Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9 results about "Heat press" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

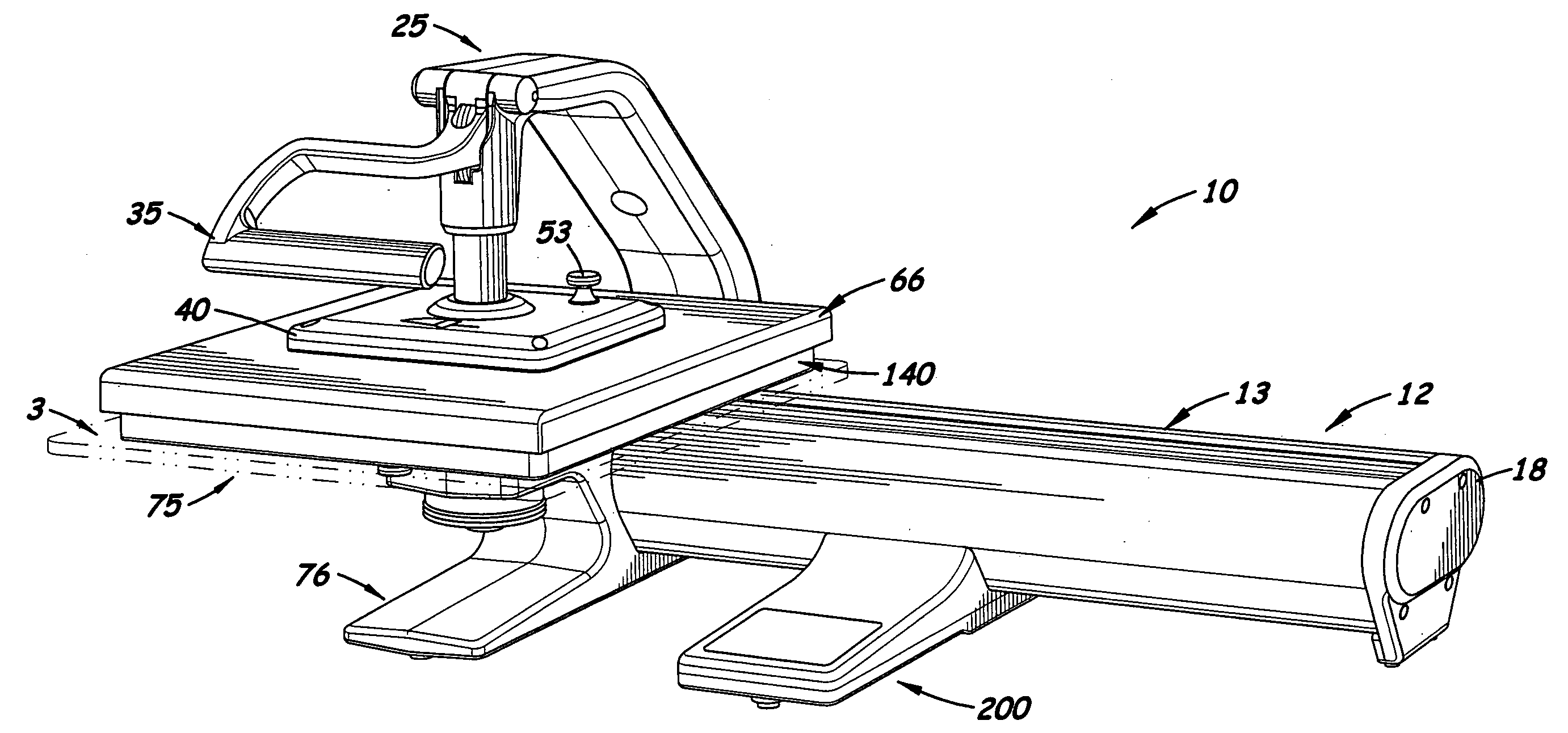

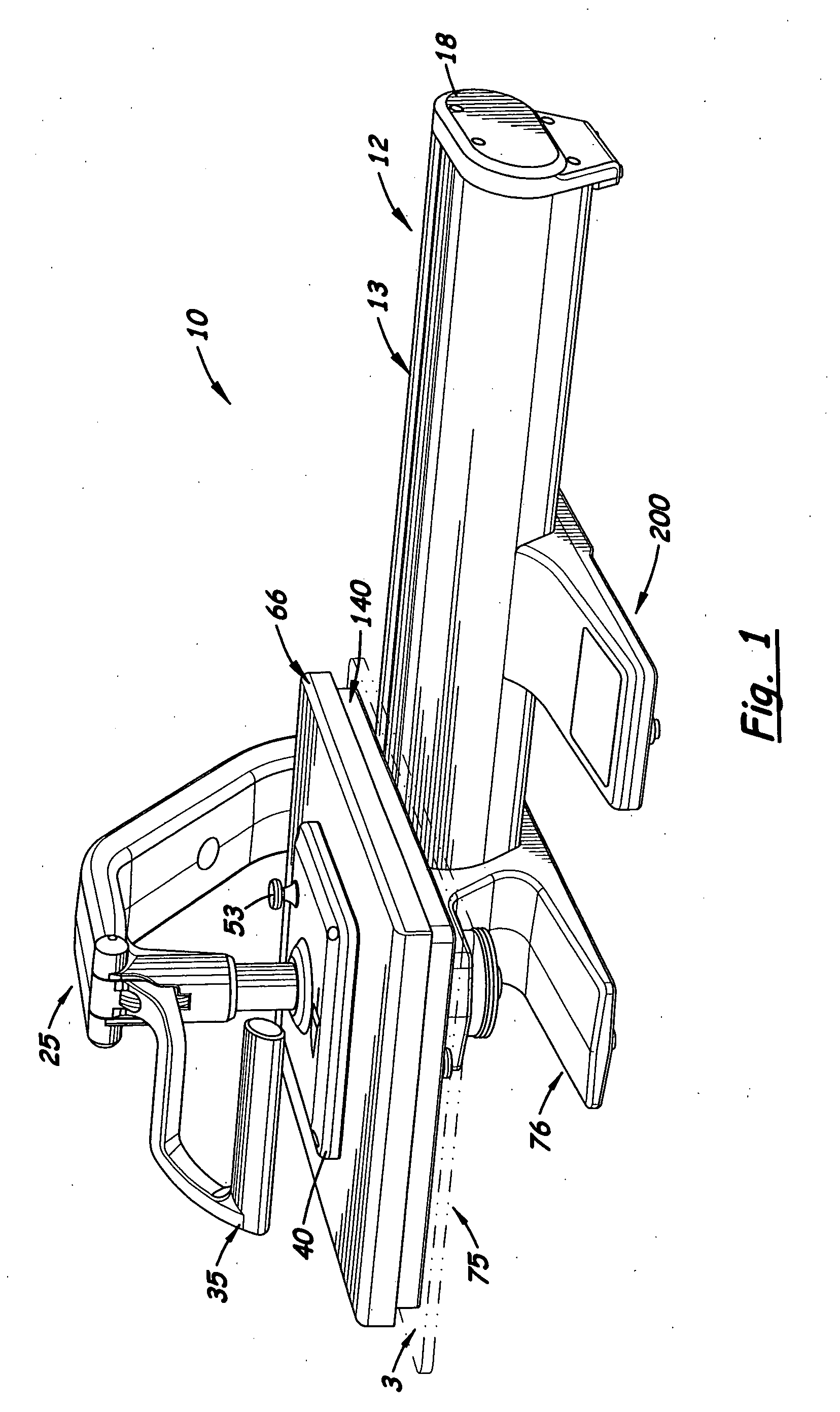

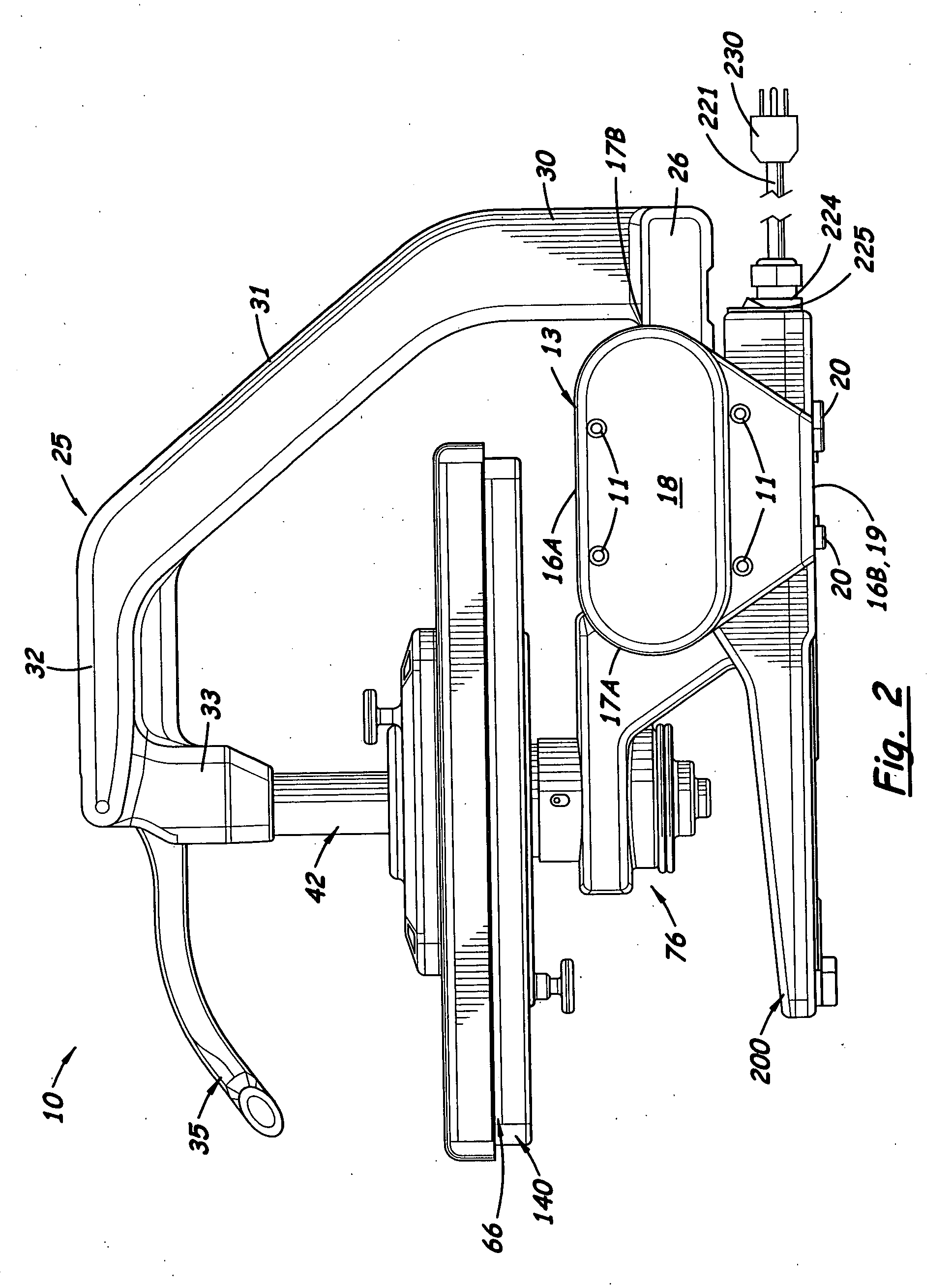

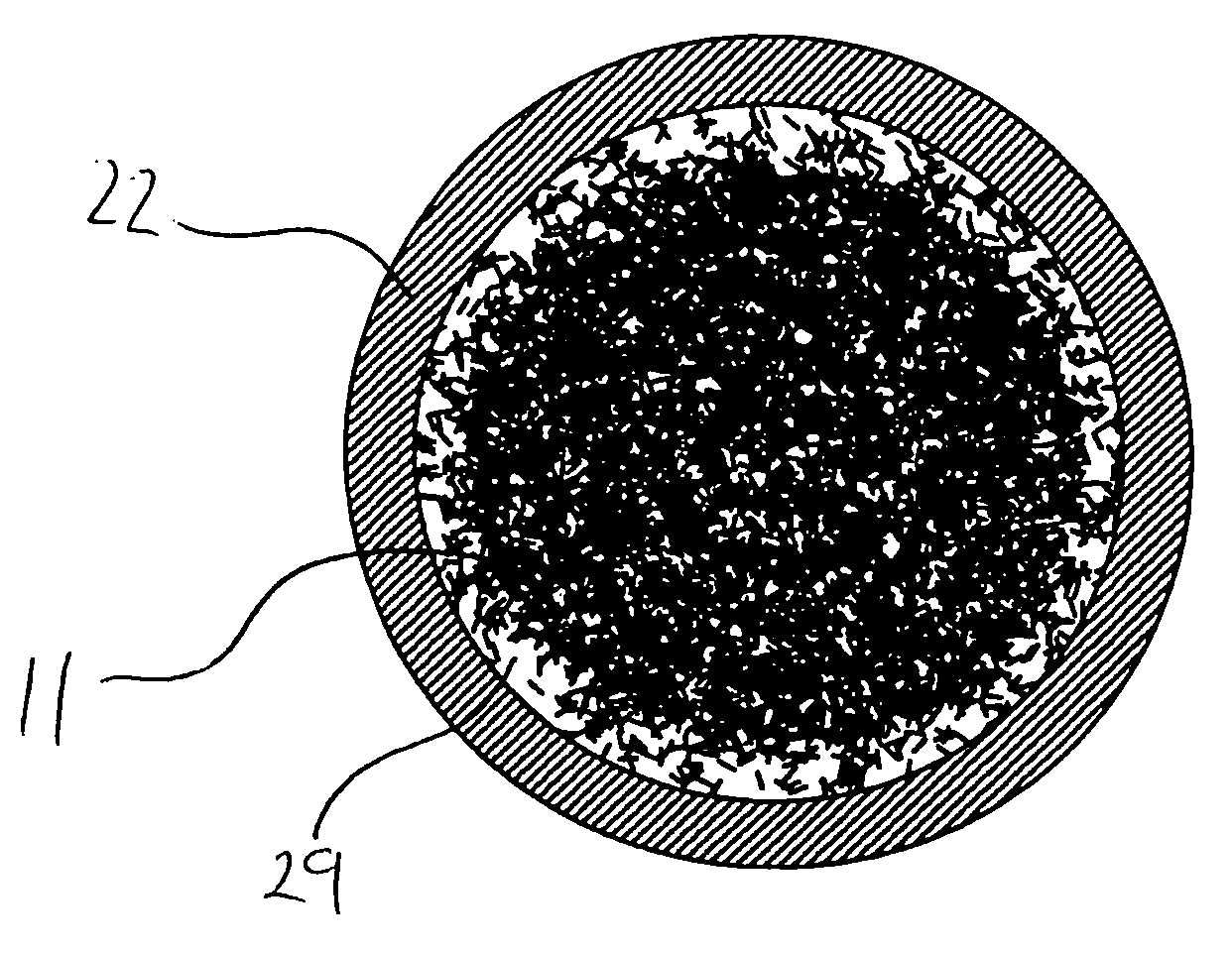

A heat press is a machine engineered to imprint a design or graphic on a substrate, such as a t-shirt, with the application of heat and pressure for a preset period of time. While heat presses are often used to apply designs to fabrics, specially designed presses can also be used to imprint designs on mugs, plates, jigsaw puzzles, caps, and other products.

Lateral heat press with long sleeve lower platen

Owner:WOODS DANIEL

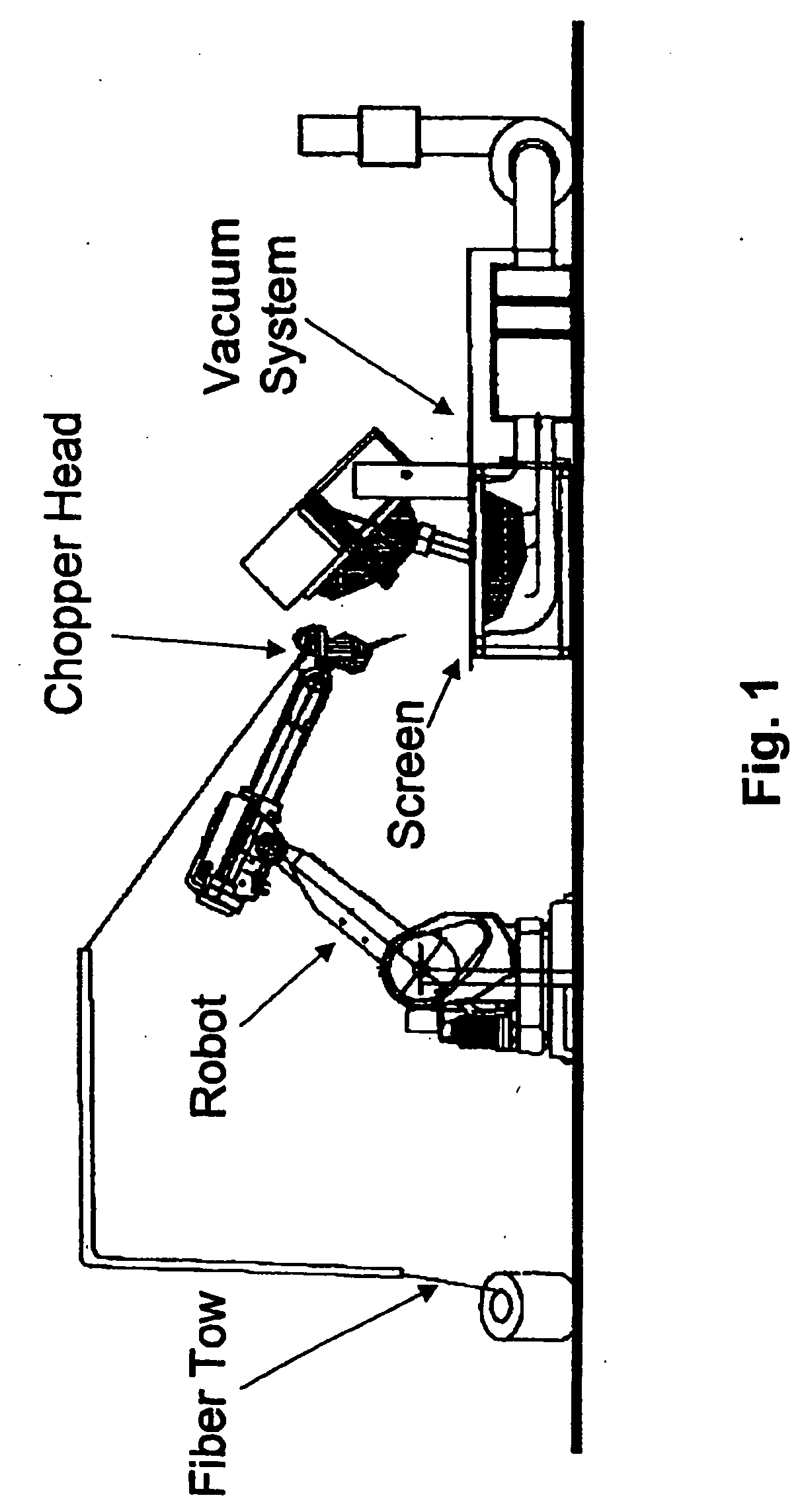

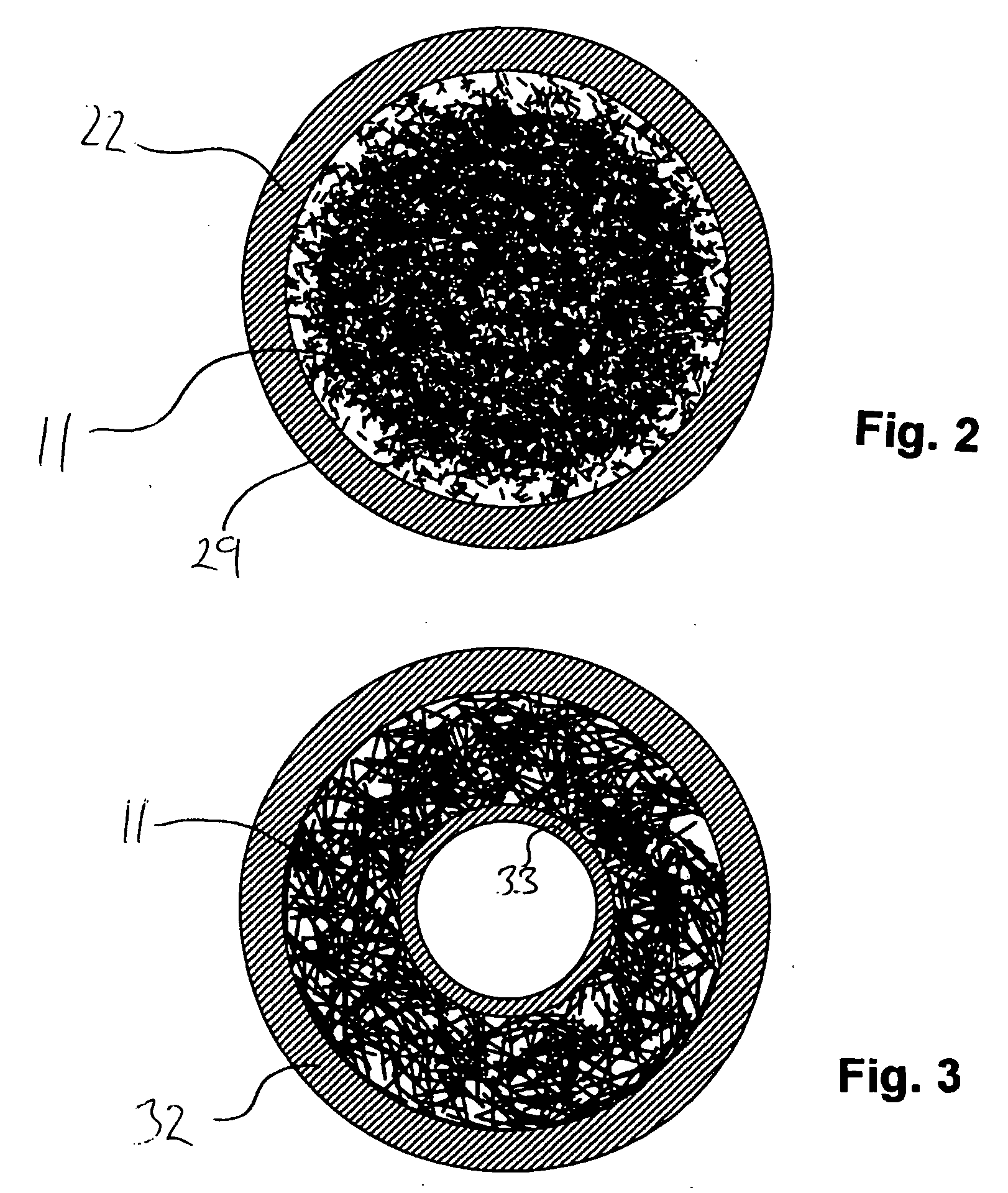

Manufacture of thick preform composites via multiple pre-shaped fabric mat layers

Owner:HONEYWELL INT INC +2

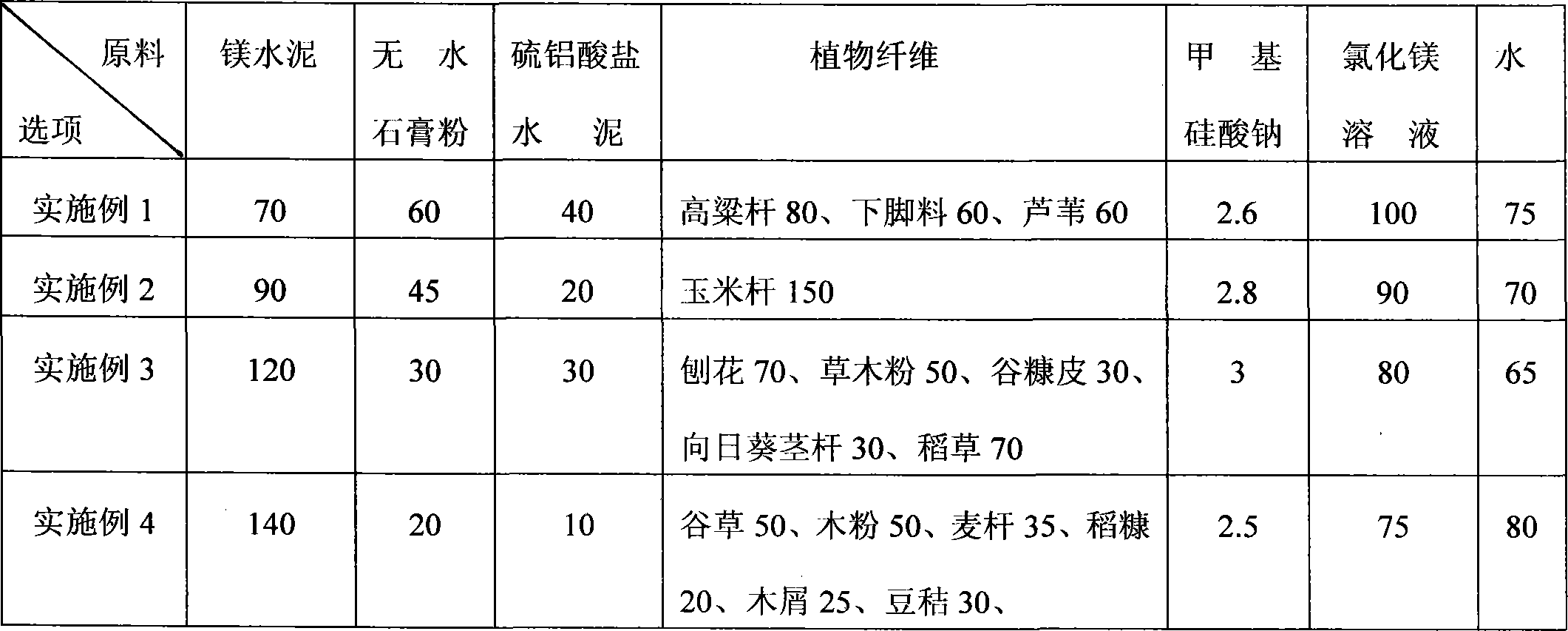

Magnesium-calcium pyrophyte pressed-fibre board and method of manufacturing the same

InactiveCN101172825AObvious beneficial effectGood effectSolid waste managementWeather resistancePlant fibre

Owner:谢涛

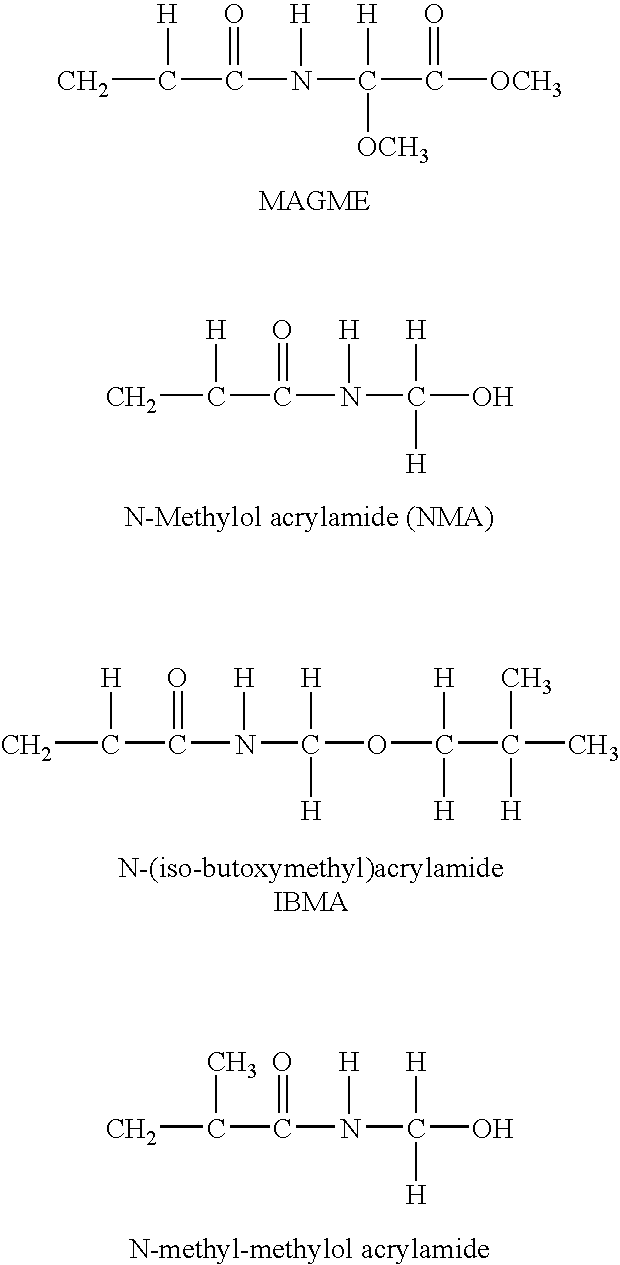

Method of production of veneer assembly

InactiveUS20030221776A1LaminationAdhesive processes with adhesive heatingNuclear engineeringHeat press

Owner:ADHESIVES RES

High-temperature resistant heat insulating material using vermiculite as main raw material and method for manufacturing same

InactiveCN101560087ASolve the strength problemSolve temperature problemsSolid waste managementMixing operation control apparatusPhosphateVolumetric Mass Density

Owner:佛山市冠富贸易有限公司 +1

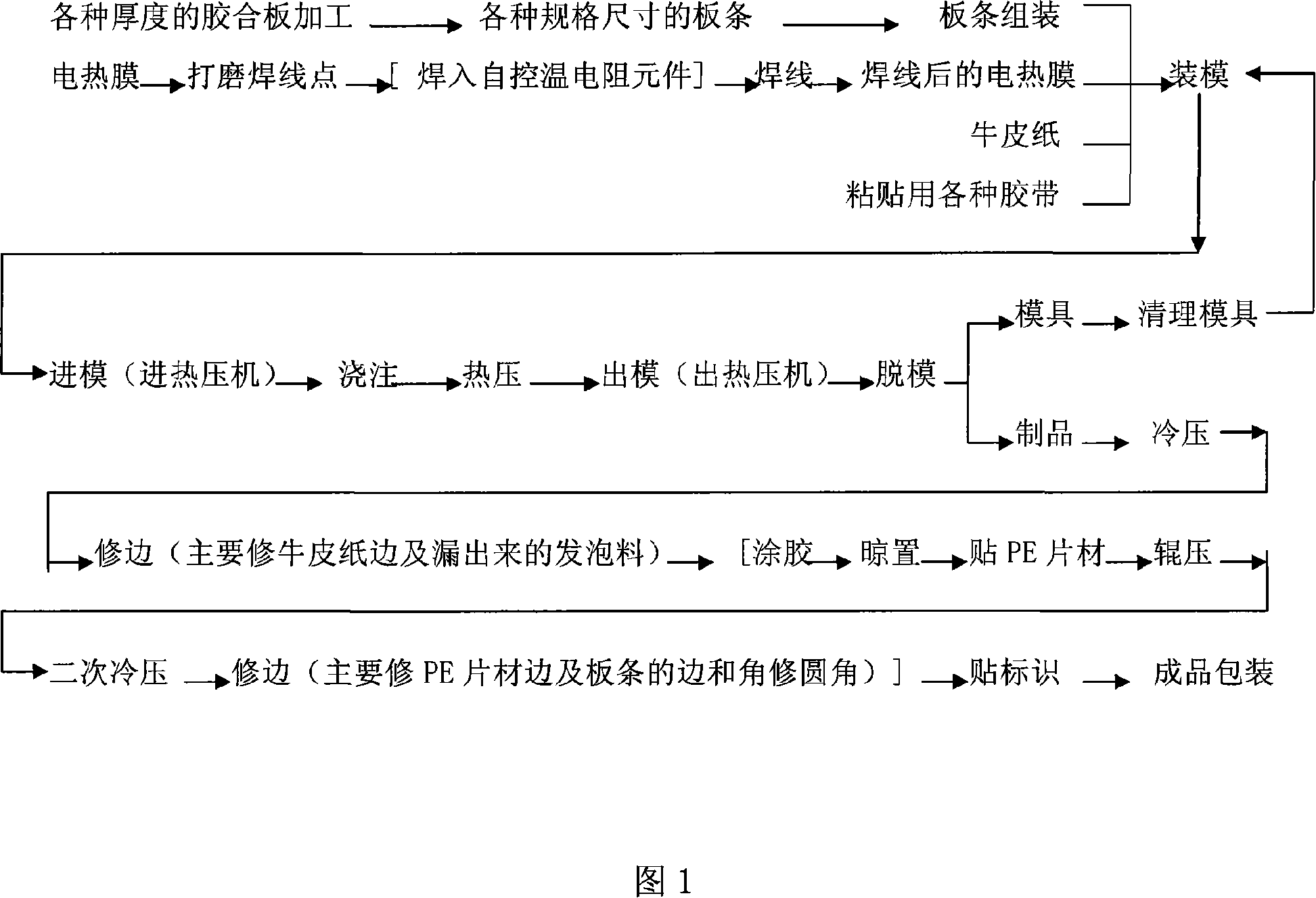

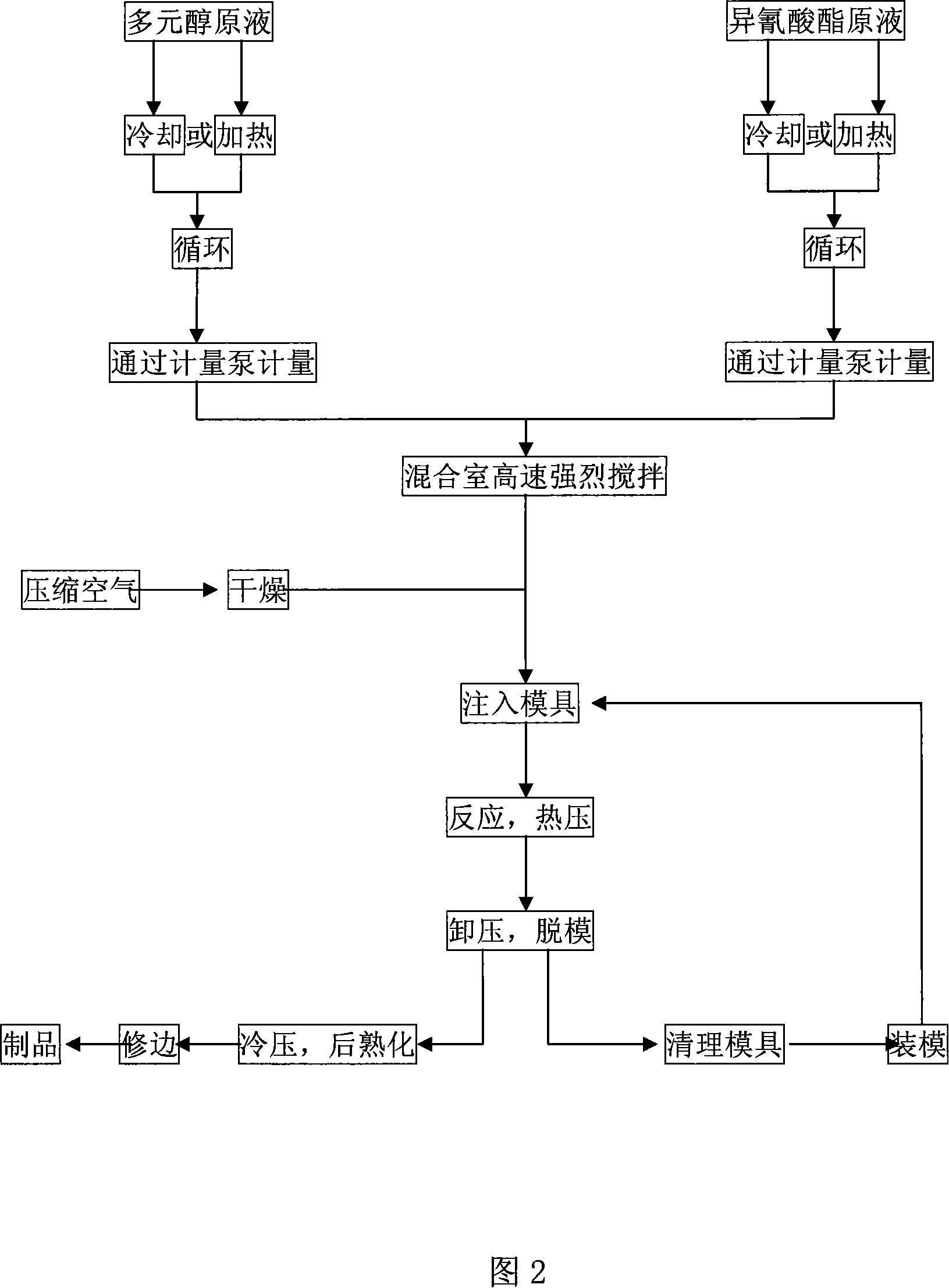

Making method for compound electric heating plate

Owner:新疆和融热力有限公司 +1

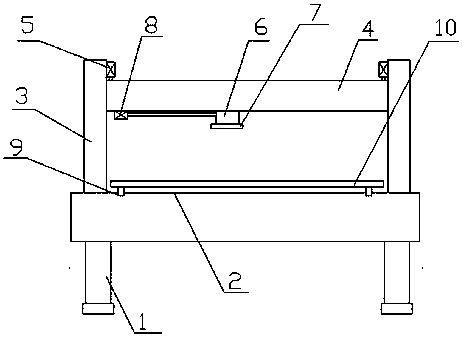

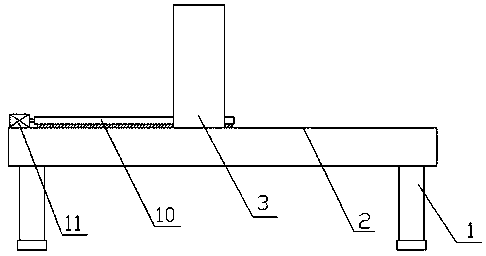

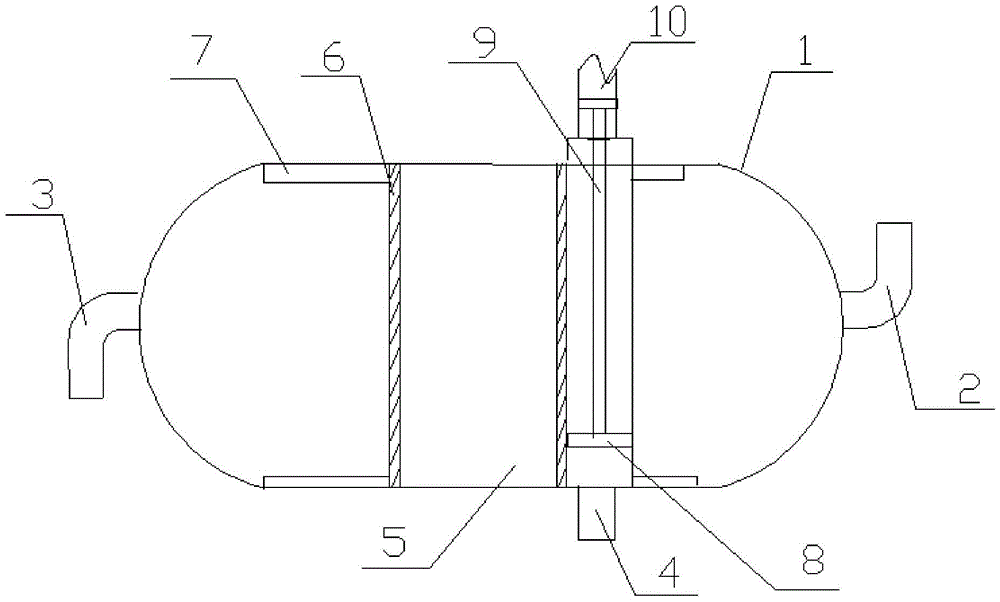

Hot press machine for bamboo wood veneering

InactiveCN105666601AExtended service lifePrevent adhesionLaminationLamination apparatusPulp and paper industryCirculating pump

Owner:ANHUI FUQIANG BAMBOO IND CO LTD

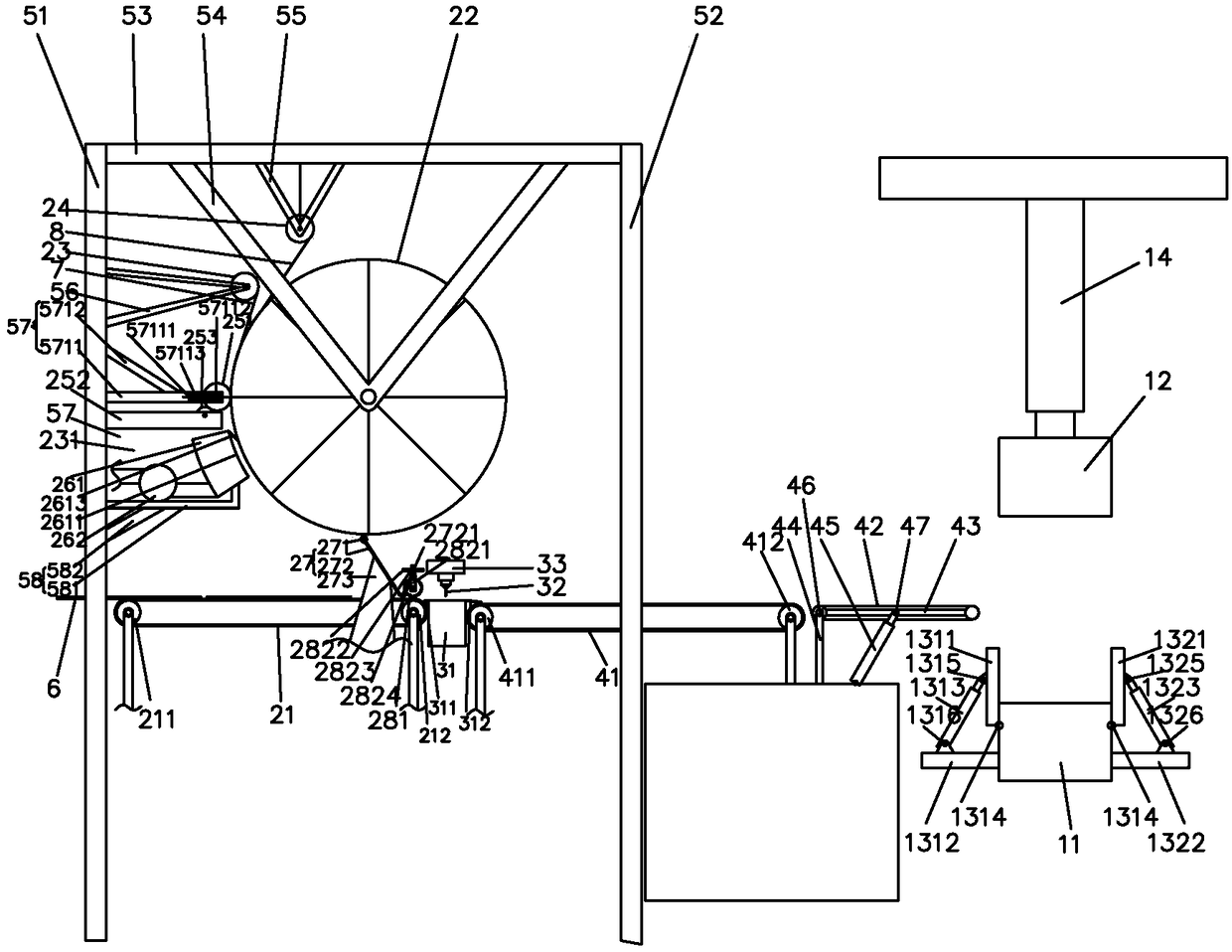

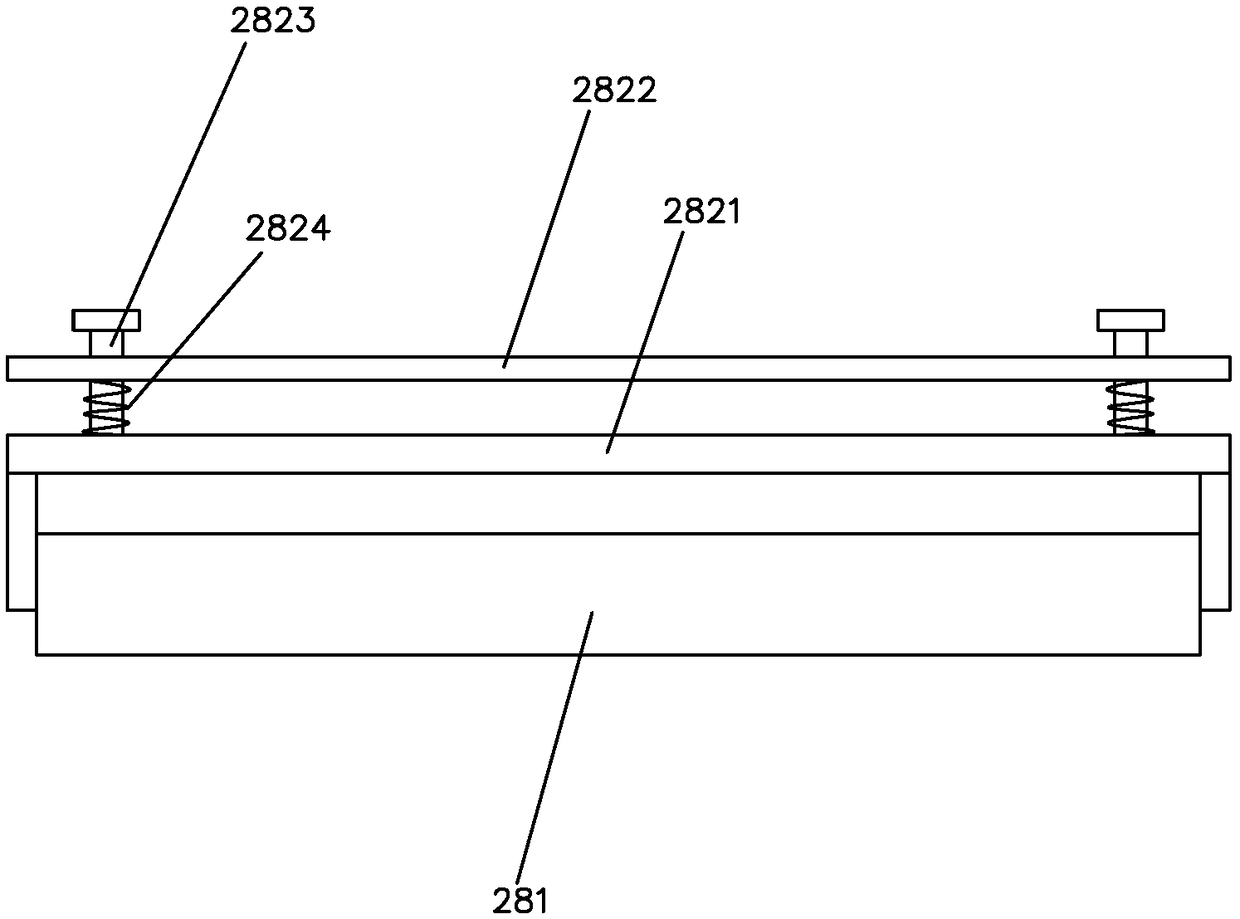

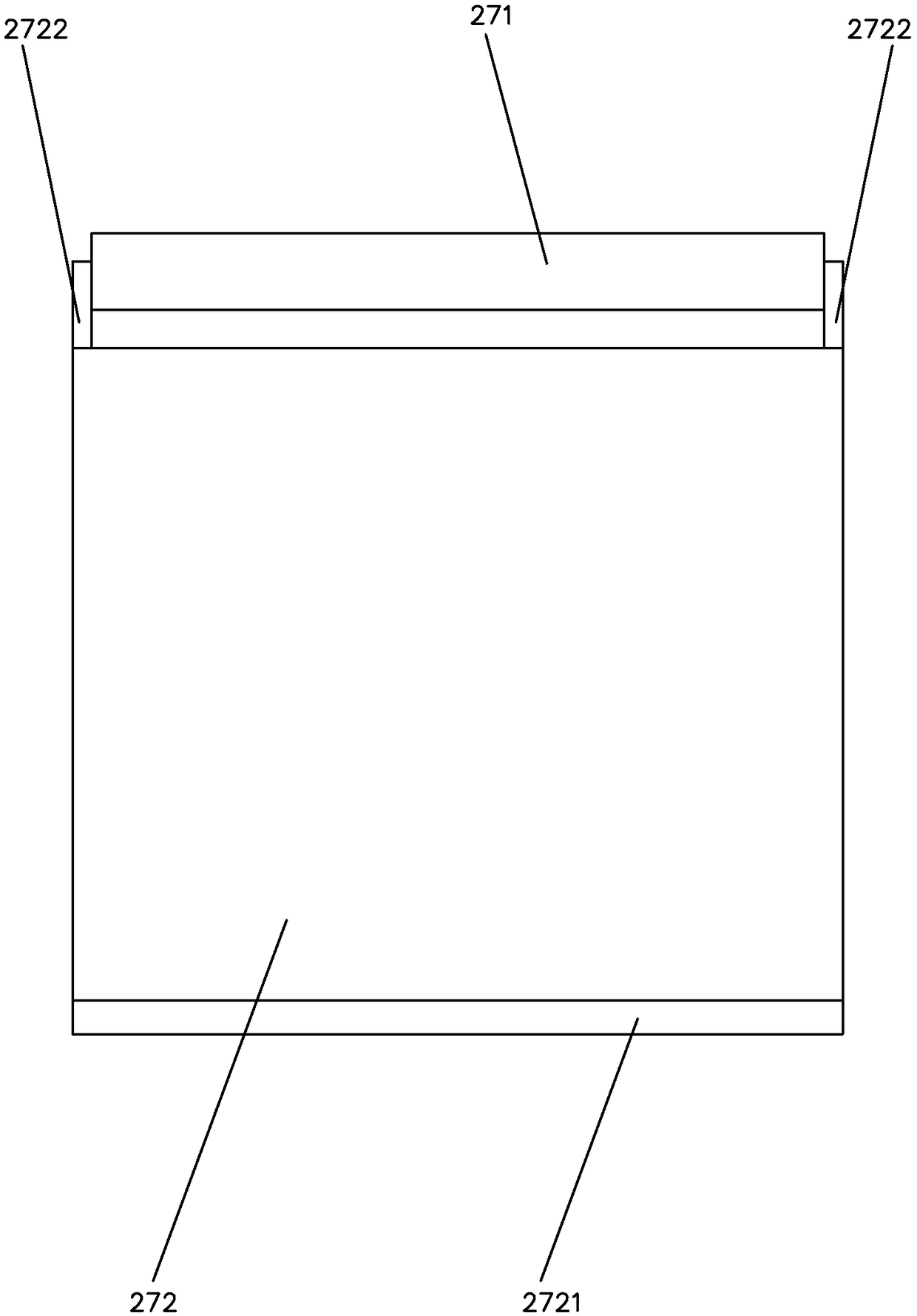

Efficient full-automatic veneering hot press production line

ActiveCN109049184APlywood pressesVeneer pressesThermal compressionHeat press

Owner:漳州鑫华成机械制造有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap