Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Titanium nitride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium nitride (TiN; sometimes known as Tinite) is an extremely hard ceramic material, often used as a coating on titanium alloys, steel, carbide, and aluminium components to improve the substrate's surface properties.

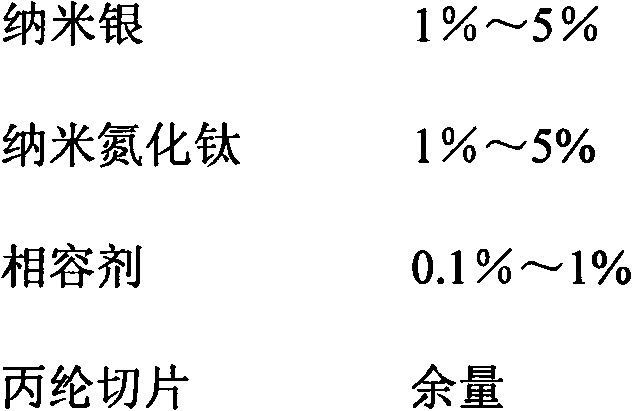

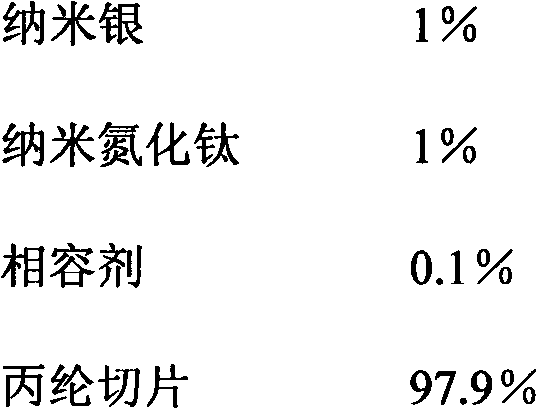

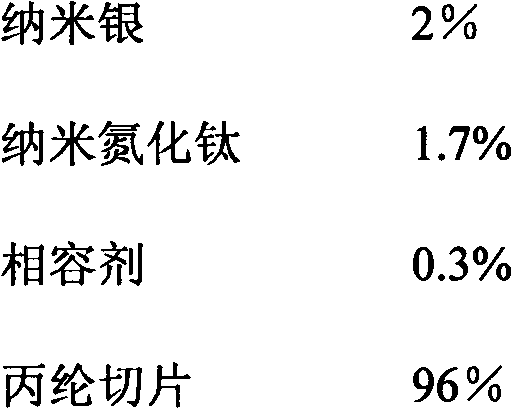

Antibacterial functional polypropylene fiber as well as preparation method and application thereof

InactiveCN102011206AImprove antibacterial propertiesImprove securityMonocomponent polyolefin artificial filamentArtifical filament manufactureMasterbatchTitanium nitride

Owner:上海歌灵新材料科技有限公司

Plastics products and preparation method thereof

InactiveCN101396890AImprove wear resistanceFeel goodVacuum evaporation coatingSynthetic resin layered productsCopper coatingCeramic coating

The invention relates to a plastic product, comprising plastic substrate. The plastic product is characterized in that the product also comprises a copper coating, a nickel coating, a chrome coating and a ceramic coating from the surface of the plastic substrate to the outside in sequence; the ceramic coating is one or more layer of titanium nitride, titanium carbide and titanium carbonitride. The plastic product made by the invention has excellent wearing resistance, the film formed on the surface of the plastic product has excellent adhesiveness, and the plastic product that is obtained finally also has ceramic texture and good handfeel.

Owner:BYD CO LTD

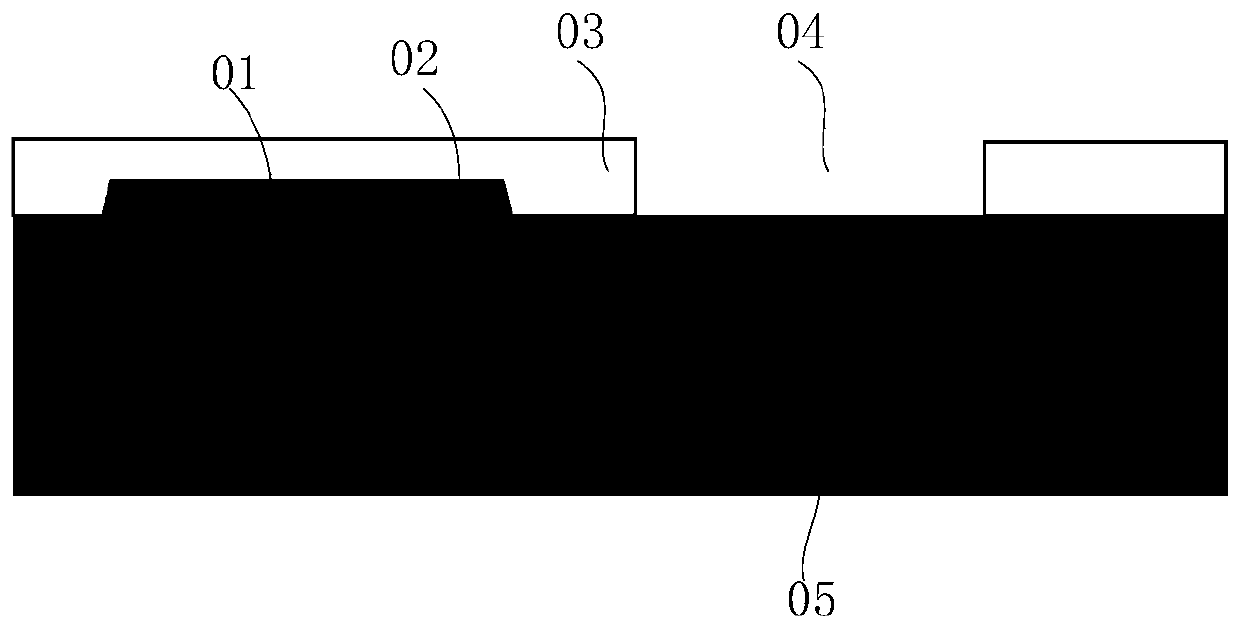

Method for making metallized capacitor

InactiveCN1482667AStop the spreadPrevent leakageSemiconductor/solid-state device manufacturingElectrical conductorTantalum nitride

The invention discloses a method of making metallic capacitor comprising, providing a semi-conductor substrate with a copper studded arrangement, then forming a sheet metal on the copper studded arrangement, and forming a metallic capacitor on the sheet metal, which includes an electrode layer composed of tantalum nitride layer or titanium nitride, forming an insulation side wall layer on the side wall of the metal capacitor. íí

Owner:TAIWAN SEMICON MFG CO LTD

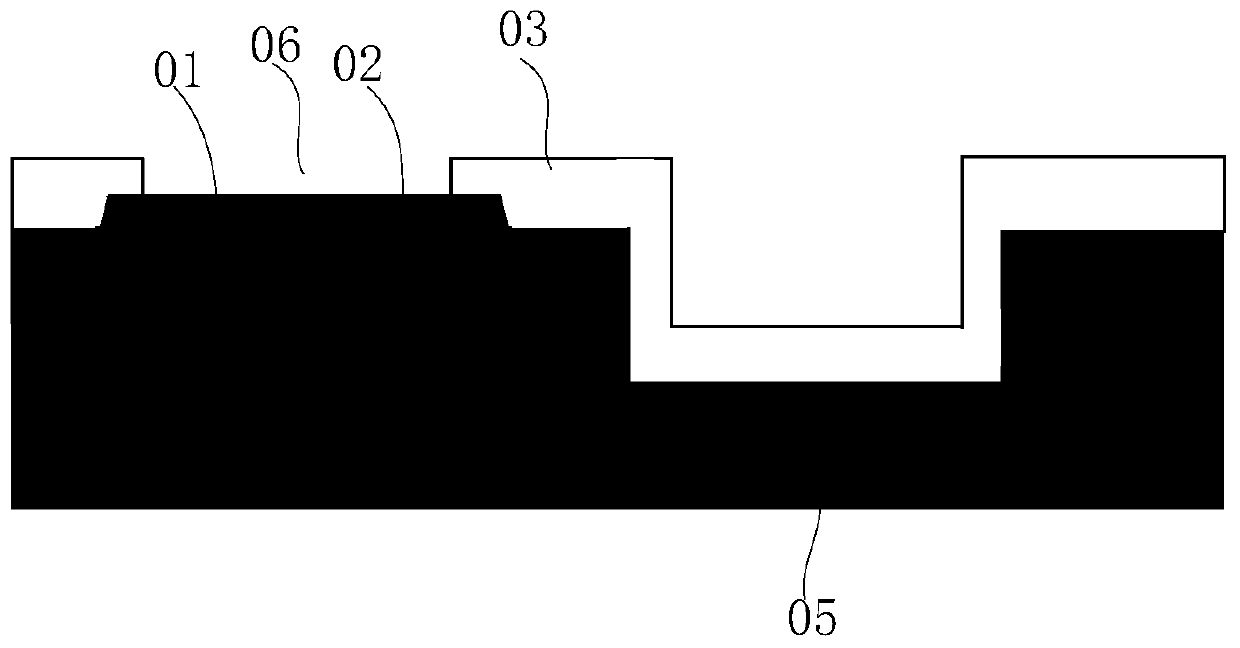

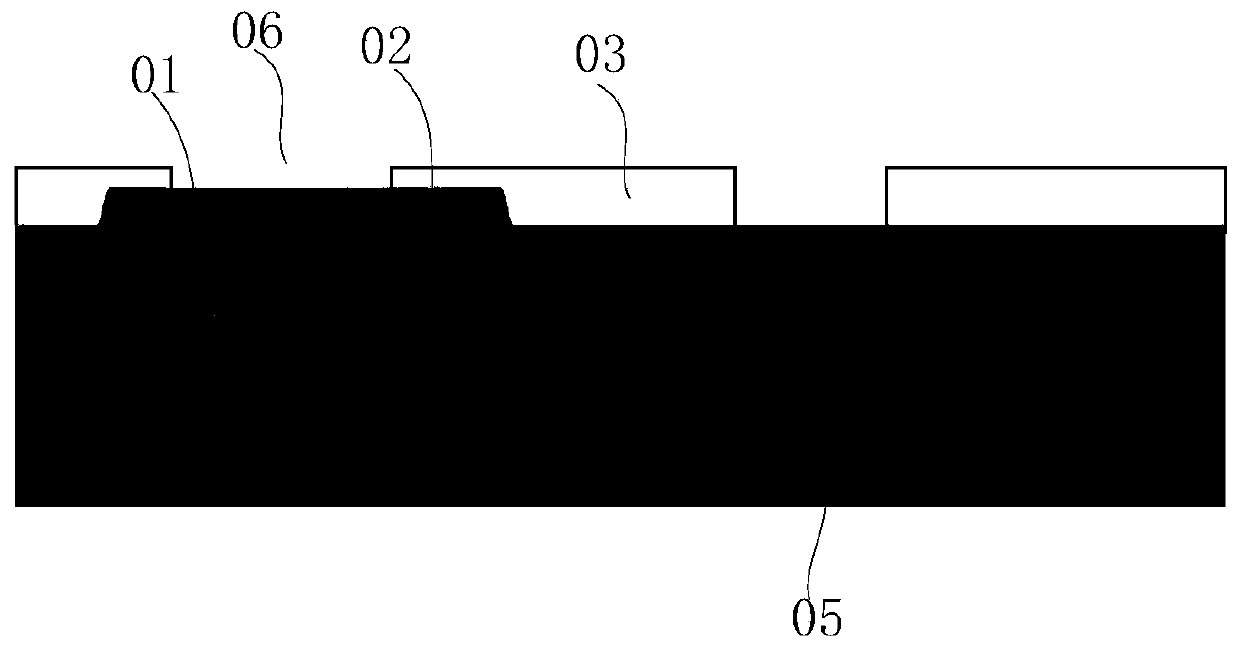

Method for preventing metal fuse from being excessively etched

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap