Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Low oxygen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

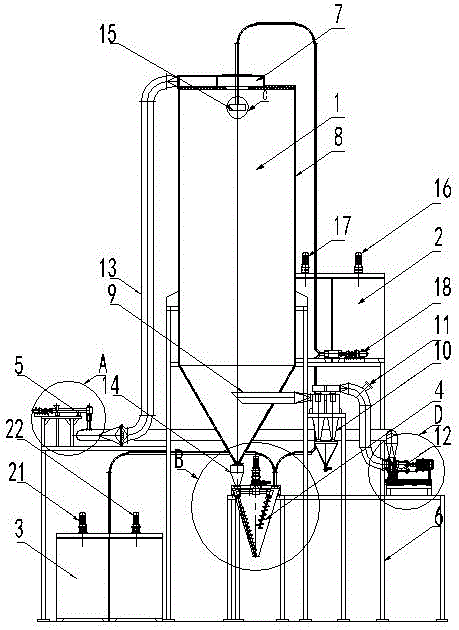

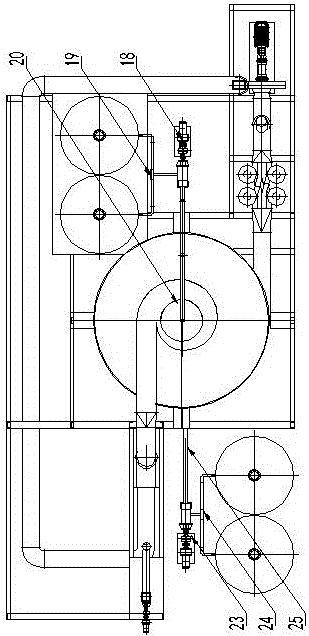

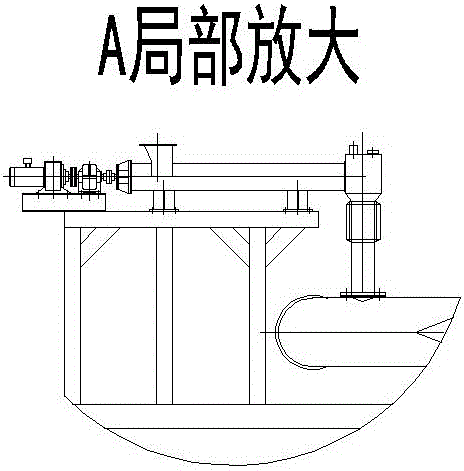

Special preparation device for boiler flue gas desulfurization tower repairing agent

ActiveCN106079100AAvoid pollutionReduce investmentMixing operation control apparatusPretreatment controlFluidized bedFlue gas

Owner:桐乡市金琪塑料包装有限公司

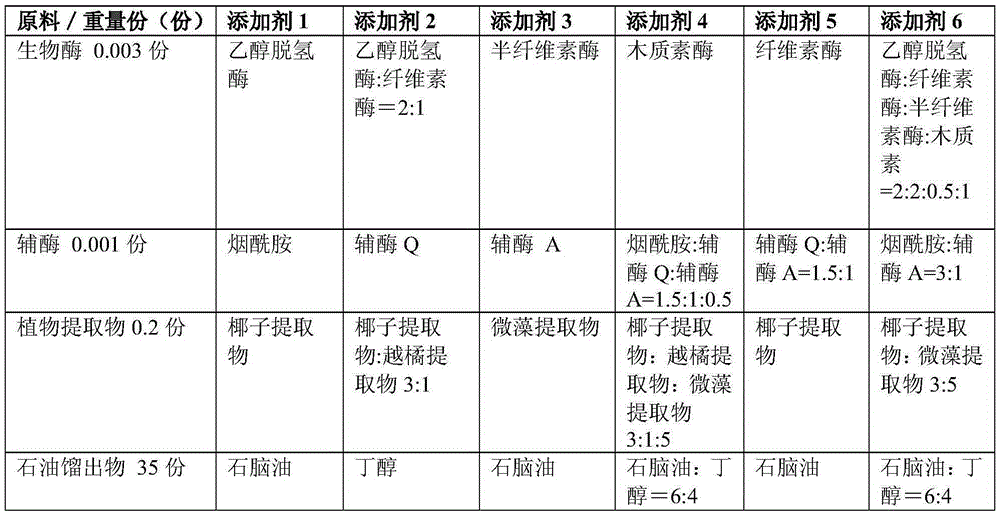

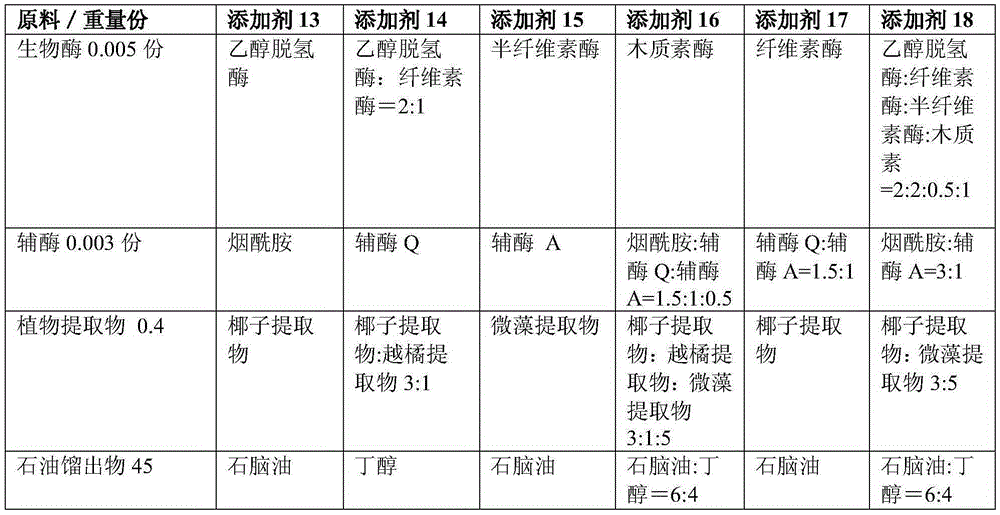

Gasoline environmental-protection and energy-saving additive and environmental-protection and energy-saving gasoline

InactiveCN106590775AReduce consumptionImprove synchronous combustionLiquid carbonaceous fuelsEngineeringPetroleum

Owner:国科蓝天清洁能源技术有限公司

Duct burner for diesel engine

ActiveCN110953580AImprove fire conditionsGuaranteed normal combustionBurnersExhaust apparatusCombustorFlue gas

The invention provides a duct burner for a diesel engine. The outer cylinder wall of the burner is arranged on the outer part of the inner cylinder wall of the burner in a nesting mode, the end of theinner cylinder wall is sealed and provided with an ignition gun and an oil gun, the other end of the inner cylinder wall of the burner is opened as a flue gas outlet, and flue gas inlets are formed in the inner cylinder wall of the burner and the outer cylinder wall of the burner; a firing stabilizer is arranged in the inner cylinder wall of the burner and located on the rear side of the oil gun,and a fire detection device is arranged on the rear part of a nozzle of the firing stabilizer. According to the duct burner, the fuel ignition conditions are improved by preheating air, and when theduct burner is operated at low power and low oxygen content, the normal combustion of the small-flow fuel is ensured; because of the two-stage atomization mode, the particle diameter of the fuel is smaller, the distribution is more uniform, and the combustion is better under the low-power and low-oxygen environment; by adjusting the relative position of inner and outer casings of the oil gun, thefuel flow can be adjusted auxiliarily, and the exhaust gas temperature is facilitated to be more accurately controlled; and the fuel and an atomizing medium can be fully accelerated by a two-stage spray pipe structure of the head of the oil gun, the atomization effect is enhanced, and thus the fuel is better ignited and burned.

Owner:SHANGHAI POWER EQUIP RES INST

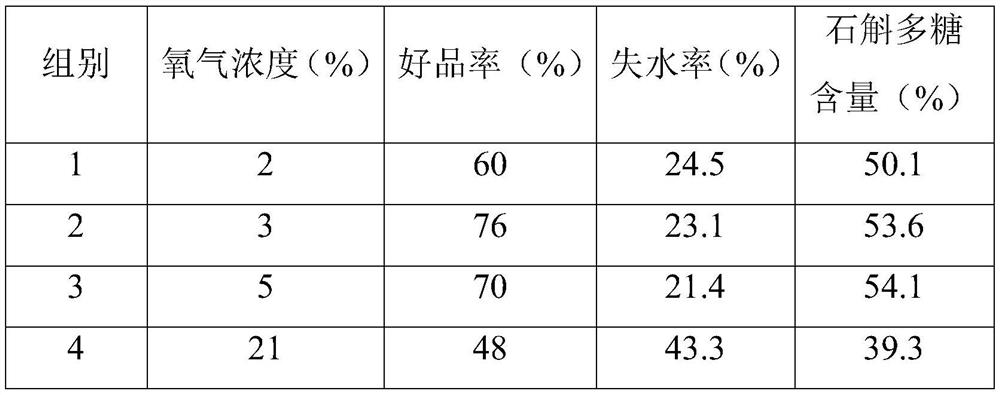

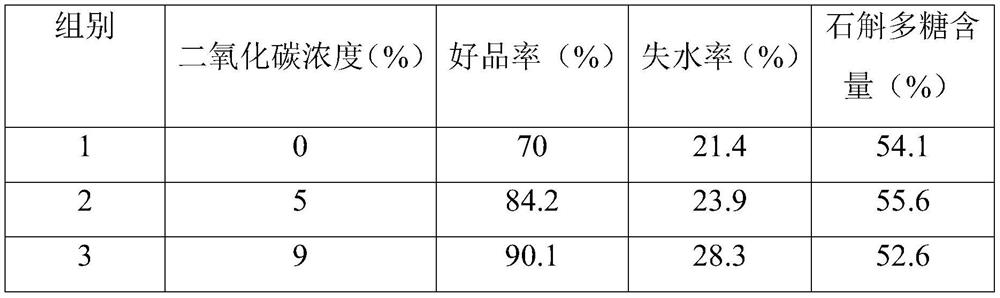

Dendrobium nobile preservation method

Owner:TIANJIN CNRO SCI TECH

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap