Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7 results about "Silica glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silica Glass - Characteristics. Silica glass is a kind of glass as the name is implied, but silica glass is composed of by almost only SiO 2, while, on the other hand, other glasses are composed of by various kinds of elements.

Low-attenuation bending insensitive single-mode optical fiber

ActiveCN105334570AReduced germanium dopingReduce the attenuation factorOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingUltrasound attenuationRelative refractive index

The invention relates to a low-attenuation bending insensitive single-mode optical fiber for an optical communication transmission system. The optical fiber comprises a core layer and a cladding layer. The optical fiber is characterized in that the refractive index of the core layer is distributed according to an alpha-order parabola, and the distribution index alpha is 1.5-9.0; the cladding layer is sequentially formed by an inner cladding layer, an intermediate cladding layer and an outer cladding layer from inside to outside; the maximal refractive index difference delta 1 of the parabola core layer is 0.25-0.45 percent, and the radius R1 of the core layer is 5.0-7.0mu u; the relative refractive index different delta 2 of the inner cladding layer is -0.20-0 percent, and the radius R2 of the inner cladding layer is 7.0-10.0mu m; the relative refractive index difference delta 3 of the intermediate cladding layer is -0.20-0 percent, and the radius R3 of the intermediate cladding layer is 10.0-20.0mu m; and the outer cladding layer is a pure quartz glass layer. The low-attenuation bending insensitive single-mode optical fiber has reasonable refractive index section design and low doping amount, and has excellent attenuation resistance and bending resistance.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

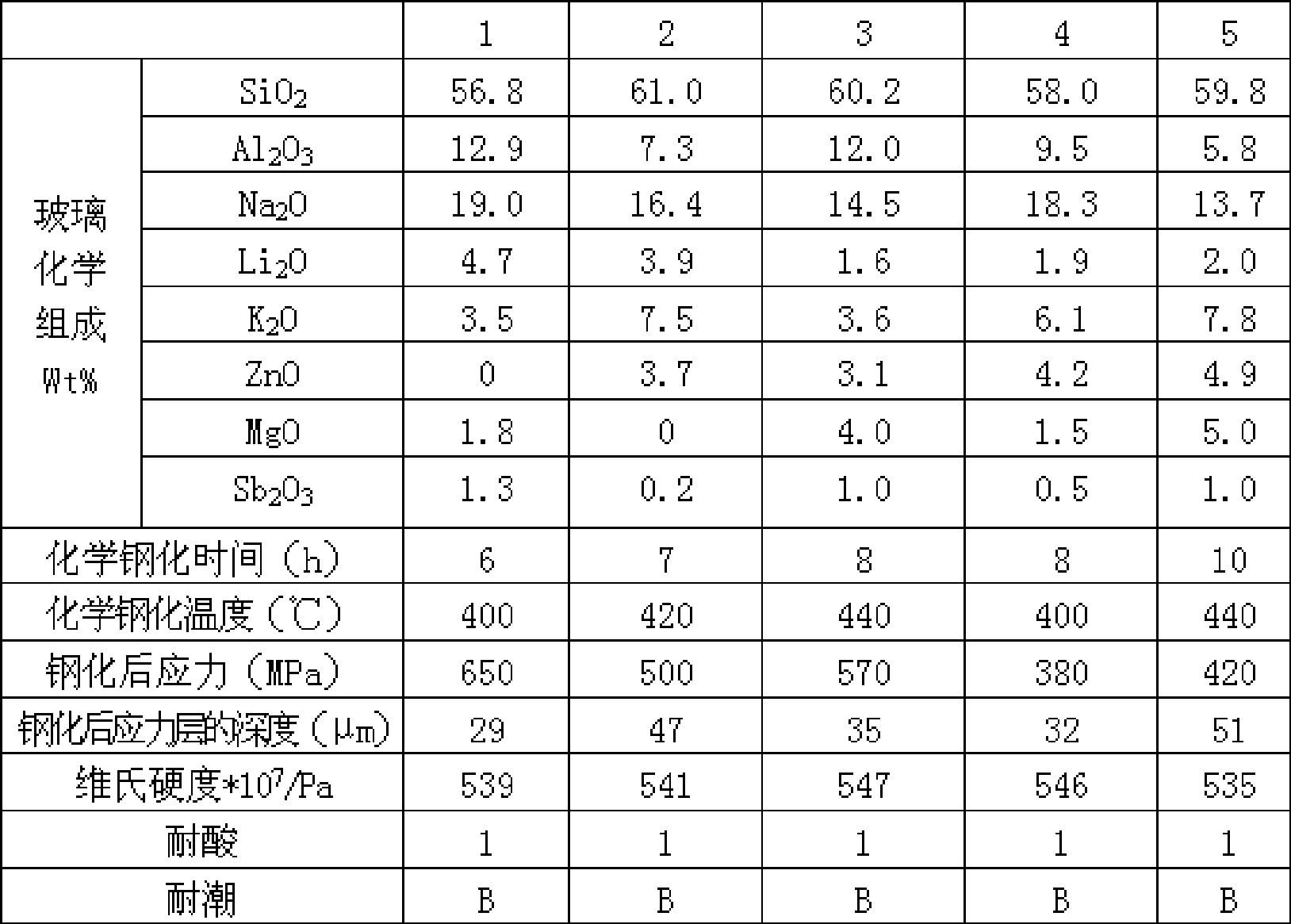

Glass suitable for chemically tempering and chemical tempered glass

ActiveCN101508523AReduce manufacturing difficultyLower melting temperatureGlass tempering apparatusGlass productionIon exchangeShock resistance

Owner:CDGM OPTICAL GLASS

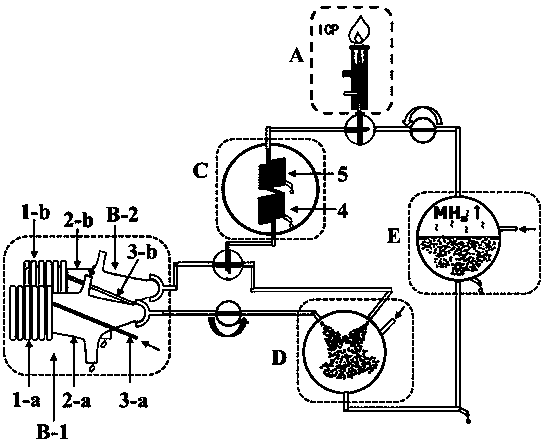

Highly-ionized energy element sampling system of inductively coupled plasma emission spectrometer

PendingCN110865068AReduce sensitivityHigh detection sensitivityAnalysis by thermal excitationHydrogenation reactionOptical spectrometer

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

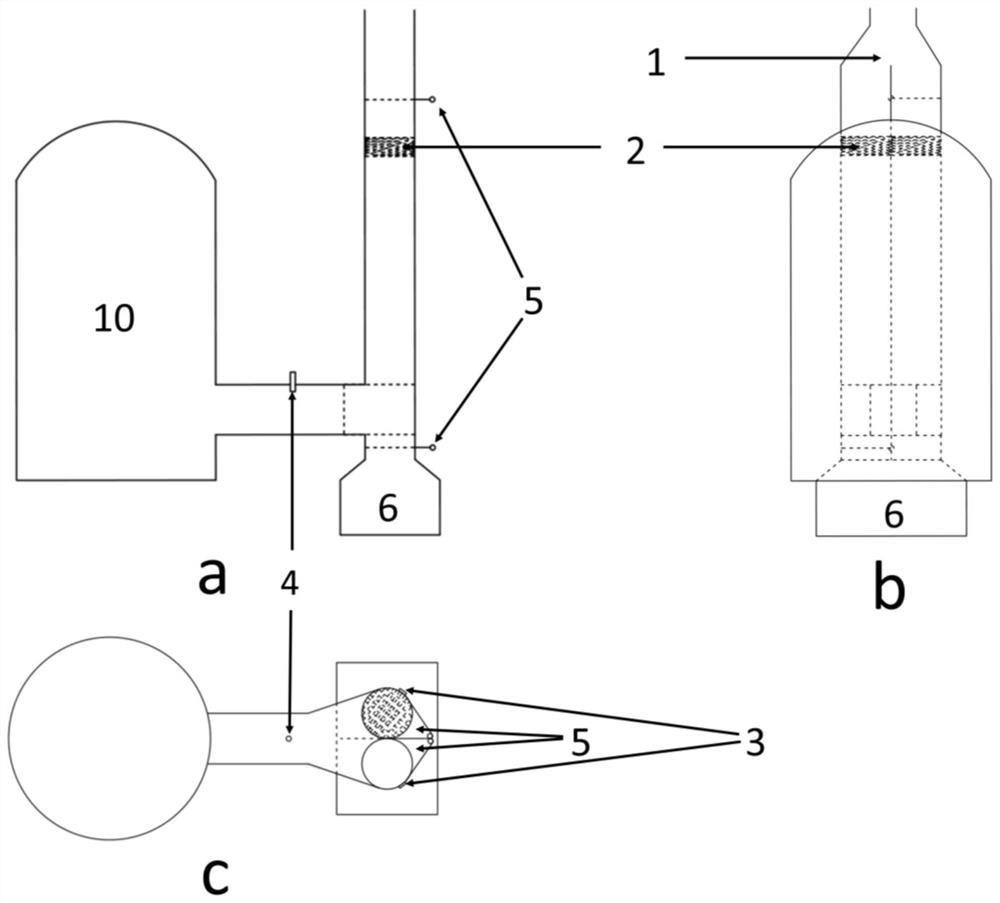

Heat treatment method of quartz glass

PendingCN110655305ALow stress birefringenceShort holding timeGlass shaping apparatusGlass productionVitrificationThermal insulation

The invention provides a heat treatment method of quartz glass. The heat treatment method adopts a vitrification molding and heat treatment integrated process, and comprises: (1) vitrifying a silicondioxide raw material to obtain a transparent quartz glass; (2) directly cooling the vitrified high-temperature transparent quartz glass to a heat treatment temperature, and carrying out thermal insulation; and (3) cooling the obtained quartz glass to a room temperature at a certain annealing rate to obtain the transparent quartz glass with low stress birefringence. According to the method of the invention, vitrification forming and heat treatment are carried out in the same sintering furnace, the temperature after vitrification forming is directly reduced to the heat treatment temperature, andthermal insulation is carried out, so that the heat treatment thermal insulation time is effectively shortened, the pollution risk is reduced, the production efficiency is improved, and the stress birefringence of the prepared quartz glass is smaller than 1.8 nm / cm.

Owner:ZHONGTIAN TECH

Preparation technology for neodymium-doped quartz glass used for laser

InactiveCN108264217AIncrease the doping concentrationEasy to operateGlass furnace apparatusGlass shaping apparatusAluminium chlorideNeodymium chloride

Owner:JIANGSU SHENGDA QUARTZ PROD CO LTD

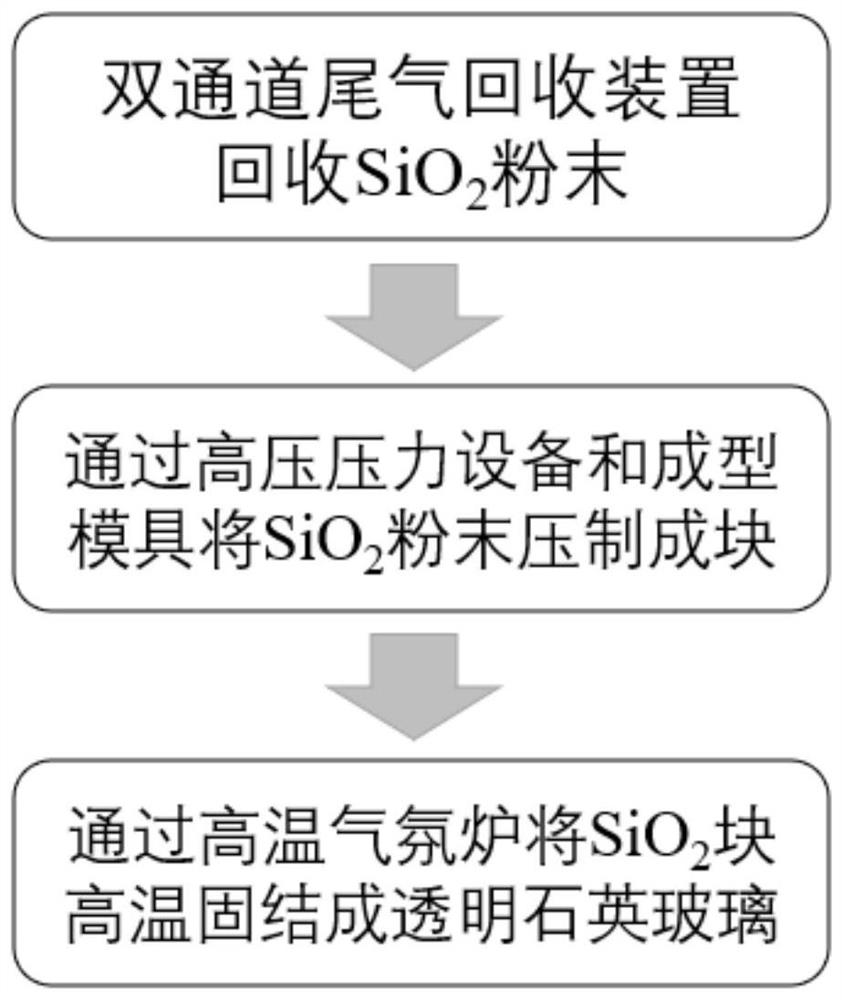

Method and device for recycling SiO2 powder from tail gas

Owner:CHINA BUILDING MATERIALS ACAD

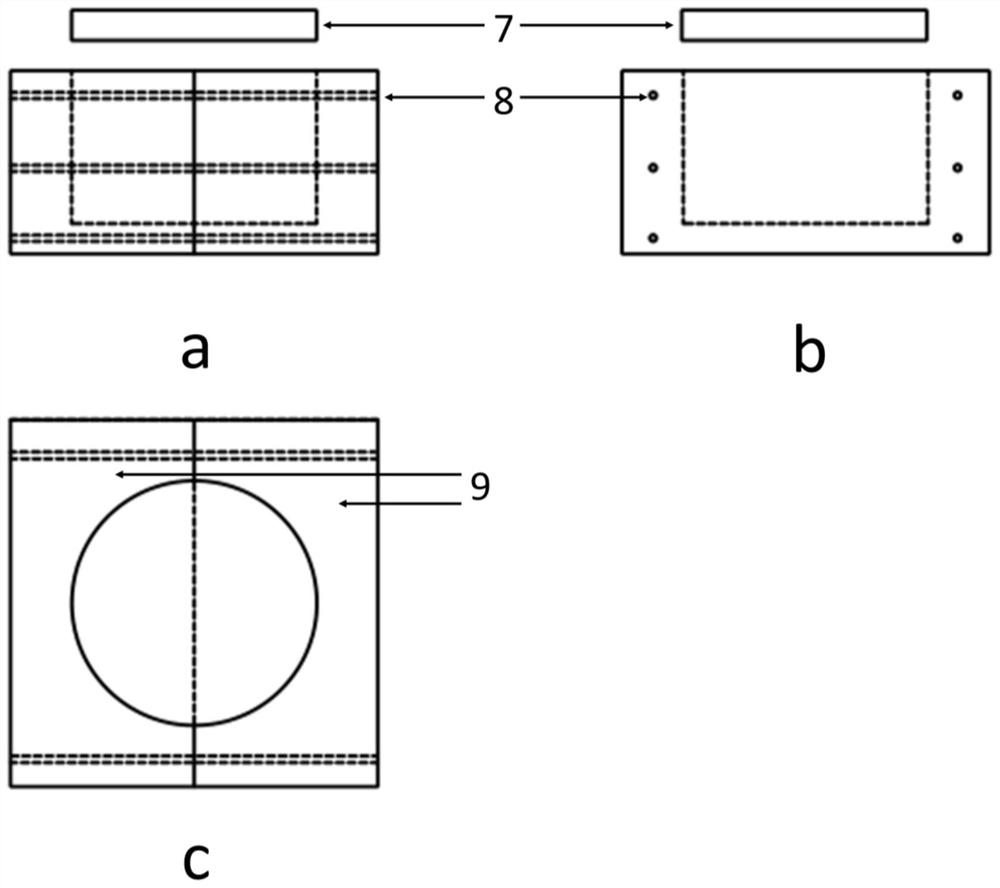

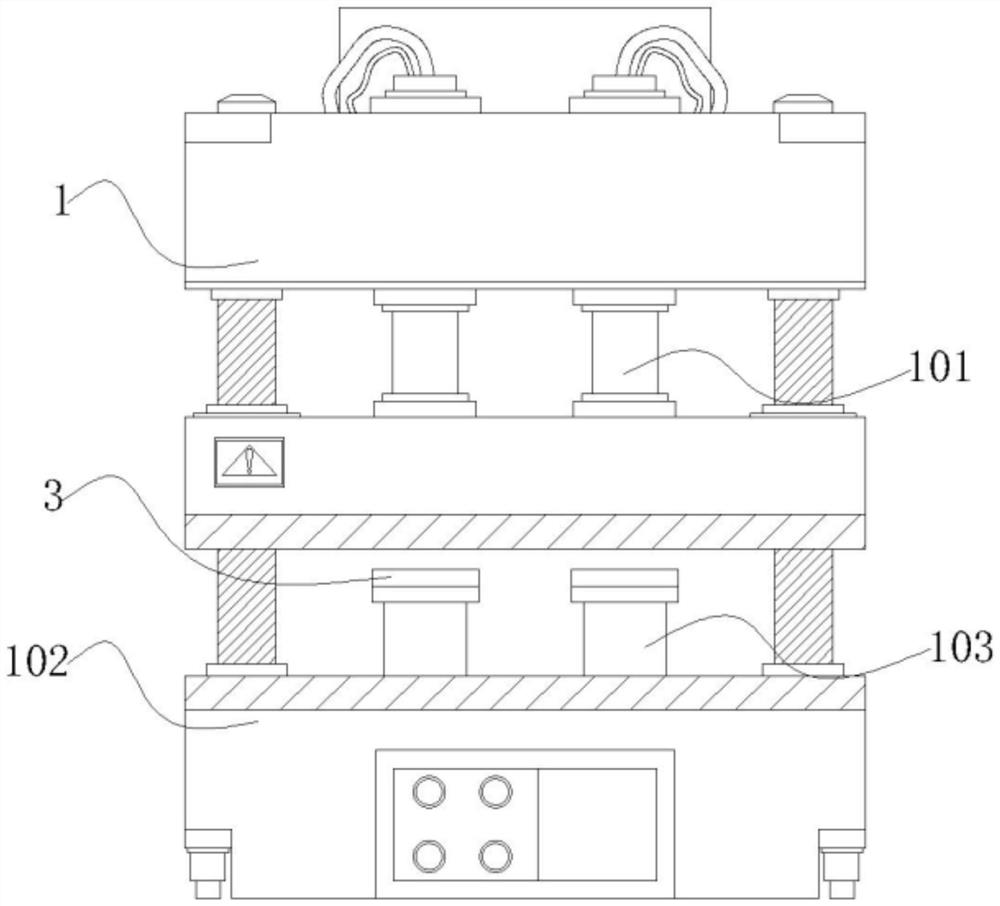

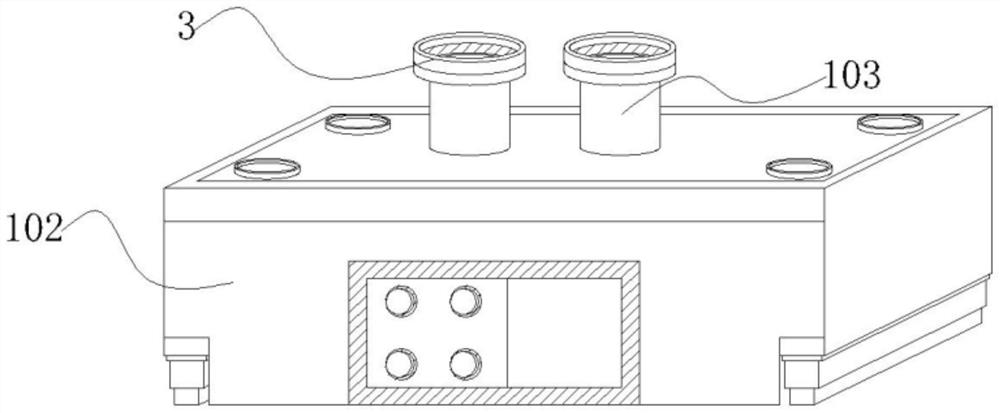

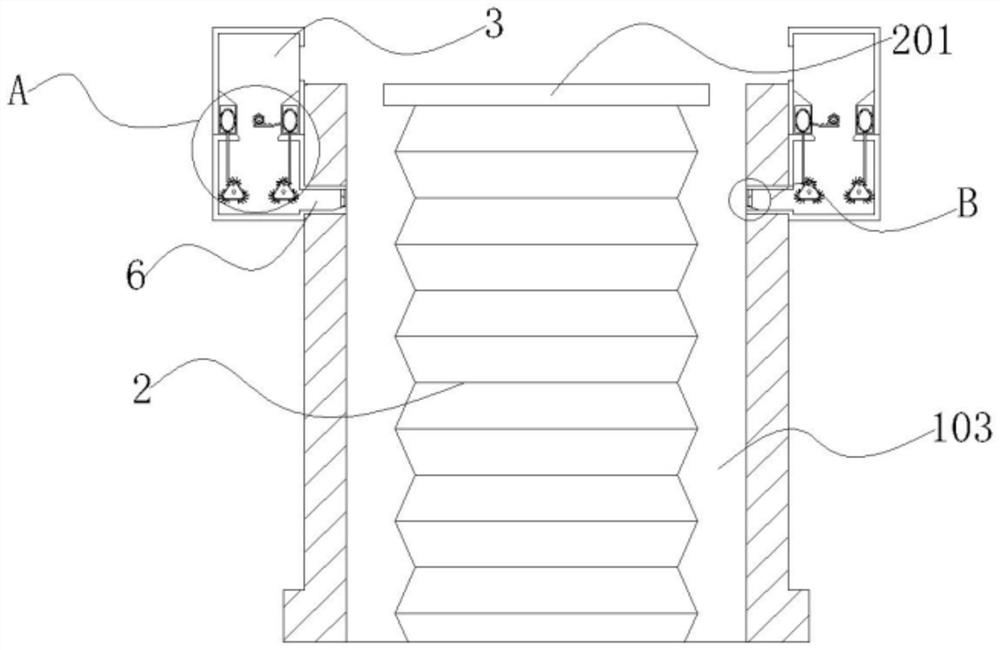

High-efficiency and high-precision quartz glass tube forming equipment

PendingCN114031270AAvoid easy displacementHigh forming precisionGlass pressing apparatusHydraulic pumpEngineering

Owner:新沂市东方石英玻璃有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap