Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Inlet manifold" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In automotive engineering, an inlet manifold or intake manifold (in American English) is the part of an engine that supplies the fuel/air mixture to the cylinders. The word manifold comes from the Old English word manigfeald (from the Anglo-Saxon manig [many] and feald [repeatedly]) and refers to the multiplying of one (pipe) into many.

Engine energy-saving carbon-reduction efficiency improving assisting device

InactiveCN103775255AIncrease oxygen contentImprove combustion efficiencyElectrolysis componentsNon-fuel substance addition to fuelPower flowHydrogen

The invention provides an engine energy-saving carbon-reduction efficiency improving assisting device. An electrolytic cell in which pure water can be injected is formed in a vehicle and is electrically connected with a vehicle storage battery, and the electrolytic cell electrolyze the injected pure water into hydrogen and oxygen after the storage batter supplies currents for the electrolytic cell. The hydrogen and the oxygen are transmitted to an engine gas inlet manifold and a fuel pipe through a first gas transmission pipe and a second gas transmission pipe respectively, so that the hydrogen and fuels are fixed to be supplied to an engine steam cylinder to be burnt, and the oxygen is fed into the engine steam cylinder to assist burning through the gas inlet manifold; or the oxygen and the hydrogen are transmitted to the engine gas inlet manifold through the first gas transmission pipe and a second gas transmission pipe respective and fed into the engine steam cylinder to be burnt after being mixed according to the set optimum proportion, and accordingly, energy-saving and carbon-reduction purposes are achieved.

Owner:陈温乐

Large-scale pitch sphere oxidation non-fusible preparation process and device

ActiveCN104927890AReality of large-scale oxidation without meltingIncrease production capacityWorking-up pitch/asphalt/bitumen by chemical meansElectricityCoupling

A large-scale pitch sphere oxidation non-fusible preparation process comprises the following steps: pitch spheres are uniformly distributed on ring-shaped screen frames (1); screen frame combination boxes (4) are combined through quick couplers (3) to form trolleys; worms (8) rotate to enable the first trolley to enter a first trolley storage chamber from a waiting position (22); turbines (7) drive the ring-shaped screen frames (1) to rotate through screen frame shafts (2); a blower (P) extract fresh air from an air inlet manifold (21), so that all the trolley storage spaces are filled with preheated air; electrical heating plate components (11) are preheated to the preset temperature, so that pitch sphere oxidation non-fusible preparation can be started; when the preset oxidation non-fusible preparation time is up, the second trolley at the waiting position is pushed to the first trolley storage chamber while the first trolley is pushed to the second trolley storage chamber, then pitch sphere oxidation non-fusible preparation can be re-performed, and so on. The advantages that large-scale production can be realized and the glossiness of the pitch spheres is not damaged are achieved.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Breathing boost device of automobile engine

InactiveCN102168635AIncreased air intakeIncrease powerMachines/enginesAir intakes for fuelAir filterEngineering

Owner:SHAOXING UNIVERSITY

Engine EGR system and diagnosis method thereof

InactiveCN114251202AQuickly judge whether it is blockedEasy to detectExhaust gas recirculationMachines/enginesExhaust fumesExhaust gas recirculation

The invention discloses an engine EGR (Exhaust Gas Recirculation) system and a diagnosis method thereof, and the engine EGR system comprises an EGR pipeline, a first temperature sensor, an intake manifold and a second temperature sensor. An EGR cooler and an EGR valve are arranged on the EGR pipeline, the first temperature sensor is connected to the EGR pipeline behind an outlet of the EGR valve so as to detect the temperature of waste gas at the gas outlet end of the EGR valve, the gas inlet manifold is connected with the EGR pipeline, and the second temperature sensor is connected to the gas inlet manifold so as to detect the temperature of the gas inlet manifold. According to the engine EGR system, whether the EGR pipeline is blocked or not can be directly judged according to the exhaust gas temperature, detected by the first temperature sensor, of the gas outlet end of the EGR valve and the temperature, detected by the second temperature sensor, of the gas inlet manifold, detection is simple, implementation is easy, and the detection cost is low.

Owner:SHENZHEN ZHENYU NEW ENERGY POWER TECH CO LTD

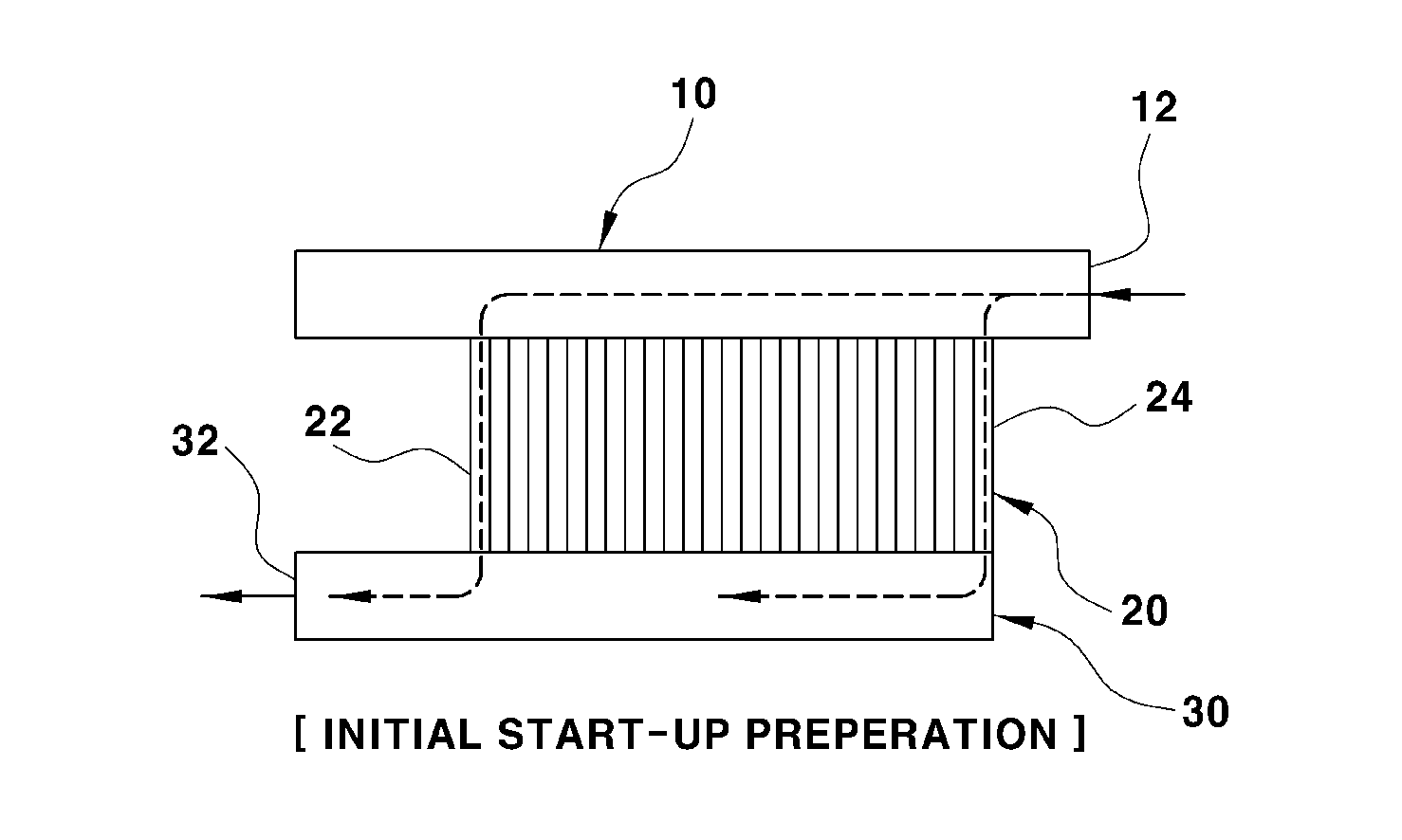

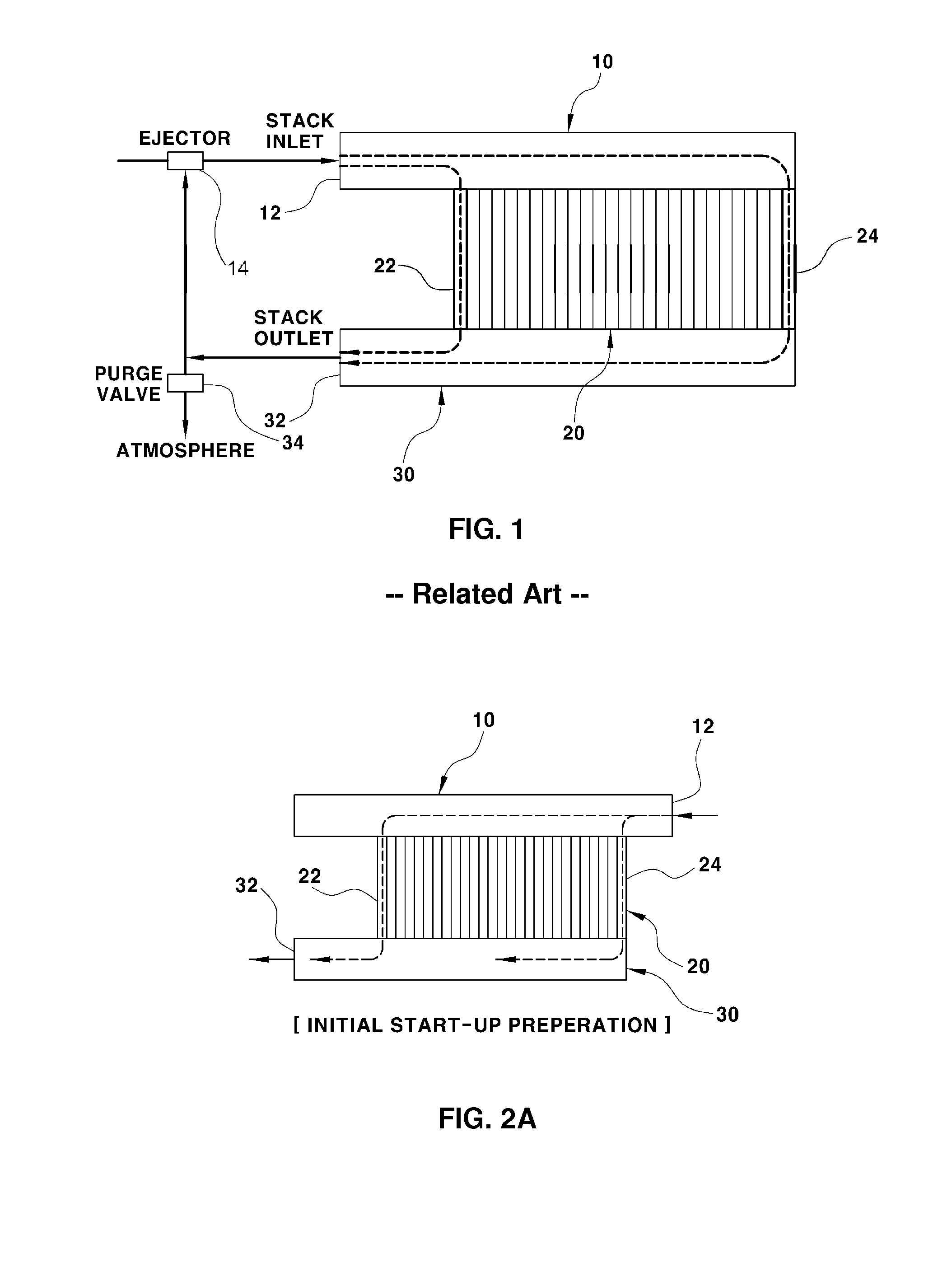

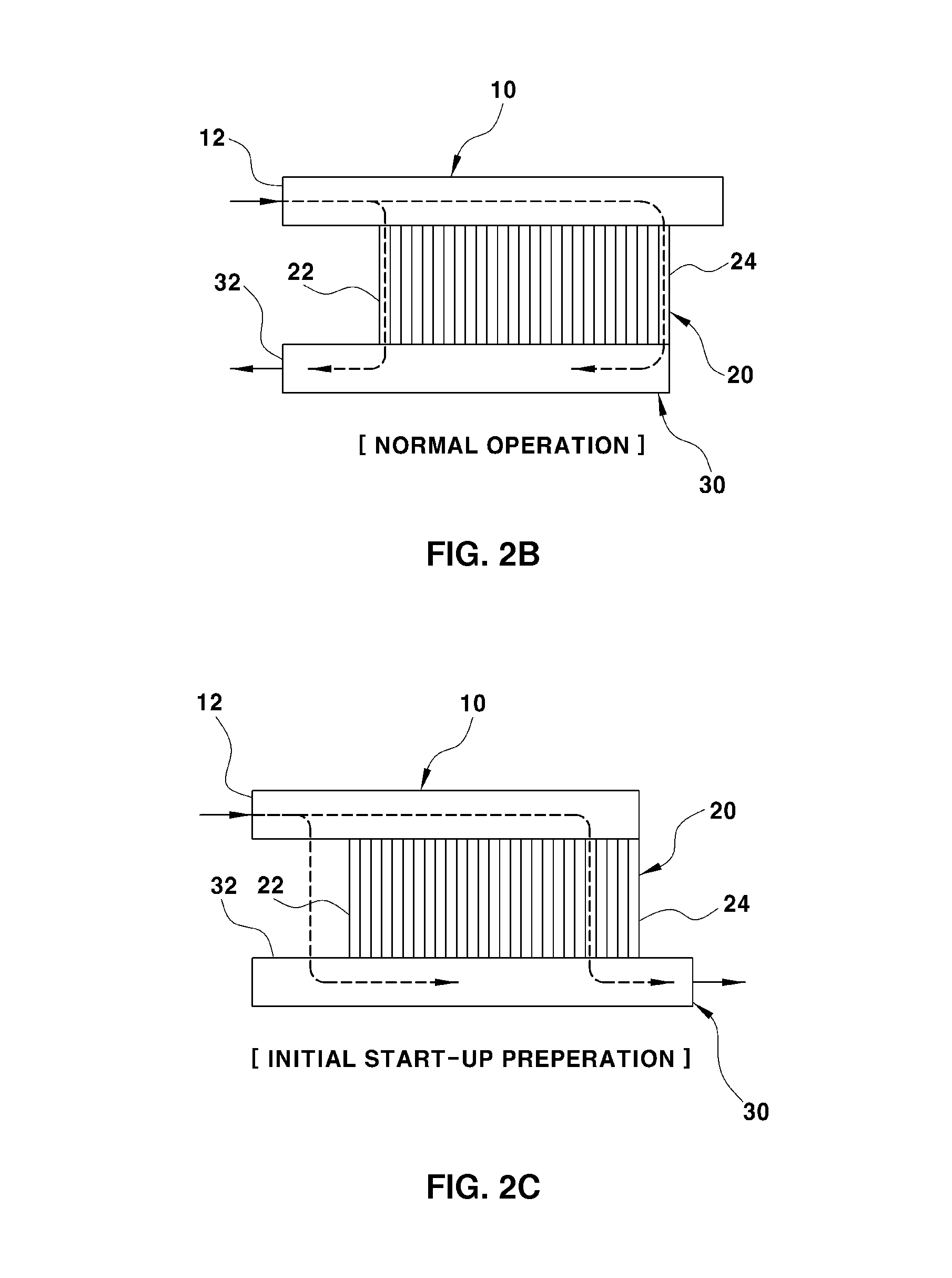

Device for changing anode inlet and anode outlet of fuel cell stack

ActiveUS20160322656A1Quantity minimizationImprove fuel efficiencyReactant parameters controlMotive system fuel cellsControl flowFuel cells

Owner:HYUNDAI MOTOR CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap