Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Kerosene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Kerosene, also known as paraffin, lamp oil, and coal oil (an obsolete term), is a combustible hydrocarbon liquid which is derived from petroleum. It is widely used as a fuel in aviation as well as households. Its name derives from Greek: κηρός (keros) meaning wax, and was registered as a trademark by Canadian geologist and inventor Abraham Gesner in 1854 before evolving into a genericized trademark. It is sometimes spelled kerosine in scientific and industrial usage. The term kerosene is common in much of Argentina, Australia, Canada, India, New Zealand, and the United States, while the term paraffin (or a closely related variant) is used in Chile, eastern Africa, South Africa, Norway, and in the United Kingdom. The term lamp oil, or the equivalent in the local languages, is common in the majority of Asia and "Earth Oil" in some parts of southern Asia.Liquid paraffin (called mineral oil in the US) is a more viscous and highly refined product which is used as a laxative. Paraffin wax is a waxy solid extracted from petroleum.

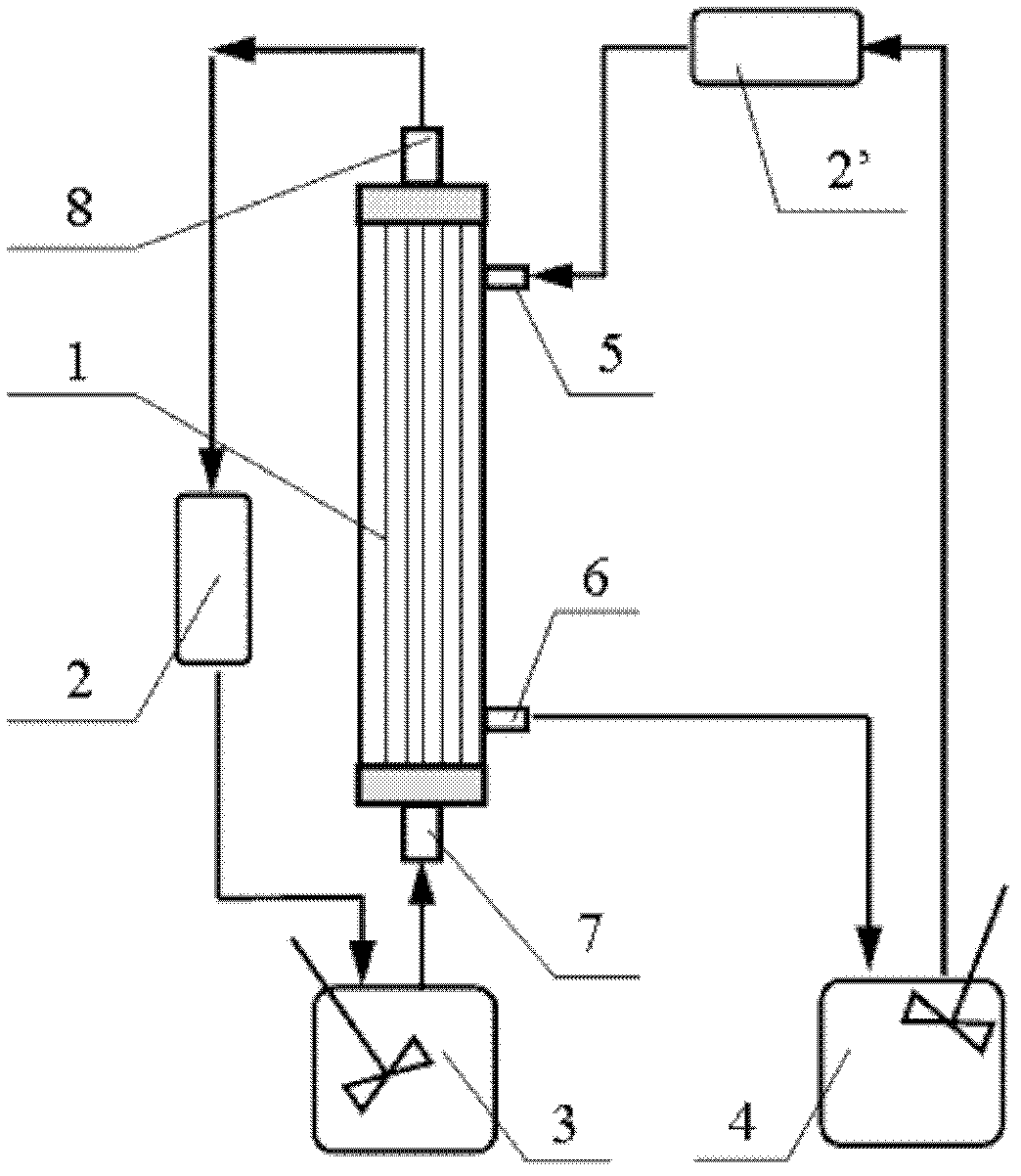

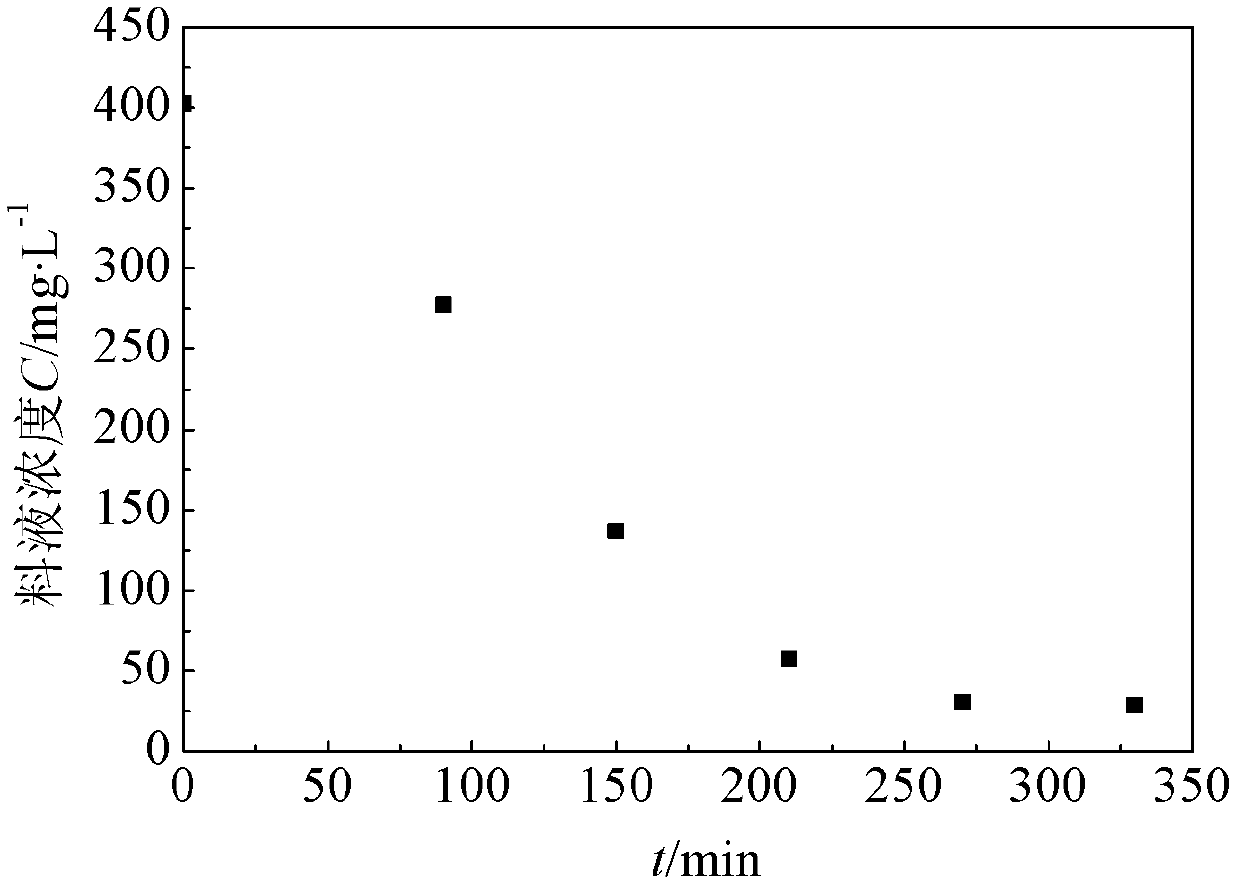

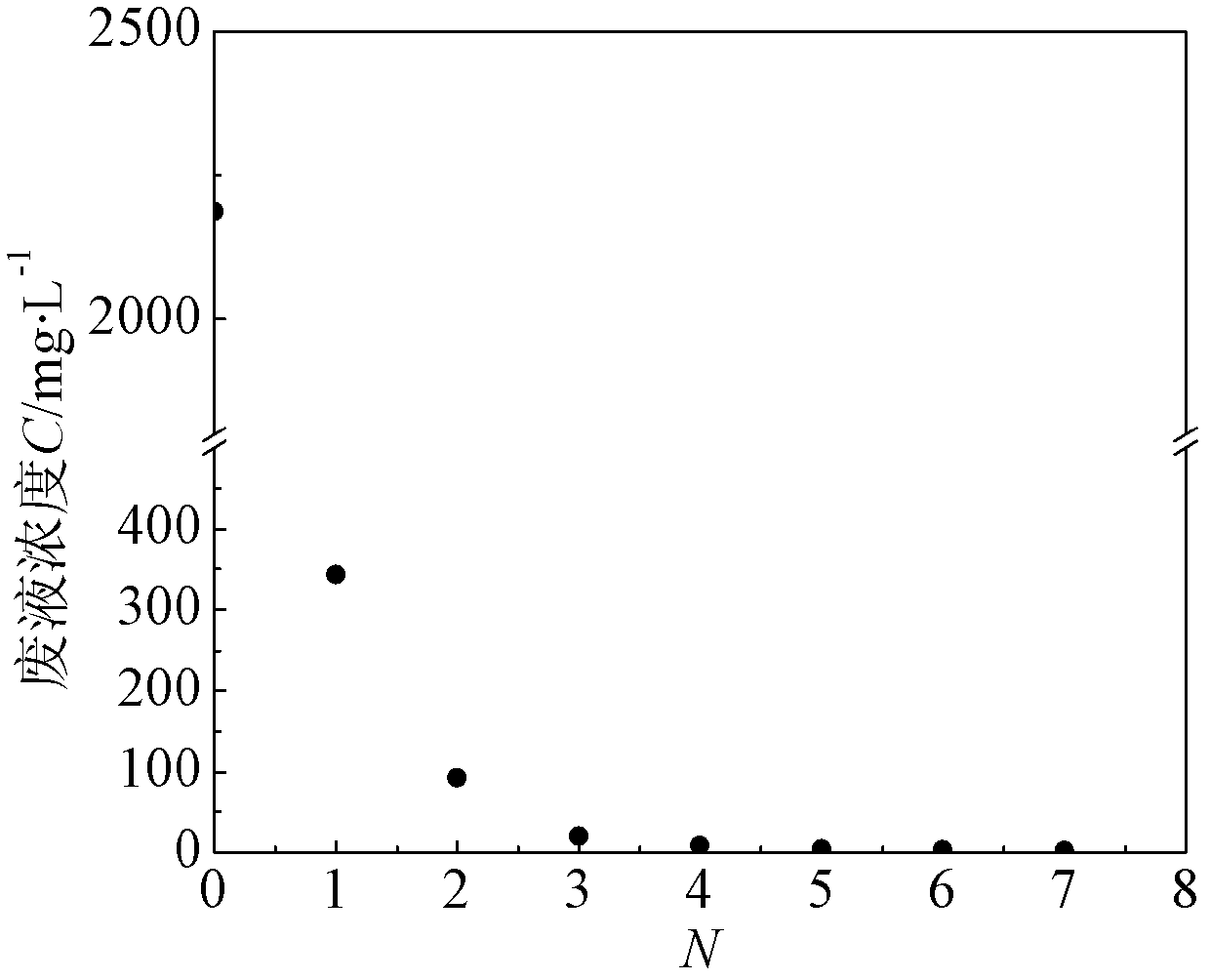

Method for removing phenol in phenol contained wastewater by using hollow fiber membrane

InactiveCN103304005AImprove stabilityImprove mass transfer efficiencyWater contaminantsWater/sewage treatment bu osmosis/dialysisHollow fibre membraneBenzene

Owner:BEIJING UNIV OF CHEM TECH

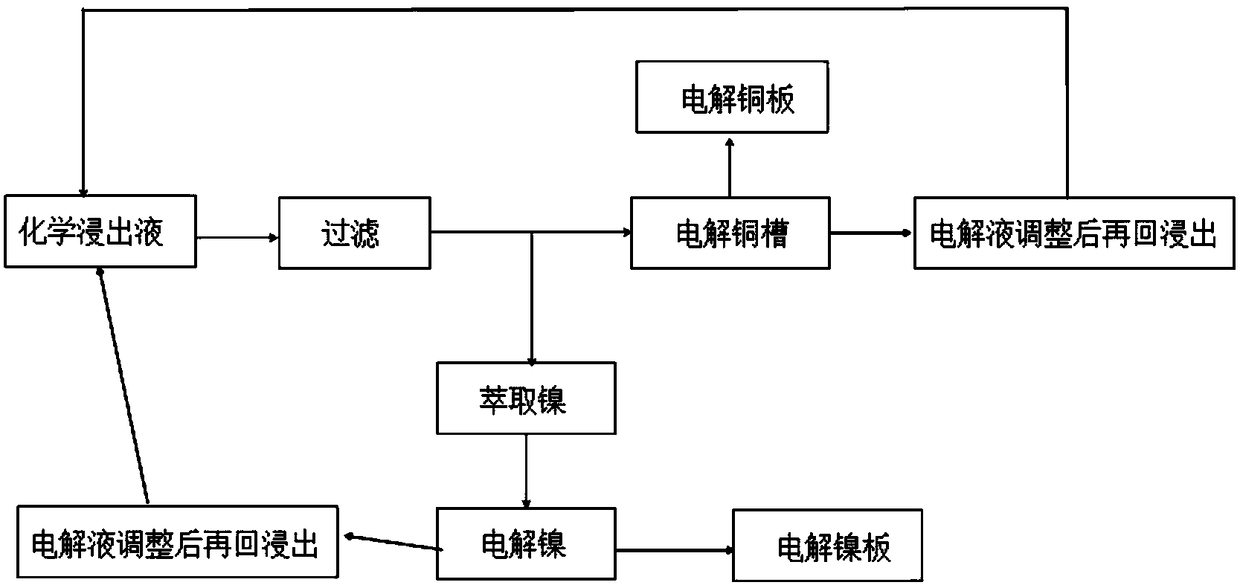

Metal recycling process for waste plastic electroplating parts

InactiveCN109161694APhotography auxillary processesProcess efficiency improvementKeroseneMetal recycling

Owner:广东明方科技有限公司

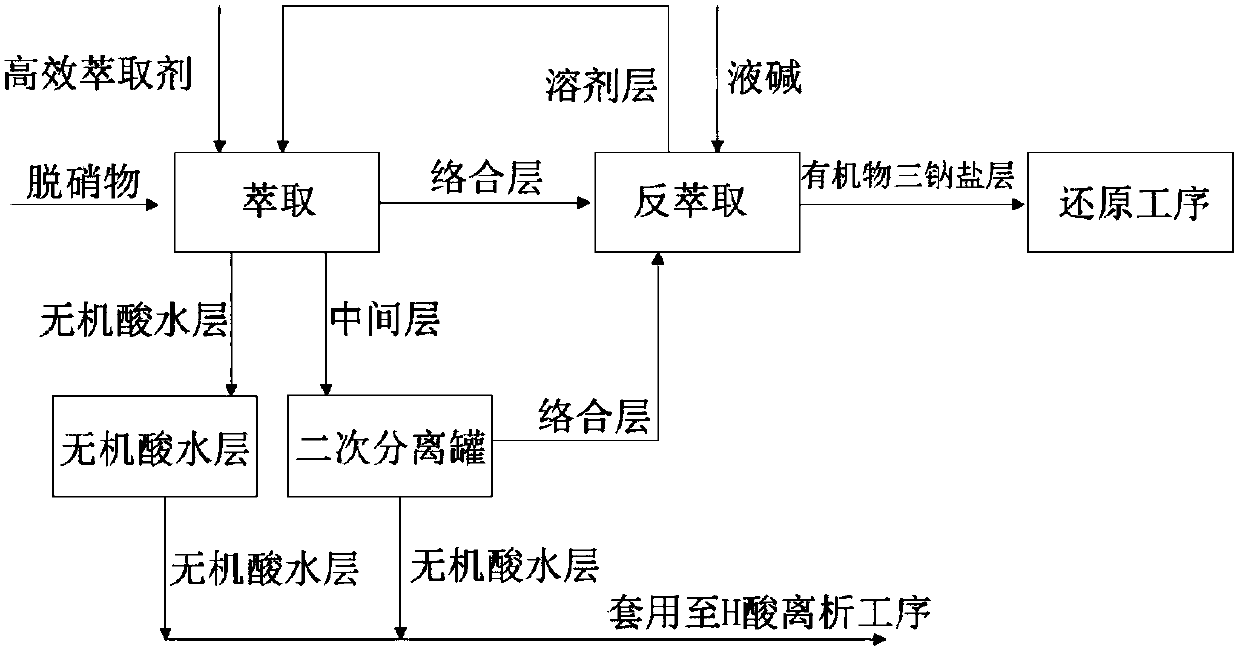

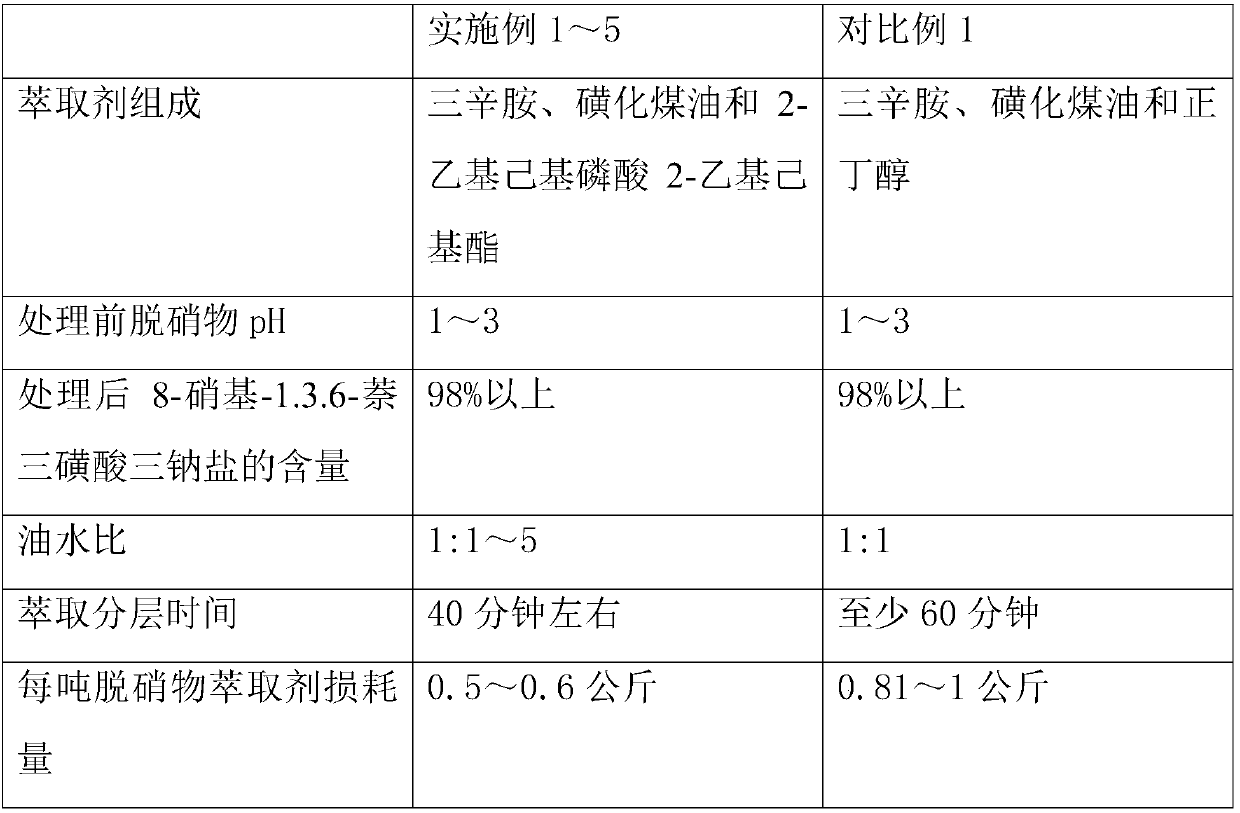

Extraction method and extraction agent for denitration procedure in H acid production process

ActiveCN108043067ALiquid solutions solvent extractionKeroseneOrganic chemicals

Owner:湖北丽康源化工有限公司

Full-tooth continuous quenching method for slewing bearing

PendingCN114317906AHigh hardnessImprove mechanical propertiesFurnace typesIncreasing energy efficiencyRare-earth elementKerosene

Owner:安徽省宁国顺昌机械有限公司

Method for baking the automobile paint surface penetrant at high temperature

InactiveCN103962293AAchieve scratch resistanceAchieve acid and alkali corrosion resistancePretreated surfacesSpecial surfacesCleansers skinKerosene

Owner:湖南御瓷炼环保科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap