Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7 results about "Reactive dye" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In a reactive dye, a chromophore (an atom or group whose presence is responsible for the colour of a compound) contains a substituent that reacts with the substrate. Reactive dyes have good fastness properties owing to the covalent bonding that occurs during dyeing. Reactive dyes are most commonly used in dyeing of cellulose like cotton or flax, but also wool is dyeable with reactive dyes. Reactive dyeing is the most important method for the coloration of cellulosic fibres. Reactive dyes can also be applied on wool and nylon; in the latter case they are applied under weakly acidic conditions. Reactive dyes have a low utilization degree compared to other types of dyestuff, since the functional group also bonds to water, creating hydrolysis.

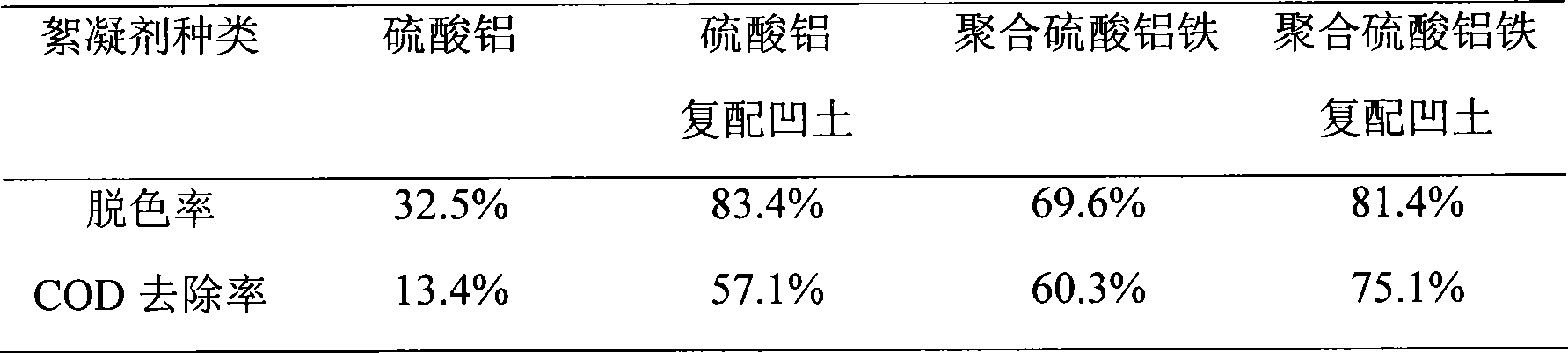

Method for preparing composite flocculant for treating printing and dyeing wastewater using reactive dye as main component

InactiveCN101423274AWide variety of sourcesLow costWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationFiltrationDyeing wastewater

Owner:DONGHUA UNIV

Alkaline pad dyeing method for nylon 56 and cellulose fiber blended fabric

The invention provides an alkaline pad dyeing method for blended fabric of nylon 56 and cellulose fibers. According to the method, a vat dye, a reactive dye, a direct dye and a sulfur dye are adoptedto carry out one-bath pad dyeing on the blended fabric of the nylon 56 fibers and the cellulose fibers, the pad dyeing of the blended fabric can be completed by adopting a set of dyes, after dyeing, the fabric is bright in color and dark in color, the friction resistance and the water resistance can reach more than grade 3-4, the color fastness to sunlight can reach more than grade 5, the processis simple, and energy conservation and emission reduction are achieved.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA

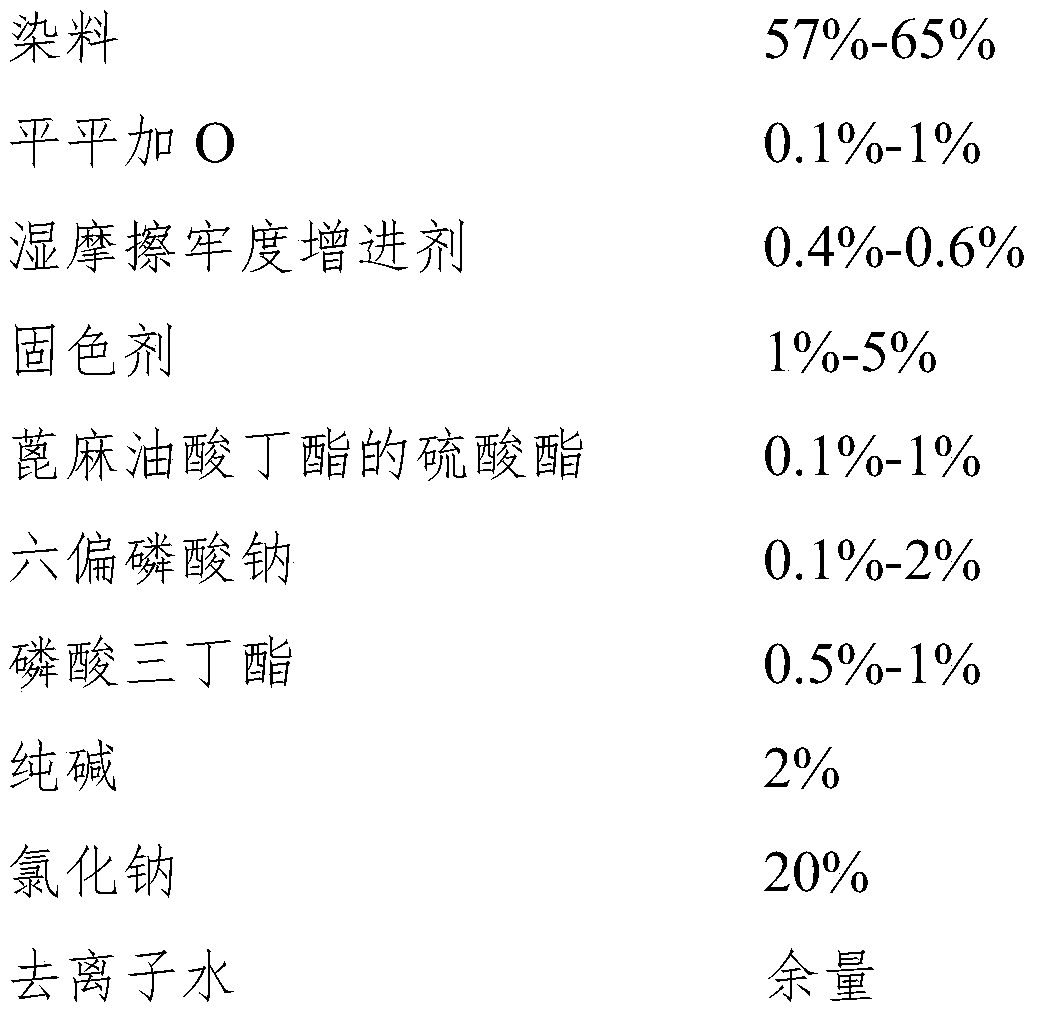

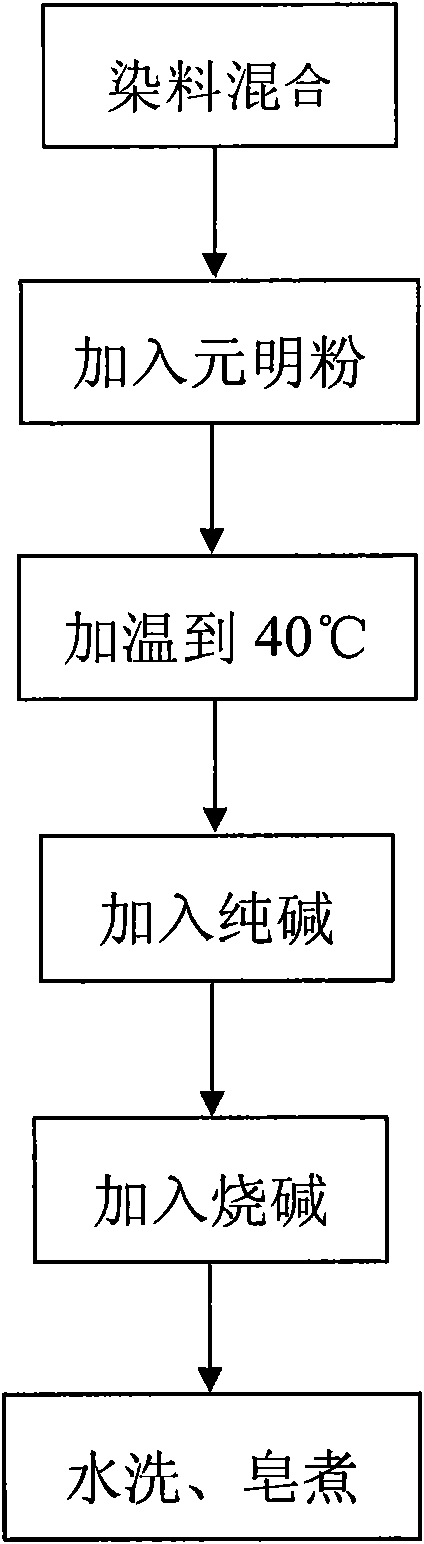

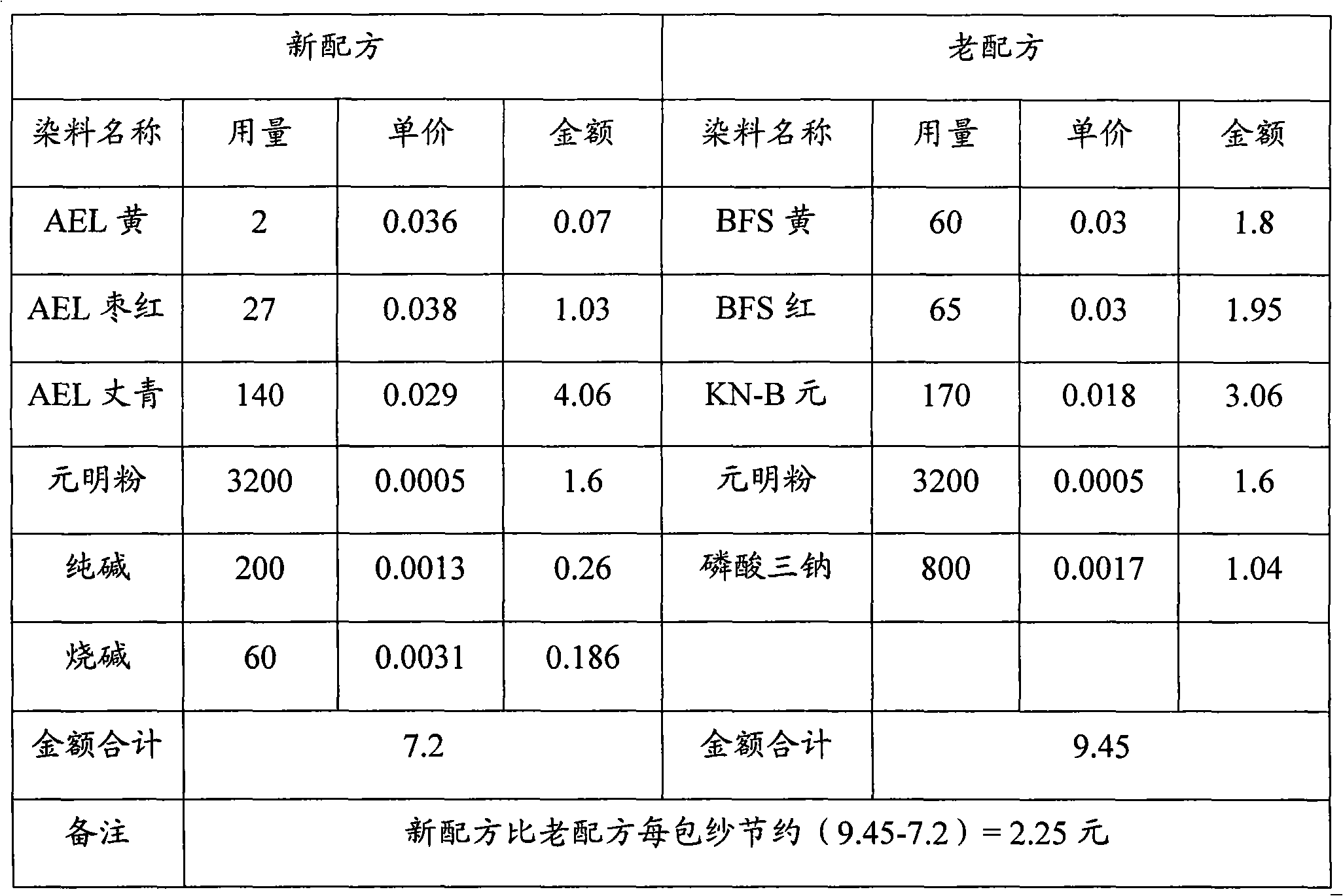

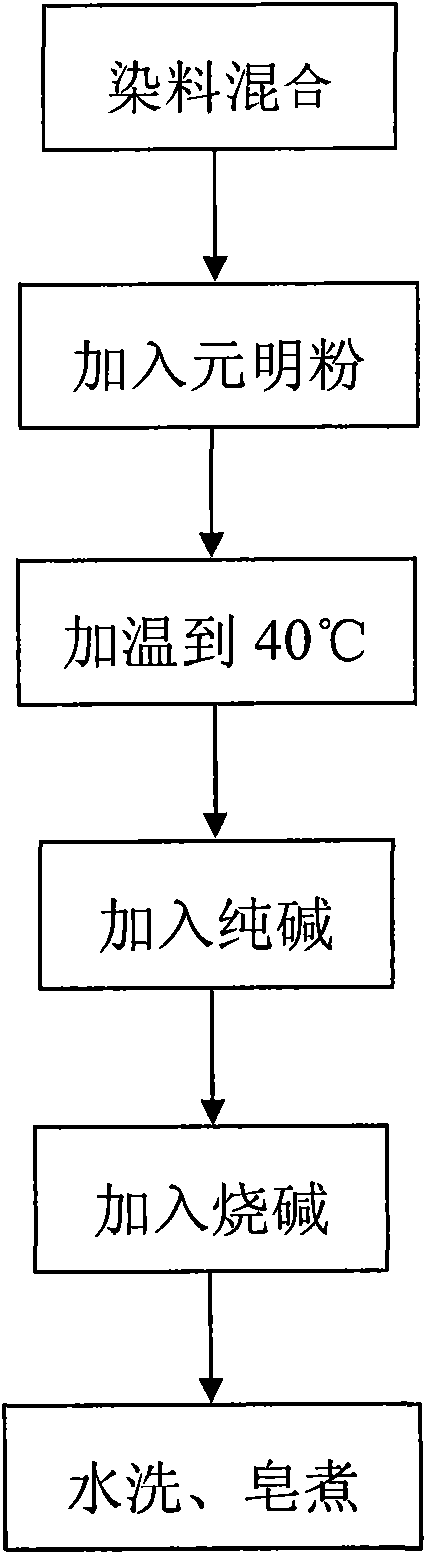

Reactive dye formula for cotton/linen blending and preparing method thereof

InactiveCN105507027AImprove wet rubbing fastnessHigh color fixing rateDyeing processRubbingRicinoleic acid

Owner:XIAO COUNTY TAI DA DRESS PROD

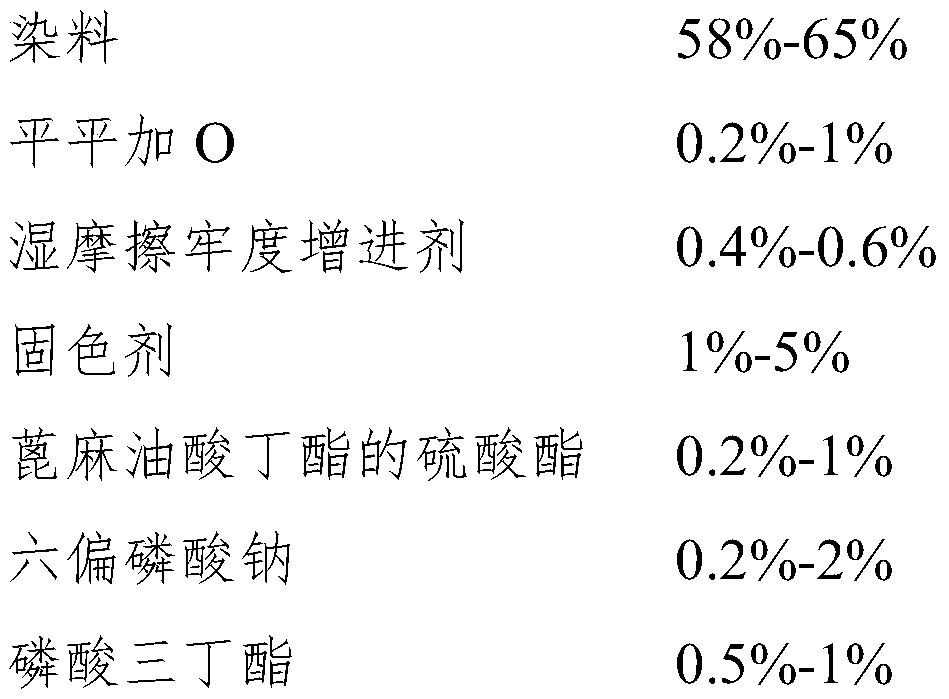

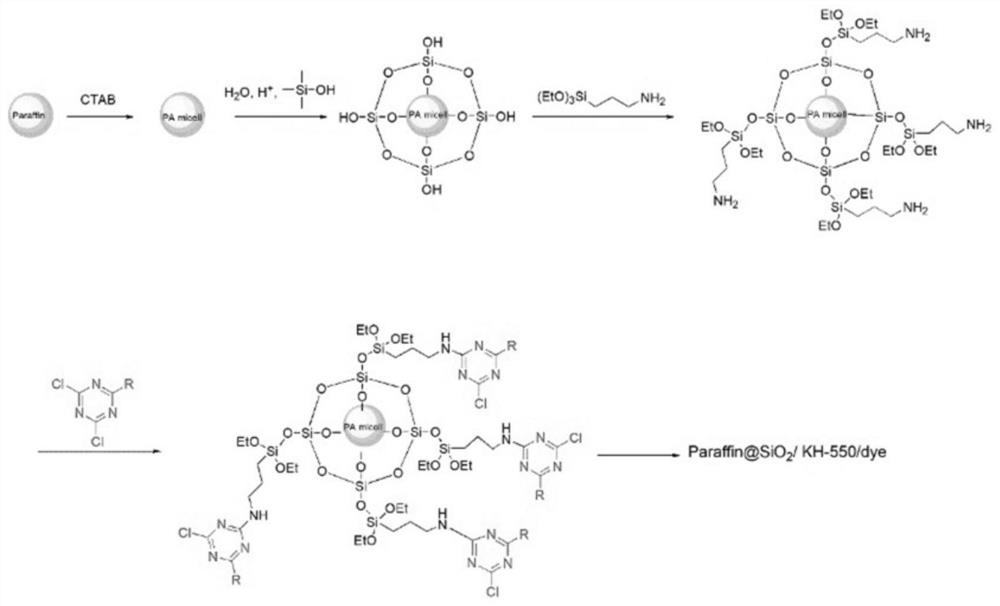

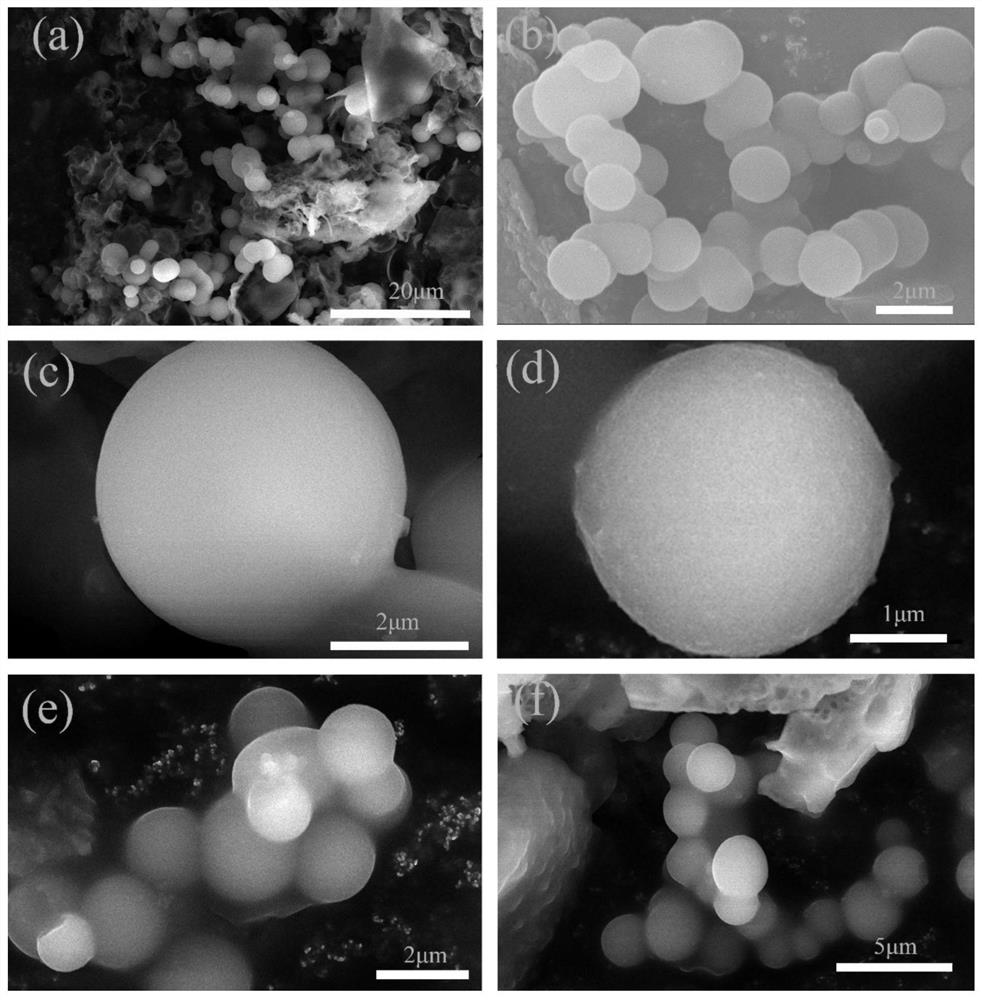

Paraffin coated SiO2 color phase change microcapsule as well as preparation method and application thereof

ActiveCN113429938AImproves UV protectionIncreased UV AbsorptionHeat-exchange elementsRadiation-absorbing paintsParaffin waxThermal insulation

Owner:XIAO HLDG

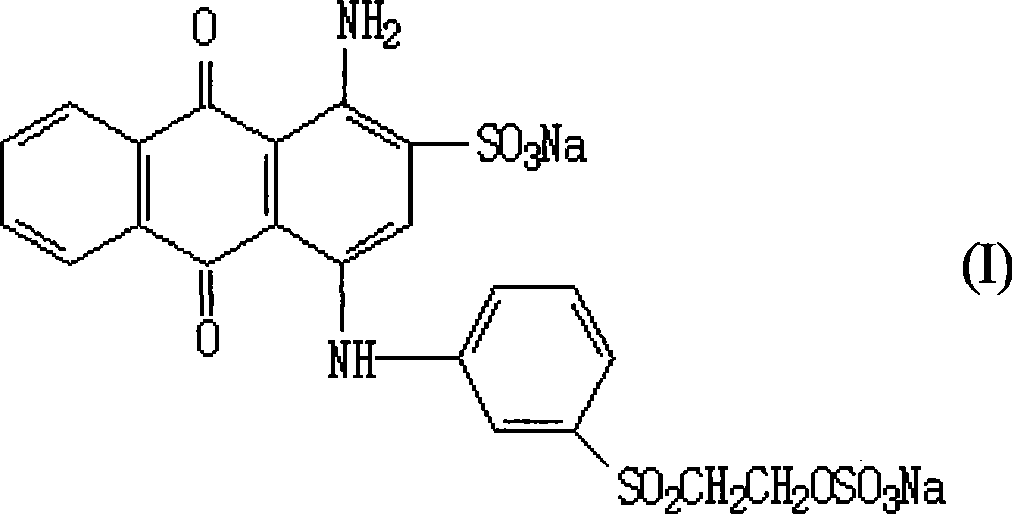

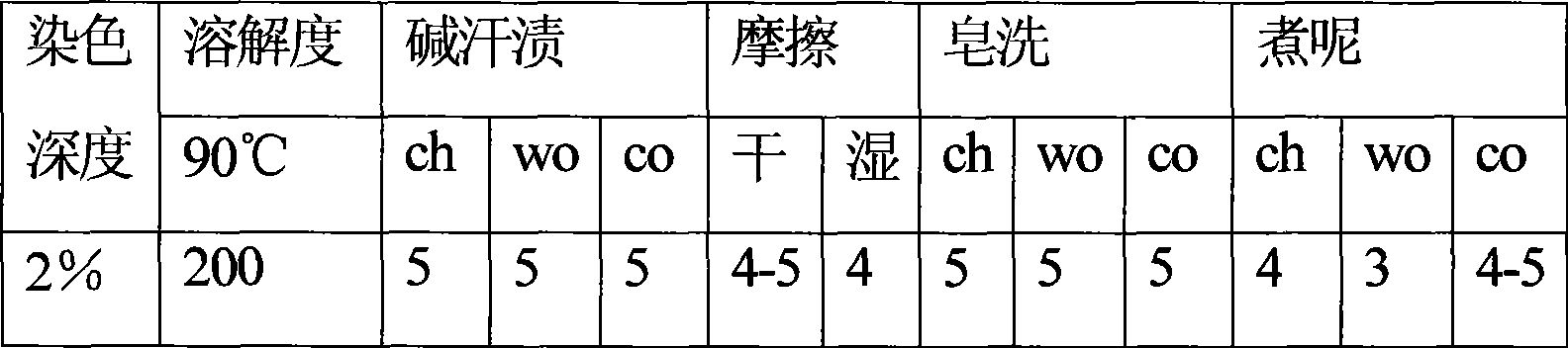

Preparation of brilliant blue KN-R

Owner:TIANJIN DEK CHEM

Deep navy reactive dye fixing agent and production process thereof

InactiveCN101993613AReduce pollutionReduce manufacturing costOrganic dyesDyeing processPurplish redRoom temperature

Owner:HAIAN COUNTY FUXING BLEACHING & DYEING

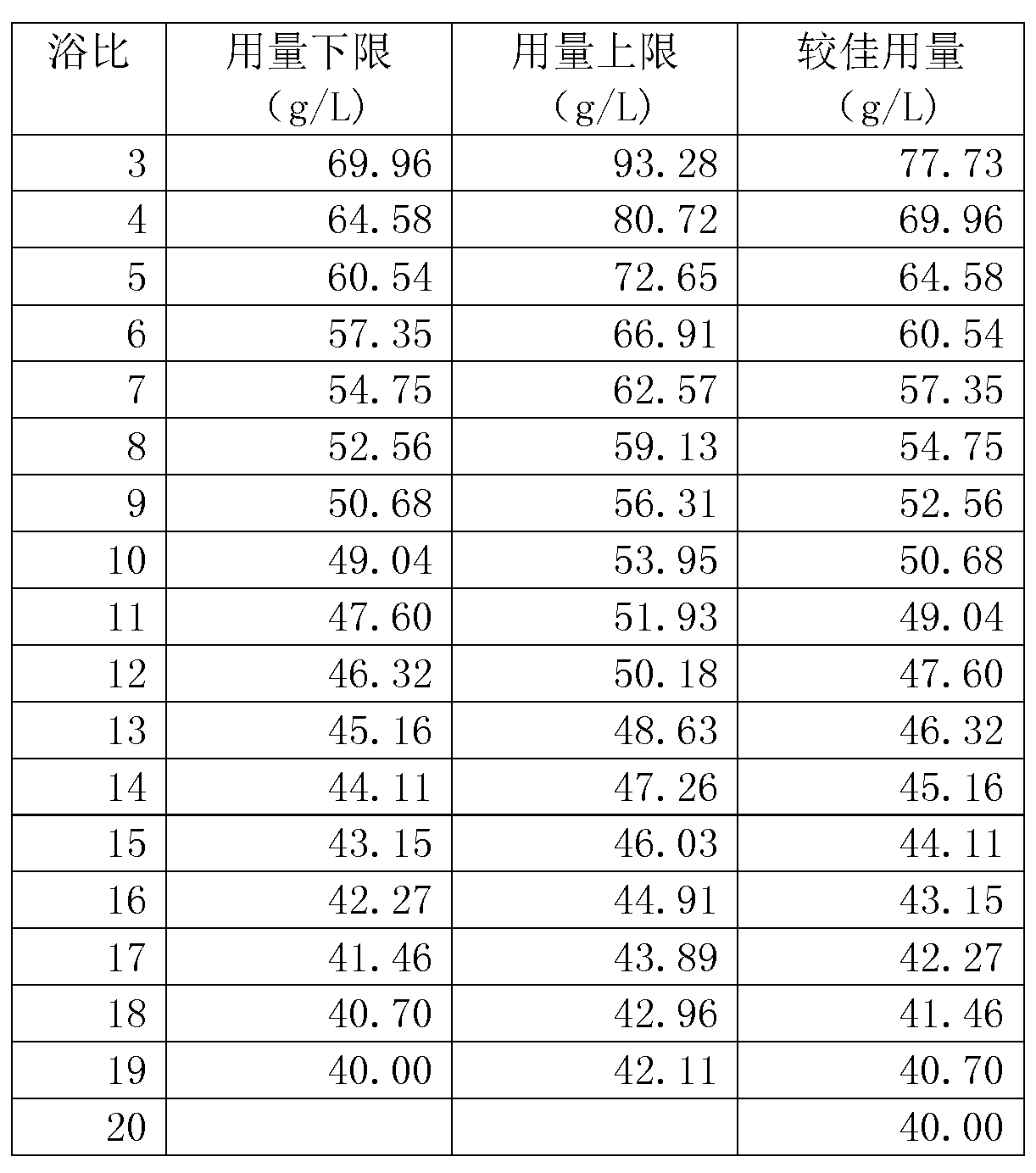

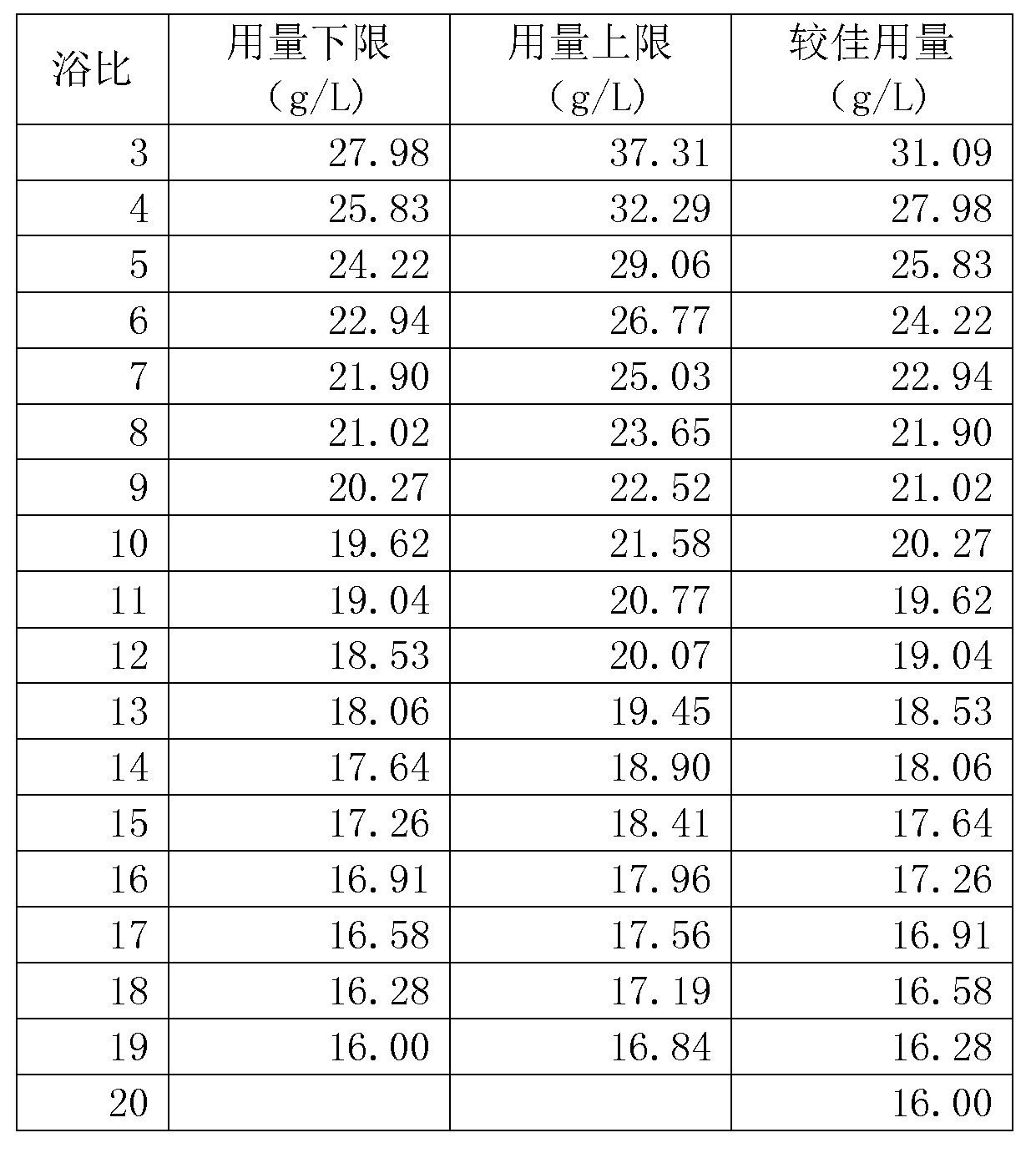

Method for converting traditional bath ratio reactive dye dyeing prescription into small bath ratio reactive dye dyeing prescription

ActiveCN102797169AEasy and fast conversion methodDyeing depth conforms toDyeing processLower limitDissolution

Owner:ZHEJIANG YIDE CHEM

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap