Method of preparing carbon quantum dots with high quantum yield in oil phase

A carbon quantum dot, high quantum technology, applied in the field of carbon quantum dot preparation, can solve the problems of large-scale application limitation, low quantum yield of carbon dots, complex conditions, etc., and achieves low toxicity, simple equipment and conditions, and high quantum yield. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

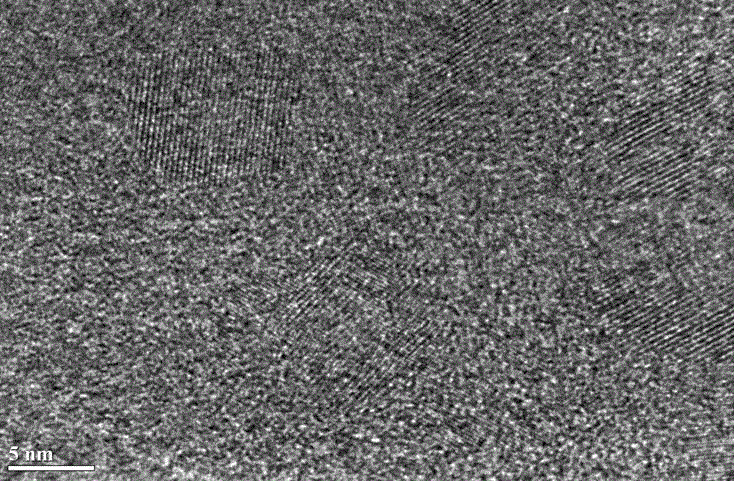

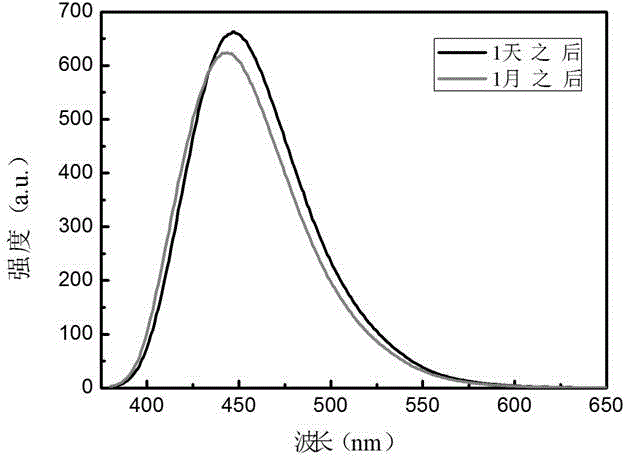

[0021] Example 1, using 1 g of citric acid as a carbon source, dissolved in 2 ml of 0.5 mol / L nitric acid solution. Add 3ml of oleic acid and 7mL of octadecene, and magnetically stir for 10min, react the mixture at 180°C for 1.5h, cool to room temperature, add 24ml of methanol and ultrasonically mix for 5min, then centrifuge at high speed. The obtained supernatant is the carbon quantum dot solution. figure 1 This is a picture of the obtained sample under a high-resolution transmission electron microscope, and it can be seen that the particle size is uniform, about 7nm. image 3 It is a comparison chart of the fluorescence spectrum measured after 1 day and 2 months after the product of Example 1, which shows that it has higher stability.

Embodiment 2

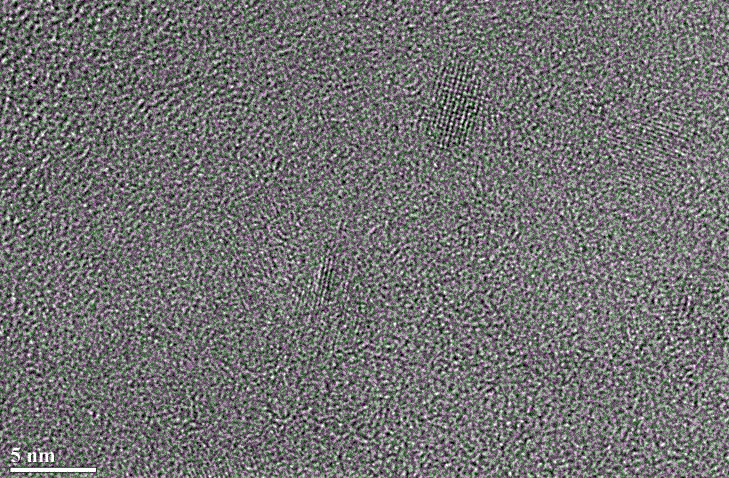

[0022] Example 2, using 1 g of citric acid as a carbon source, dissolved in 2 ml of 0.5 mol / L nitric acid solution. Then add 3ml oleic acid and 7mL octadecene, and magnetically stir for 10min, react the mixture at 250°C for 1h, after cooling to room temperature, add 24ml methanol and ultrasonically mix for 5min, then centrifuge at high speed. The obtained supernatant is the carbon quantum dot solution. figure 2 In the high-resolution transmission electron microscope picture of the obtained sample, it can be seen that the particle size is uniform, about 7nm.

Embodiment 3

[0023] In Example 3, 2 g of citric acid was used as a carbon source and dissolved in 2 ml of 0.5 mol / L nitric acid solution. Then add 2ml oleic acid and 8mL octadecene, and magnetically stir for 10min, react the mixture at 180°C for 1.5h, after cooling to room temperature, add 24ml methanol and ultrasonically mix for 5min, then centrifuge at high speed. The obtained supernatant is the carbon quantum dot solution. Figure 4-5 The comparisons of the ultraviolet-visible absorption spectrum and the fluorescence spectrum of the product of Example 3 and quinine sulfate respectively show that the carbon dots have a higher quantum yield.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap