Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Tool bit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tool bit is a non-rotary cutting tool used in metal lathes, shapers, and planers. Such cutters are also often referred to by the set-phrase name of single-point cutting tool, as distinguished from other cutting tools such as a saw or water jet cutter. The cutting edge is ground to suit a particular machining operation and may be resharpened or reshaped as needed. The ground tool bit is held rigidly by a tool holder while it is cutting.

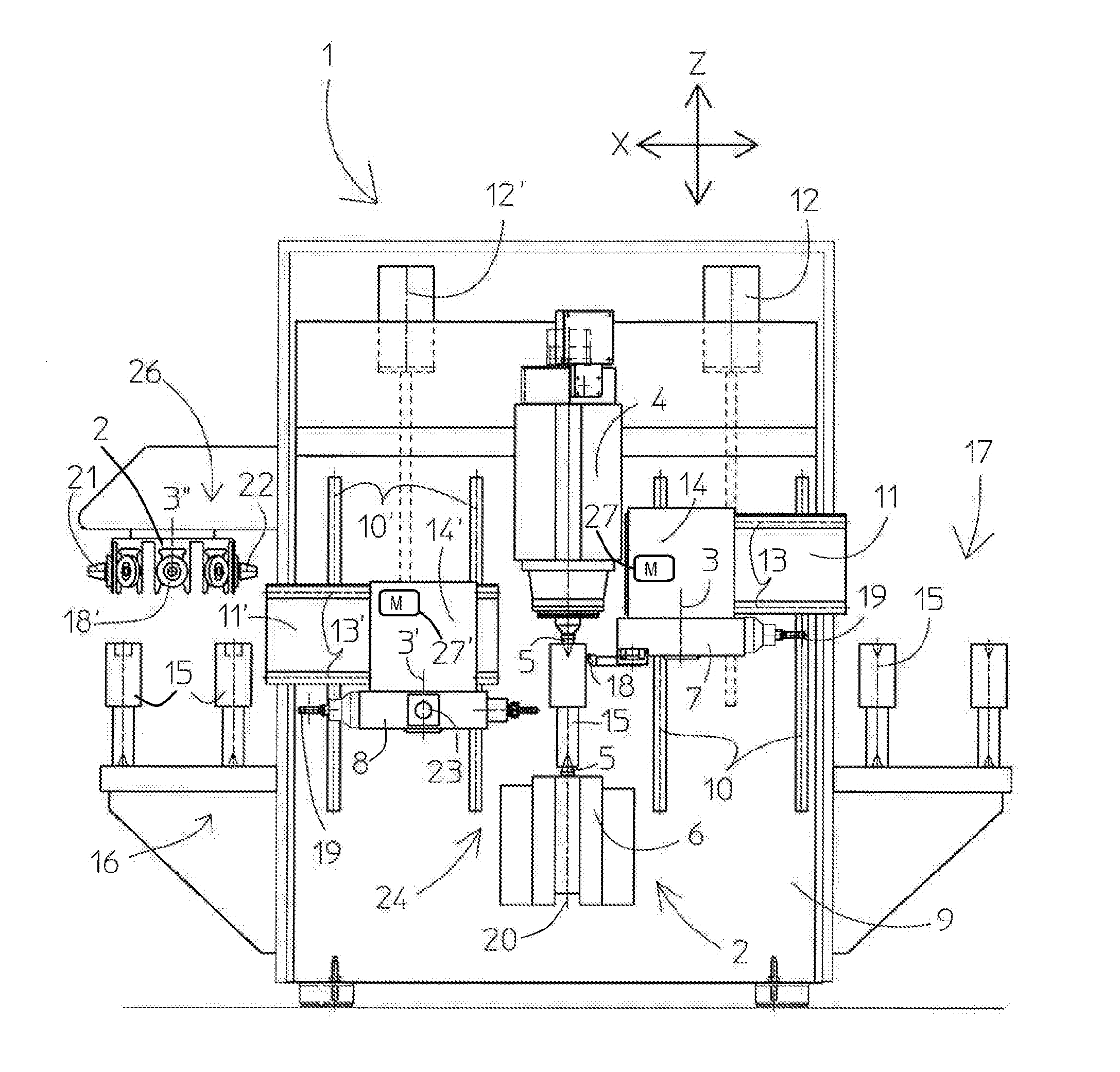

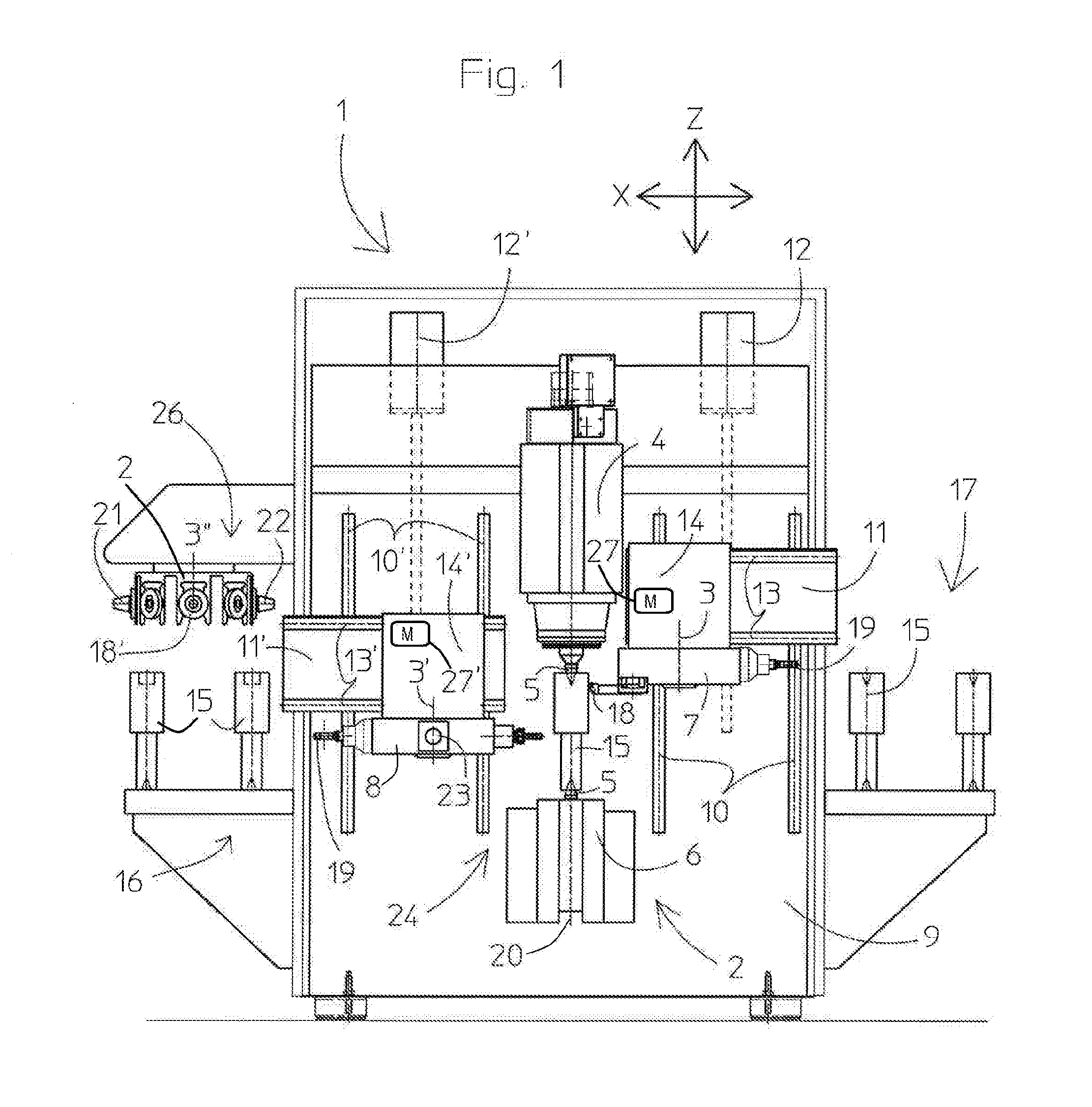

Machining apparatus

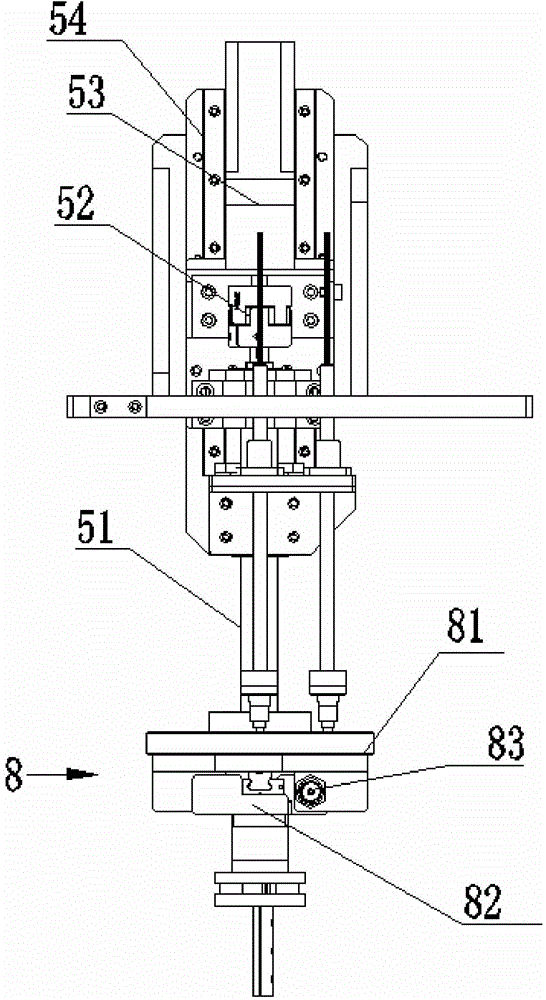

ActiveUS20140157559A1Simple mechanismEasy to controlAutomatic/semiautomatic turning machinesTurret lathesTool bitVertical plane

Owner:EMAG HLDG GMBH

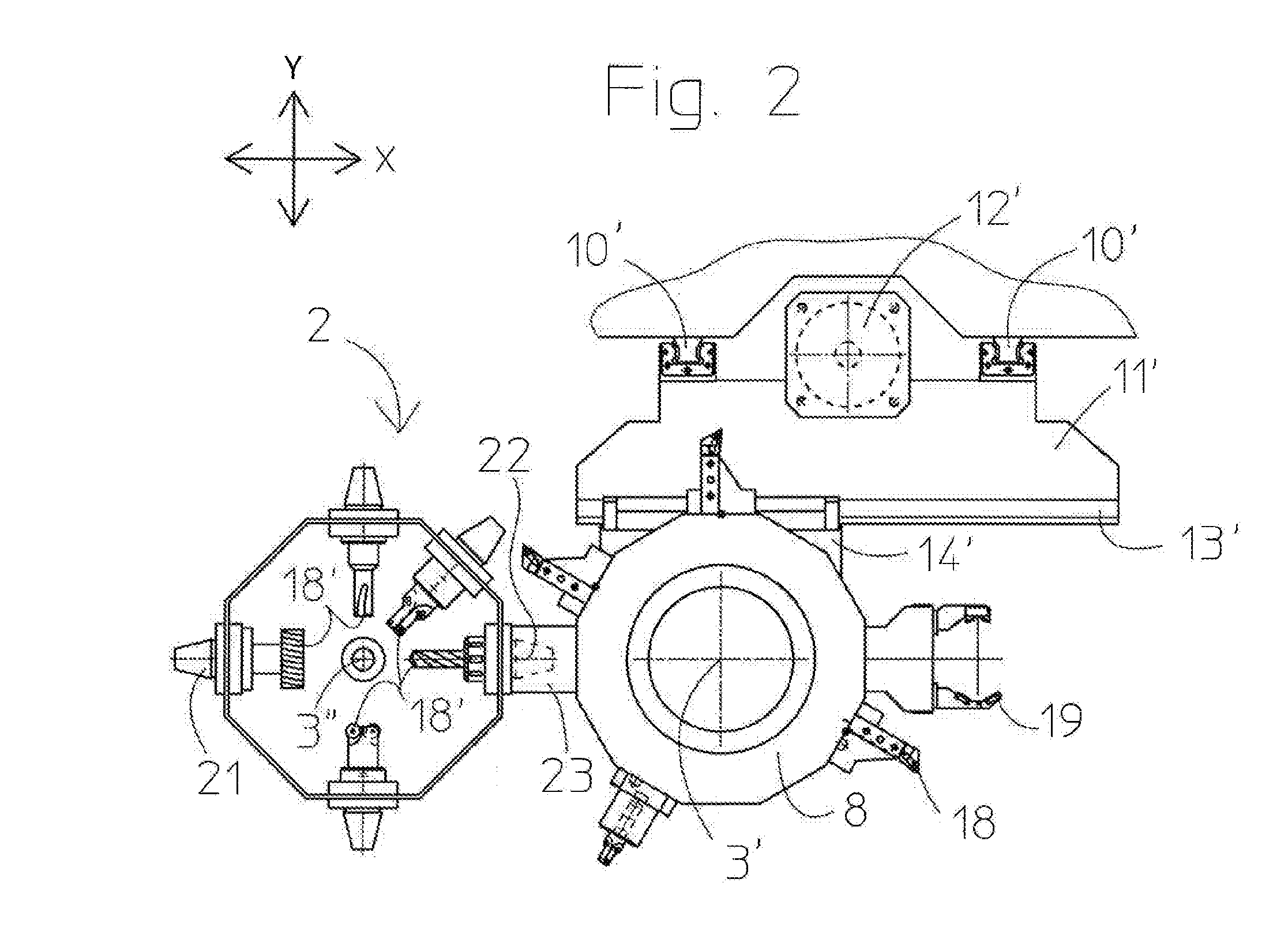

Automatic reversing edge trimmer

Owner:SUZHOU SHENGCHENG SOLAR EQUIP

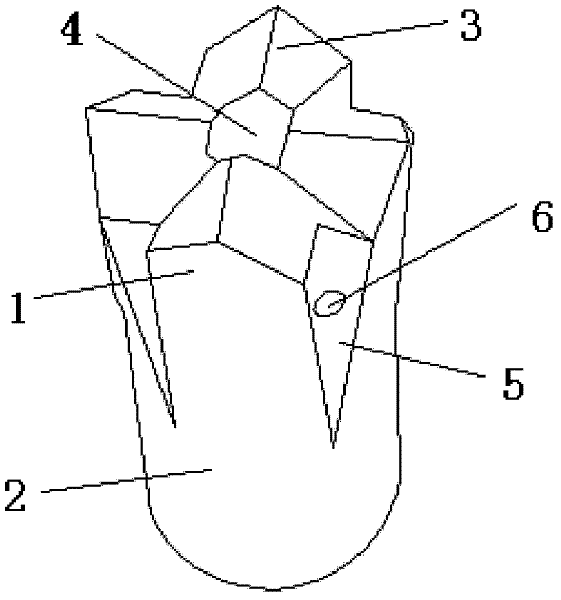

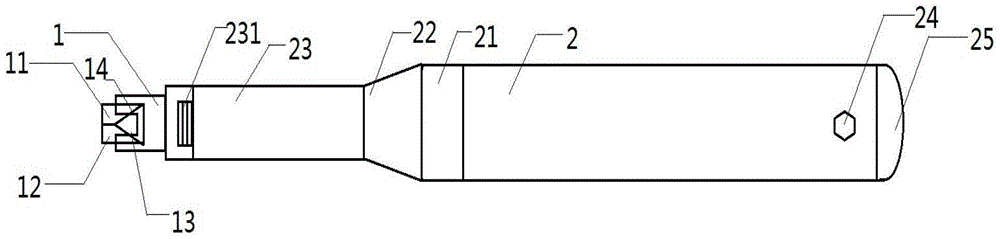

Cross drill bit

InactiveCN102444384AReduce the temperatureExtended service lifeDrill bitsTool bitAgricultural engineering

Owner:TONGLING JIUTAI HEAVY IND MINE EQUIP

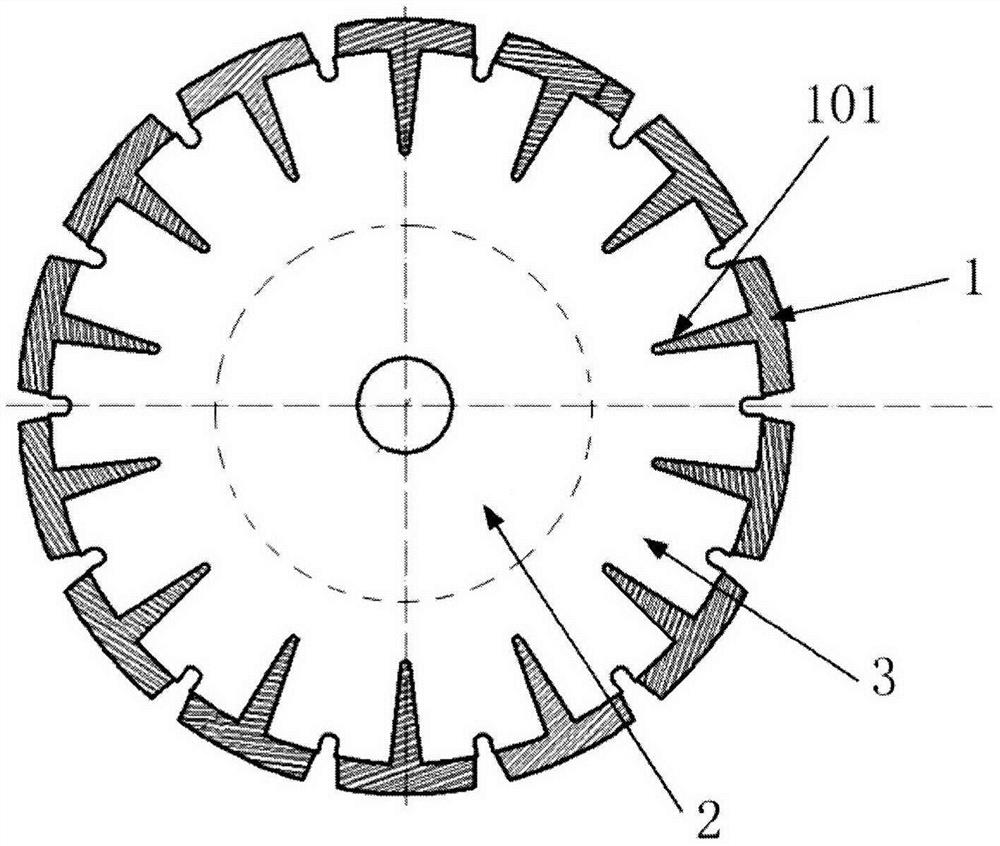

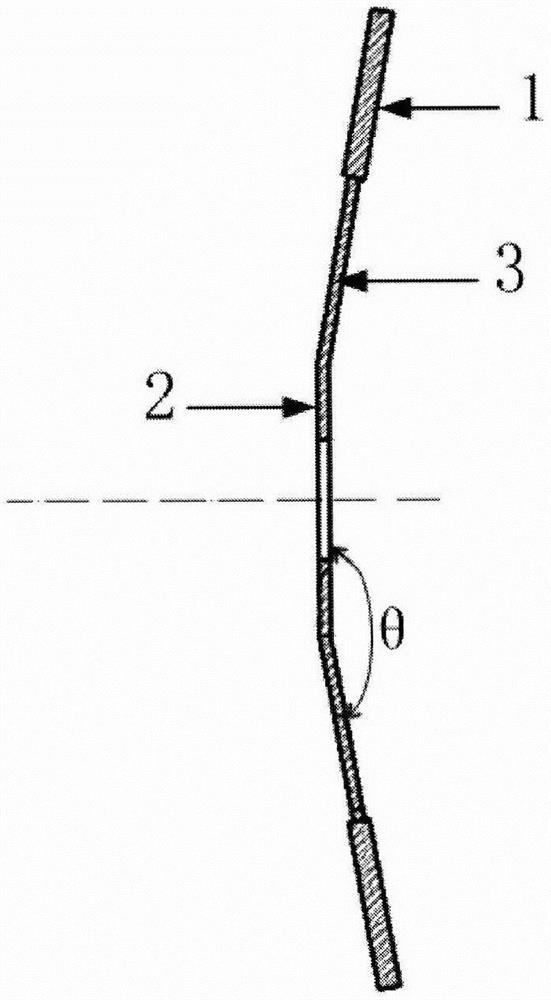

Spiral bevel gear rough milling cutter of novel structure

InactiveCN112404608AWarranty requirementsGear teeth manufacturing toolsGear teethTool bitMilling cutter

The invention discloses a spiral bevel gear rough milling cutter product. The spiral bevel gear rough milling cutter product comprises cutter heads, an angular positioning pin, two compression screws,a cutter disc, a gasket and a blind rivet, and is characterized in that the cutter heads are clamped on the cutter disc, the angular direction is determined through the angular positioning pin, clamping is conducted in the radial direction through the two compression screws, the two compression screws are placed on the rear end face of a hole of the cutter disc, and the blind rivet penetrates through the gasket and is screwed into threaded holes in the rear ends of the cutter heads. The cutter heads are clamped on the cutter disc and are uniformly distributed at 24 positions in the circumferential direction to form cutter teeth of the product, the assembled product is ensured to meet the requirements that the axial run-out requirement is 0.04 and the radial run-out is 0.02, and the clamped cutter disc is clamped on a special cutter shaft. The spiral bevel gear rough milling cutter product mainly aims to change the structural shapes of the cutter disc and the cutter teeth and reduce the machining difficulty of the cutter teeth. Therefore, a universal high-precision grinding machine can be used for machining products.

Owner:HARBIN DONGAN LIFENG CUTTER

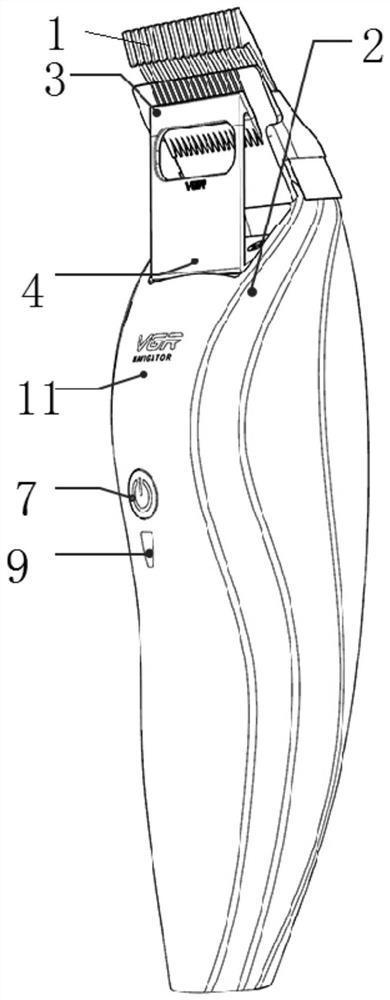

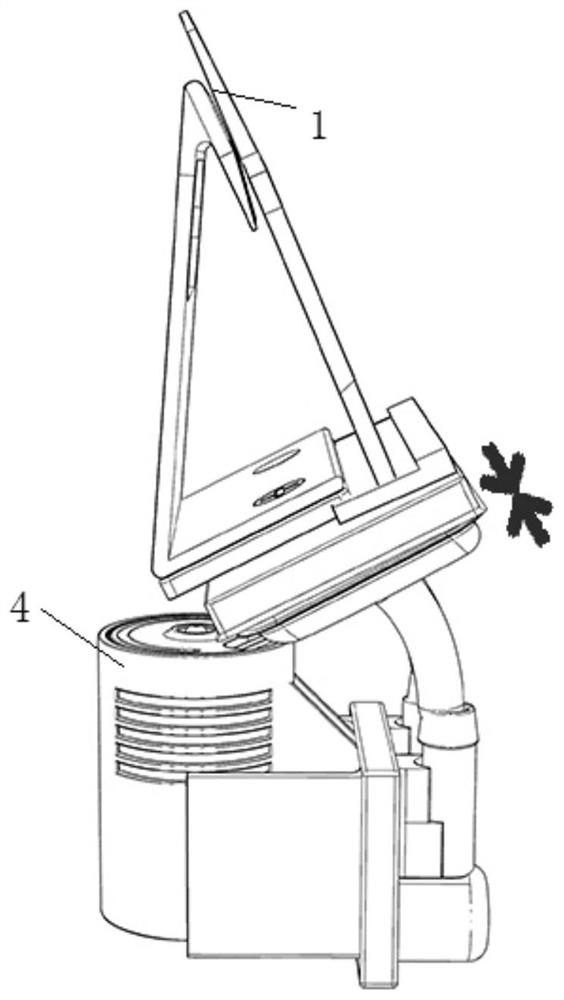

Air pump and air bag type propelling up-down reciprocating motion hair clipper

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

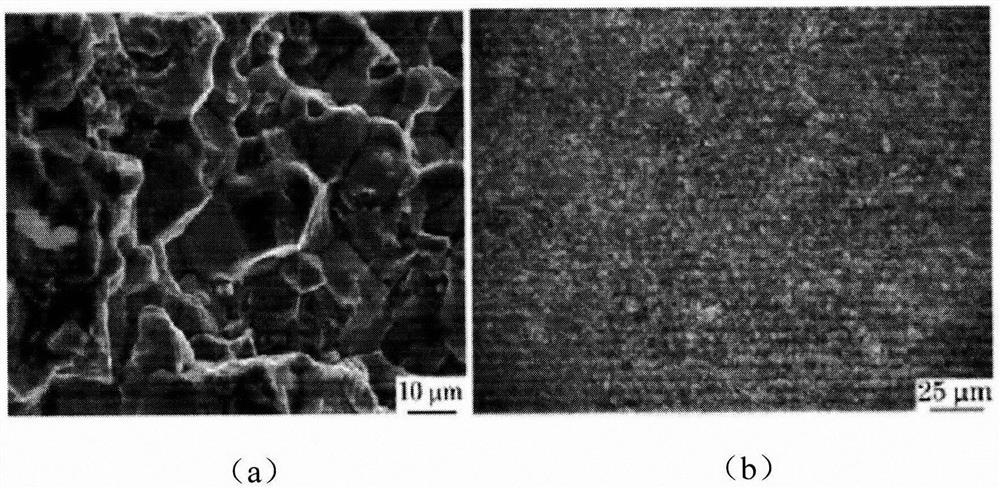

Diamond saw blade

ActiveCN112092204AMetal sawing tool makingStone-like material working toolsHot pressTool bit

Owner:丹阳市龙威工具有限公司

Metal cutting tool

Owner:TIANJIN JINSHENGDE METAL PROD

Processing and production device for spiced duck

Owner:重庆真本味食品有限公司

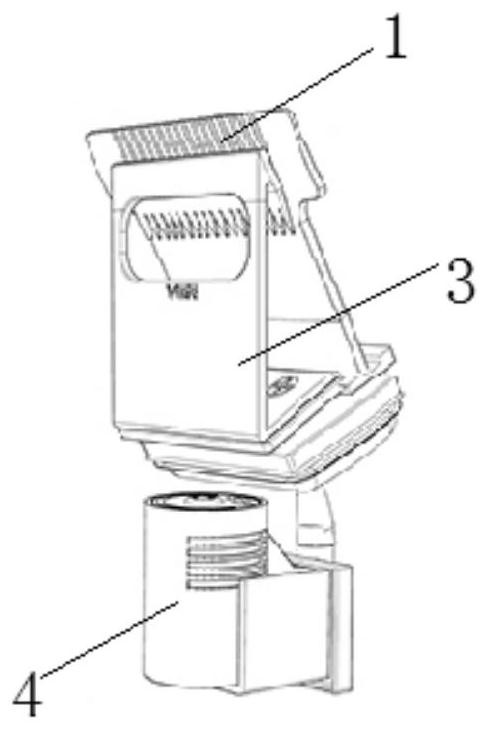

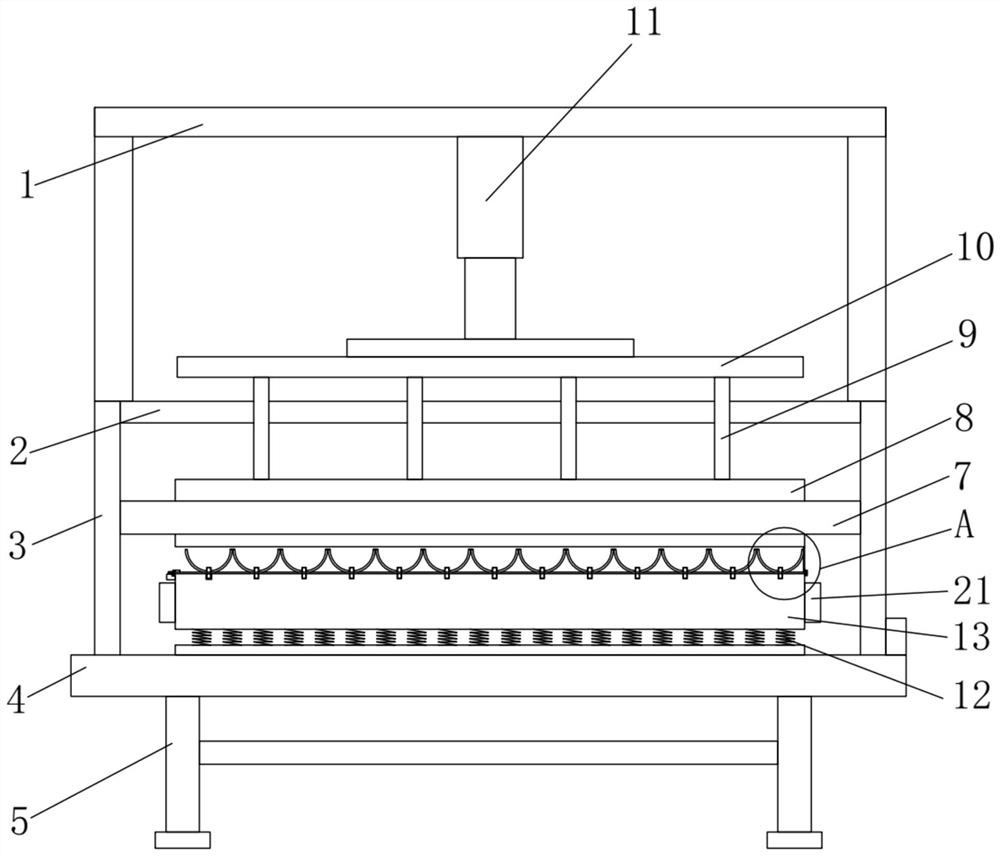

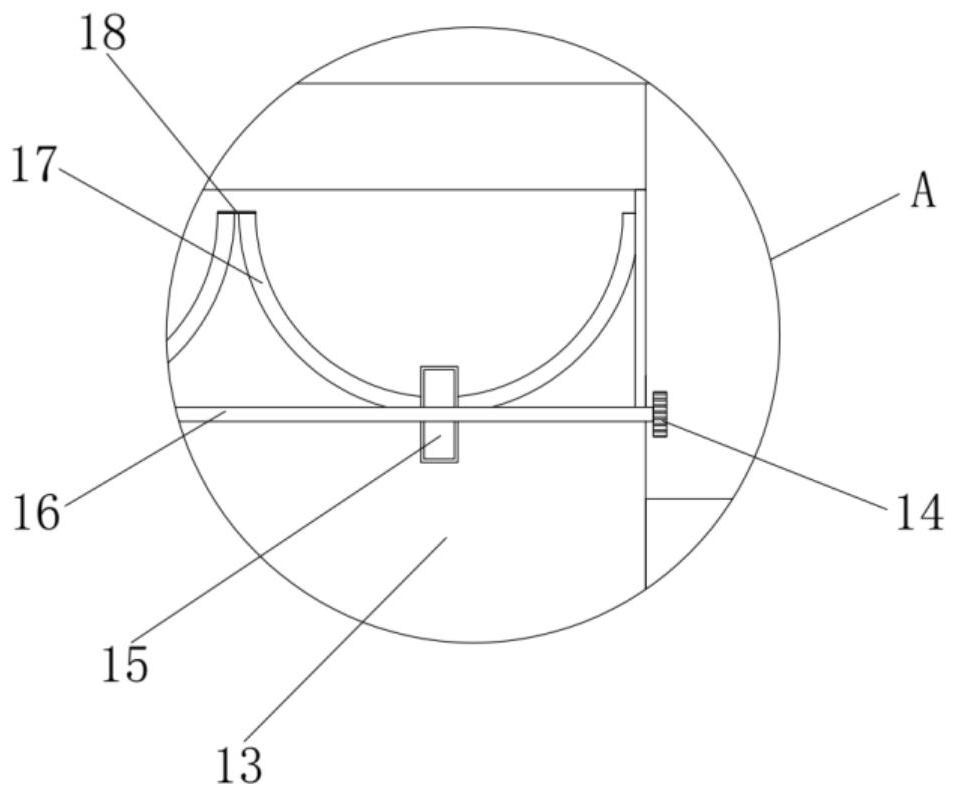

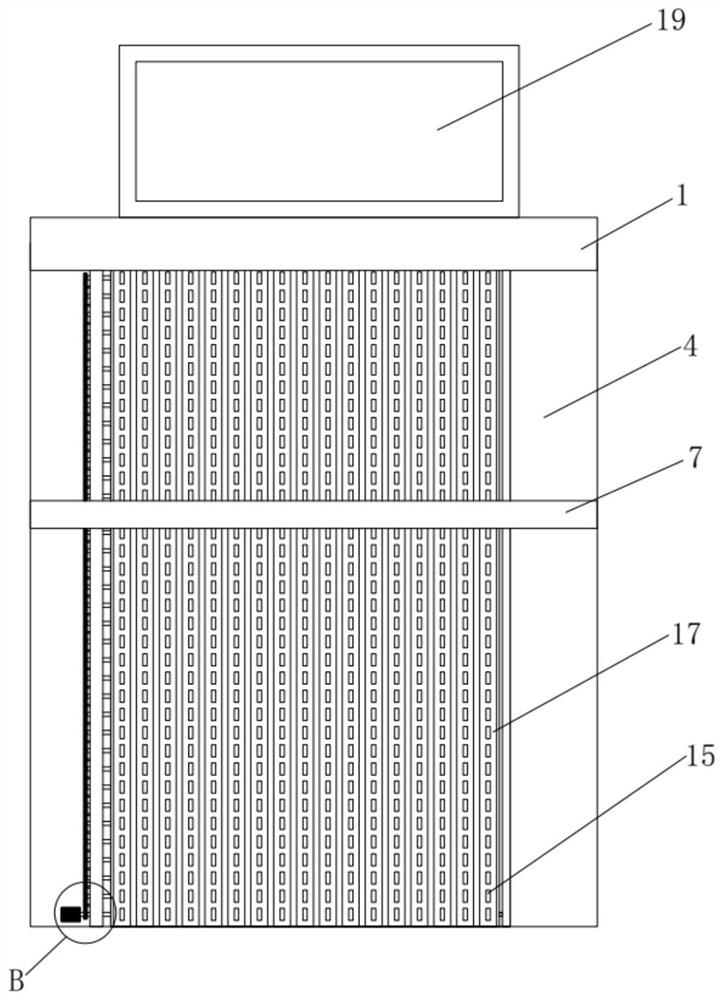

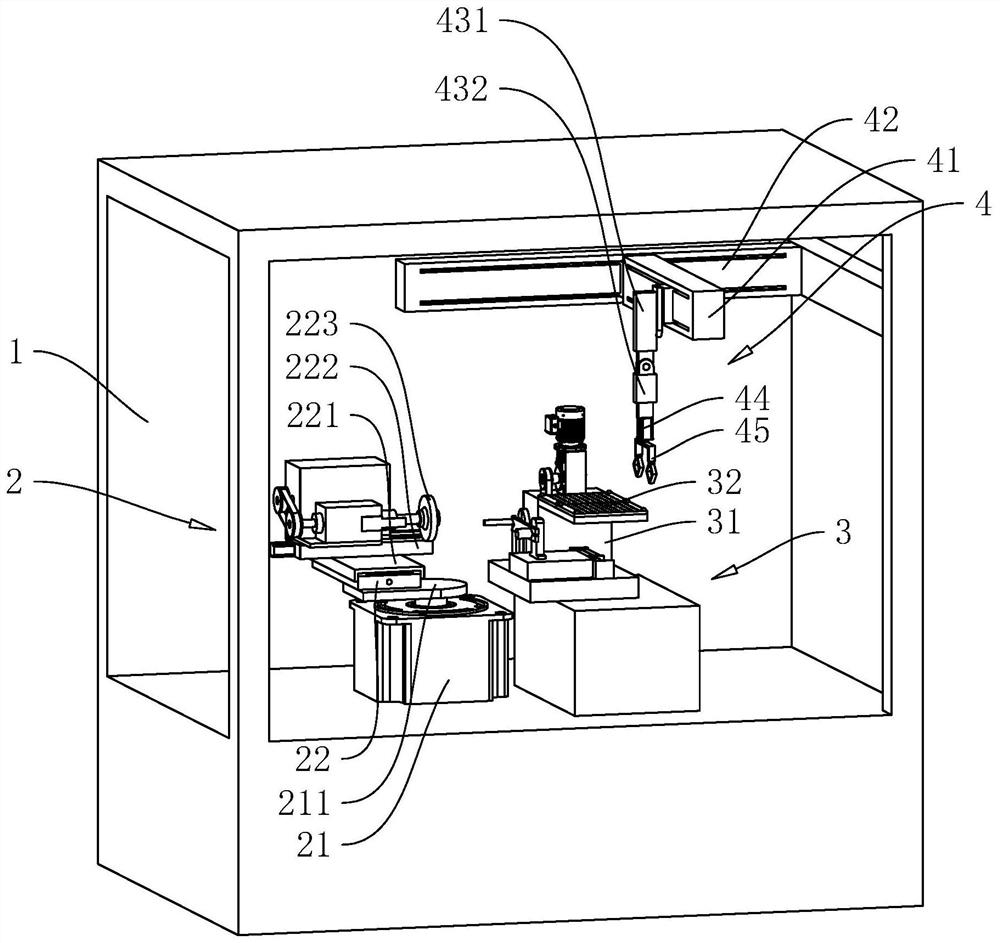

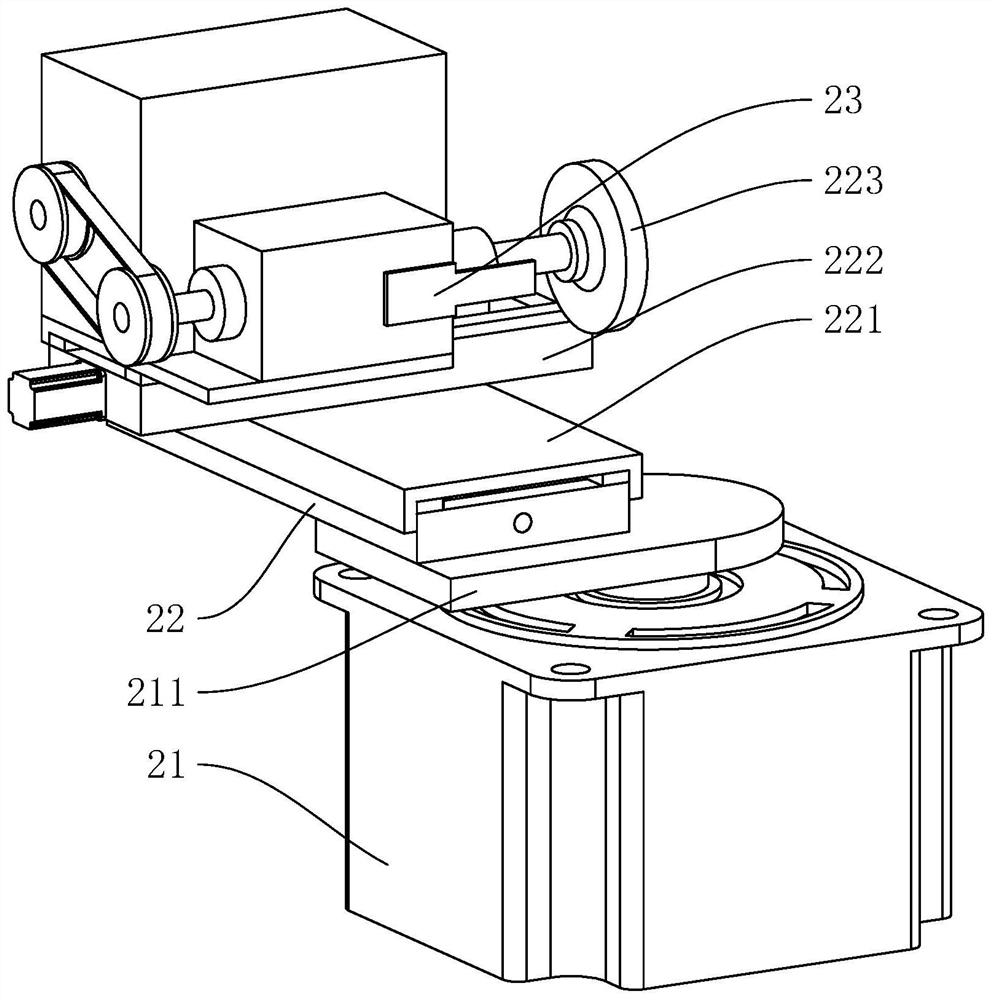

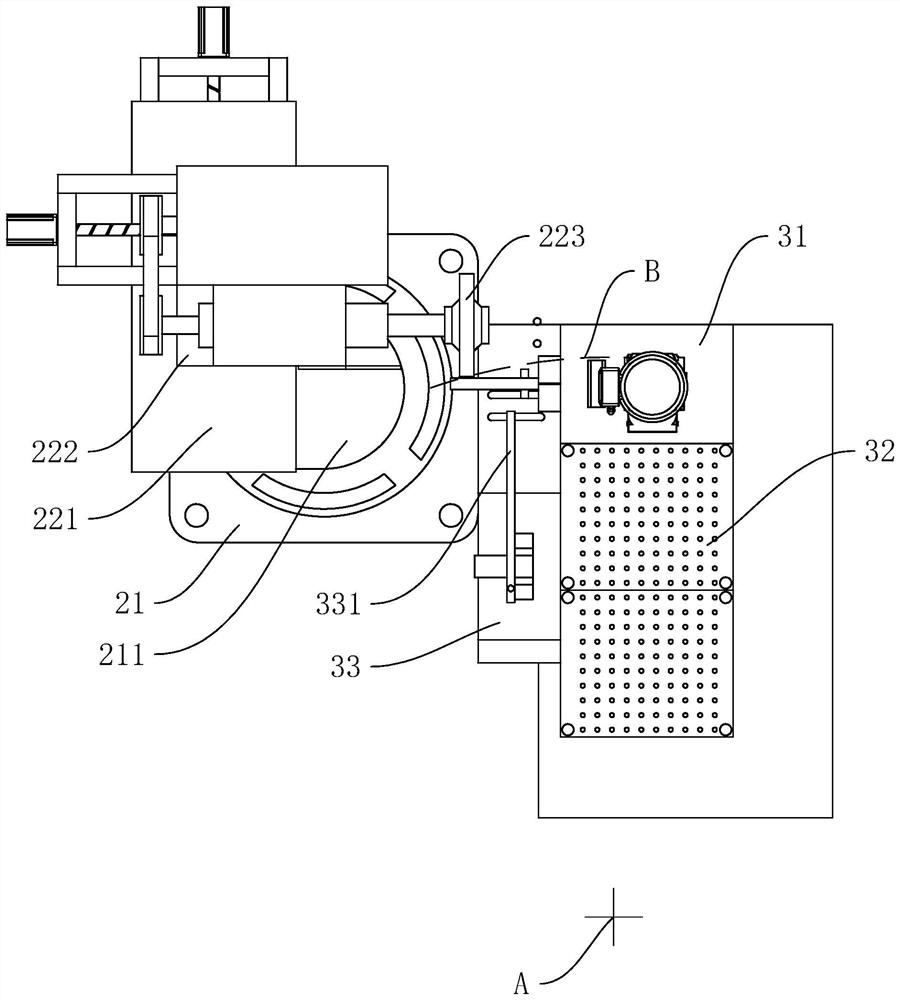

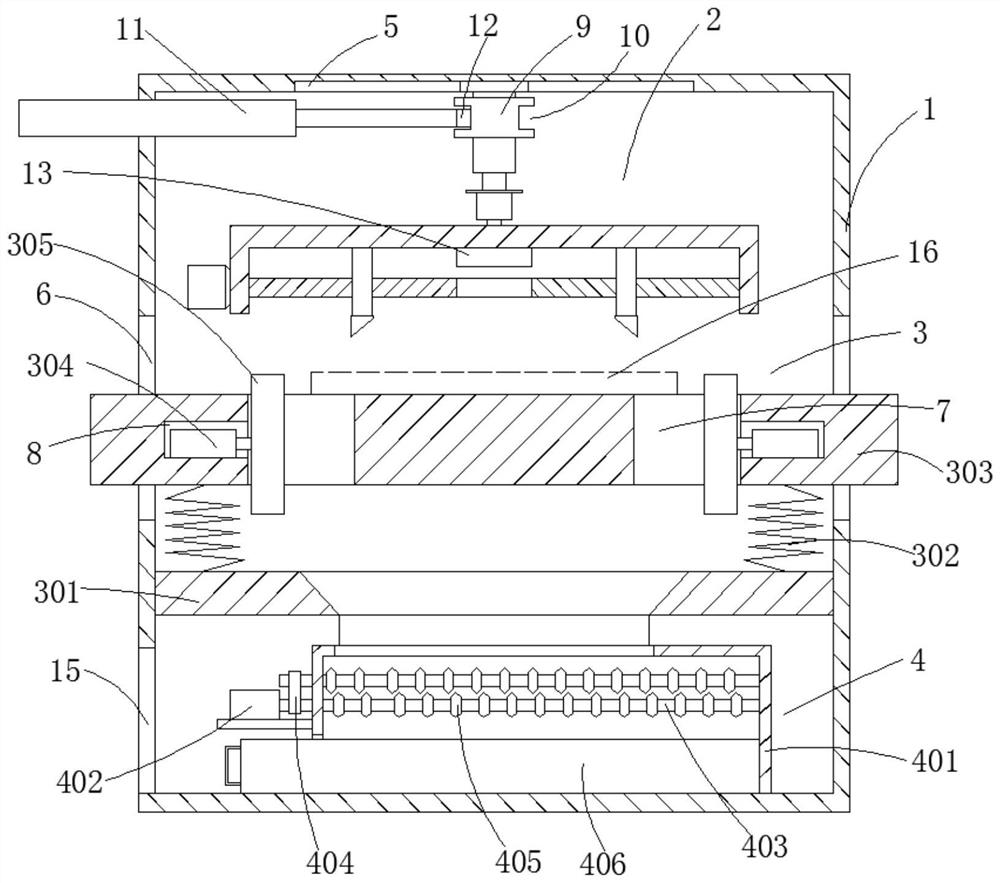

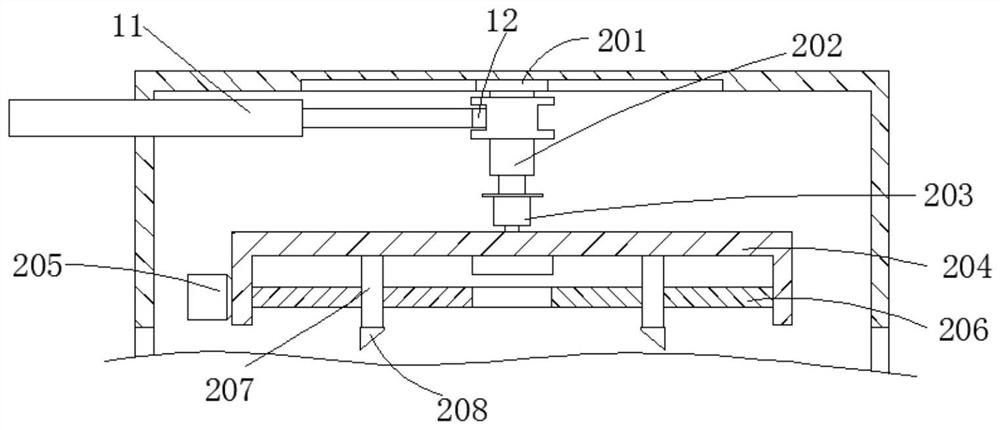

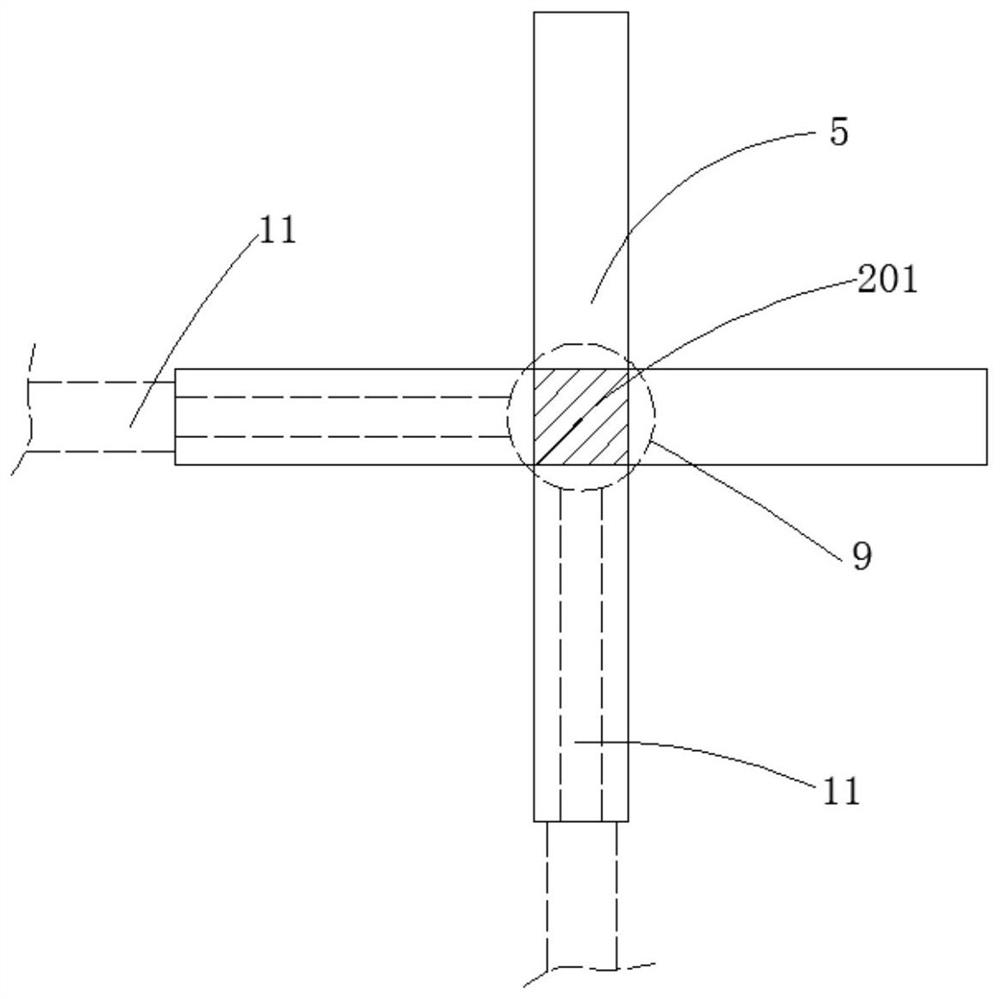

Cutter head molding machine

PendingCN114770235AGood for one-shot moldingImprove processing efficiencyGrinding carriagesOther manufacturing equipments/toolsTool bitMolding machine

Owner:SHANGHAI WELL SUN PRECISION TOOLS

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap