Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Coal dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal dust is a fine powdered form of coal, which is created by the crushing, grinding, or pulverizing of coal. Because of the brittle nature of coal, coal dust can be created during mining, transportation, or by mechanically handling coal. It is a form of fugitive dust.

Crushing device for producing moulded coal

The invention provides a crushing device for producing moulded coal. The crushing device comprises a crushing mechanism, a vibration mechanism and a coarse material recycling mechanism. The crushing mechanism comprises a crushing machine body, a crushing motor and a scraper motor. The lower end of the crushing mechanism is provided with the vibration mechanism which is a vibration screen. The interior of the vibration screen is provided with screen cloth with the particle size being 3 mm, the upper portion of the vibration screen is provided with a coarse material outlet, and the lower portion of the vibration screen is provided with a discharge outlet. The coarse material recycling mechanism comprises a receiving hopper, an air cylinder and a telescopic rod, wherein the receiving hopper is arranged at the lower end of the coarse material outlet, and the air cylinder is arranged on a fixed rod and connected with a moving rod; the moving rod is in axial connection with the telescopic rod, and an air cylinder switch is connected to the air cylinder; and the bottom of the receiving hopper is provided with a slide plate and a slipway matched with the slide plate. The crushing device for producing the moulded coal has the beneficial effects that by arranging the coarse material recycling mechanism, not only can continuous operation of a production line be ensured, but also coarse materials can be recycled through recrushing, and coal dust can be prevented from flying through a hopper cover.

Owner:TIANJIN BEIFANG YULIANG TECH

Production raw material for preparing calcium oxide by using calcium carbide furnace gas purified ash and preparation process thereof

InactiveCN109179468AEasy to operateSave energyCalcium/strontium/barium oxides/hydroxidesCombustionCoal dust

Owner:石嘴山市鹏盛化工有限公司

A New Method of Preventing Coal Dust Explosion in Underground Coal Mine

InactiveCN102261260AReduce concentrationLower explosion limitDust removalFire preventionSprayerPolyvinyl alcohol

Owner:梁红

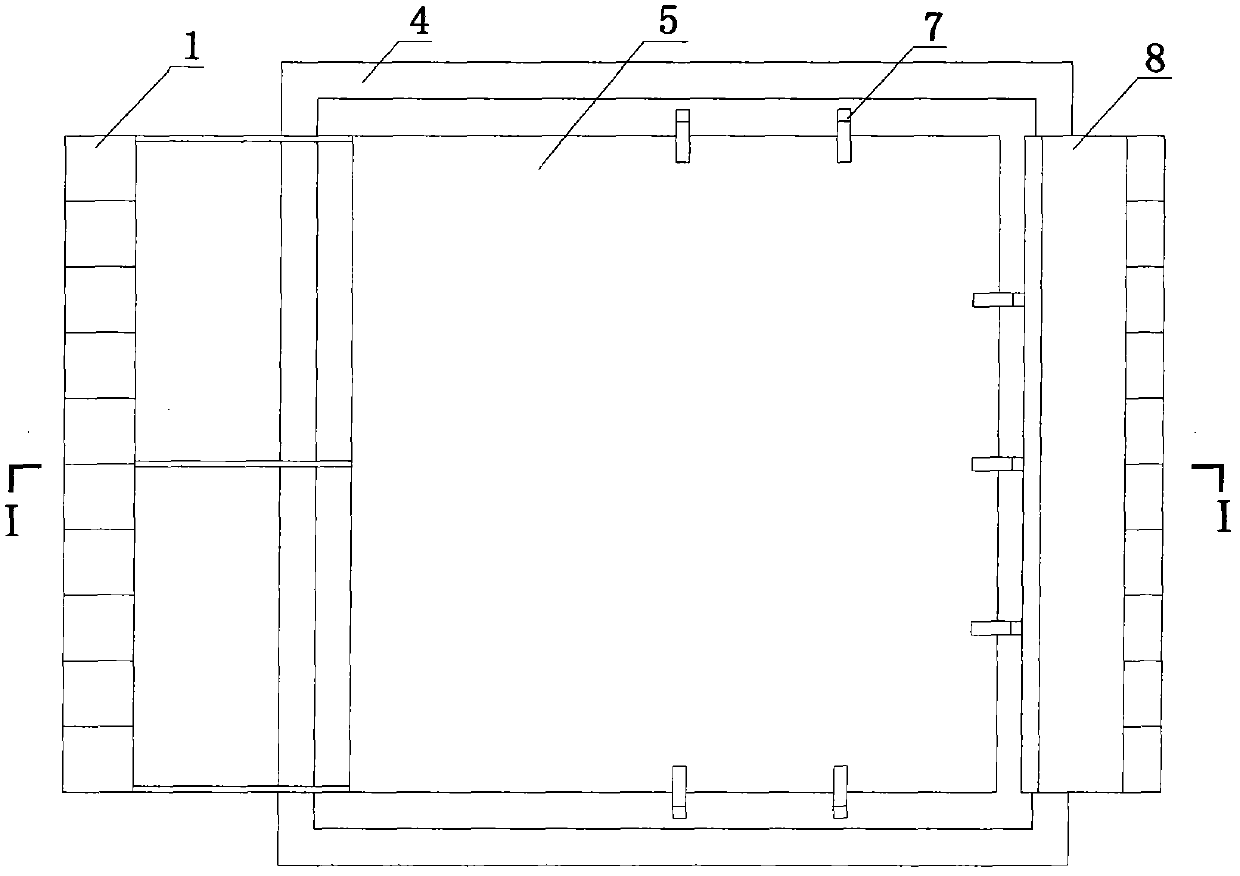

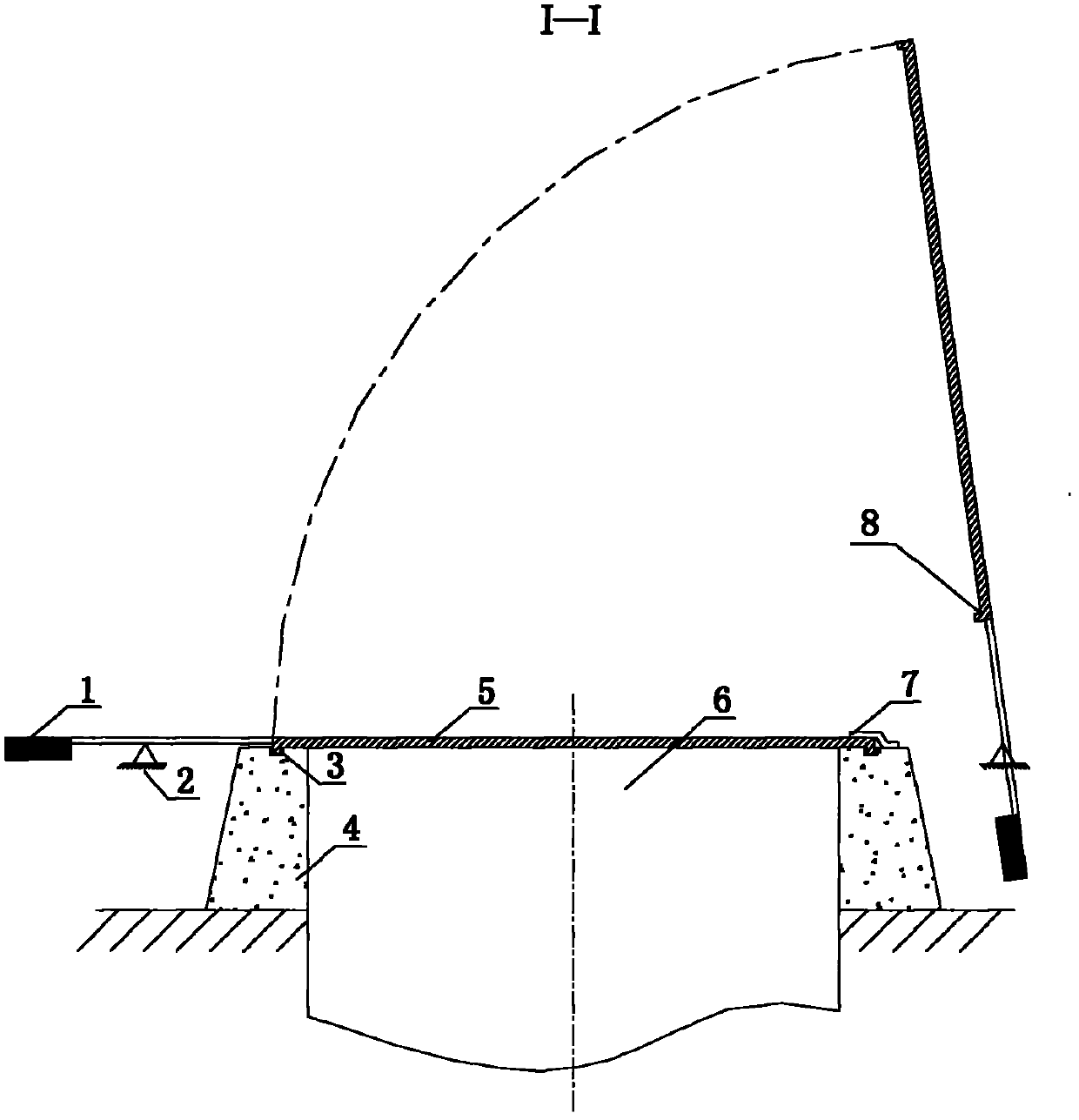

Novel anti-explosion door of vertical air shaft

InactiveCN103375173AGuarantee the safety of lifeAvoid magnificationMining devicesTunnel/mines ventillationCoal dustDust explosion

Owner:辛嵩 +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap