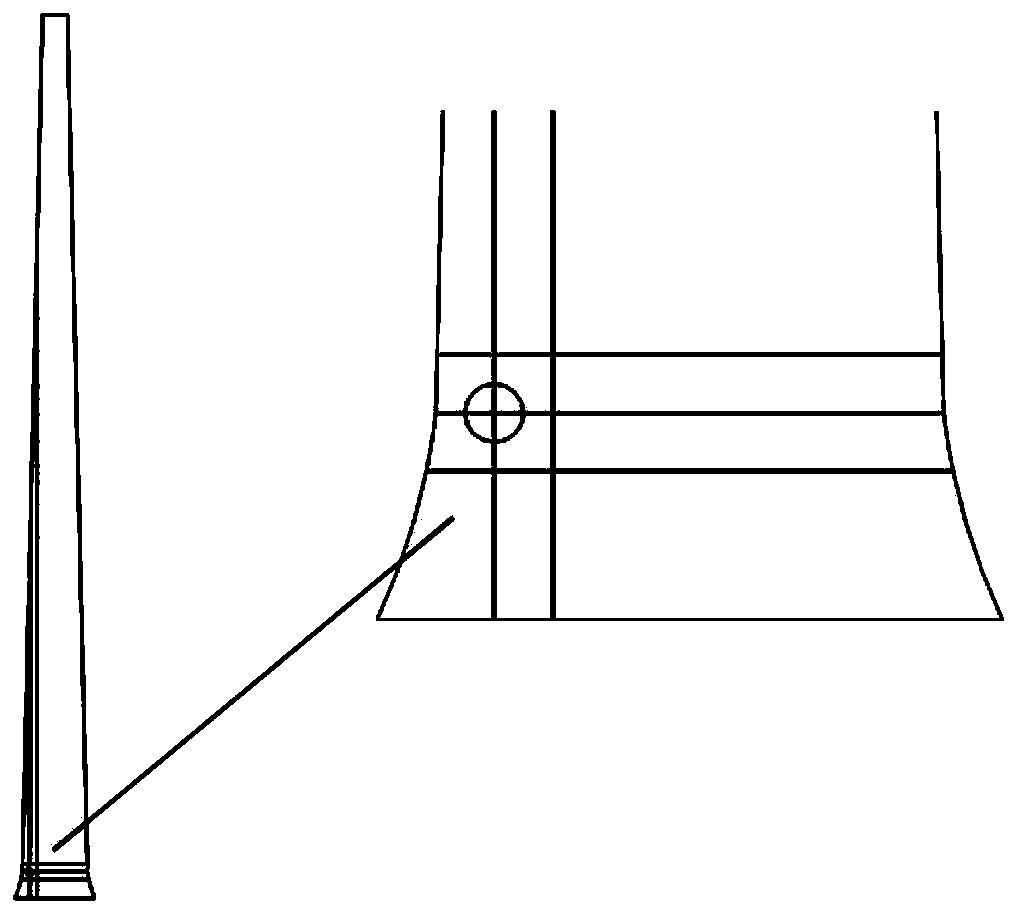

Exhaust steering support plate for unloading cavity of aero-engine

PendingCN113982707AAvoid damageEvenly blendedGas turbine plantsEngine componentsCombustion chamberEngineering

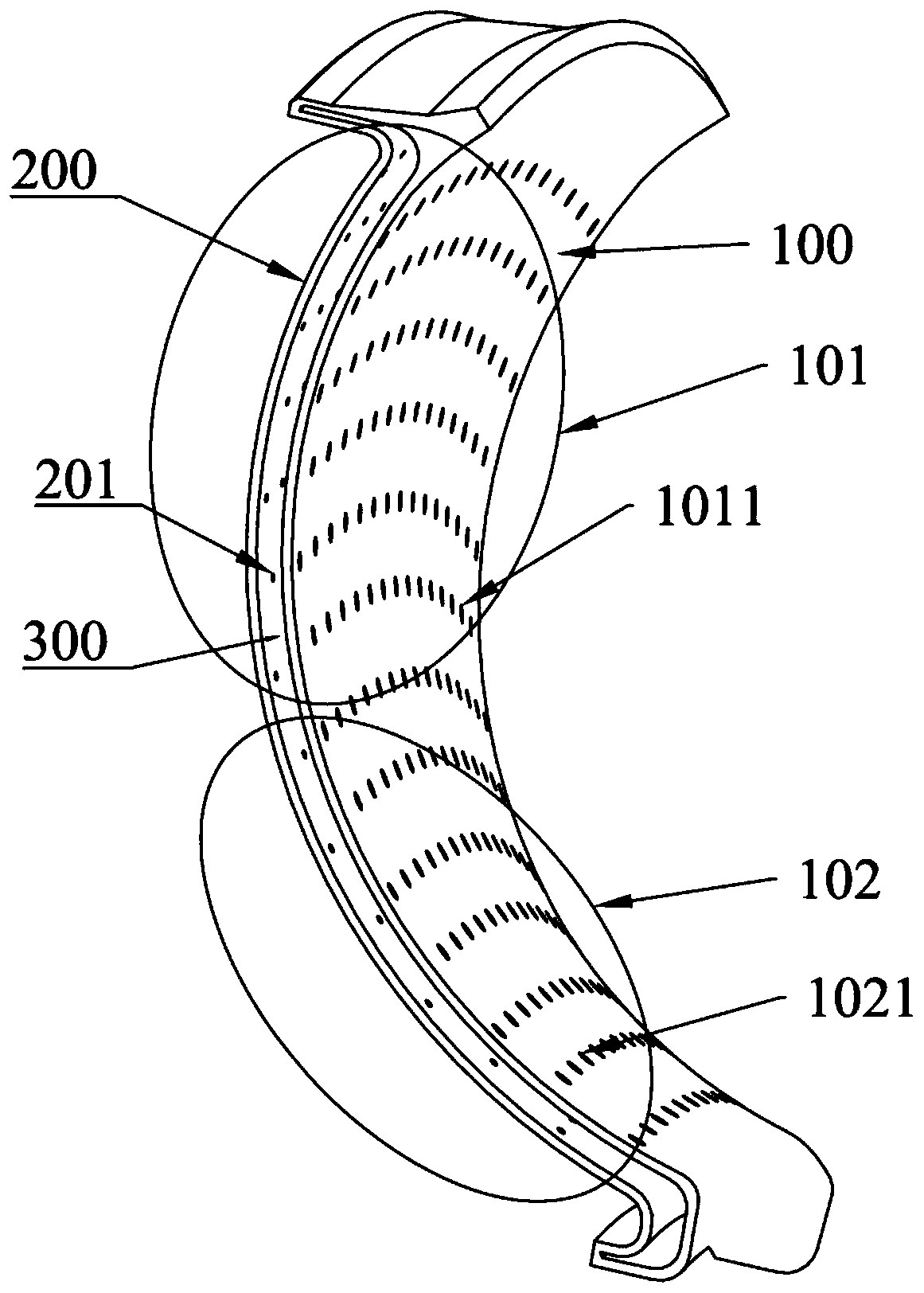

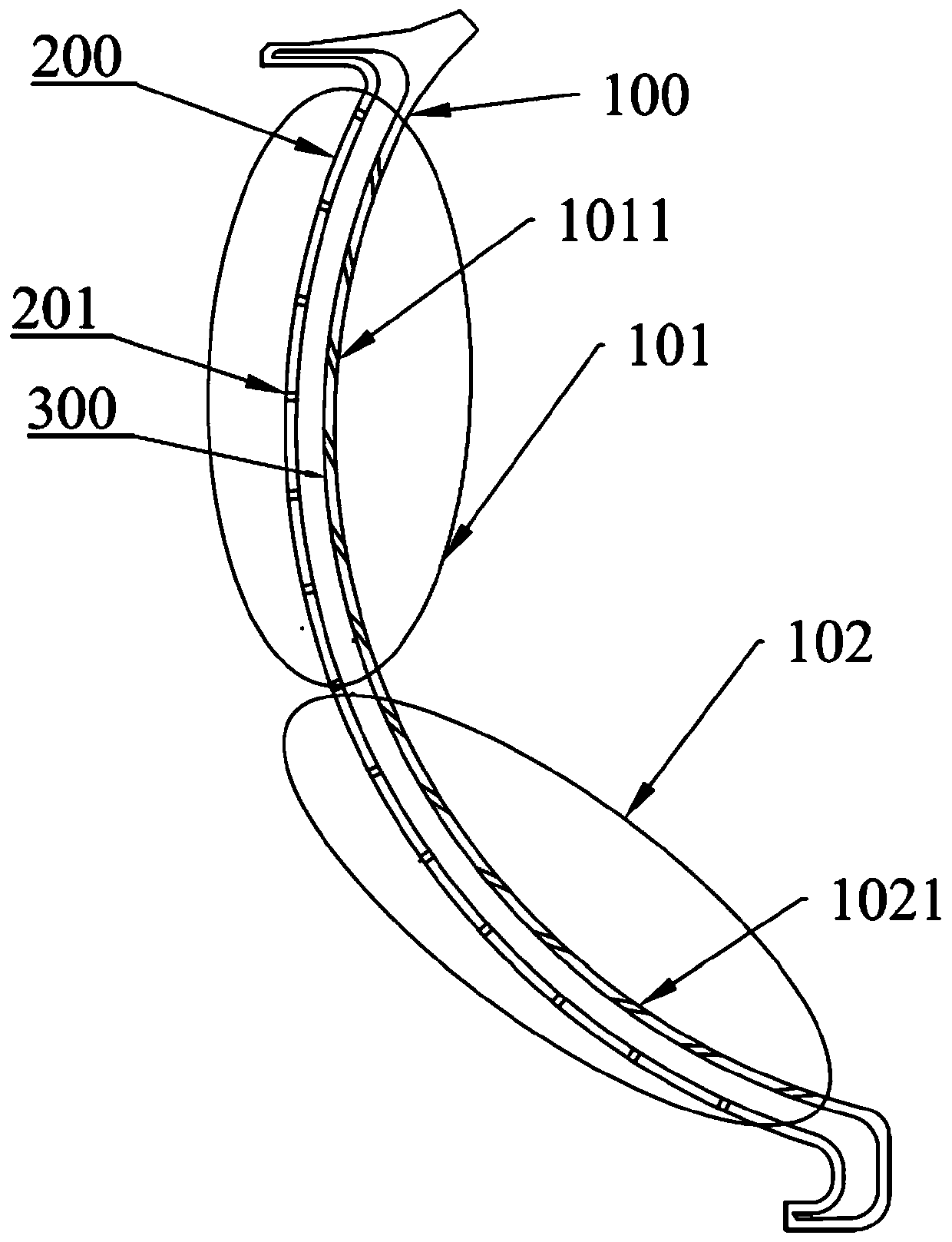

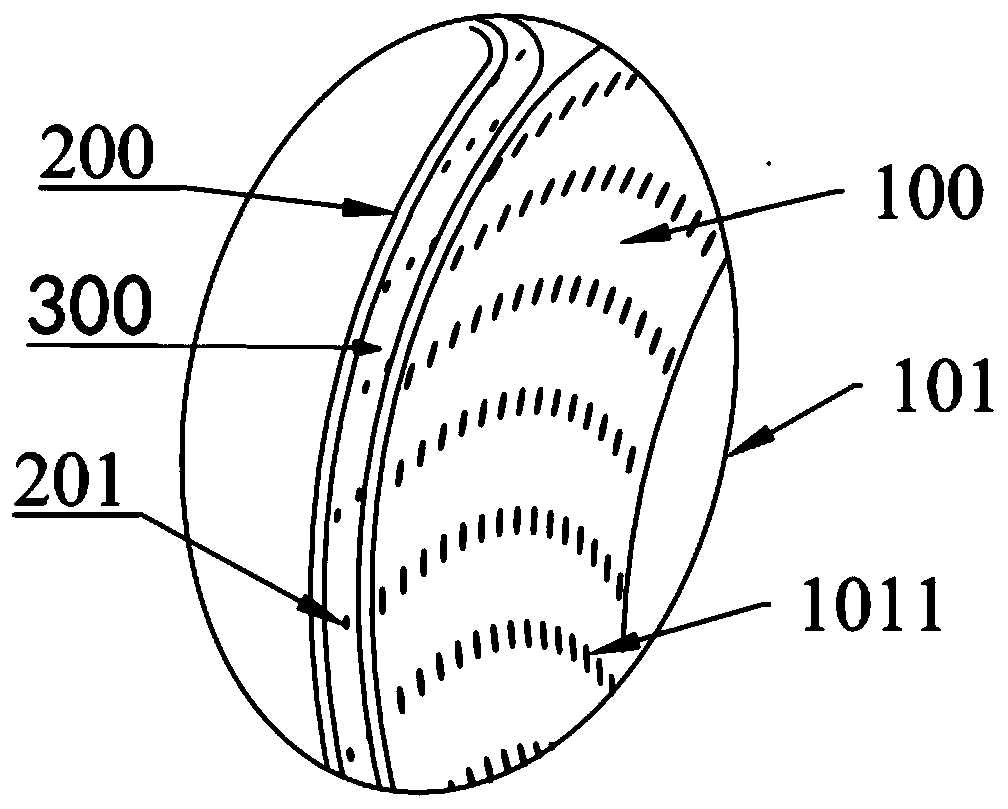

The invention belongs to the field of mechanical parts, and particularly relates to an exhaust steering support plate for an unloading cavity of an aero-engine. According to the technical scheme, the exhaust steering support plate for the unloading cavity of the aero-engine comprises a wedge-shaped shell and an installation base, the interior of the wedge-shaped shell is a cavity, the top of the wedge-shaped shell is a sealing face, the bottom of the wedge-shaped shell is an opening, the periphery of the wedge-shaped shell is a wide vertical face, a narrow vertical face and two wedge-shaped side molded faces, and densely distributed exhaust holes are formed in the narrow vertical surface and the two wedge-shaped side molded surfaces; and the installation base is arranged at the bottom of the wedge-shaped shell. According to the exhaust steering support plate for the unloading cavity of the aero-engine, high-temperature airflow in the inner cavity of a combustion chamber casing can be led out in the outer culvert airflow direction, airflow clusters are changed from being dense to being dispersed, high-temperature airflow and low-temperature airflow are mixed more evenly, damage to the outer culvert casing is prevented, and the service life is prolonged.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

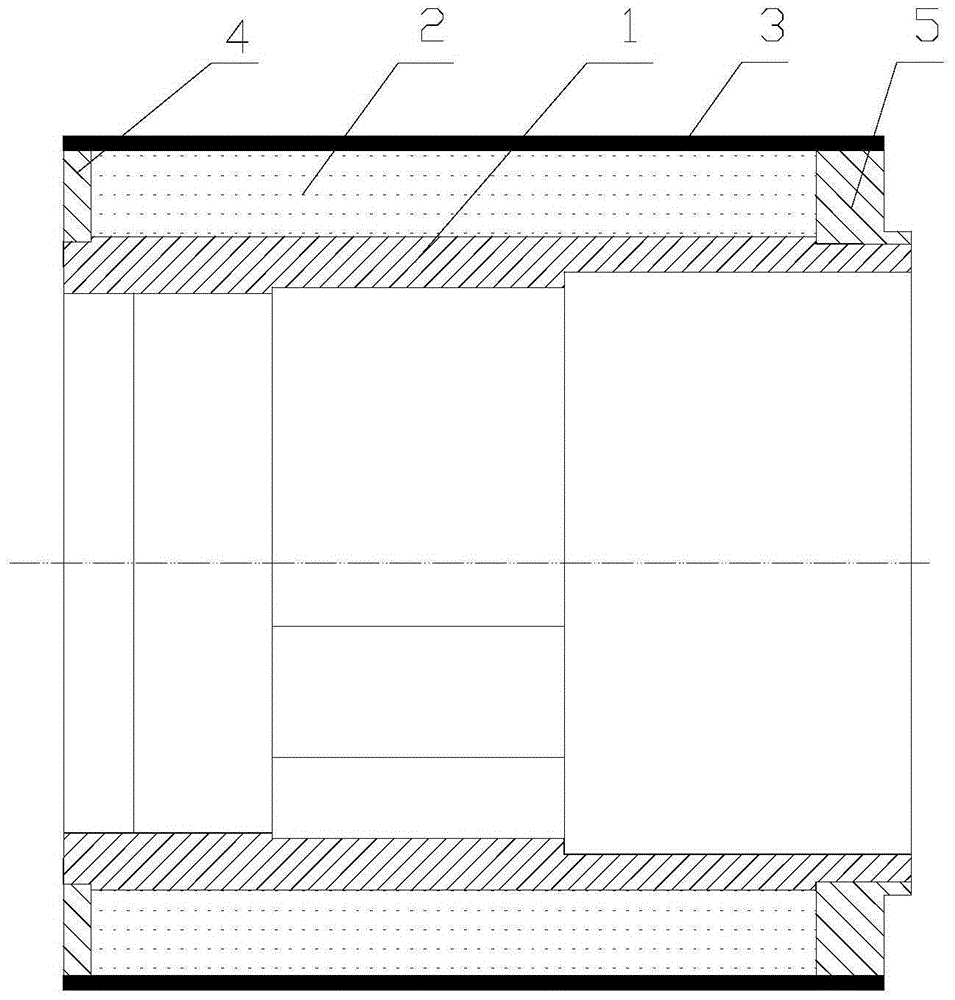

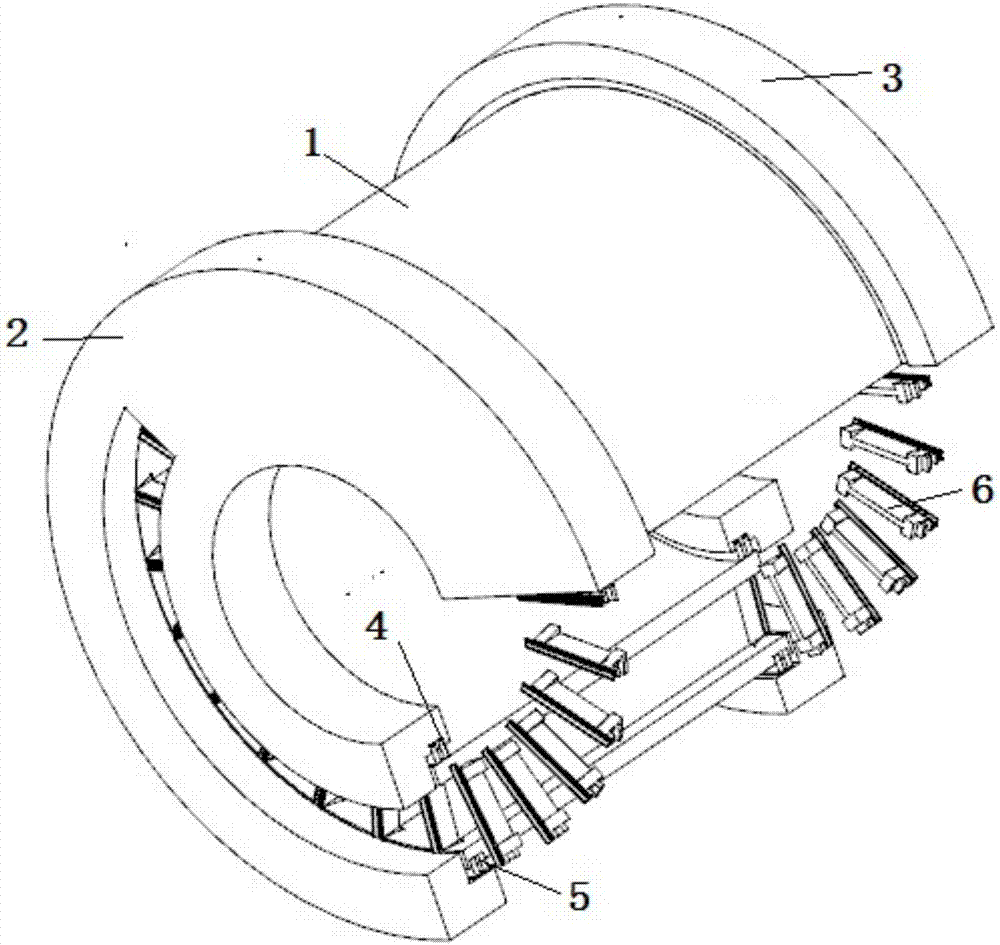

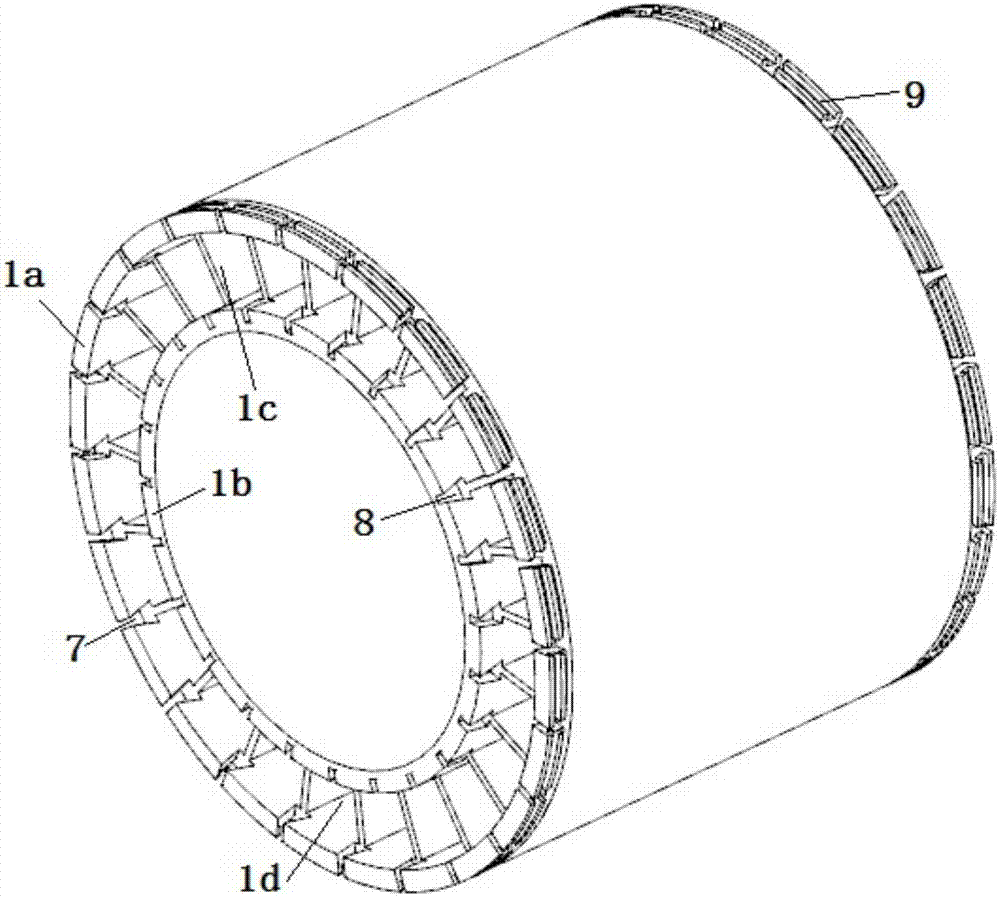

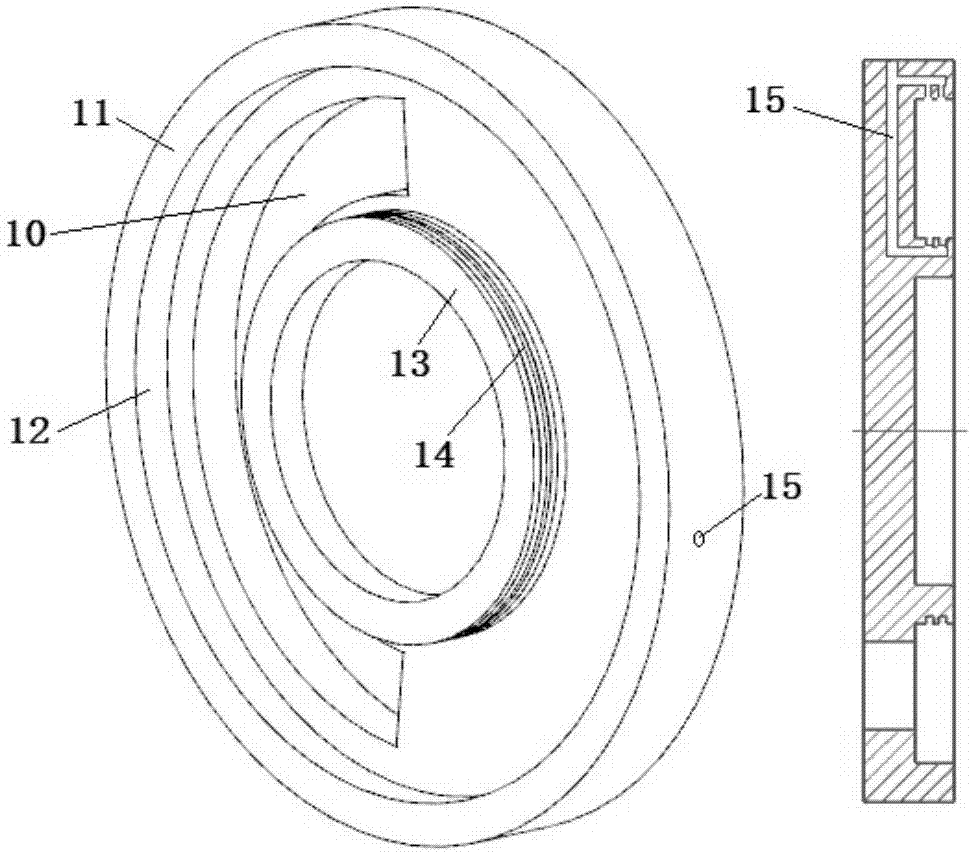

Expansion ring and sealing brush combined internal combustion wave rotor

ActiveCN106930839AImprove sealingReduce frictionEngine sealsGas turbine plantsAviationCombustion chamber

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap