Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12 results about "Brake pad" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Brake pads are a component of disc brakes used in automotive and other applications. Brake pads are composed of steel backing plates with friction material bound to the surface that faces the disc brake rotor.

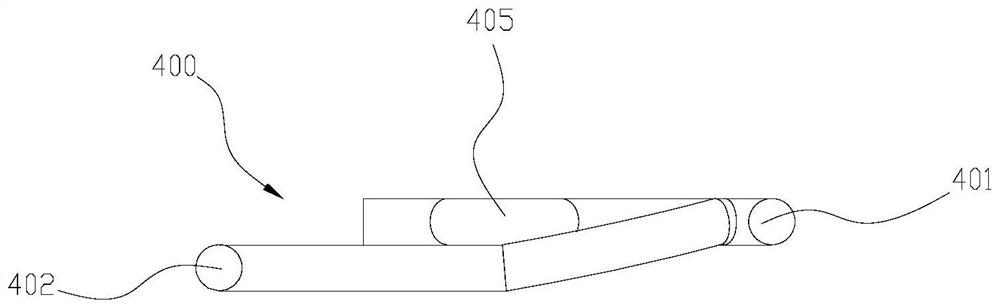

Cable tension adjusting device

InactiveCN105060022AGuaranteed reliabilityEasy to processFilament handlingEngineeringMechanical engineering

The invention relates to a cable tension adjusting device which is simple in structure, convenient to operate and convenient for tension adjustment. The cable tension adjusting device comprises a rack, a pay-off roller, a guide roller, a driving mechanism I, a driving mechanism II and a braking mechanism, wherein the rack is provided with a vertical plate I, a vertical plate II and a top plate, the pay-off roller and the guide roller are movably arranged between the vertical plate I and the vertical plate II, and the pay-off roller is positioned above the guide roller; the driving mechanism I comprises a driving wheel I, a driving wheel II and a support, and the driving wheel I and the driving wheel II are movably arranged on the support; the driving mechanism II comprises a driving wheel III, a hinge rod, a pull rod I and a pull rod II, the driving wheel III is connected to the hinge rod, and the hinge rod is hinge to the vertical plate II; the braking mechanism comprises a brake block and a brake disc, the brake disc is connected to the pay-off roller, and the brake block is connected to the pull rod II through a cross rod. The cable tension adjusting device has the advantages of being convenient to process and low in cost.

Owner:HUZHOU CHENFENG WIRE &CABLE CO LTD

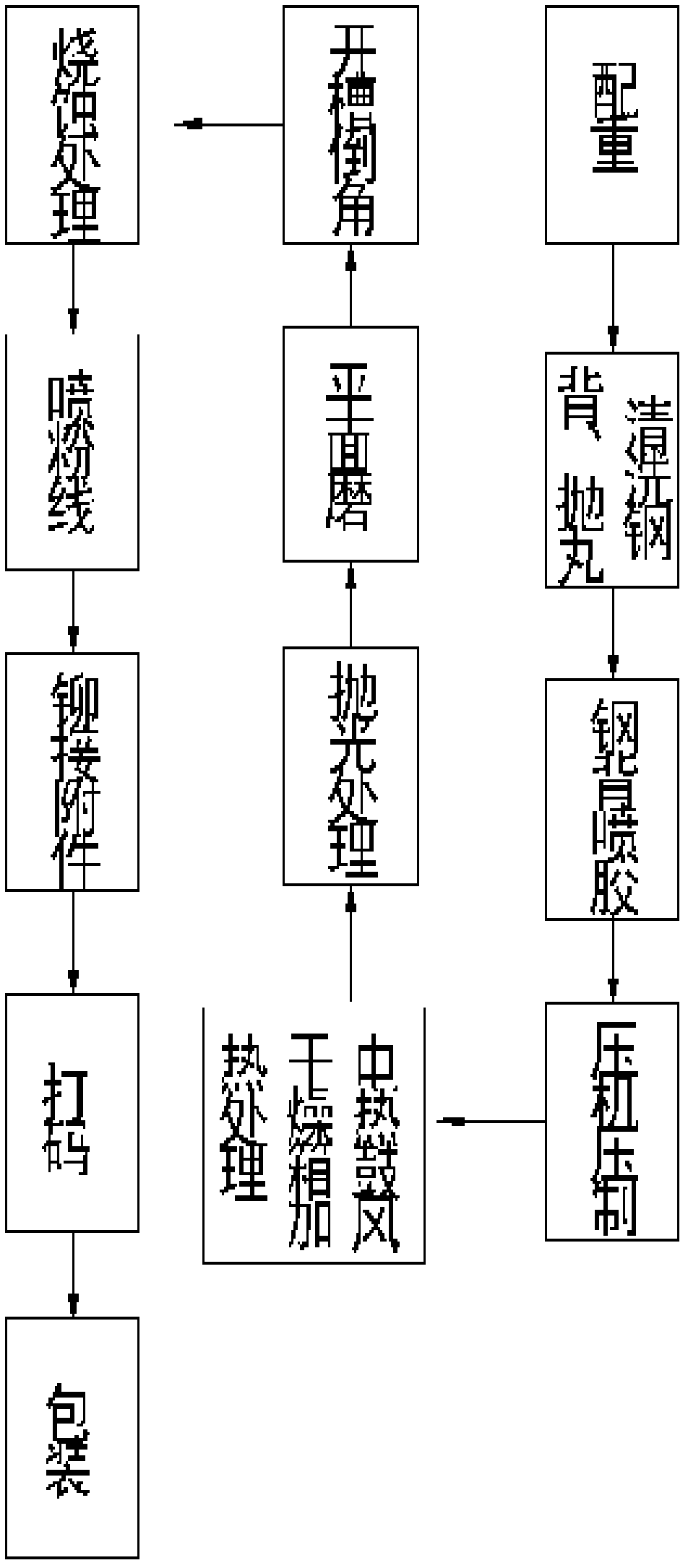

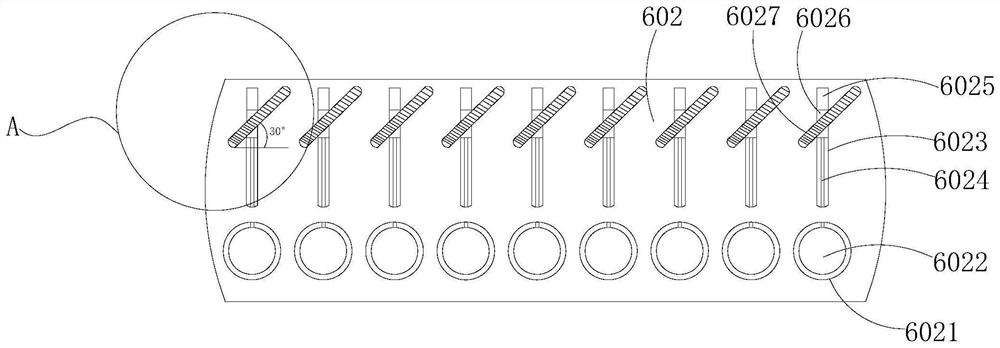

Brake pad production system

Owner:安徽省中力车辆制动系统制造有限公司

Clip for Use in a Disc Brake Assembly and Disc Brake Assembly Including Such a Clip

ActiveUS20160131210A1Performance is not affectedAxially engaging brakesSlack adjustersEngineeringMechanical engineering

A brake clip adapted for use in a disc brake assembly comprises a brake clip configured to be disposed between an anchor bracket and at least one brake pad of the disc brake assembly. The brake clip has at least one tab extending therefrom which is configured to initially contact and prevent the at least one brake pad from falling free prior to installation of the disc brake assembly on a vehicle.

Owner:KELSEY HAYES CO

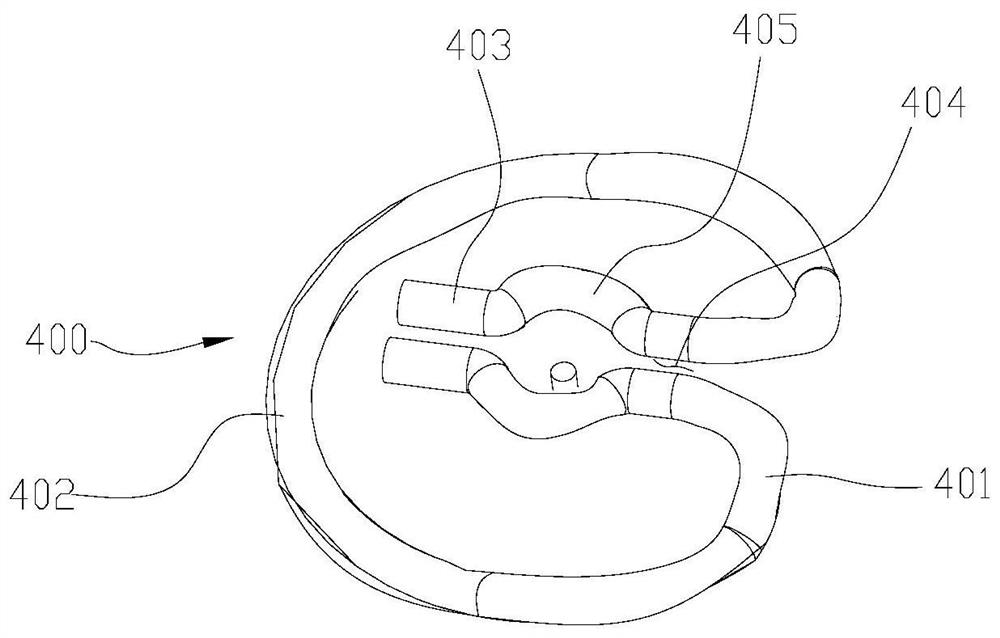

Safety speed reducer for roller skates

ActiveCN112076459AImprove securityIncrease frictionSkate-boardsRoller skatesRoller skatingClassical mechanics

Owner:佛山市顺德区圣顺体育用品有限公司

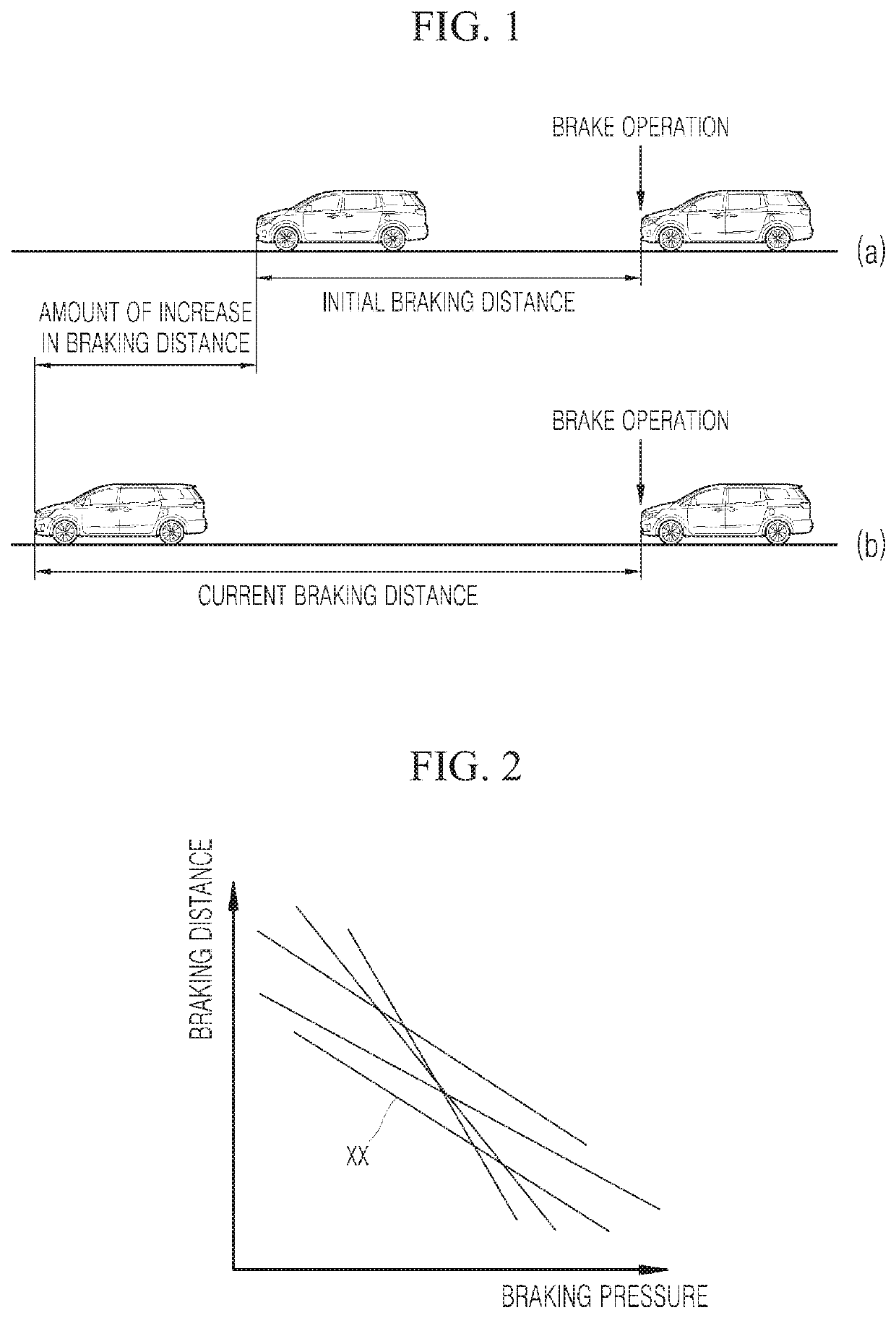

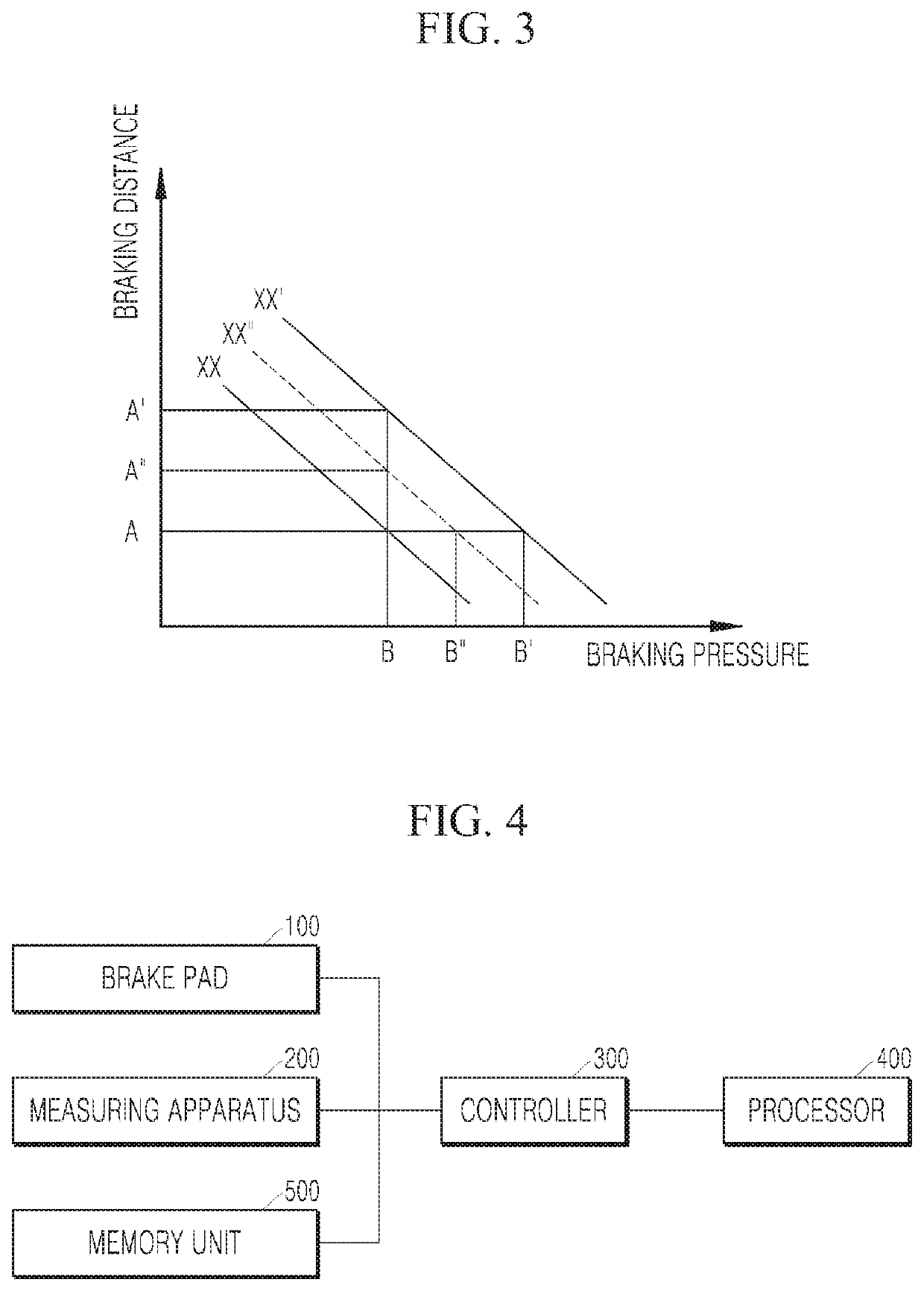

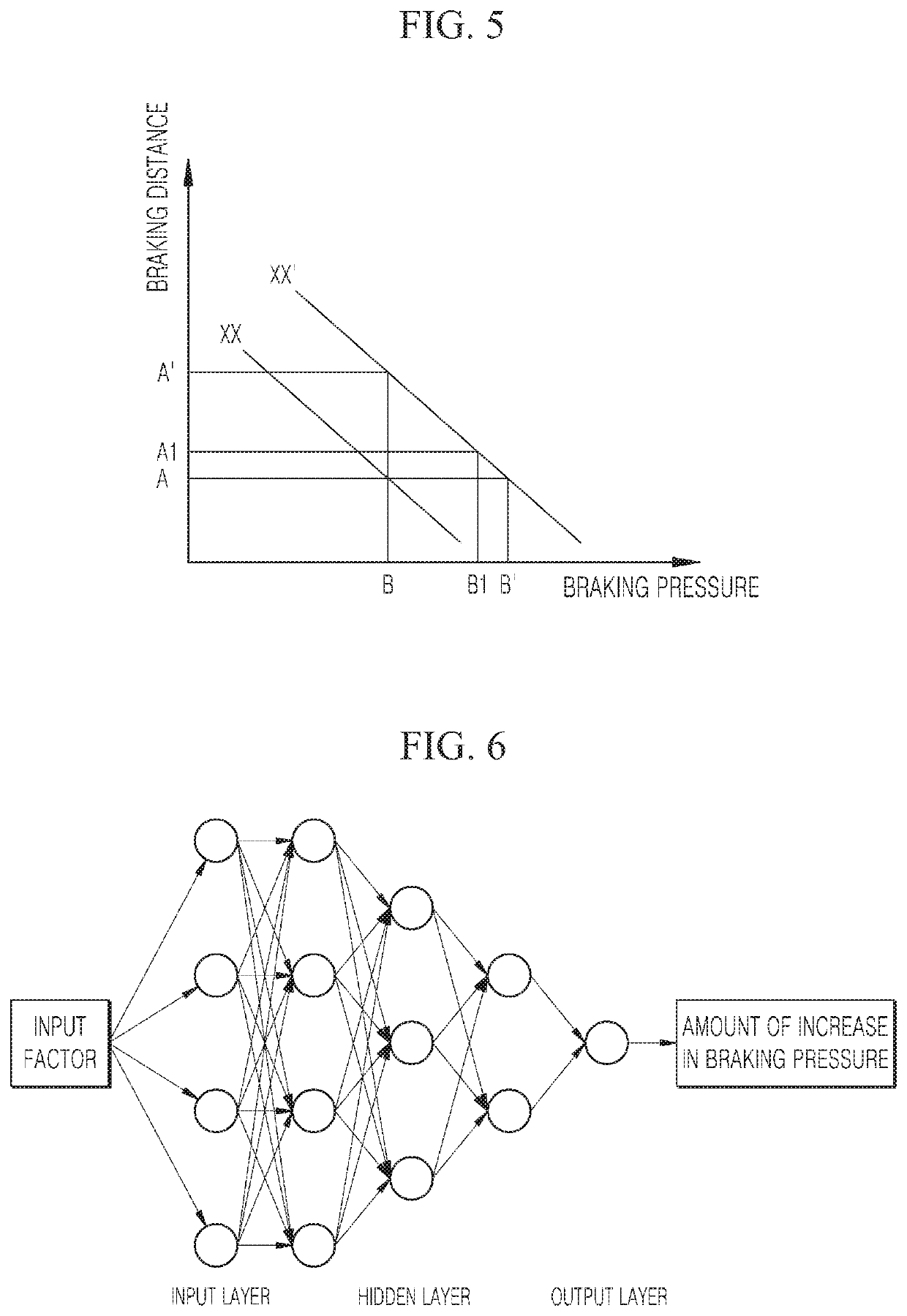

Brake control system used in a vehicle and control method thereof

ActiveUS20190389442A1Increase brake pressureShorter braking distanceBraking element arrangementsAxially engaging brakesControl systemBraking distance

Owner:LG ELECTRONICS INC

New energy automobile disk type brake pad

ActiveCN105545998AReduce the number of times of long-term transient high-temperature wearAverage forceBraking elementsFriction liningNew energyAlternative fuel vehicle

Owner:周兵经

Drum brake block pressure casting production line

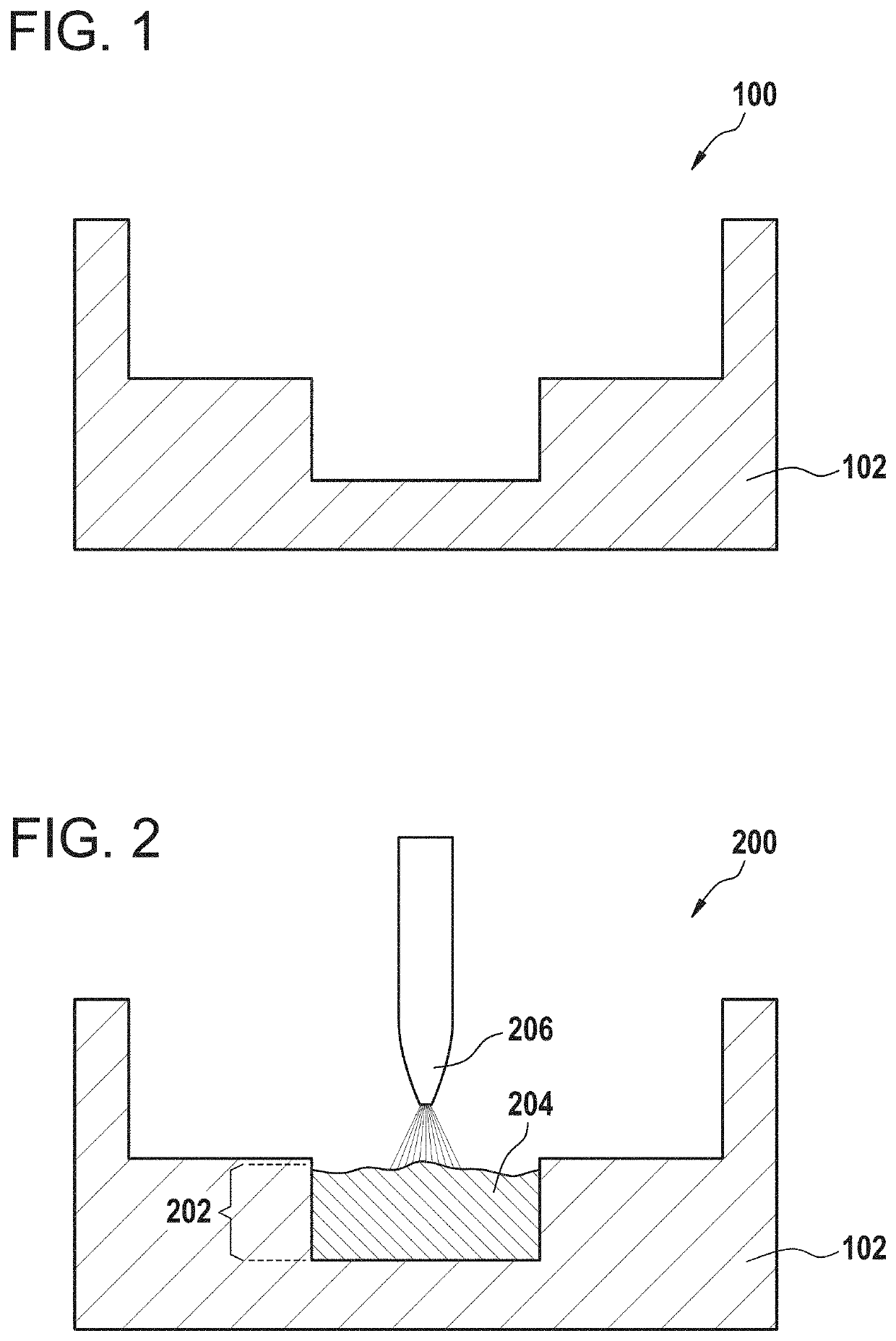

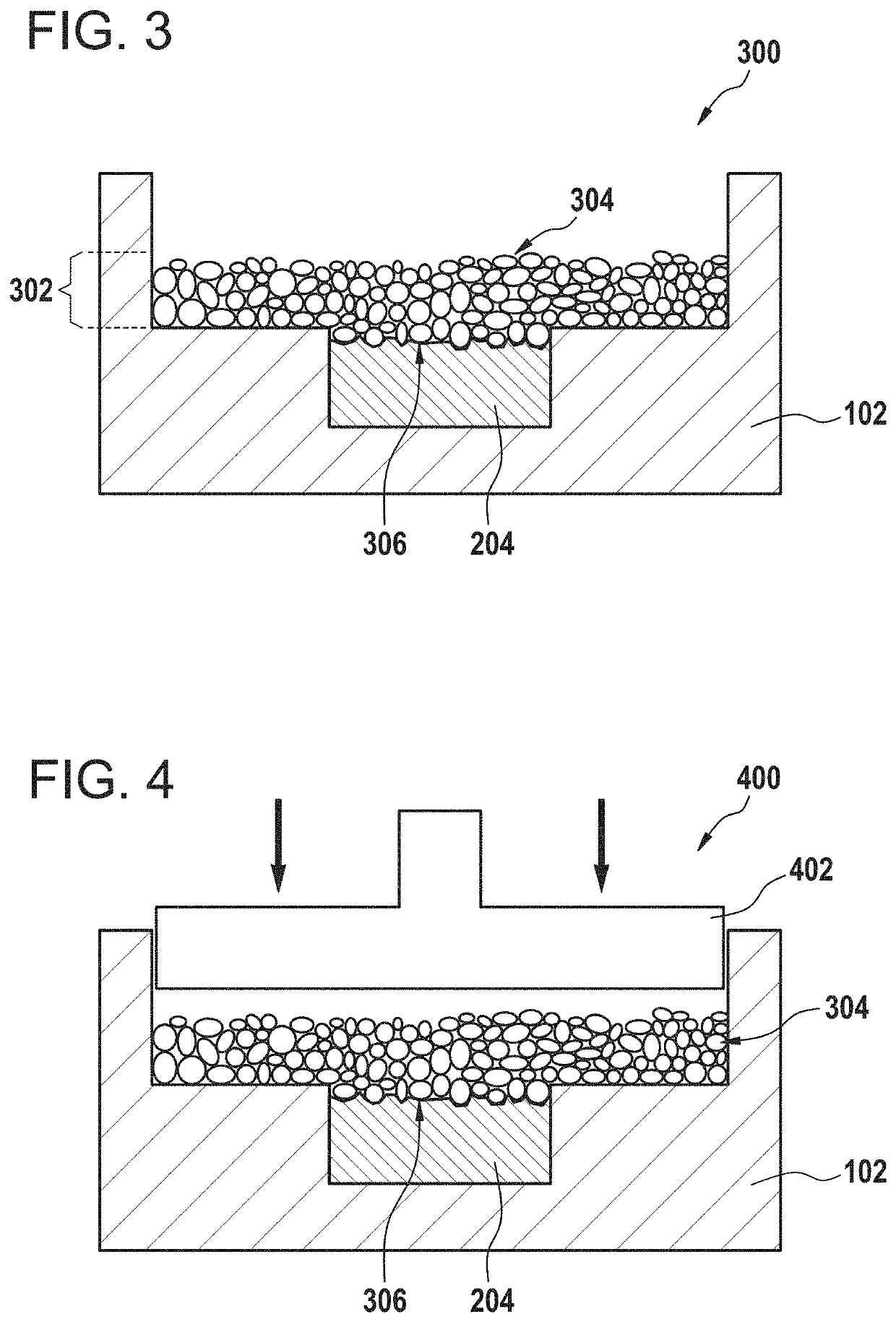

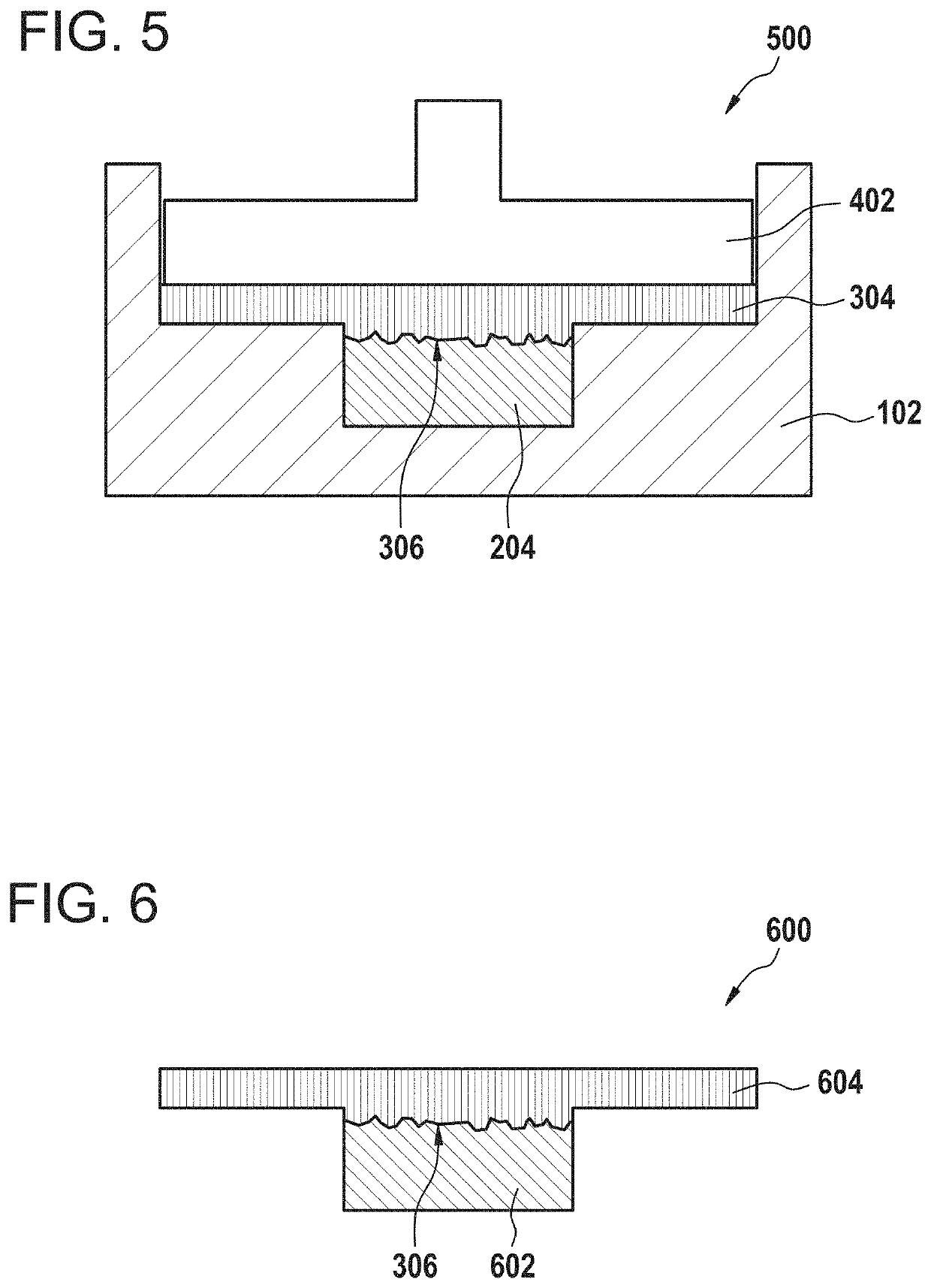

InactiveCN109108248AImprove transportation efficiencySolve the time-consuming and labor-intensive problem of manual movementProduction linePressure casting

The invention discloses a drum brake block pressure casting production line. The drum brake block pressure casting production line comprises a die bracket. An air cylinder is mounted at the top of thedie bracket. An upper die is mounted below the air cylinder. A lower die is mounted below the upper die. A feed machine is mounted on one side of the lower die. A discharging placing platform is mounted on the other side of the lower die. A controller is mounted on one side of the discharging placing platform. A hoisting bracket is mounted on one side of the discharging placing platform. A hoisting platform is fixedly connected below the hoisting bracket by bolts. A second motor is mounted on one side of a main mechanical arm. A rocker is mounted at the position, close to one side of the second motor, of the main mechanical arm. A conveying machine is arranged to solve the problems that the production line can not automatically convey finished products to a finished product box, and manual conveying costs time and labor. A dry feeding platform is arranged to solve the problems that heat of the drum brake block formed by pressure casting is high, and machining of the drum brake block is influenced when the drum brake block is conveyed to the next procedure without cooling processing.

Owner:孙晓锋

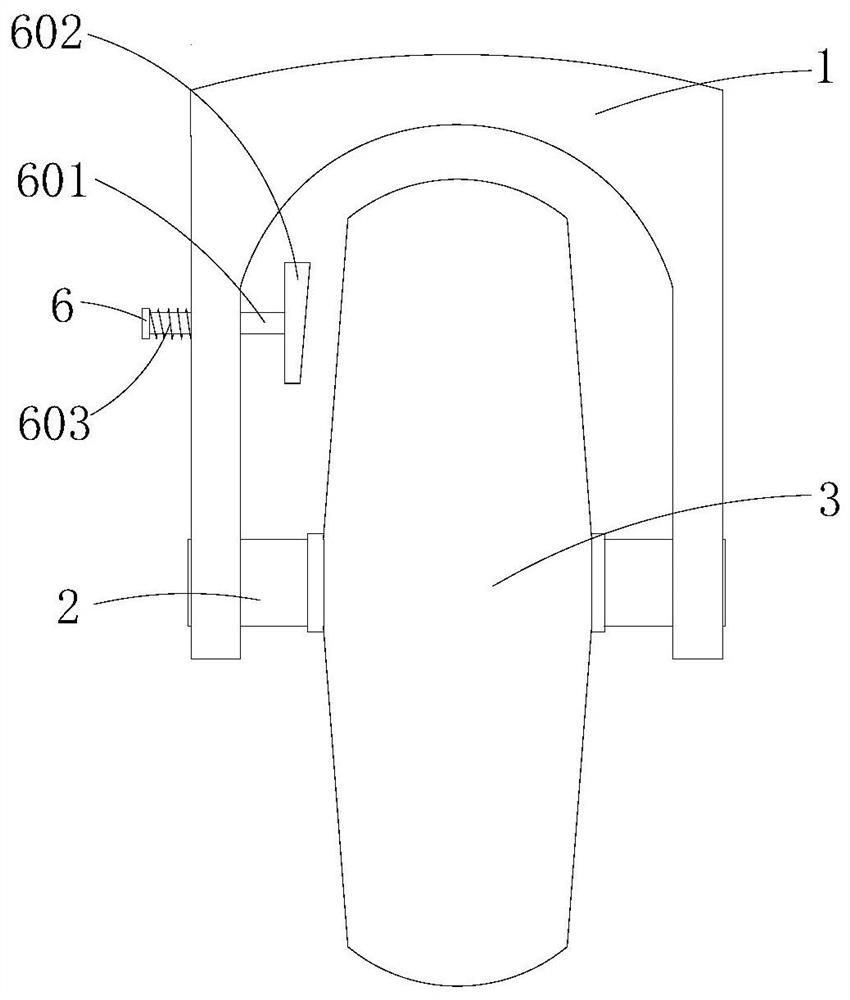

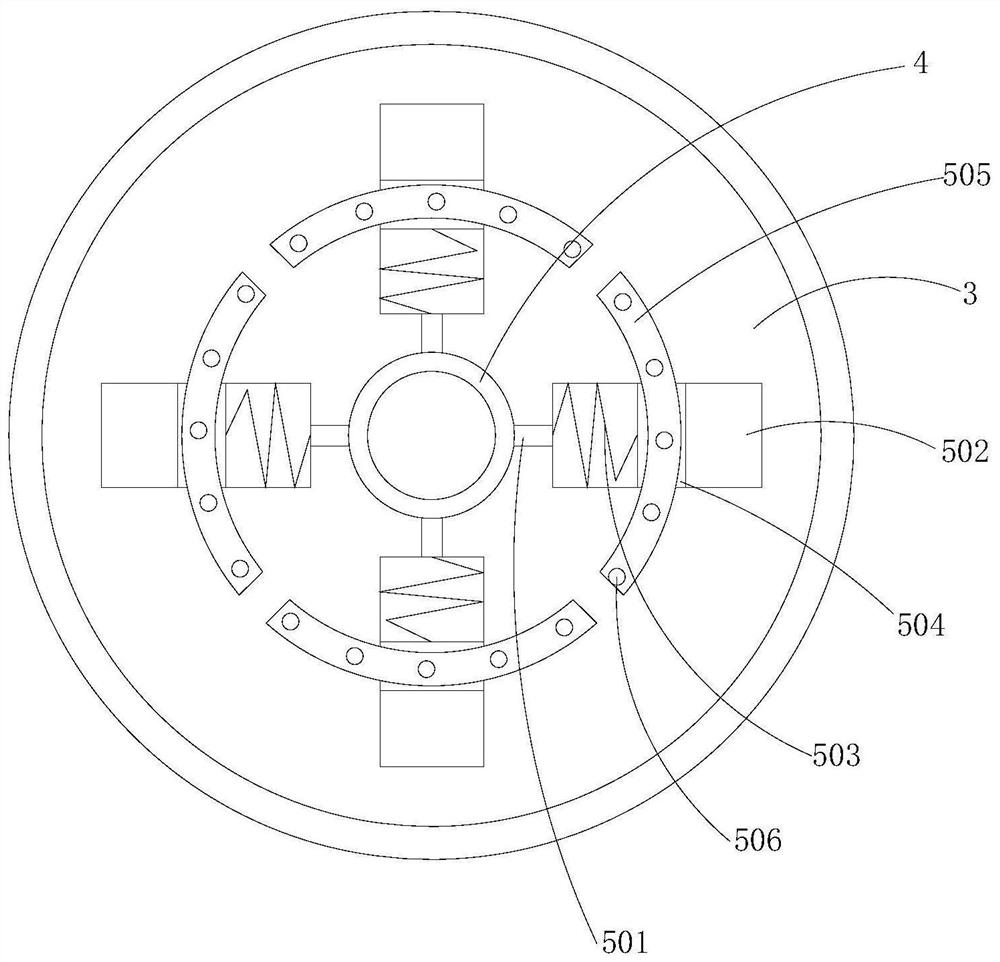

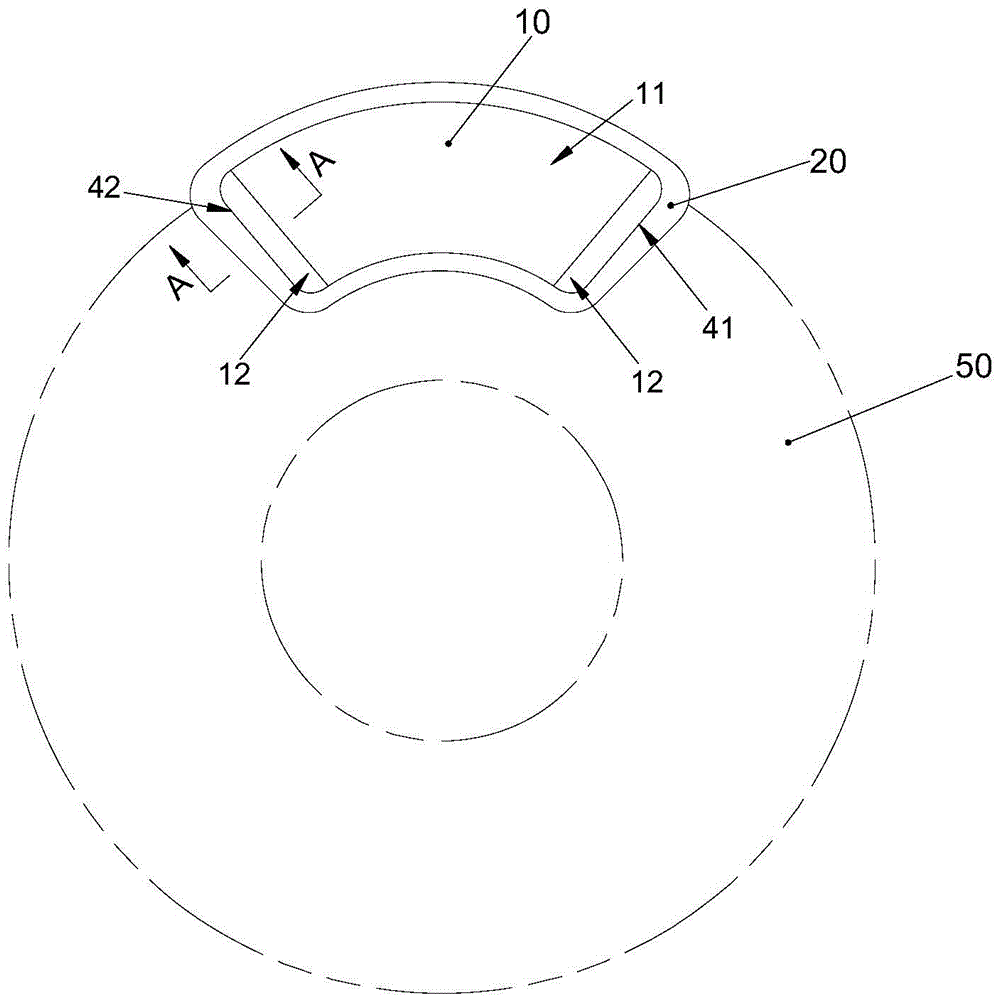

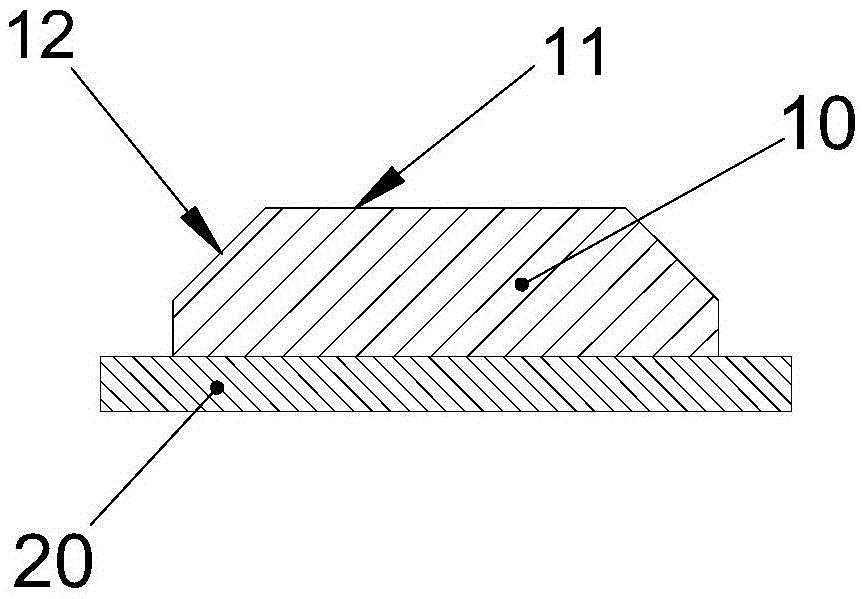

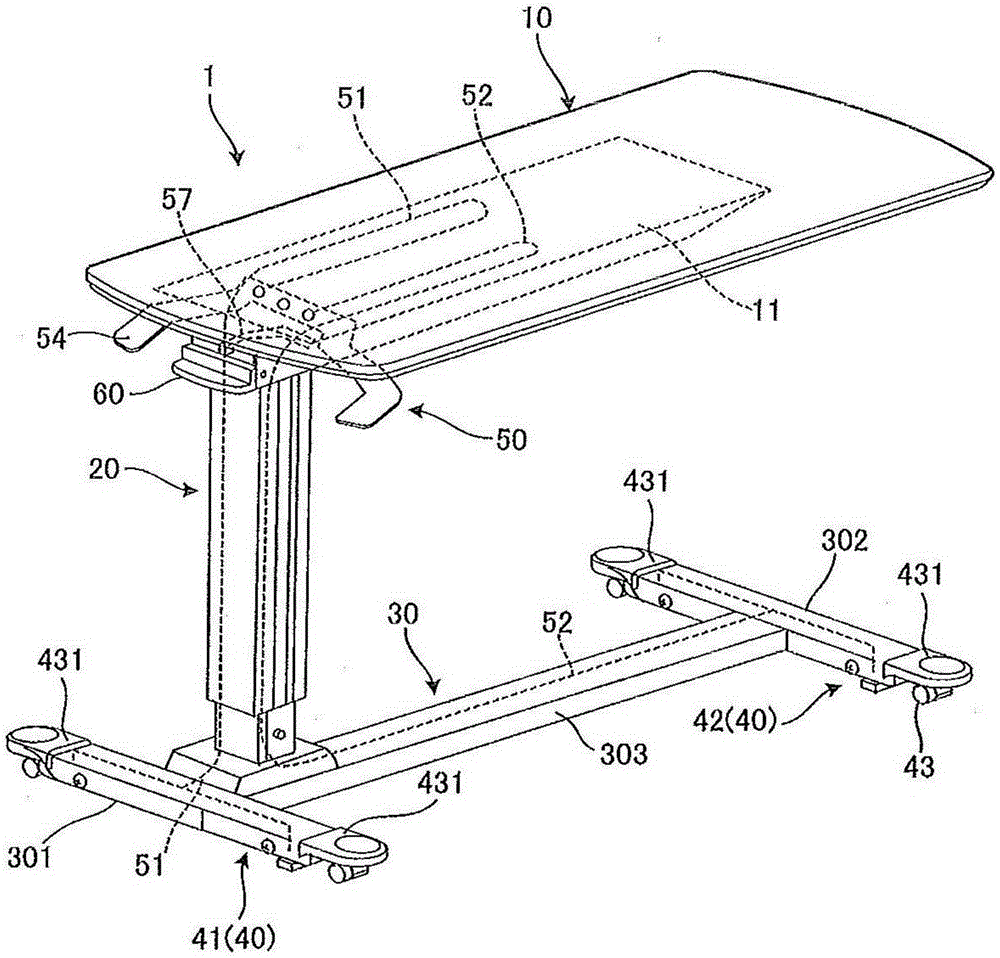

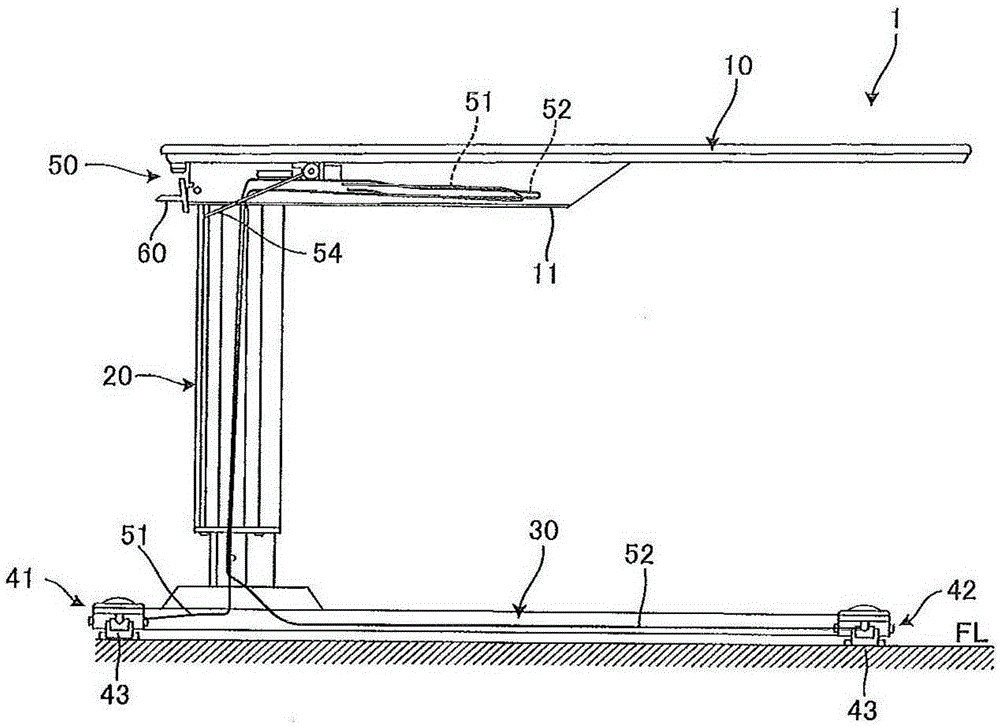

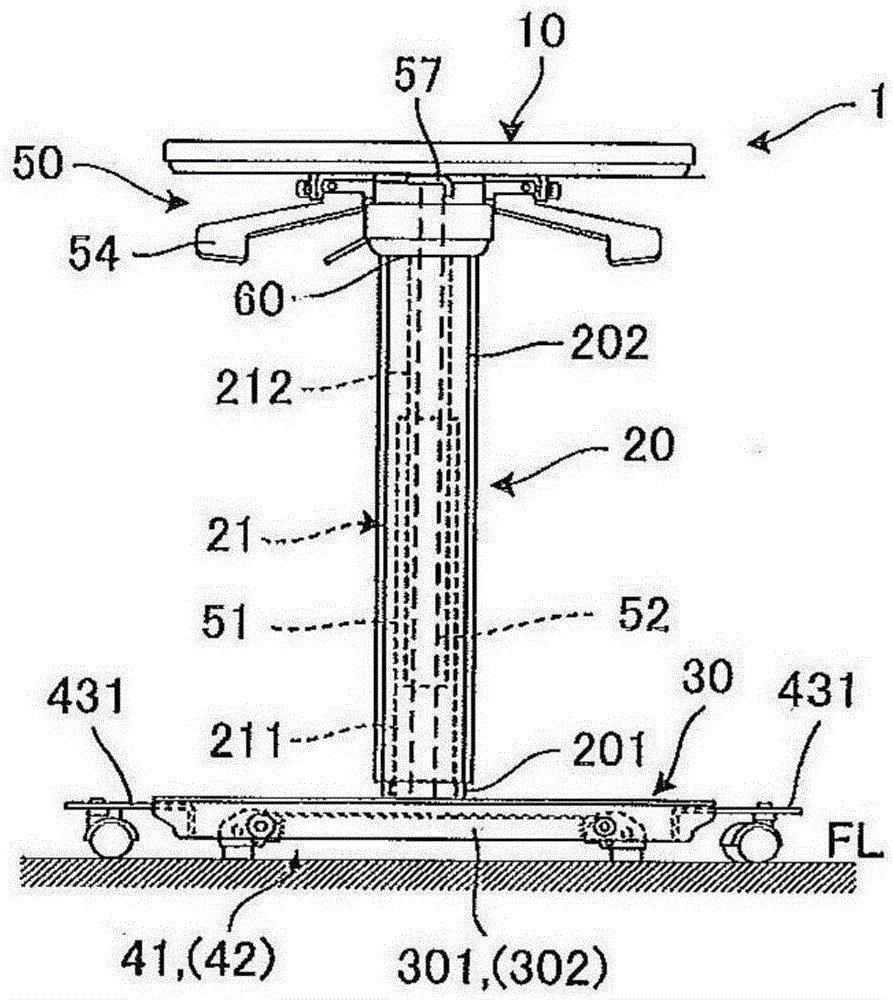

Brake mechanism and movable table provided with brake mechanism

ActiveCN105935204AEasy to operateIncrease the burdenBrake actuating mechanismsTablesCoil springEngineering

Owner:PARAMOUNT BED CO LTD

Multi-stage brake power assisting device of new energy automobile

ActiveCN114834411AAct as a brakeRealize the purpose of multi-level brake boosterBraking element arrangementsBraking action transmissionPressure transmissionNew energy

Owner:杭州重河新能源科技有限公司

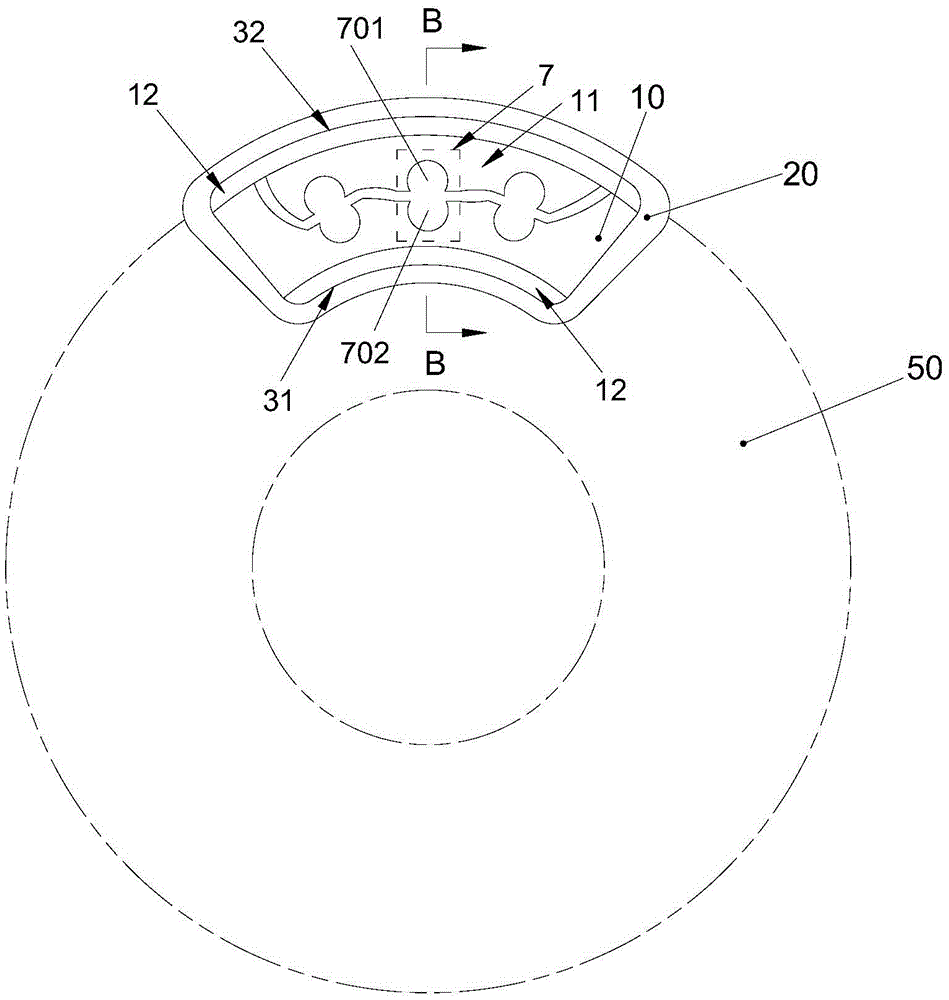

Brake pad, disk brake assembly, and vehicle

InactiveUS20200018369A1Size of and therefore adhesionImprove adhesionAxially engaging brakesBraking elementsEngineeringMaterials science

Owner:MAT COMML VEHICLE PROD GMBH

Ring chain plate-type highway long downhill machine

The invention relates to a machine used on a long downhill section of a highway, in particular to a ring chain plate-type highway long downhill machine. The ring chain plate-type highway long downhillmachine is a machine mounted on the long downhill section of the highway and specially used for carrying an automobile downhill. The ring chain plate-type highway long downhill machine comprises an upper road lead and a lower road lead, and is structurally characterized in that two ends of the downhill machine are horizontal sections flush with the upper road lead and the lower road lead and themiddle of the downhill machine is a downhill section; and two parallel I-shaped rails are arranged on a ladder pier-shaped sleeper beam frame. An automobile passes through the long downhill section ofthe highway on the downhill machine under the situations that a V-shaped groove blocks wheels of the automobile from sliding and the automobile is under full braking, as a brake pad of the automobiledoes not generate heat due to friction, a brake hub cannot be burnt out, and therefore the downhill machine can make the automobile safely pass through the dangerous section of the long downhill of the highway.

Owner:马千里

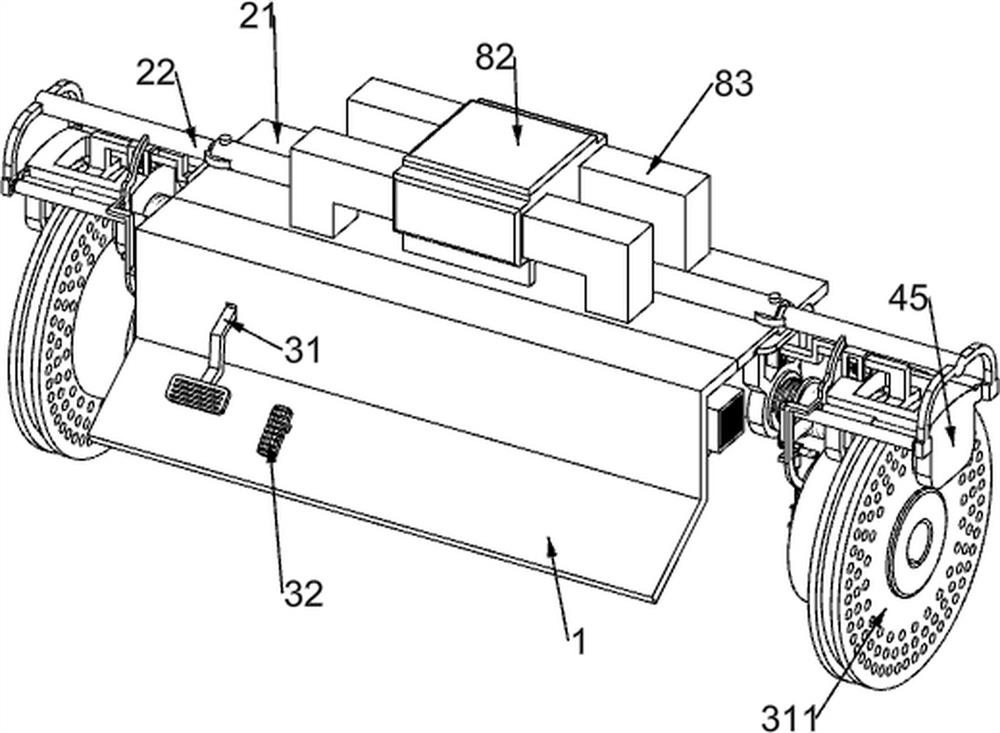

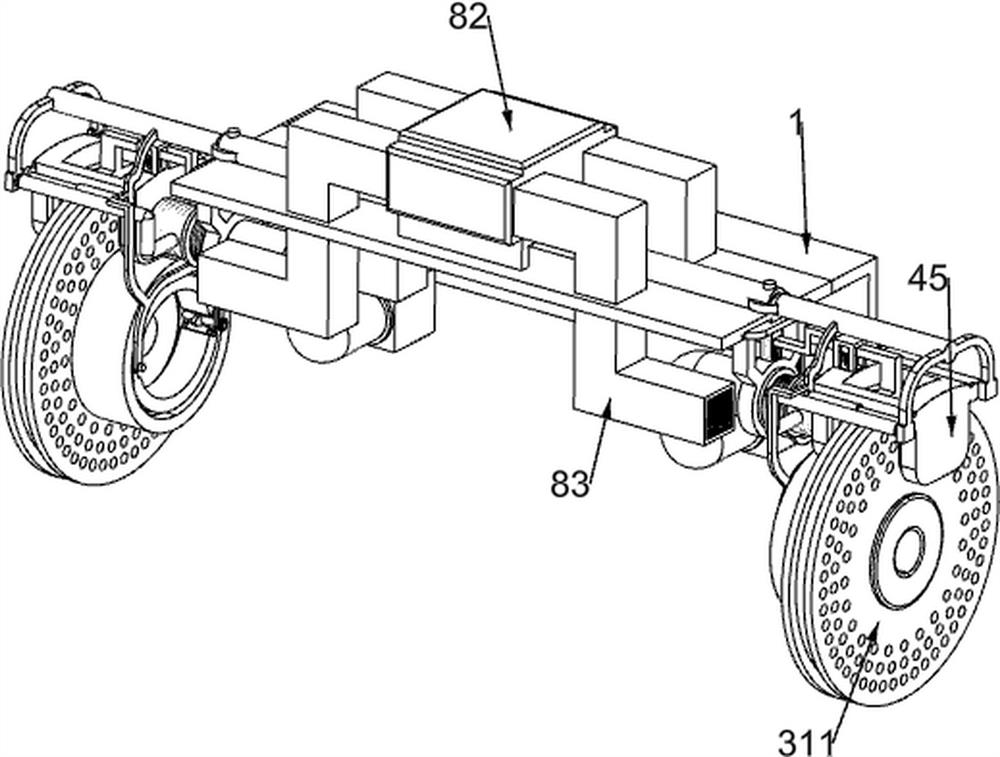

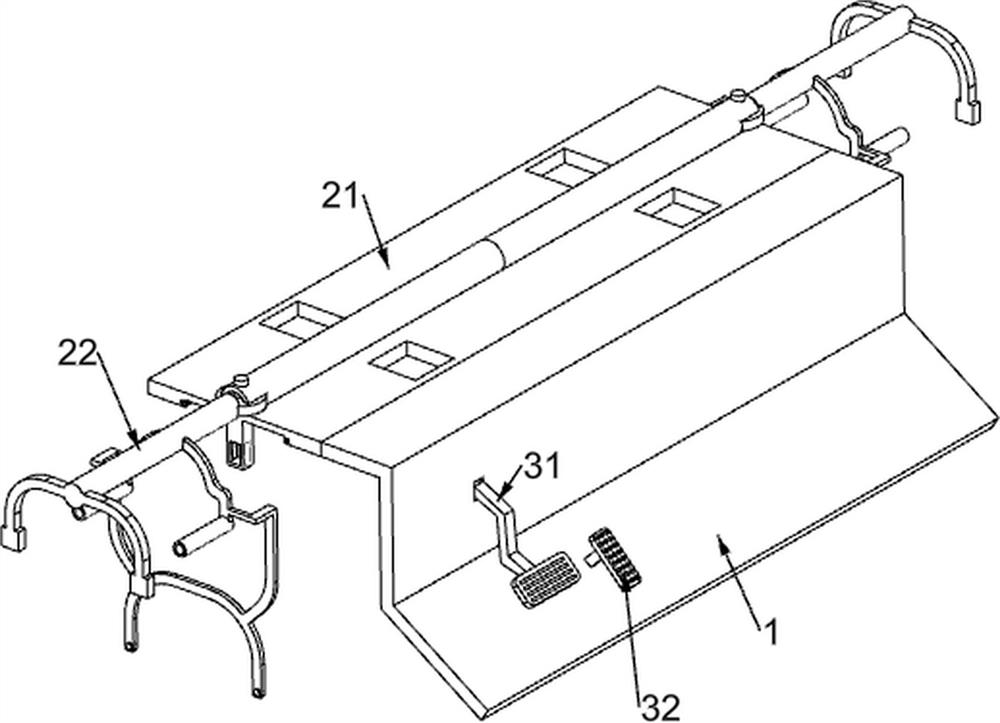

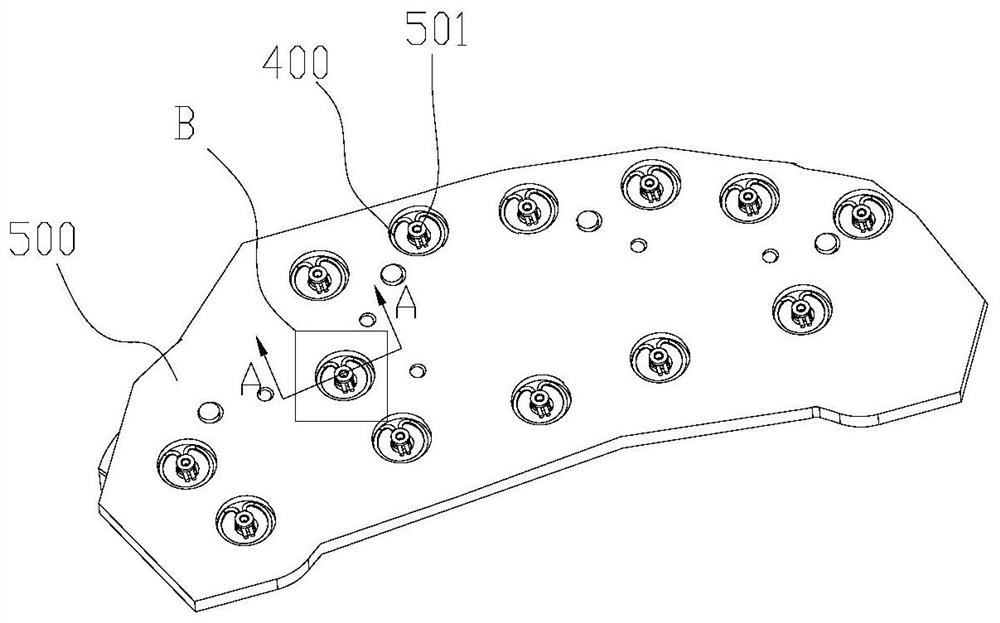

Conveying mechanism and brake pad assembling equipment

Owner:廊坊金润奥通智能装备有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap