Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8 results about "Dynamometer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A dynamometer or "dyno" for short, is a device for simultaneously measuring the torque and rotational speed (RPM) of an engine, motor or other rotating prime mover so that its instantaneous power may be calculated, and usually displayed by the dynamometer itself as kW or bhp.

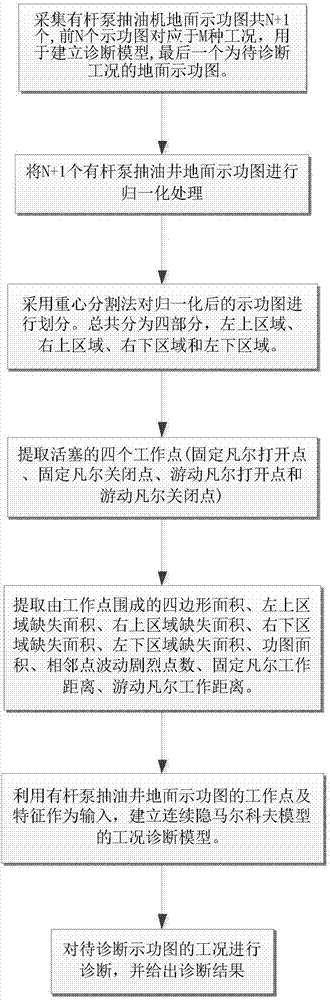

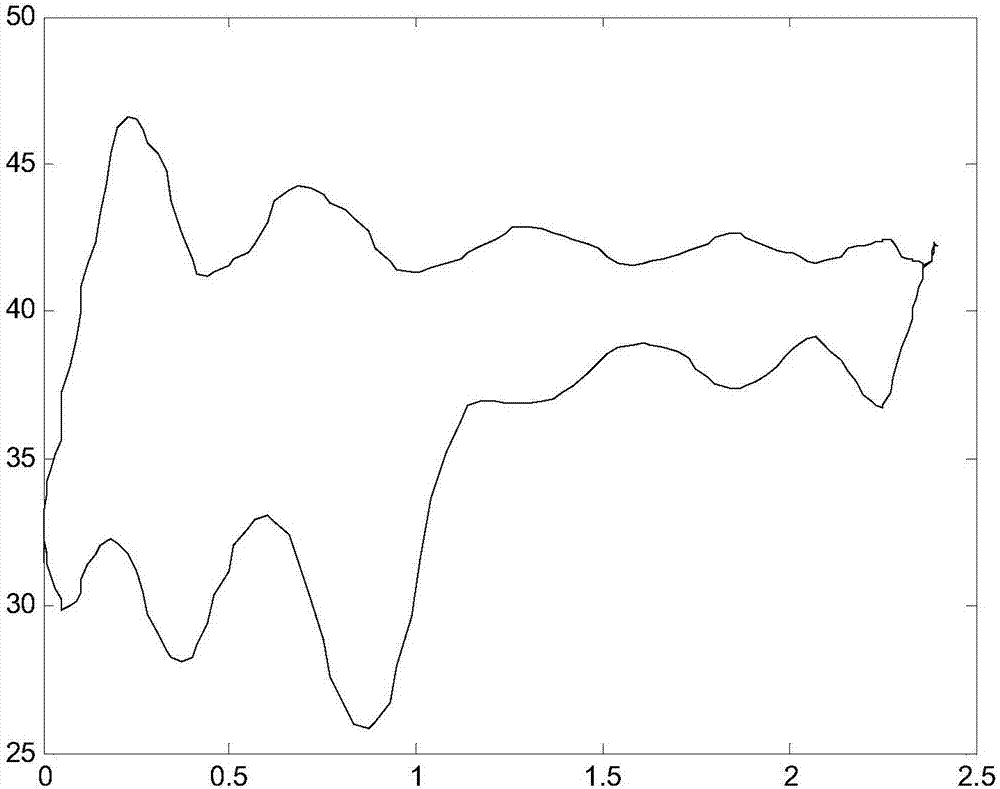

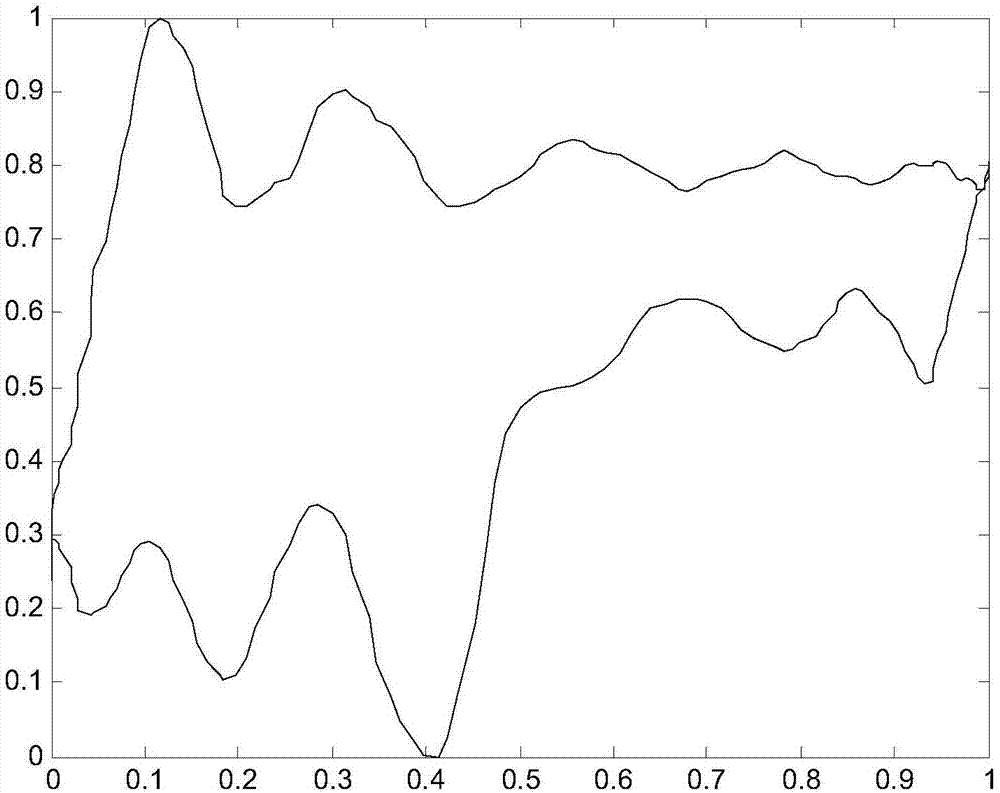

Downhole working condition diagnosis method for sucker rod pumping well based on valve working point

ActiveCN106951662AEnable real-time diagnosisReduce manufacturing costConstructionsDesign optimisation/simulationDiagnosis methodsGravity center

Owner:NORTHEASTERN UNIV

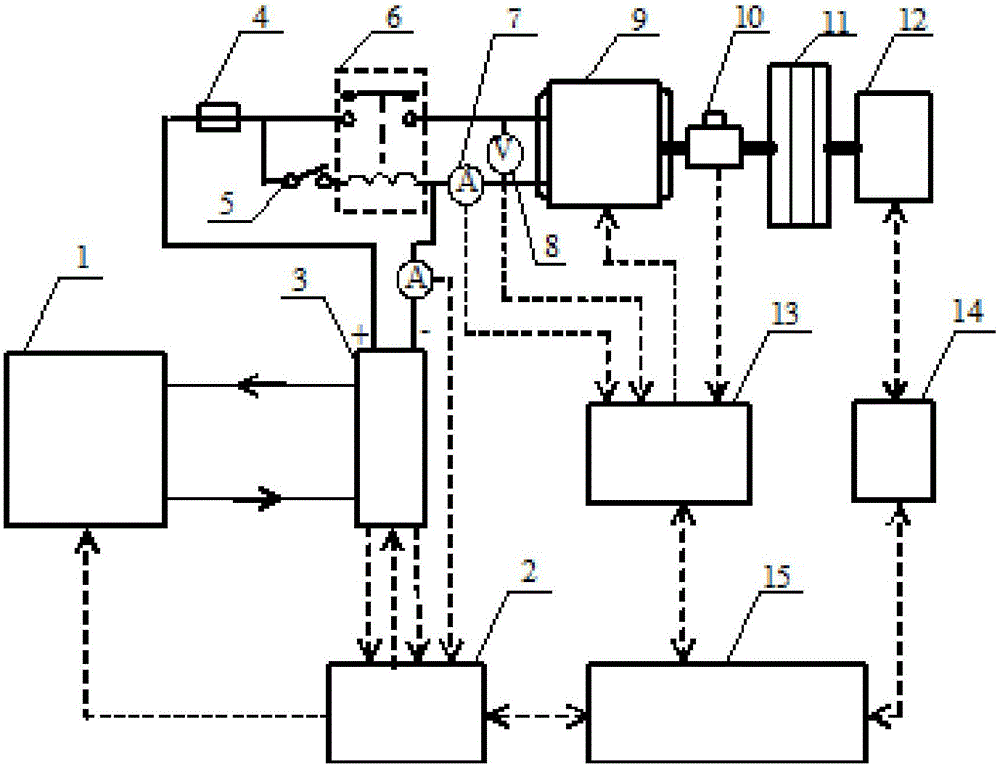

Electric vehicle three-system integrated test platform

InactiveCN105891631AAchieve balanceCompact structureDynamo-electric machine testingElectrical batteryDynamometer

Owner:BEIJING UNIV OF TECH

Aluminum shell bearing seat thermal-mechanical coupling strain measurement system and measurement method

PendingCN108896305AMaterial thermal coefficient of expansionMachine gearing/transmission testingDynamometerStrain gauge

Owner:CHINA FIRST AUTOMOBILE

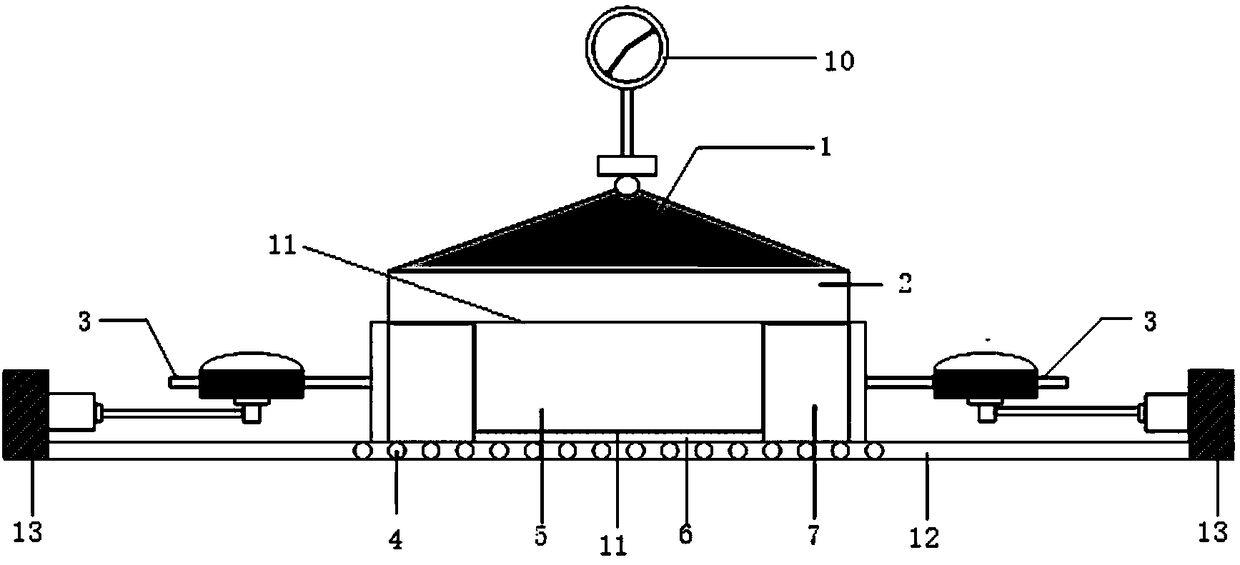

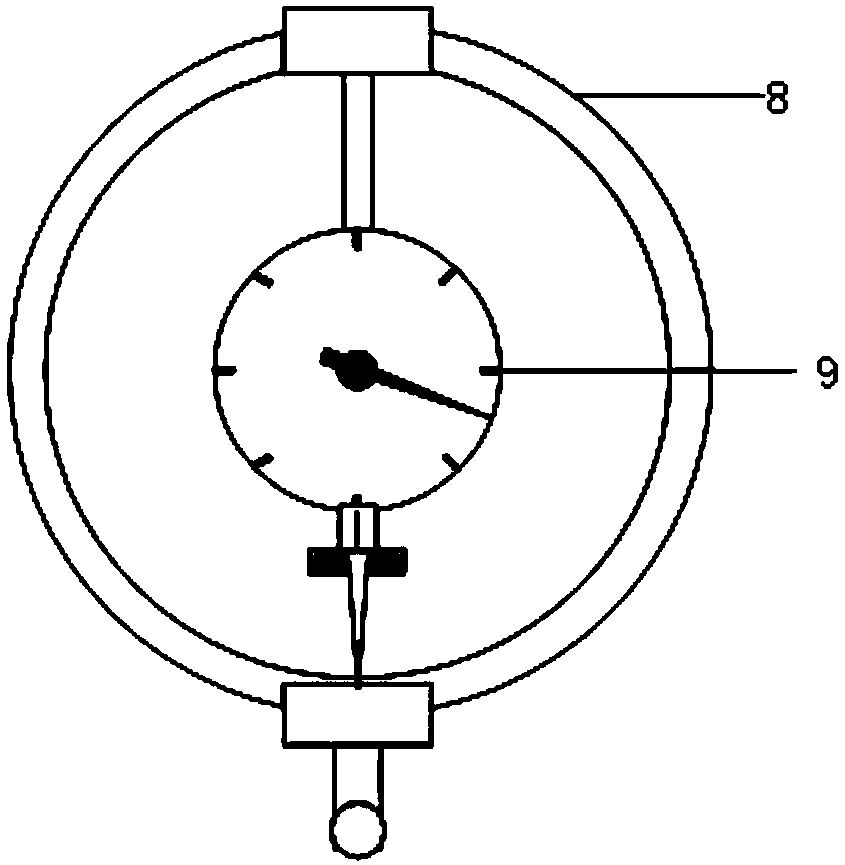

Tester for lateral expansibility of soft rock

ActiveCN108663270AFit the actual engineeringAccurate measurementMaterial strength using tensile/compressive forcesDynamometerFilter paper

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

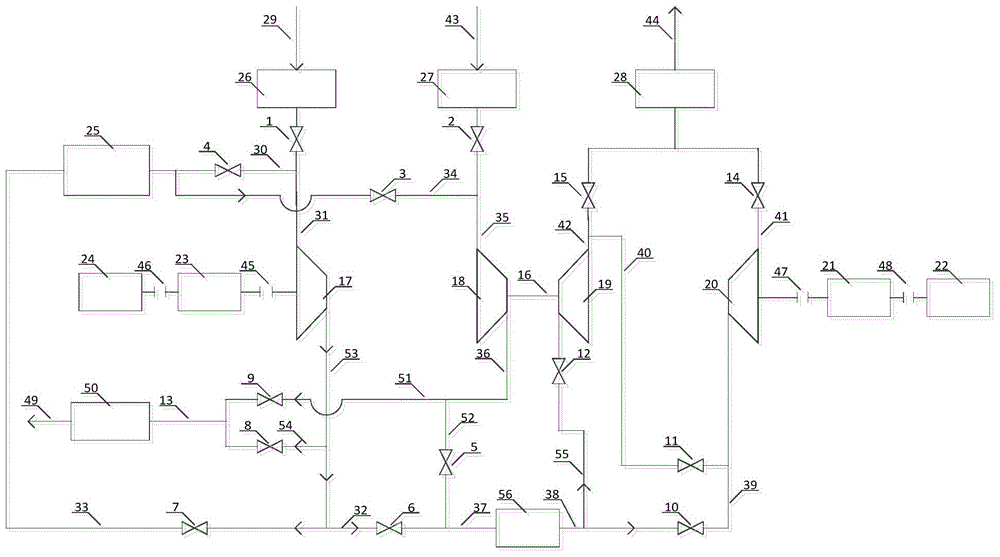

Multifunctional compound supercharging test system

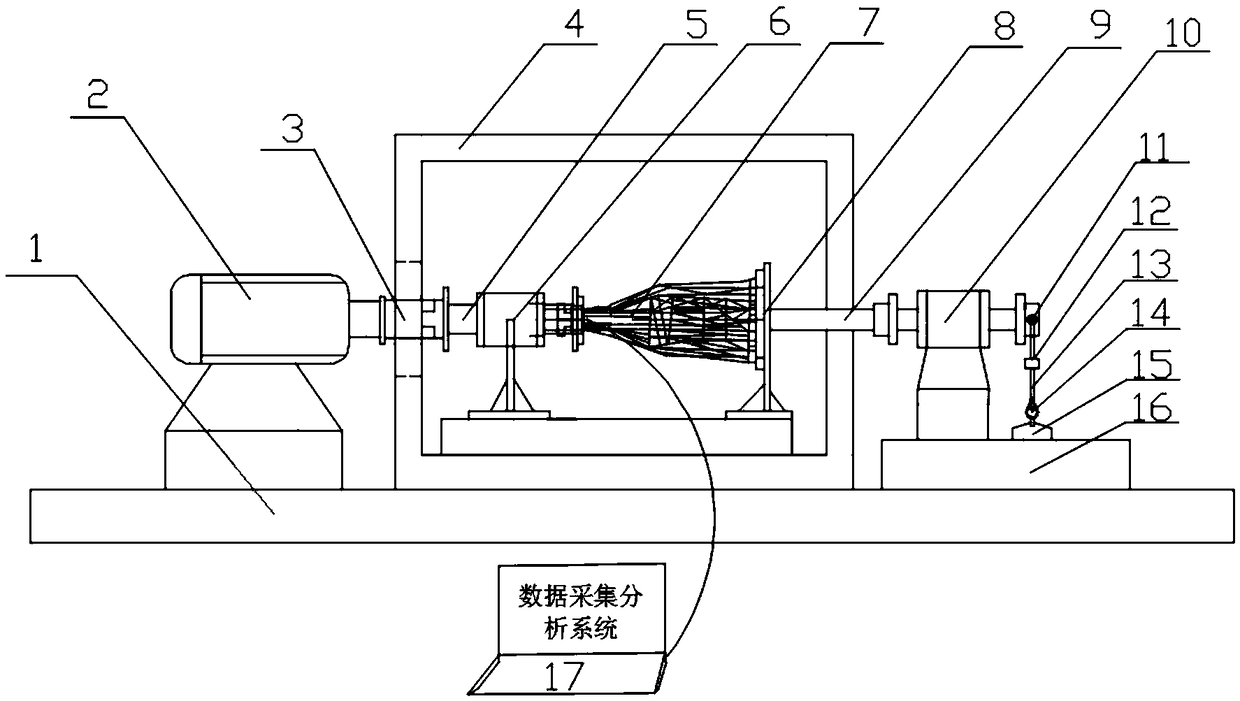

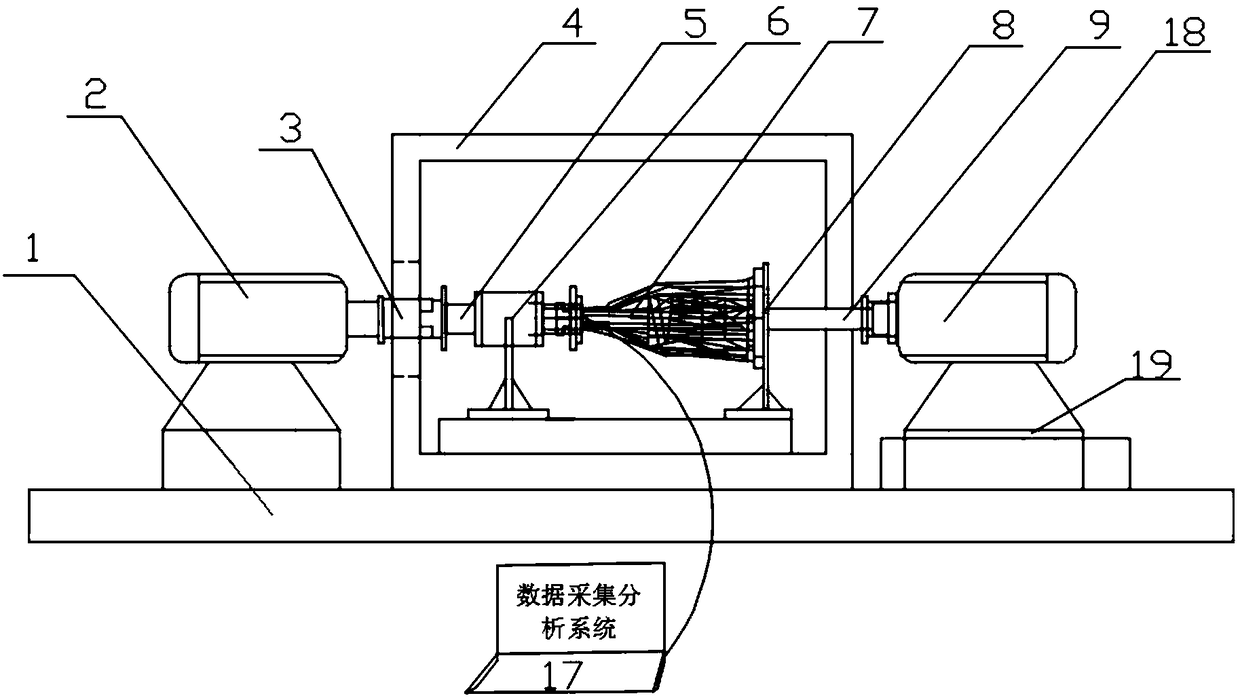

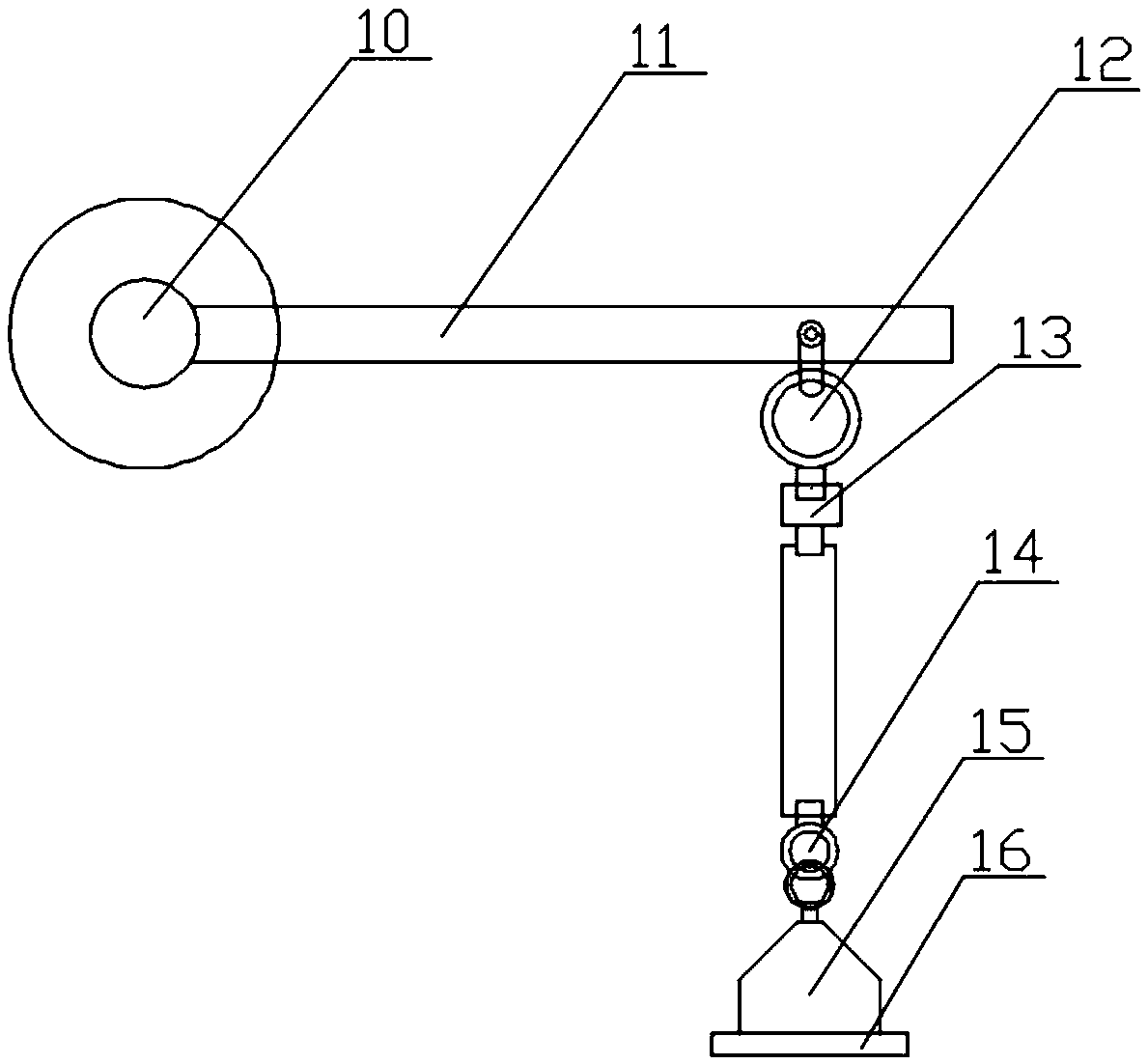

ActiveCN104155114AInternal-combustion engine testingMatching testSingle stage

Owner:HARBIN ENG UNIV

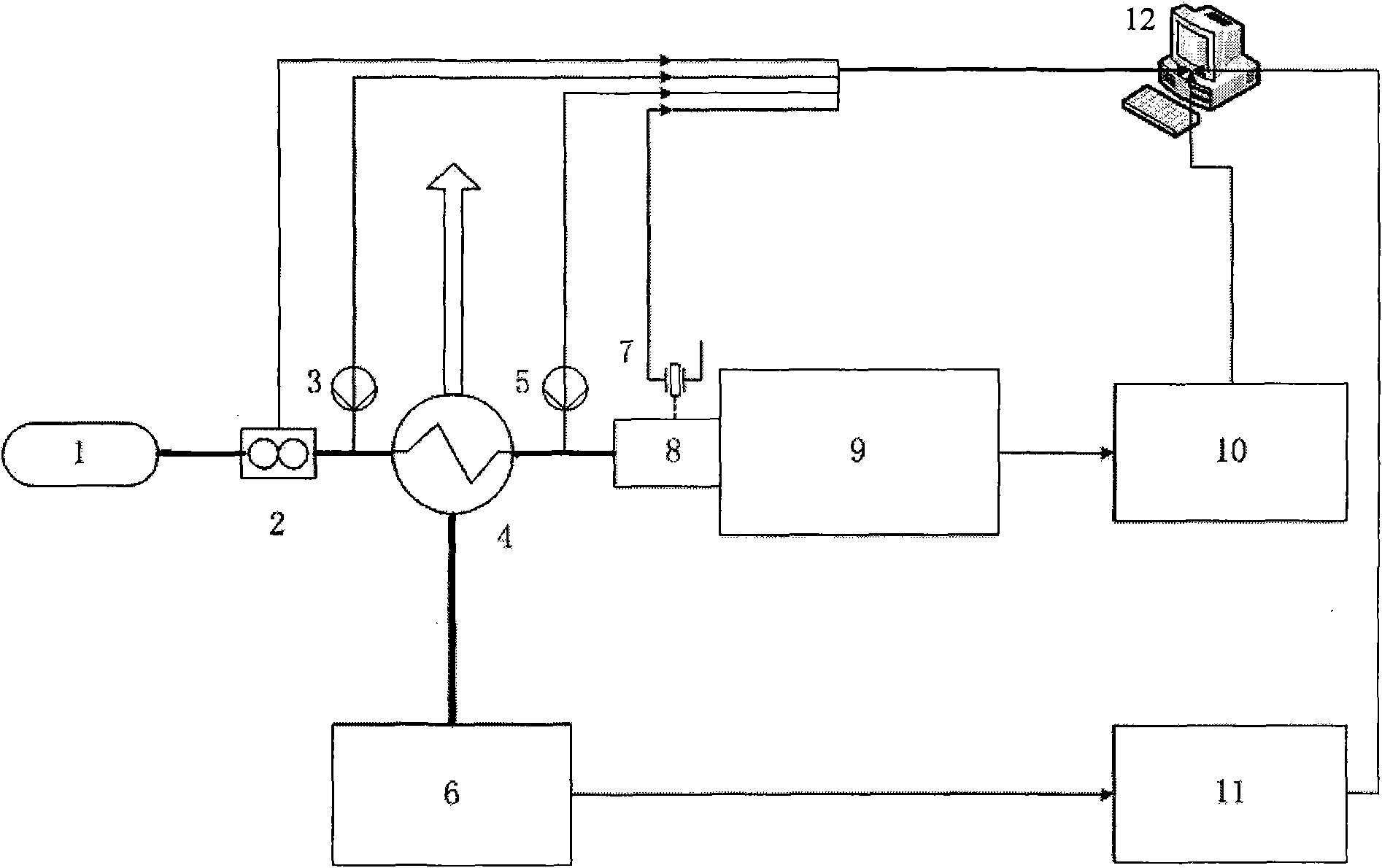

Air-fuel mixed power test system

InactiveCN101551298AReliable Experimental ParametersEngine testingPilot systemAtmospheric air

Owner:ZHEJIANG UNIV

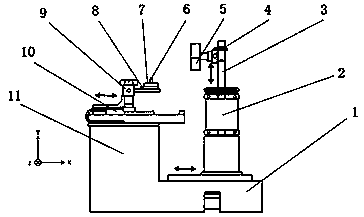

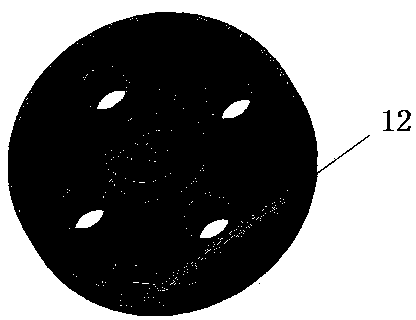

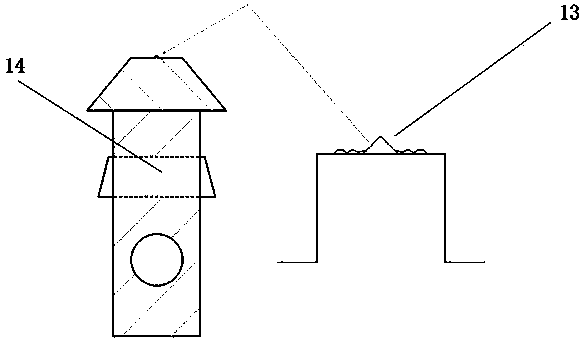

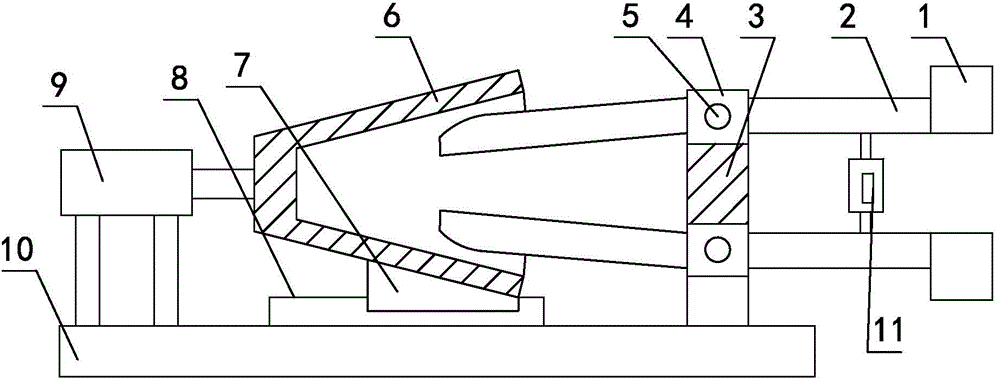

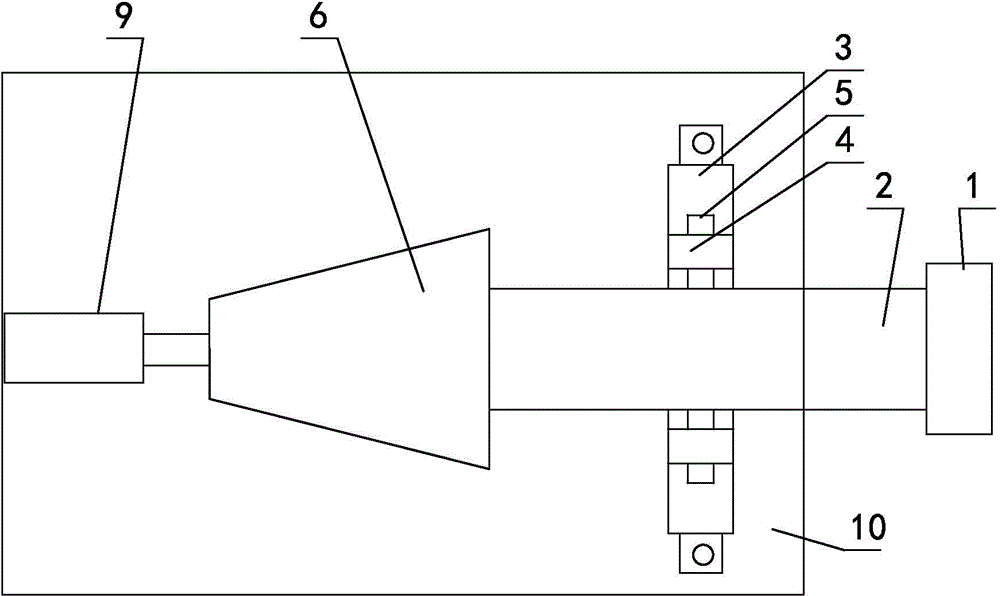

Parameter-controllable single/multiple abrasive particle high-speed etching experimental device

The invention discloses a parameter-controllable single / multiple abrasive particle high-speed etching experimental device. A main shaft of a machine tool drives a rotary disc to rotate around the mainshaft, a workpiece is fixed to the surface of a side wall of a disc matrix, and the disc can move on the Y-axis under the driving of the main shaft to change the etching depth; a precise moving workbench can drive a rotary pinboard and an etching device to move on the X-axis direction, the rotary pinboard can clamp three groups of etching devices through a clamp plate; the three groups of etchingdevices are respectively provided with single abrasive particle, two abrasive particles, four abrasive particles and a distance fine-adjusting device, and the distance fine-adjusting device can adjust a abrasive particle pressure head to slightly move on the Y-axis direction so as to adjust the exposed height of the abrasive particle. The etching space can be adjusted by moving the workbench along the X-axis direction, and the rotary pinboard rotates by taking the Y-axis direction as the axle; a high-speed industrial camera can match with a dynamometer to complete tool setting and perform real-time shoot to monitor the abrasive particle state. The experimental device can be applied to single / multiple abrasive particle high-speed etching experiments under multiparameter orthogonal.

Owner:HARBIN UNIV OF SCI & TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap