A kind of intumescent flame-retardant polyolefin and preparation method thereof

An intumescent flame retardant and polyolefin technology, applied in the chemical field, achieves the effects of simple production process, improved flame retardant performance, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034] Aiming at the problems of low comprehensive utilization efficiency of brine, low flame retardant efficiency of the intumescent flame retardant system, large added amount affecting the mechanical properties of the carrier, and high quality control costs, the present invention provides an intumescent flame retardant polyolefin and a preparation method thereof.

[0035] Paohuarine, Shandong Dongyue Group, modulus 3.28; other chemical reagents are analytical pure, purchased from Sinopharm Group;

[0036] Polypropylene (PP), S2040, Shanghai SECCO Petrochemical Co., Ltd.; ammonium polyphosphate (APP), degree of polymerization n> 1000, Shandong Shian Chemical Co., Ltd.; Pentaerythritol (PER), Sinopharm Group; Magnesium Chloride Hexahydrate, China National Pharmaceutical Group Shanghai Chemical Reagent Company. High-density polyethylene 7200 Taiwan Formosa Plastics; ethylene-vinyl acetate copolymer EVA7350M Taiwan Formosa Plastics.

Example Embodiment

[0037] Example 1

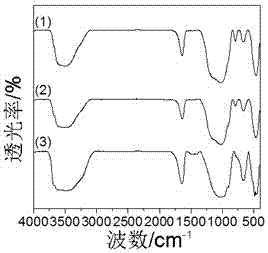

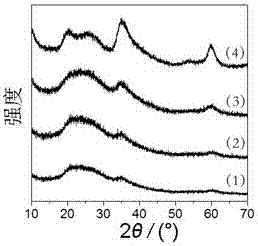

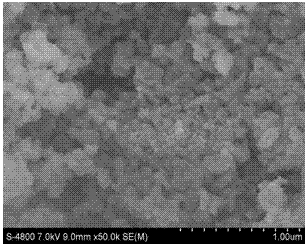

[0038] (1) Preparation of silicon-magnesium composite oxide

[0039] The magnesium chloride hexahydrate and strobilurine were added with deionized water to prepare 0.5mol / L solution, the magnesium chloride solution and strobilurine solution were measured, and the magnesium chloride solution was placed in a container, and the strobilurine solution was added dropwise while stirring , Control the molar ratio of magnesium chloride and phocaline to 1:3. After the dripping is completed, adjust the pH value to 10.5 with sodium hydroxide solution, continue to stir at room temperature for 2 hours, put the obtained mother liquor into a high temperature and high pressure reactor with a polytetrafluoroethylene lining, and react at 120°C for 24 hours, and then take out the reaction The kettle is naturally cooled to room temperature, the supernatant liquid is discarded, the precipitate obtained is filtered, and then washed with distilled water until there is no Cl - After dryi

Example Embodiment

[0045] Example 2

[0046] (1) Preparation of silicon-magnesium composite oxide

[0047] The magnesium chloride hexahydrate and strobilurine were added with deionized water to prepare 0.5mol / L solution, the magnesium chloride solution and strobilurine solution were measured, and the magnesium chloride solution was placed in a container, and the strobilurine solution was added dropwise while stirring , Control the molar ratio of magnesium chloride and phocaline to 1:2. After the dropwise addition is completed, adjust the pH to 9 with sodium hydroxide solution, continue to stir at room temperature for 1 hour, put the obtained mother liquor into a high temperature and high pressure reactor with a polytetrafluoroethylene lining, and react at 130°C for 30 hours, and then take out the reactor to cool naturally To room temperature, discard the supernatant liquid, filter the resulting precipitate, and then wash with distilled water until there is no Cl - After drying at 110°C for 10 hours,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap