Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12 results about "Collimator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A collimator is a device which narrows a beam of particles or waves. To narrow can mean either to cause the directions of motion to become more aligned in a specific direction (i.e., make collimated light or parallel rays), or to cause the spatial cross section of the beam to become smaller (beam limiting device).

Optical microscopic imaging system and imaging method

The invention relates to an optical microscopic imaging system and imaging method, belonging to field of optical microscopes. The system comprises a laser, a half-wave plate, a polarization beam splitter prism, a beam expander collimator, a microscope objective, a reflective mirror, a beam combining mirror, a CCD (Charge Coupled Device) and a computer. After the laser emits laser light, the polarization beam splitter prism divides the laser light into two light beams, and one of the light beams transmits a transparent object. The two light beams pass through the beam combining mirror and interfere with each other to form an image on the CCD, and the CCD transmits the obtained image into the computer. A microscopic strength image and a phase image of the object are obtained through digital reconstruction in the computer, so that a three-dimensional microscopic of the object is obtained.

Owner:HEBEI UNIV OF ENG

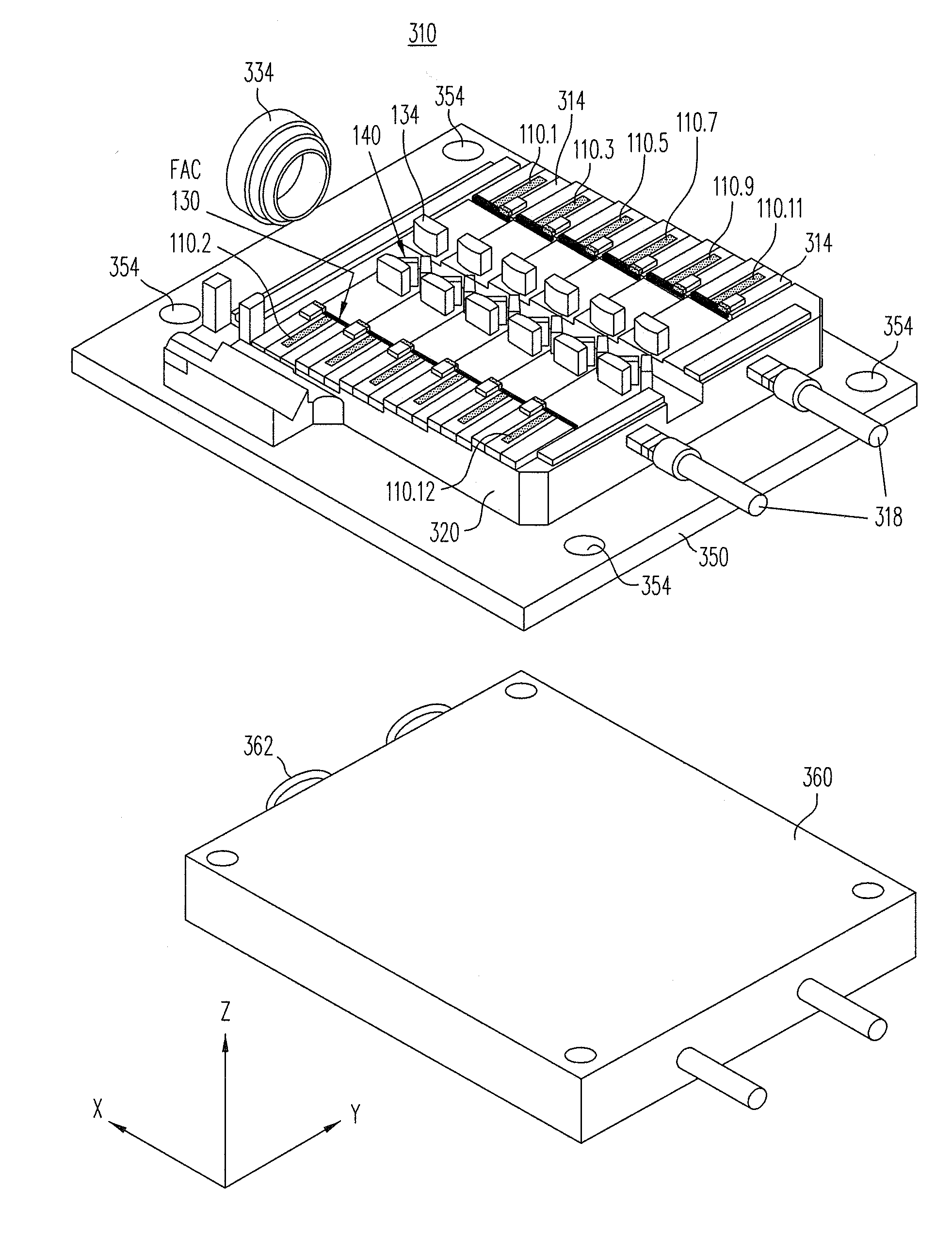

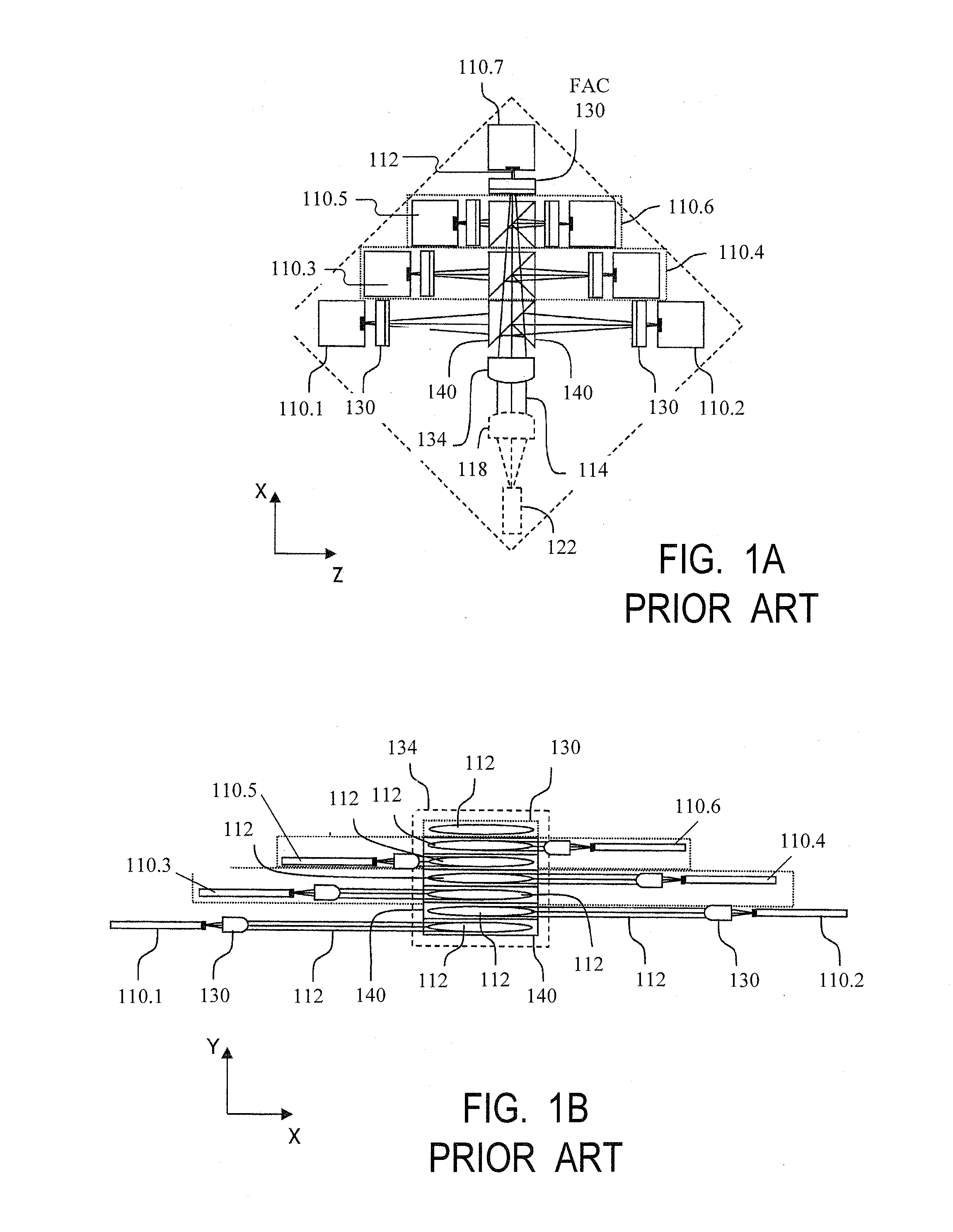

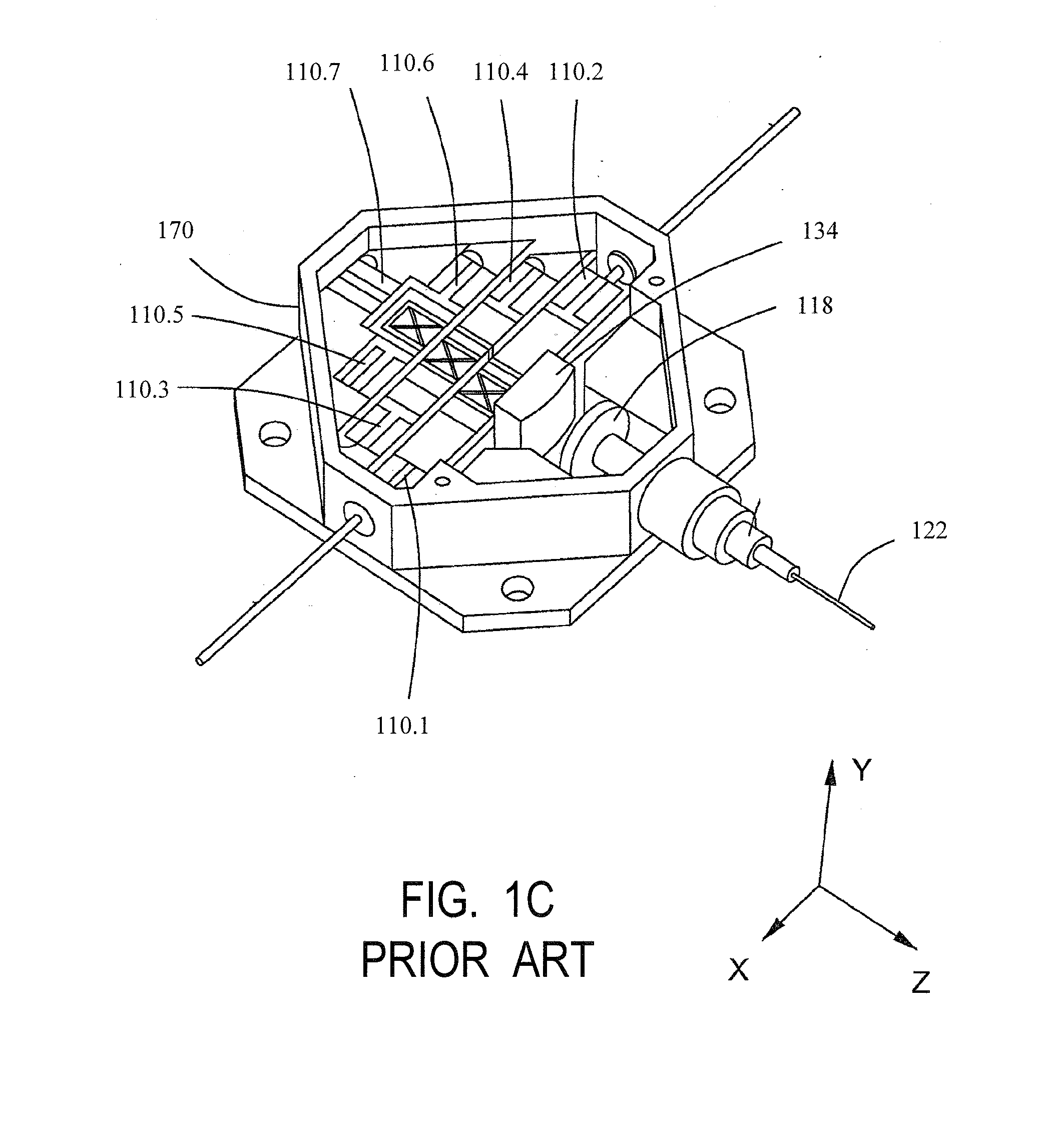

Laser diode combiner modules

InactiveUS20120081893A1Reduce the heating effectImprove thermal stabilityNon-electric lightingPoint-like light sourceLight beamThermal stability

Owner:FAYBISHENKO VICTOR

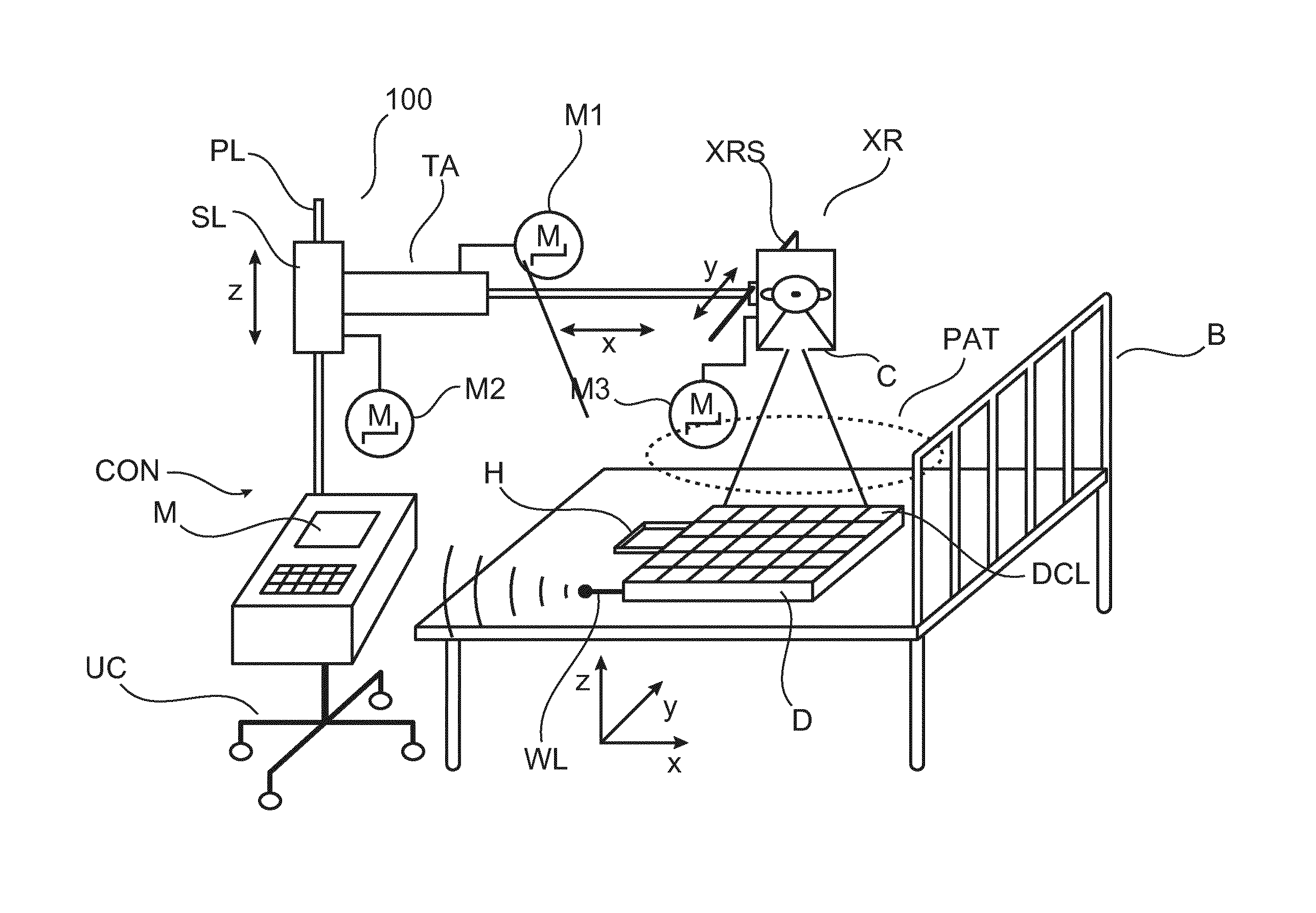

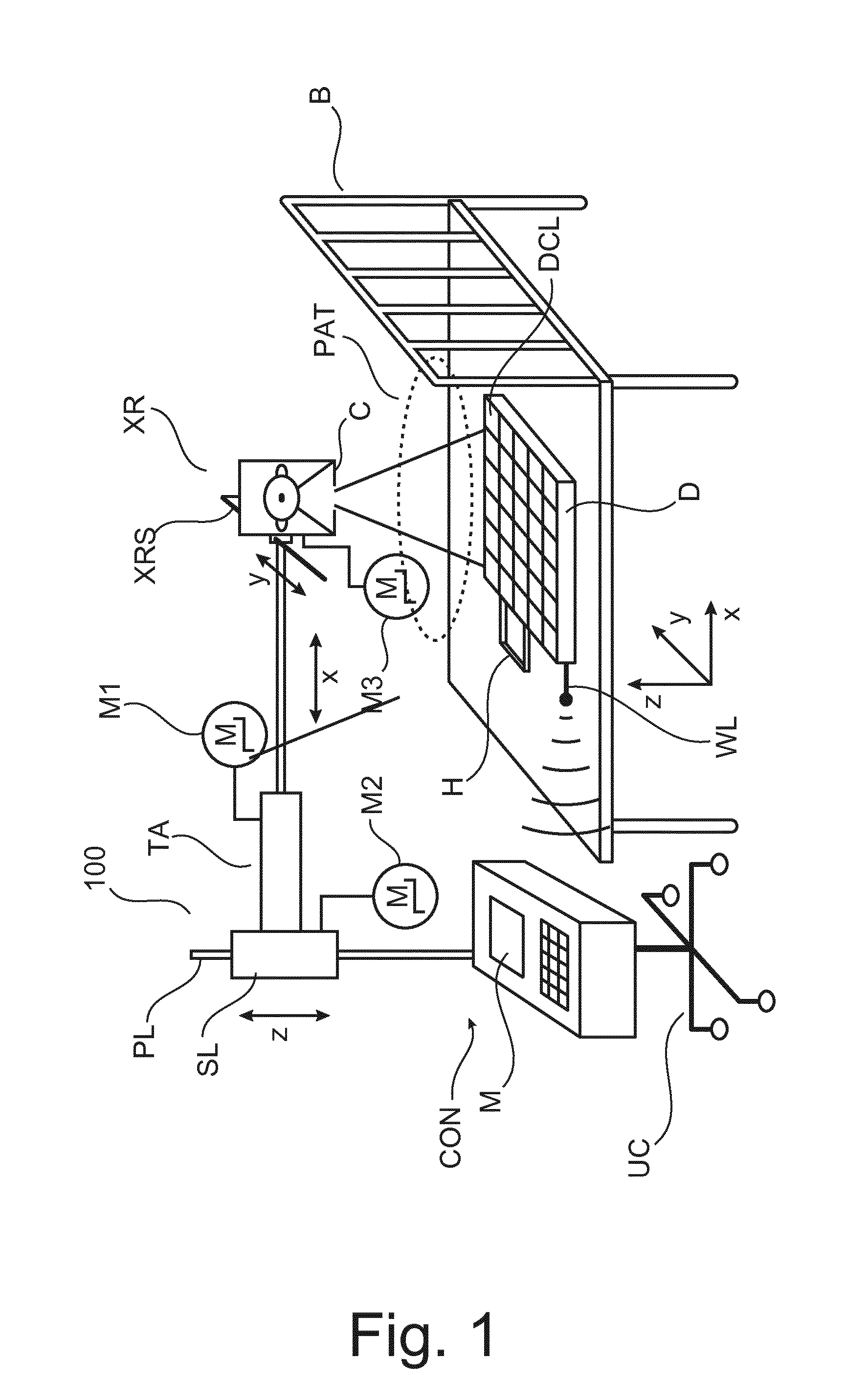

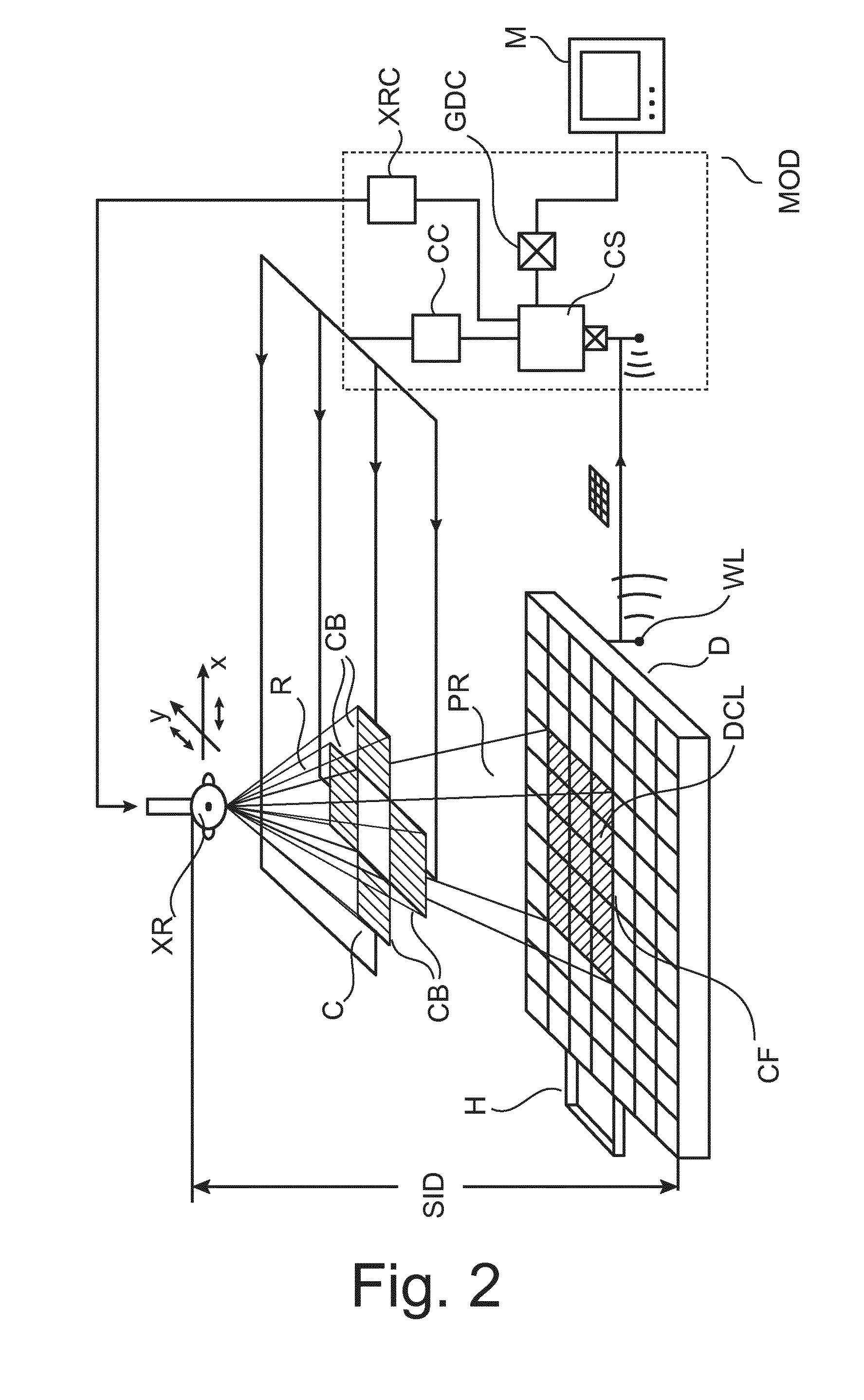

X-ray collimator size and postion adjustment based on pre-shot

Owner:KONINKLJIJKE PHILIPS NV

Projector

ActiveUS20200201155A1ProjectorsPicture reproducers using projection devicesProjection opticsFluorescence

A present disclosure relates to a projector including a light source, an excitation light source, a wavelength converter, a collimator system that parallelizes fluorescence outputted from the wavelength converter, a light separator that separates the fluorescence into second light and third light, a correction lens provided in an optical path of the second or third light, a superimposing lens, a light modulator having a plurality of pixels each including first, second, and third sub-pixels, a microlens array including a plurality of microlenses corresponding to the plurality of pixels, and a projection optical apparatus. First light is incident on a first position on the superimposing lens, the second light is incident on a second position on the superimposing lens, the third light is incident on a third position on the superimposing lens The first light passes through the microlenses and is incident on the first sub-pixels. The second light passes through the microlenses and is incident on the second sub-pixels. The third light passes through the microlenses and is incident on the third sub-pixels.

Owner:SEIKO EPSON CORP

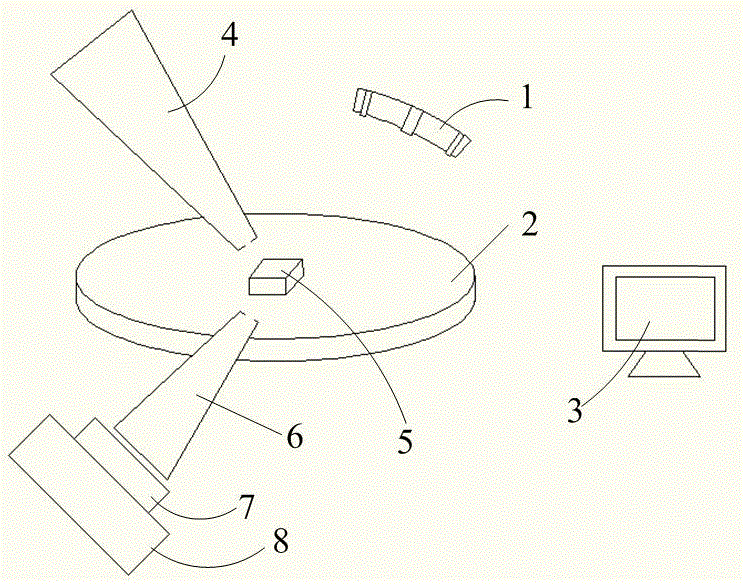

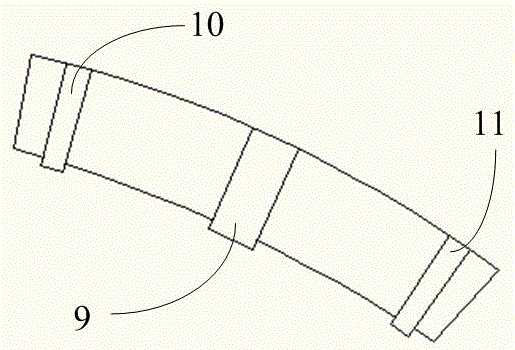

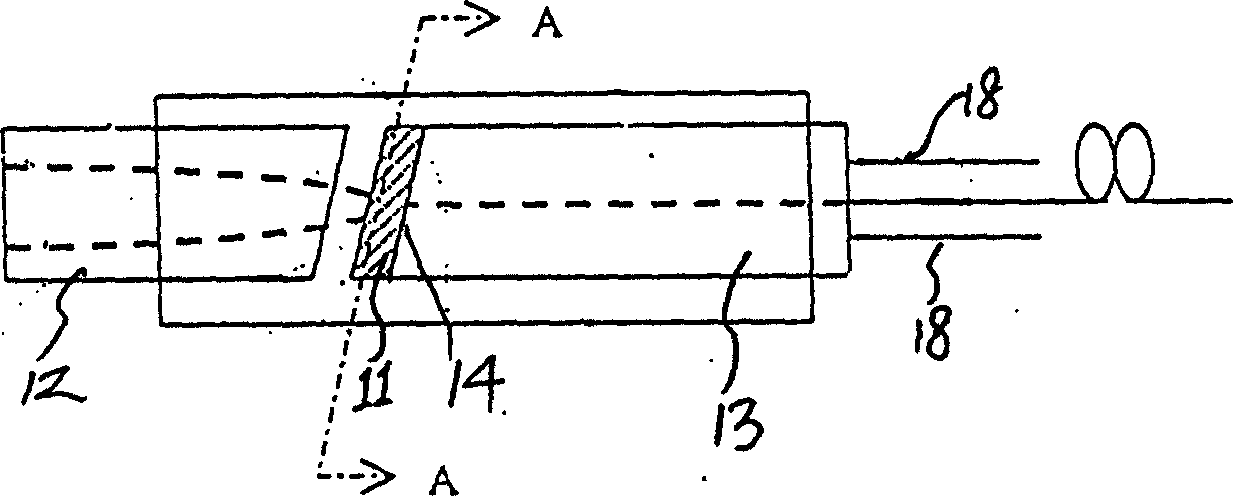

Three-dimensional calibrating measurement device for neutron diffraction stress analysis

PendingCN106770402ASmall space requirementRealize accurate 3D calibrationMaterial analysis using wave/particle radiationStress measurementMeasurement device

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Collimator positioning assembly and positioning method thereof

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

Optical athermal design effect detection system based on image processing

InactiveCN103528800AFast focusingGood repeatabilityTesting optical propertiesSignal processing circuitsBlack body

An optical athermal design effect detection system based on image processing comprises a computer, an infrared target simulation system, a temperature control system and a measurement system which are connected, wherein the infrared target simulation system comprises a black-body radiation source, a black-body controller and a collimator component; the temperature control system consists of a high-low temperature box with controllable temperature and a control part of the high-low temperature box; and the measurement system comprises an infrared imaging detector, a displacement controller and a signal processing circuit. The optical athermal design effect detection system based on image processing has higher focusing speed, good repeatability, higher accuracy and strong capacity of noise interference resistance, and can meet the demand of athermal design effect detection.

Owner:SHAANXI HI-TECH IND CO LTD

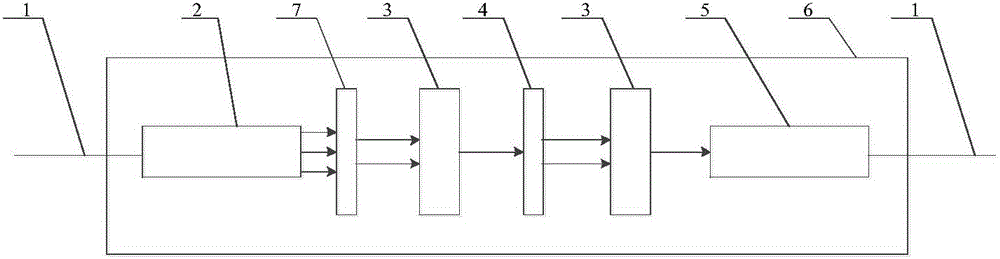

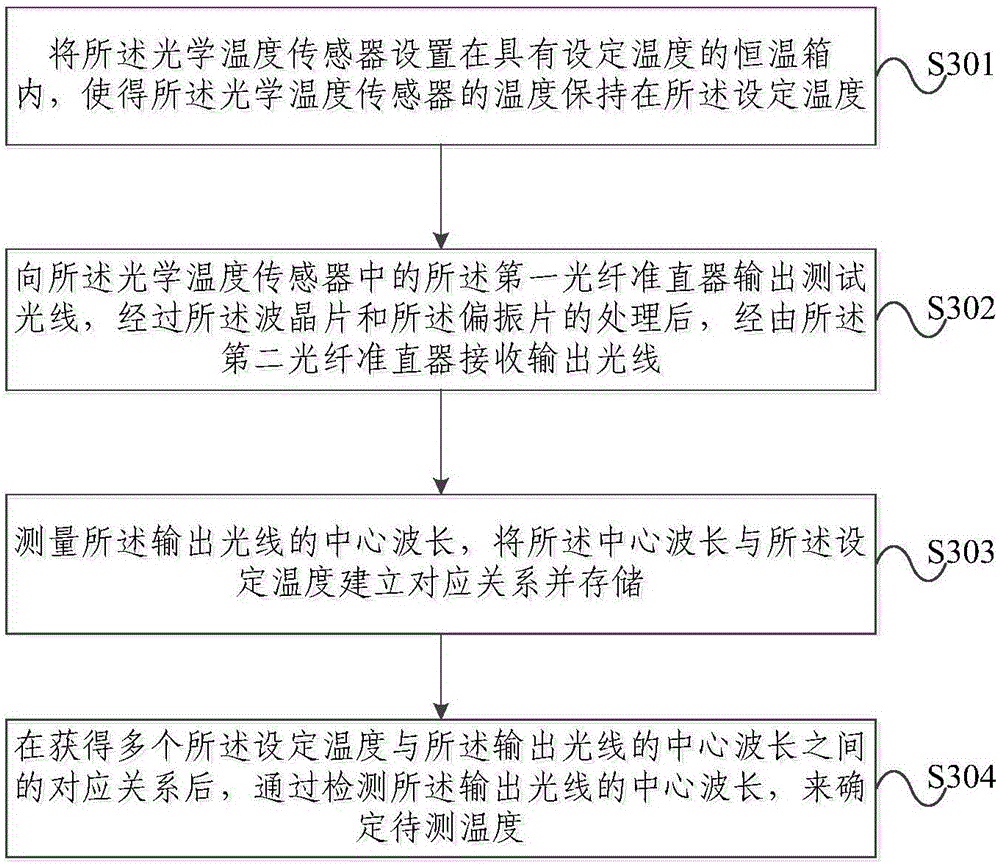

Optical temperature sensor and temperature measurement method

InactiveCN106500866AImprove stabilityThermometers using physical/chemical changesPolarizerLength wave

Owner:STATE GRID CORP OF CHINA +2

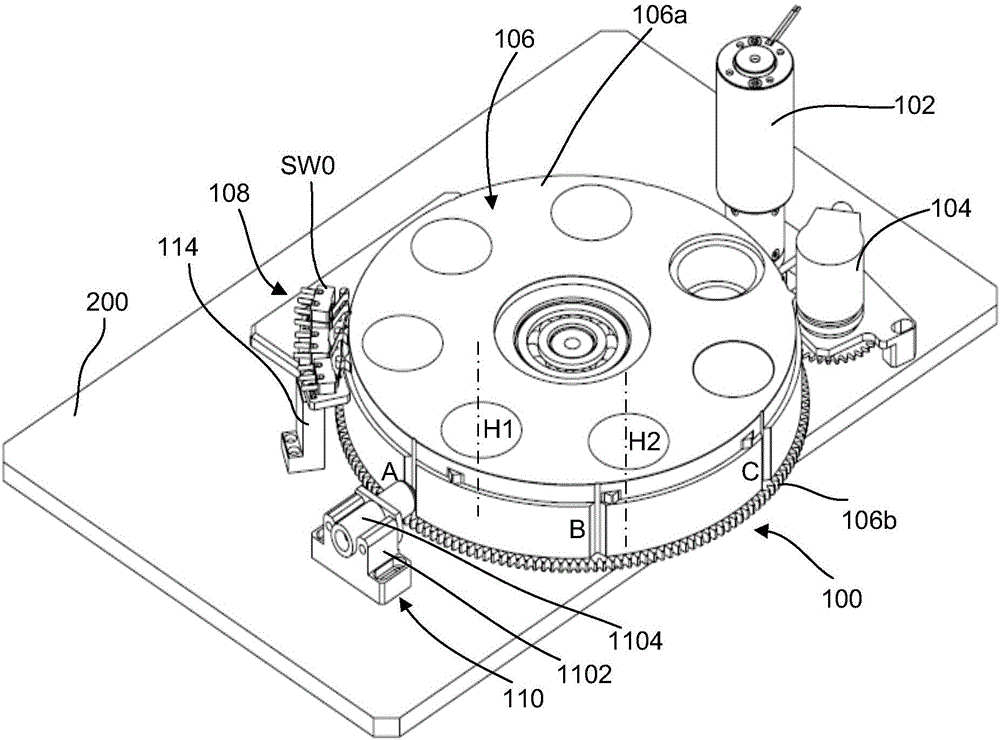

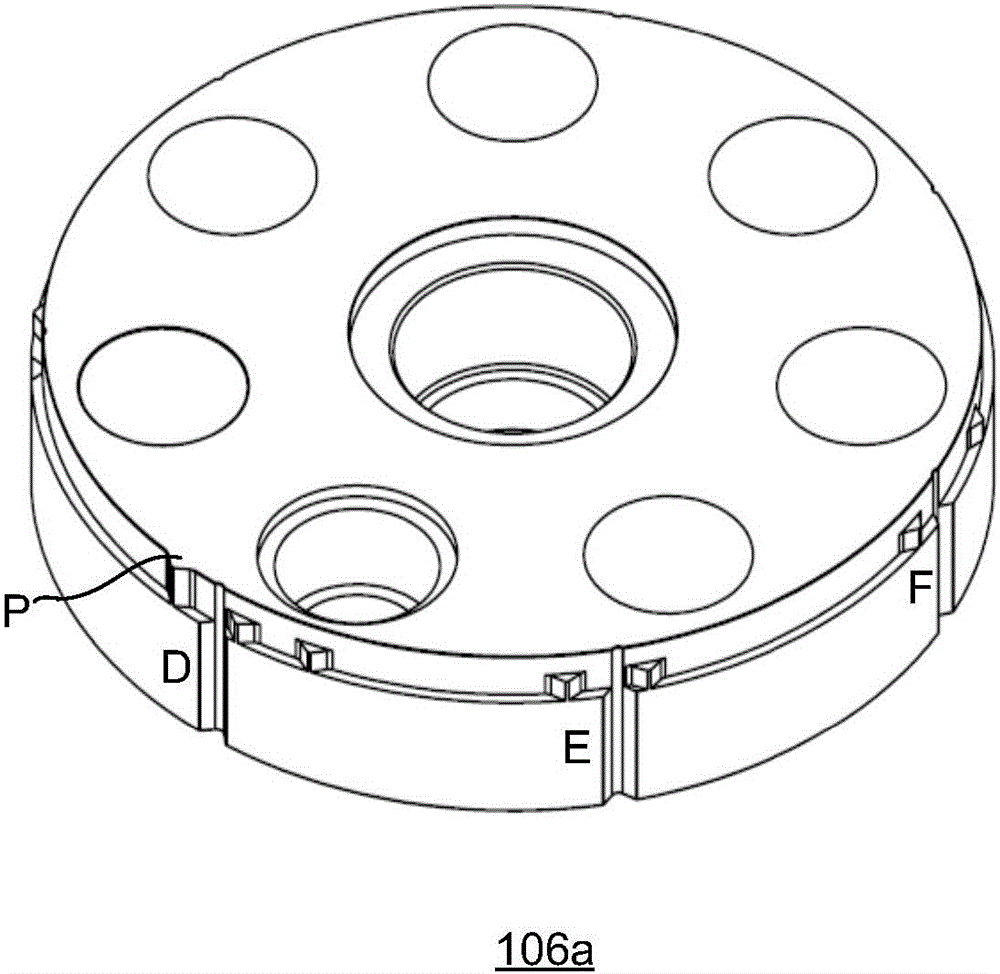

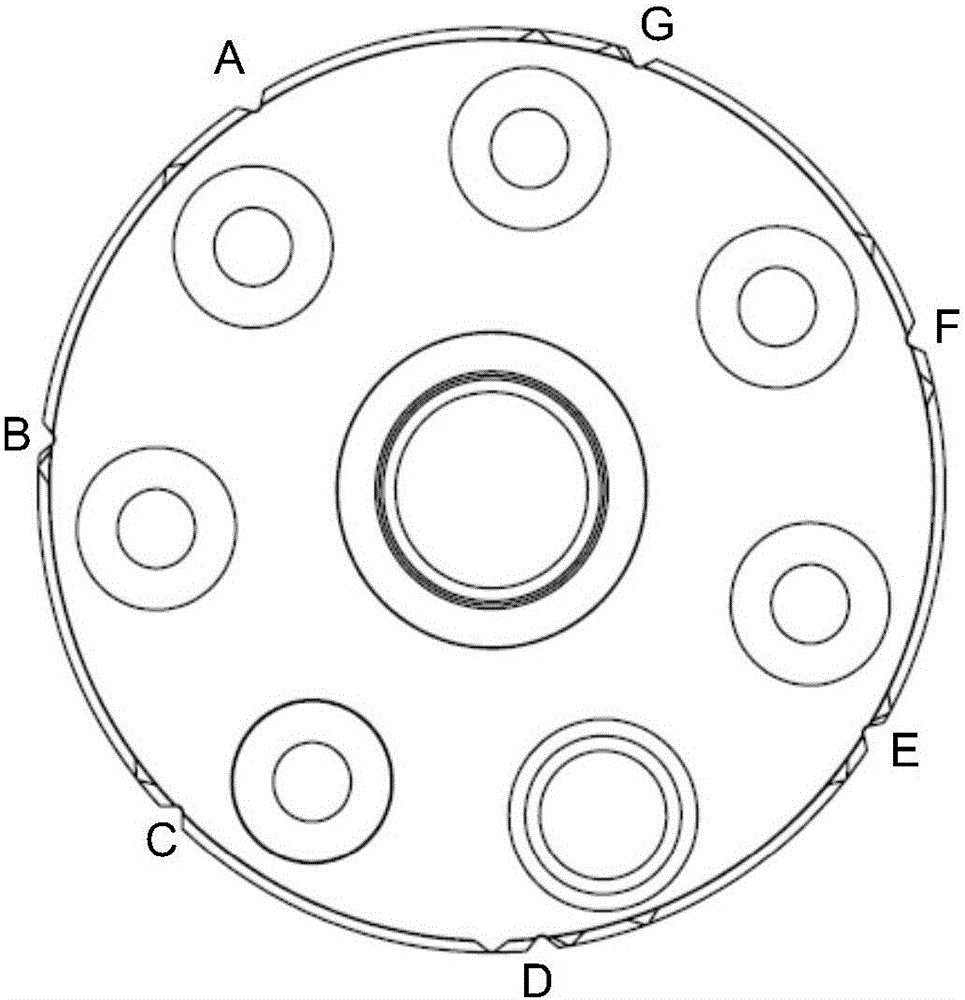

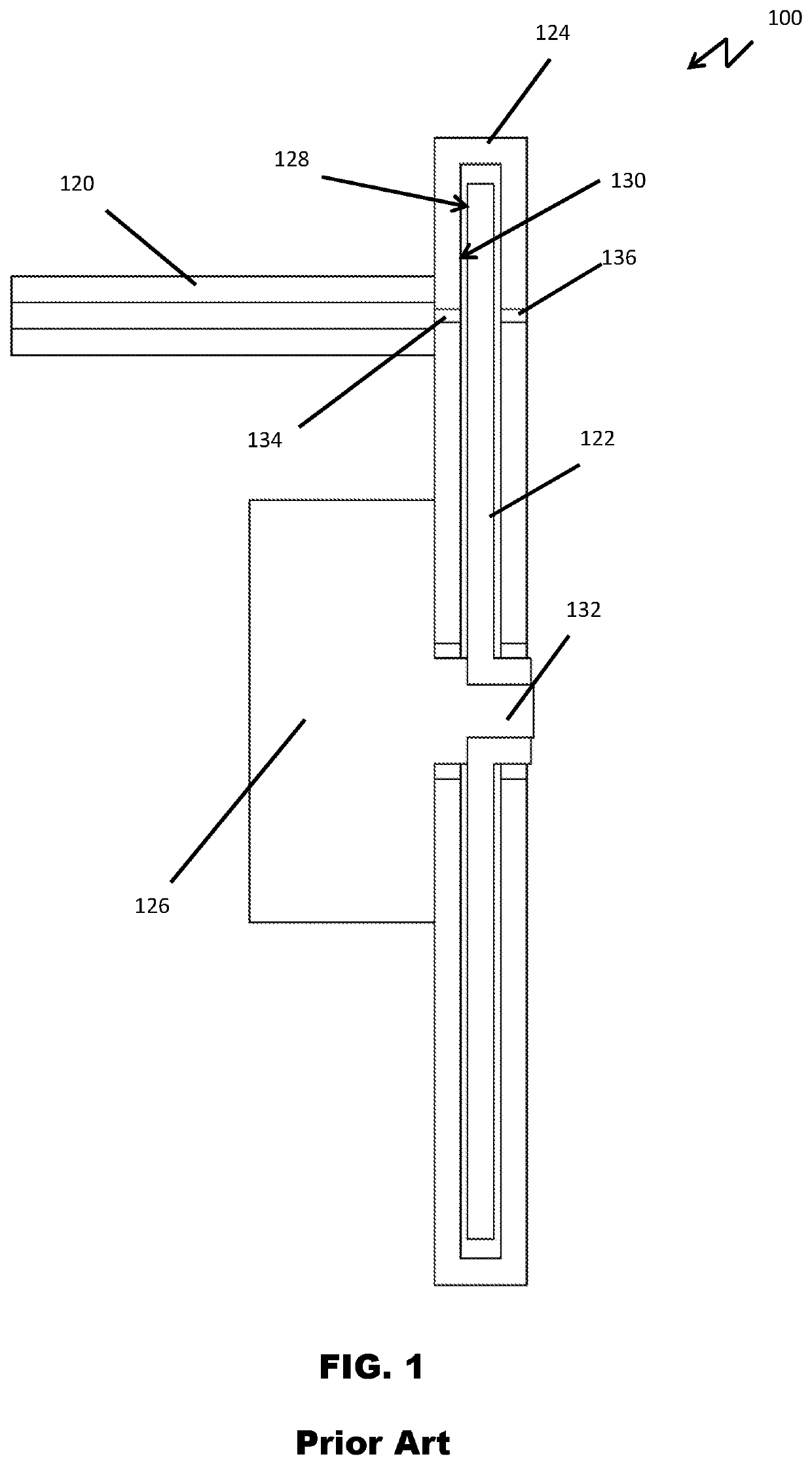

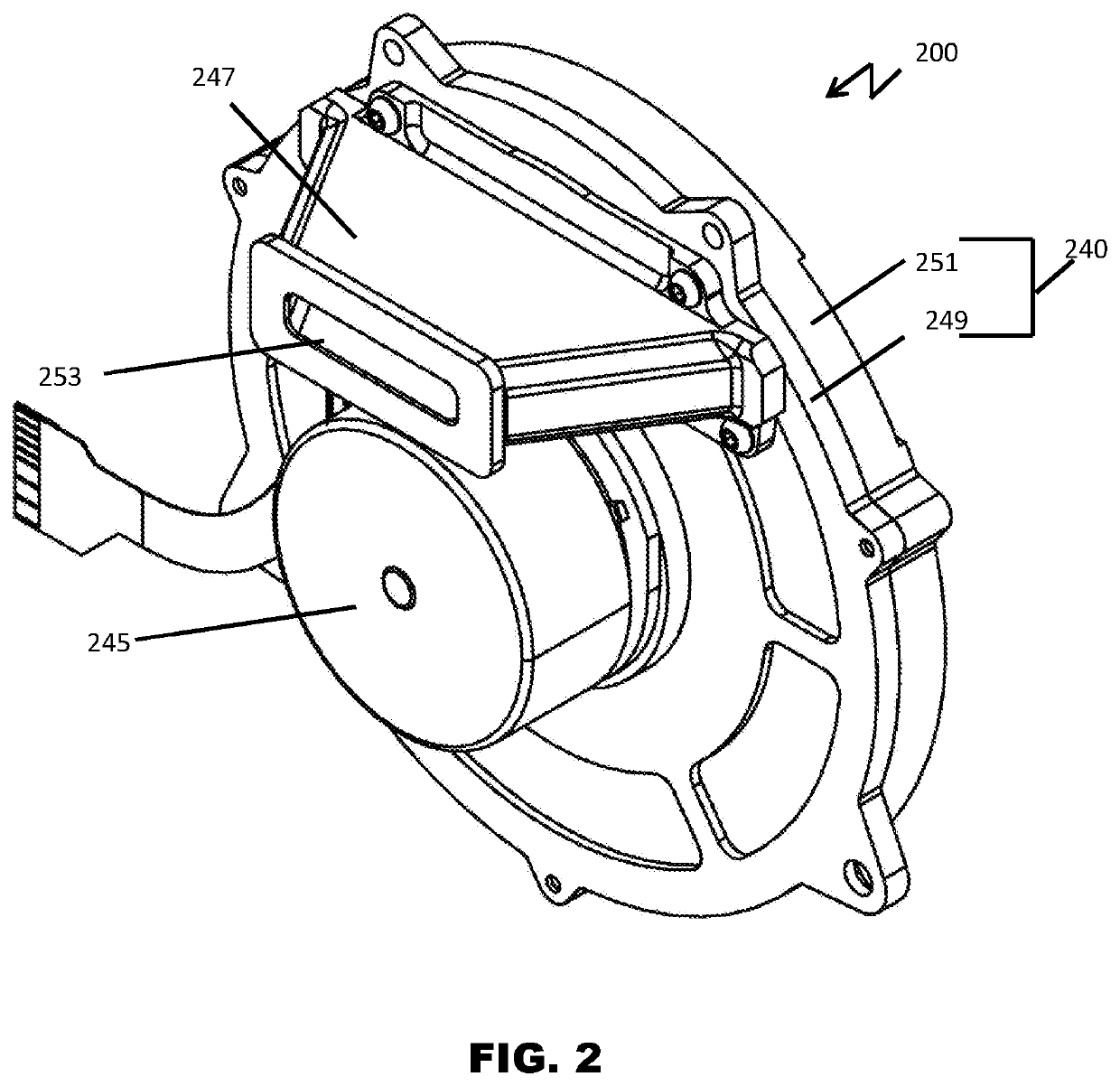

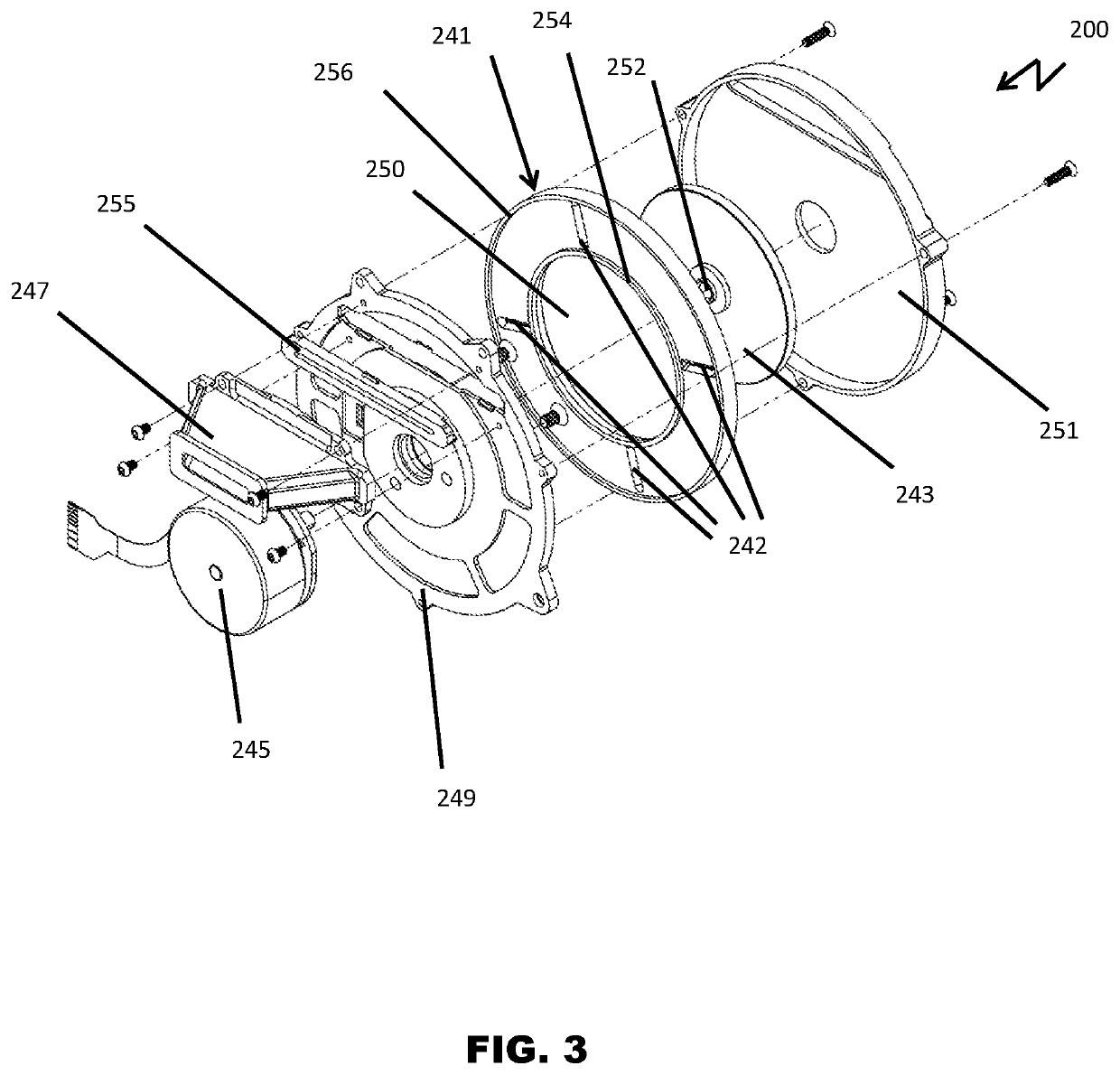

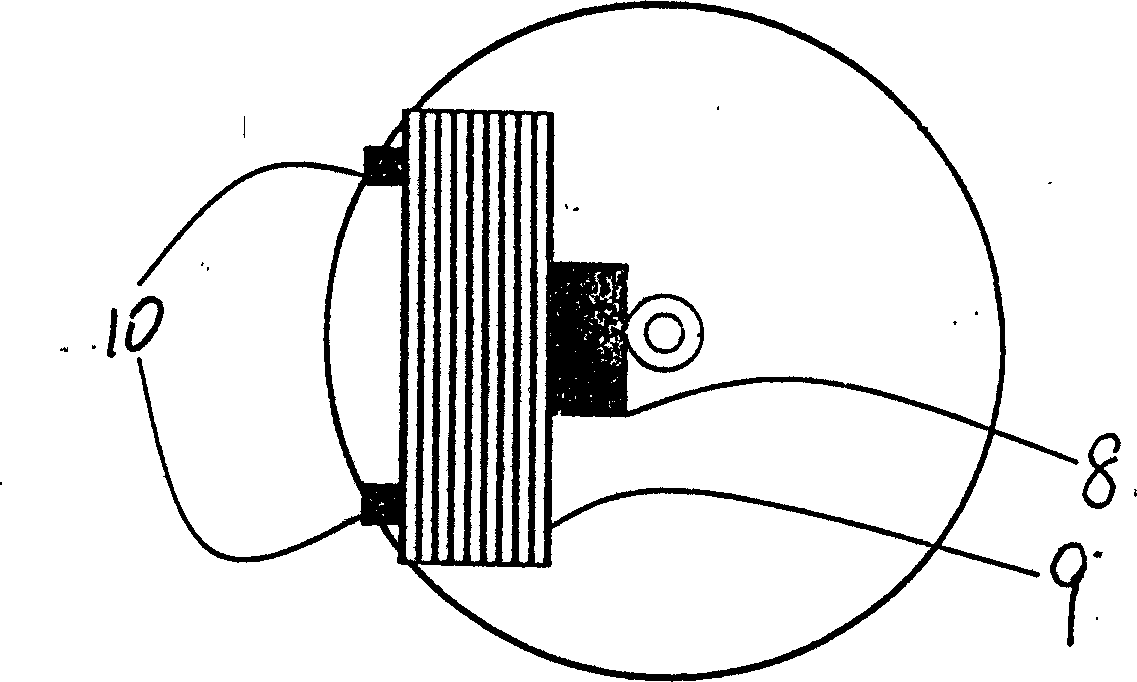

Enclosed x-ray chopper wheel

PendingUS20220283103A1Reduce decreaseIncrease energy attenuationMaterial analysis using wave/particle radiationHandling using diaphragms/collimetersEngineeringMechanical engineering

Owner:VIDERAY TECH INC

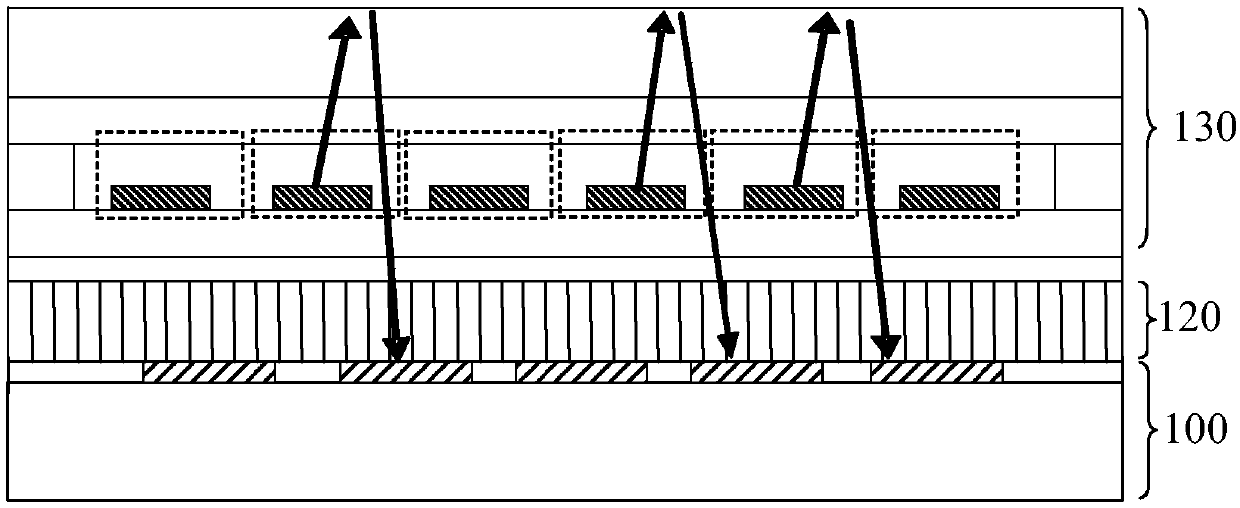

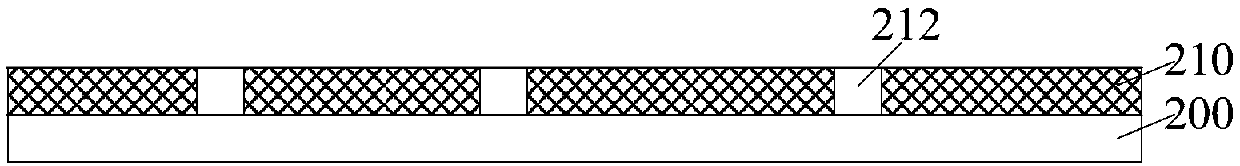

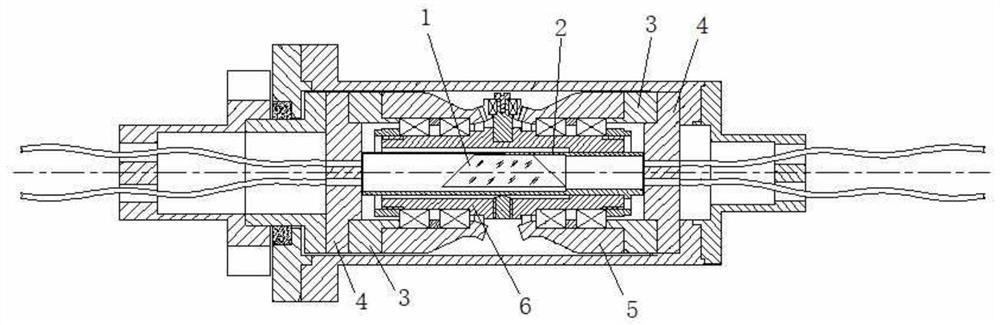

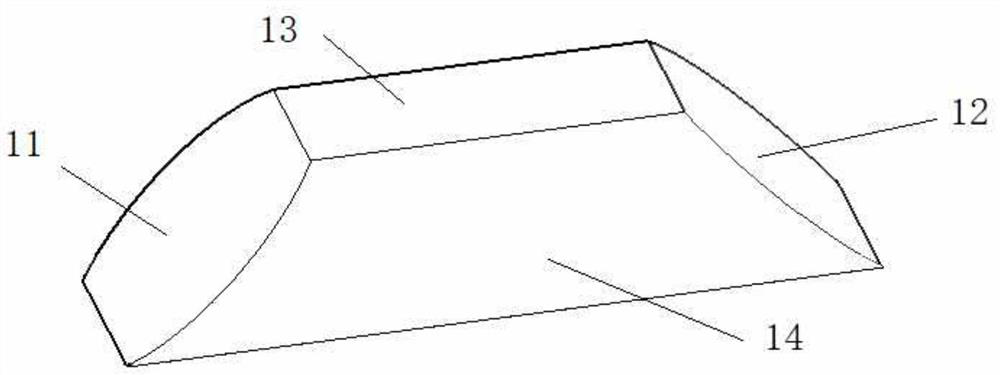

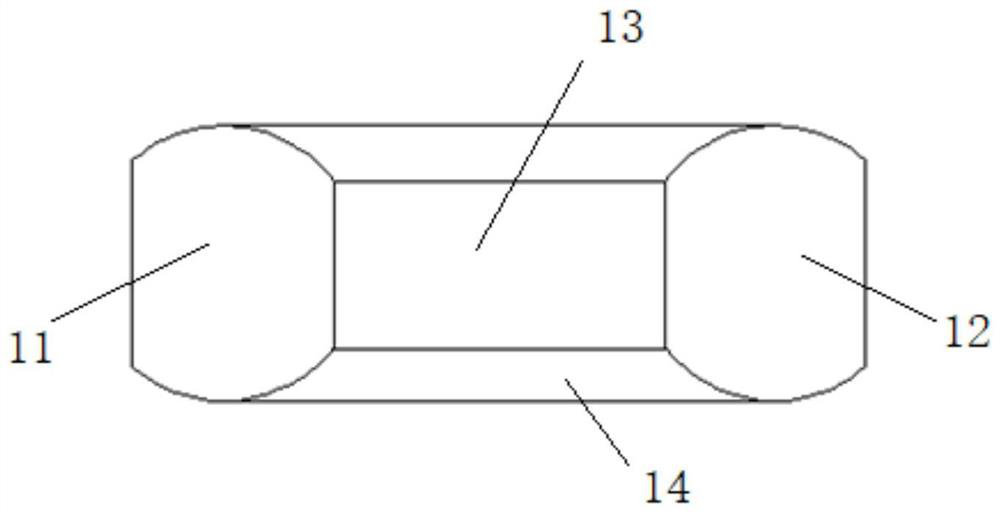

Optical collimator, forming method thereof and fingerprint sensor module

Owner:SHANGHAI OXI TECH

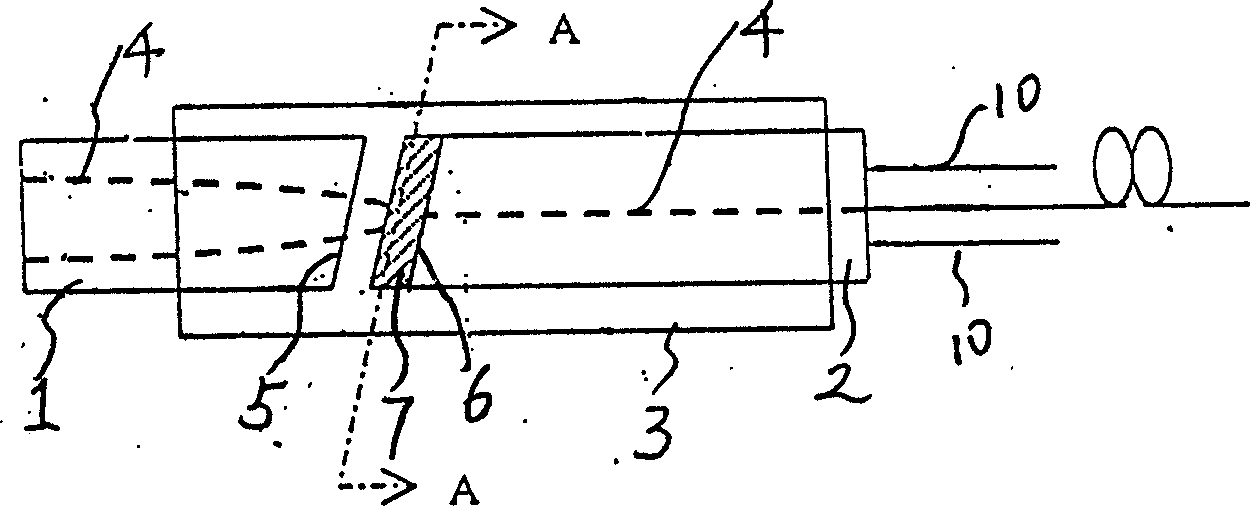

Collimator fixing end cover machining method and application thereof

PendingCN114002779AReduced assembly stepsReduce difficultyCoupling light guidesEngineeringLight signal

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap