Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Carbon deposit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device and method for magnetically grinding inner surfaces of large-diameter long and straight pipes

InactiveCN108857605ARealize finishingAchieve extrusionEdge grinding machinesPolishing machinesMotor drivePipe fitting

The invention relates to a device and a method for magnetically grinding the inner surfaces of large-diameter long and straight pipes. The device comprises a bed, spindle motors, couplings, a magneticpole disc, a motor driving slide rail device and a hoisting device. Two ends of each pipe fitting can be sealed by pipe fitting plugs and are fixed by the aid of four-jaw chucks, the four-jaw chuck at one end of each pipe fitting is connected with the corresponding spindle motor by the corresponding coupling, the four-jaw chuck at the other end of each pipe fitting is connected with a support seat by bearings, support seat slide rails are fixed onto the bed, and the support seats are slidably connected with the support seat slide rails by support seat sliders; the motor driving slide rail device is arranged at the bottom of the bed, and the magnetic pole disc is connected with the motor driving slide rail device by the hoisting device, can be lifted under the control of the hoisting device and can axially move along the pipe fittings under the control of the motor driving slide rail device. The device and the method have the advantages that finish machining can be carried out on the inner surfaces of the pipe fittings by the aid of magnetic grinding processes, and carbon deposits, oil stain and rust stain which are accumulated at grooves inside the pipe fittings can be effectivelyremoved by the aid of the device and the method.

Owner:UNIV OF SCI & TECH LIAONING

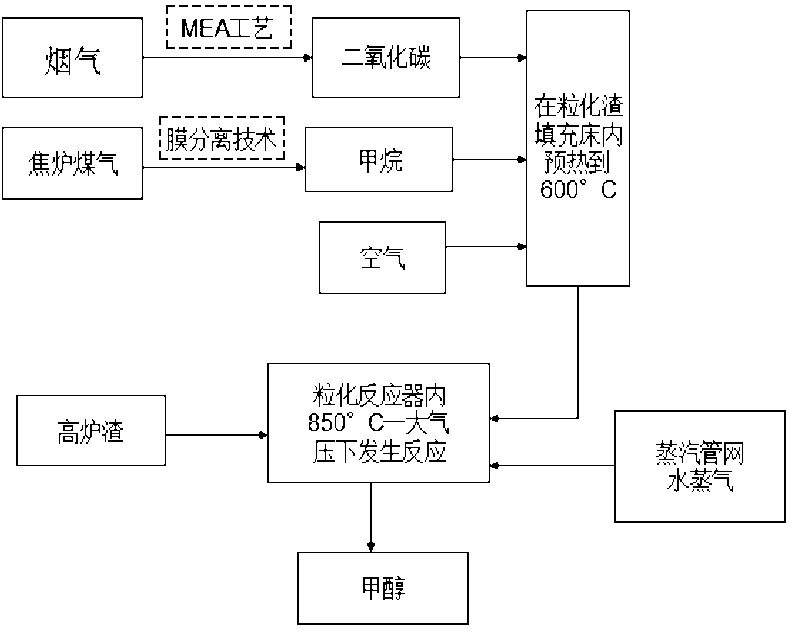

Method for preparing methanol by sensible heat of blast furnace slag

InactiveCN103304372AAlleviate or even eliminate the problem of carbon depositionEmission reductionPreparation by oxidation reactionsChemical industrySlagEnergy recovery

Owner:NORTHEASTERN UNIV

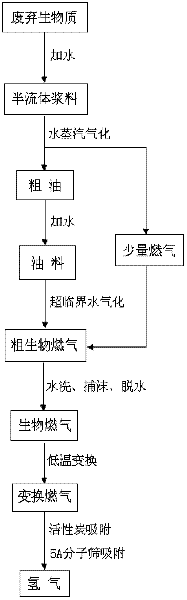

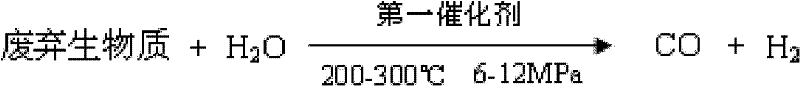

Method for preparing hydrogen by utilizing waste biomass

InactiveCN102653393AReduce pollutionReduce manufacturing costHydrogen separation using solid contactCombustible gas catalytic treatmentRare-earth elementWater vapor

Owner:北京雷恩新材料科技有限公司

Fuel oil additive mixture

Owner:黄慧娟

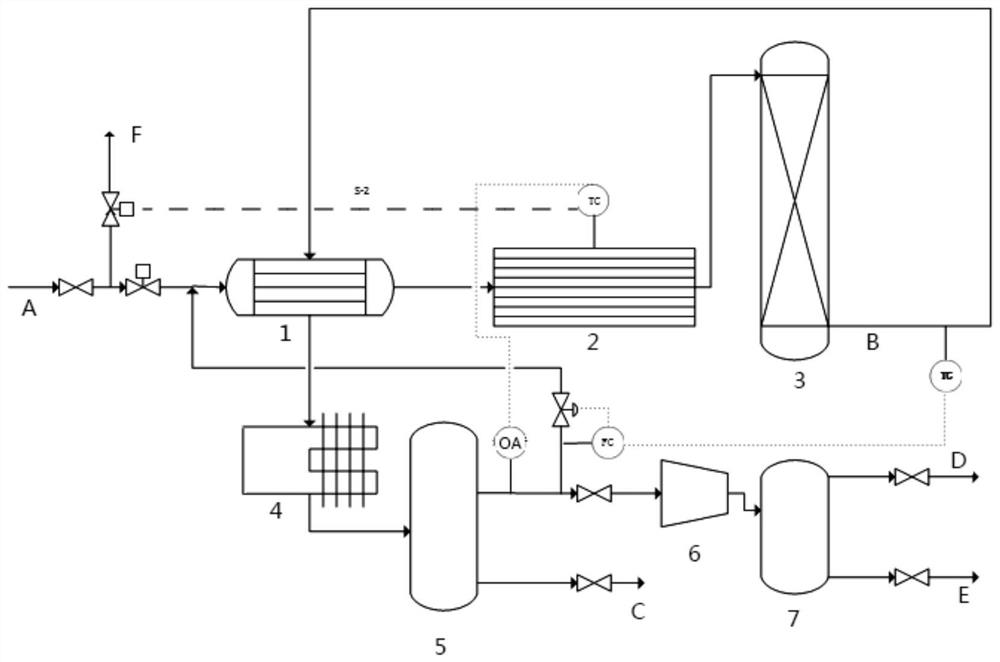

Catalyst and catalytic oxidation deoxidation method for gas containing unsaturated hydrocarbon

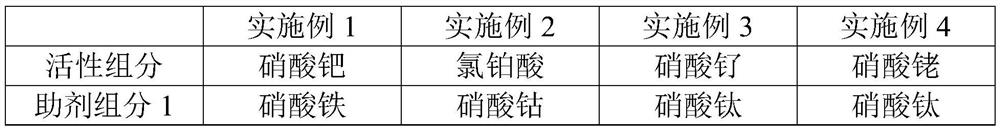

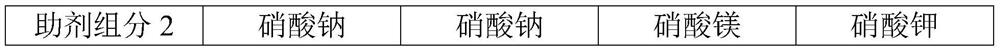

ActiveCN113244931AReduce generationSuppress generationGas treatmentHydrocarbon purification/separationAlkaline earth metalPtru catalyst

Owner:CHINA PETROLEUM & CHEM CORP +1

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap