Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Cellulose fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellulose fibers (/ˈsɛljʊloʊs, -loʊz/) are fibers made with ethers or esters of cellulose, which can be obtained from the bark, wood or leaves of plants, or from other plant-based material. In addition to cellulose, the fibers may also contain hemicellulose and lignin, with different percentages of these components altering the mechanical properties of the fibers.

Antimicrobial lubricant for wood fiber-plastic composites

ActiveUS20050256231A1Prevent rotCoatings with pigmentsNon-macromolecular organic additionSulfateWood fibre

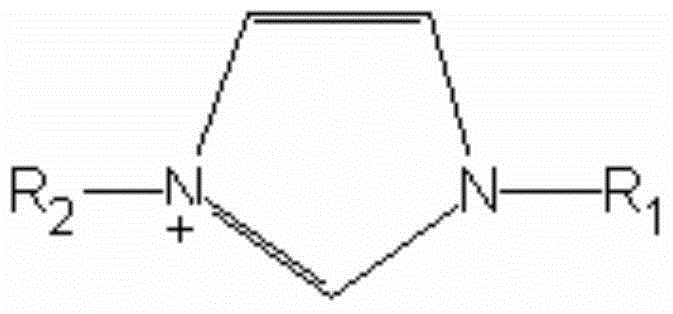

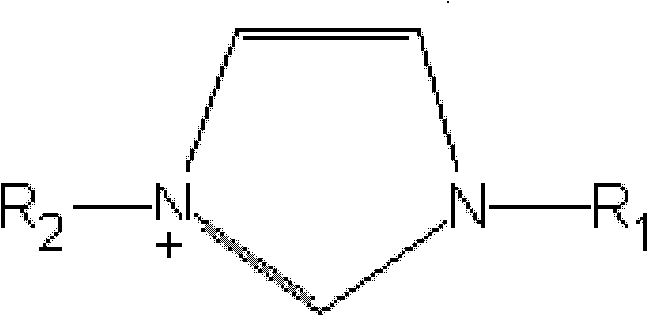

The invention relates to a polymer-cellulosic fiber composition comprising a polymer, a cellulosic fiber, and a quaternary ammonium alkyl salt wherein the latter imparts antimicrobial properties to the composition and functions as a lubricant during the formation of the composition. The quaternary ammonium alkyl salts may be alkyl carboxylate, alkyl sulfate, alkyl sulphonate, alkyl phosphate, or alkyl phosphite. Certain of the salts are new compositions of matter. The method of extruding and the extrudate are also claimed.

Owner:ARXADA LLC

Alkaline pad dyeing method for nylon 56 and cellulose fiber blended fabric

The invention provides an alkaline pad dyeing method for blended fabric of nylon 56 and cellulose fibers. According to the method, a vat dye, a reactive dye, a direct dye and a sulfur dye are adoptedto carry out one-bath pad dyeing on the blended fabric of the nylon 56 fibers and the cellulose fibers, the pad dyeing of the blended fabric can be completed by adopting a set of dyes, after dyeing, the fabric is bright in color and dark in color, the friction resistance and the water resistance can reach more than grade 3-4, the color fastness to sunlight can reach more than grade 5, the processis simple, and energy conservation and emission reduction are achieved.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA

Cellulosic fiber fabric ink jet transfer printing method

ActiveCN107780264APrevent seepageImprove bindingTransfer printing processDyeing processColour fastnessPolyethylene terephthalate

Owner:CHANGZHOU UNIV

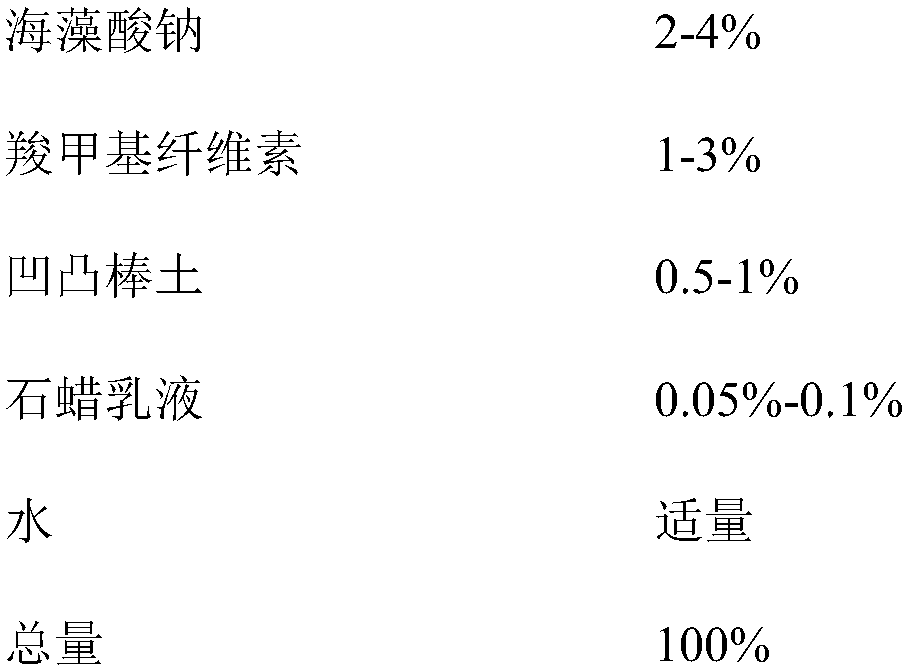

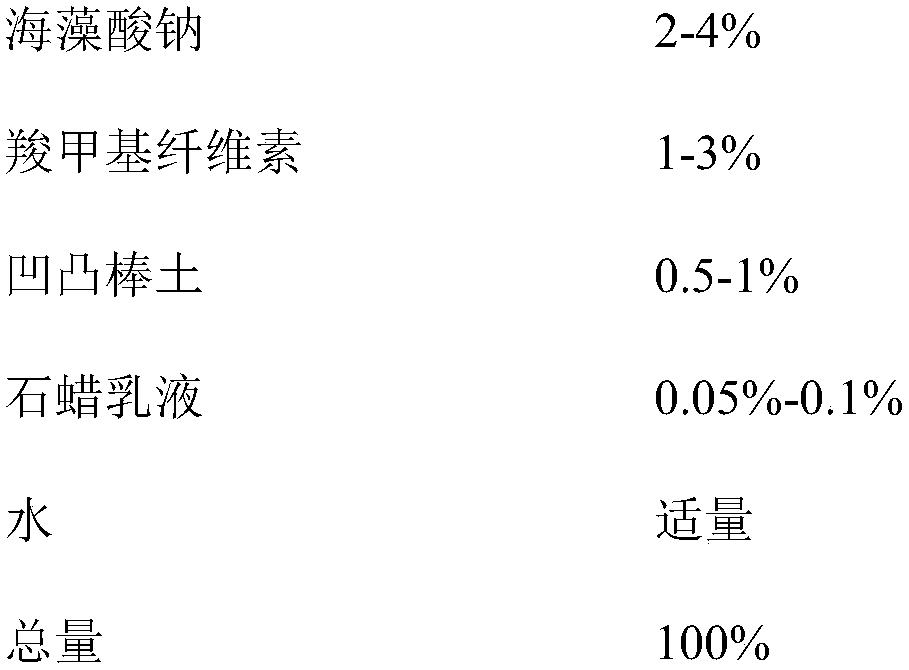

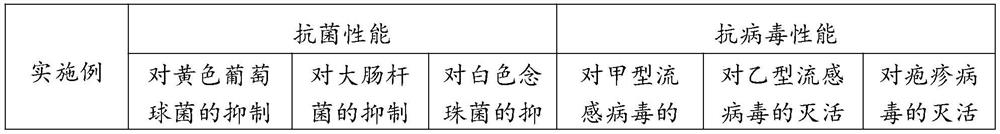

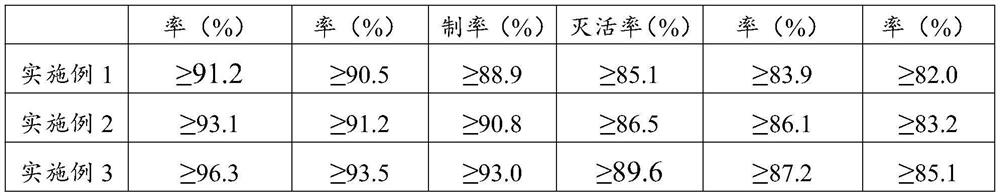

Antibacterial and antiviral cellulose fiber and preparation method and application thereof

ActiveCN112176451AGood antiviral effectDoes not affect physical propertiesPhysical treatmentBiochemical fibre treatmentRegenerating fibersCyclodextrin

Owner:青岛尼希米生物科技有限公司

Flame-resistant high visibility textile fabric for use in safety apparel

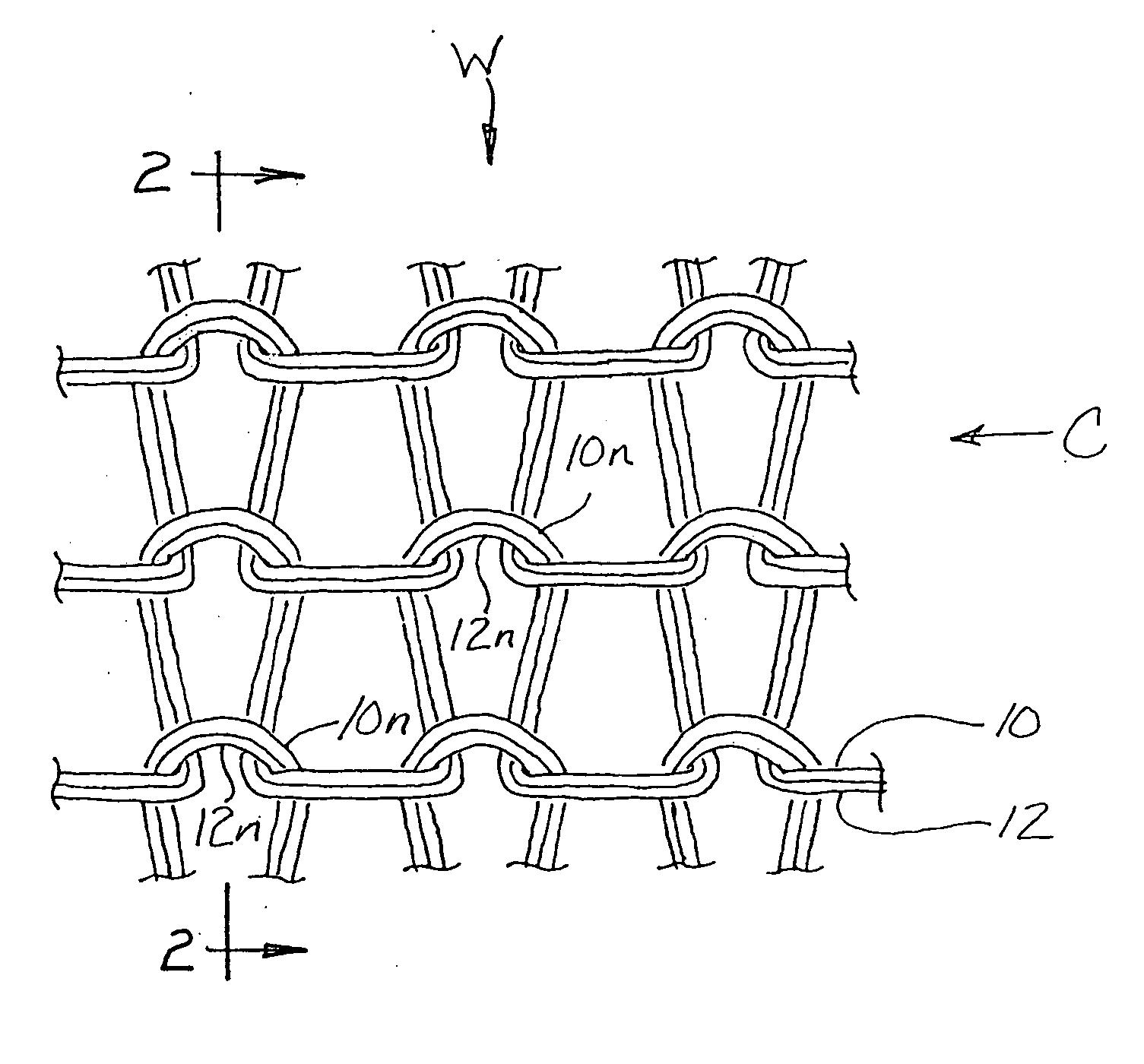

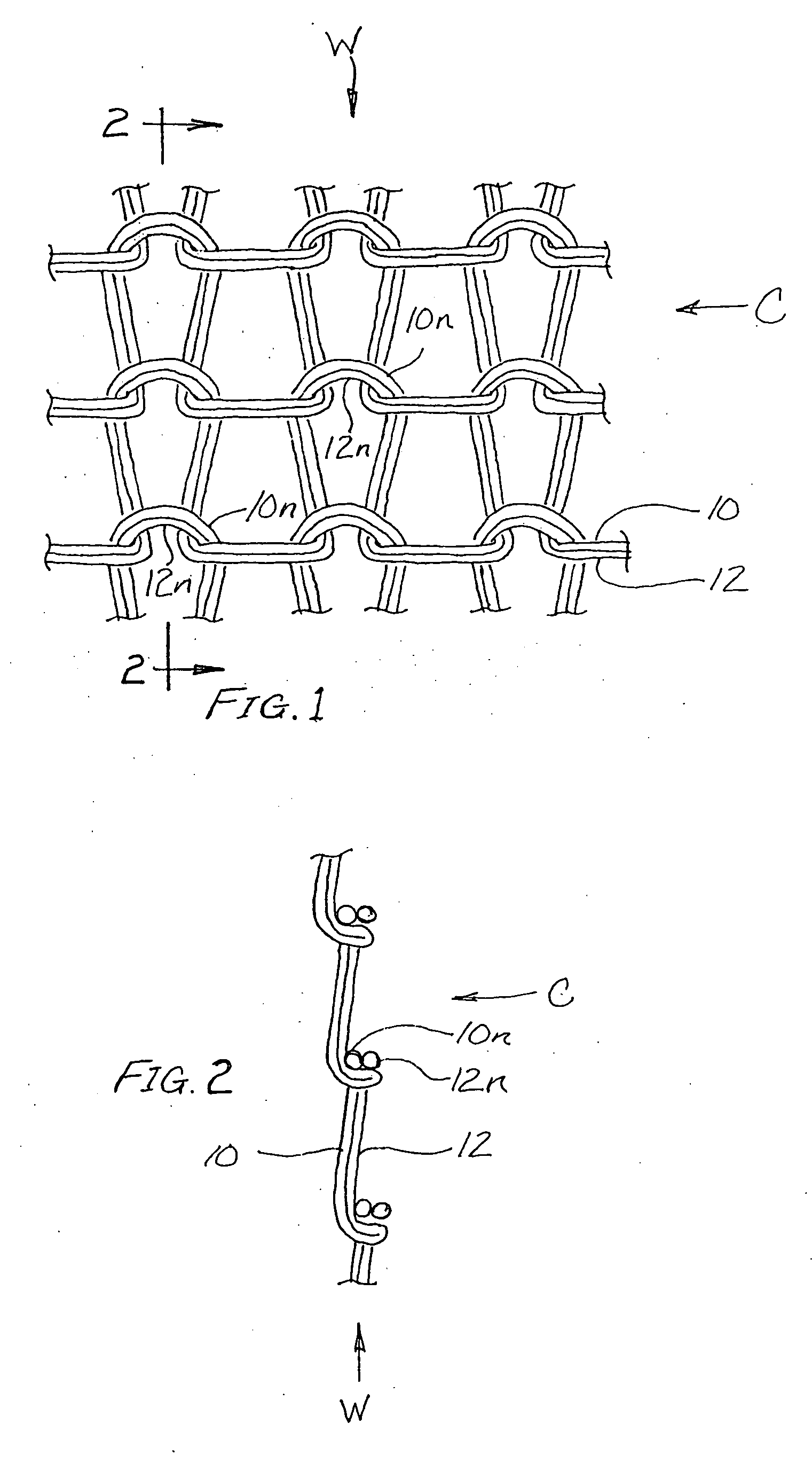

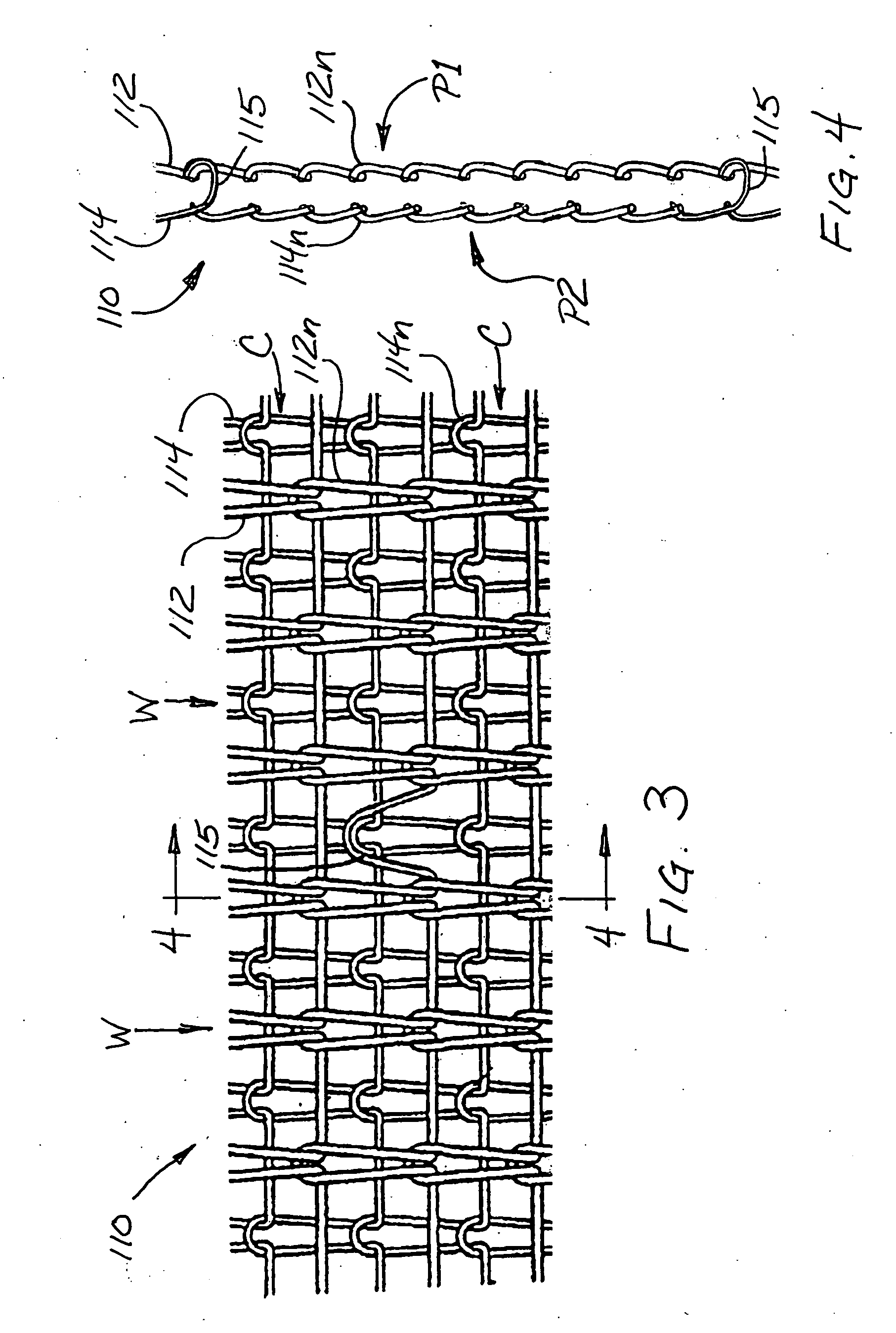

ActiveUS20100003880A1Improve visibilityFlame resistanceWeft knittingOrnamental textile articlesVisibilityYarn

Owner:INNOVATIVE TEXTILES LLC

Material comprising ultrafine cellulose fibers

ActiveUS20180265597A1Good dispersionPaper/cardboardCellulose pulp after-treatment modificationCellulose fiberAqueous medium

An object of the invention is to provide a material comprising ultrafine cellulose fibers, having good dispersibility of fine particles in an aqueous medium containing ultrafine cellulose fibers. According to the invention, there is provided a material comprising ultrafine cellulose fibers, wherein the content of the ultrafine cellulose fibers is 80% by mass or more, and the haze value of a sample, which has been prepared by adding the material comprising ultrafine cellulose fibers to pure water to a solid concentration of 0.4% by mass, and stirring the mixture with a disperser under conditions of 1500 rpm and 5 minutes, is 20% or less.

Owner:OJI HLDG CORP

Method for preparing totally chlorine-free high-whiteness cellulose fiber

ActiveCN101974797AAvoid pollutionHigh whiteness requirementArtificial filaments from viscoseWet spinning methodsWhitening AgentsWastewater

Owner:潍坊欣龙生物材料有限公司

Low acetated cellulose fibers and preparation method thereof

ActiveCN102453970BFeel smoothSoft lusterArtificial filament washing/dryingArtificial filaments from cellulose derivativesBreaking strengthCellulose fiber

Owner:CHINESE TEXTILE ACAD

Oral cleaning wet tissue

InactiveCN106619199AEffective and effective cleaningEasy to cleanCosmetic preparationsToilet preparationsGluconic acidCellulose fiber

Owner:青岛力天宏泰新能源科技有限公司

Preparation method of modified intumescent flame-retardant cellulose fibers

ActiveCN113818105ATo achieve the effect of synergistic flame retardancyReduce the amount addedCellulose/protein filament chemical after-treatmentPolymer scienceLimiting oxygen index

Owner:潍坊欣龙生物材料有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap