Color conversion layer preparation method and display device

A color conversion and green technology, applied in semiconductor/solid-state device manufacturing, diodes, semiconductor devices, etc., can solve the problem of complex and cumbersome color conversion layer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

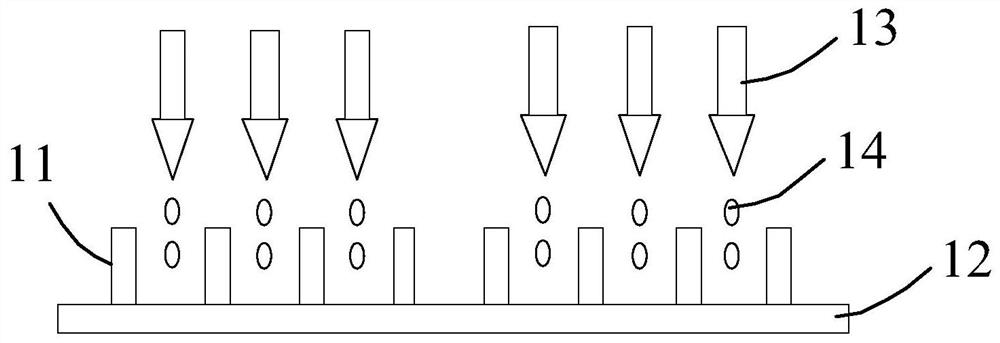

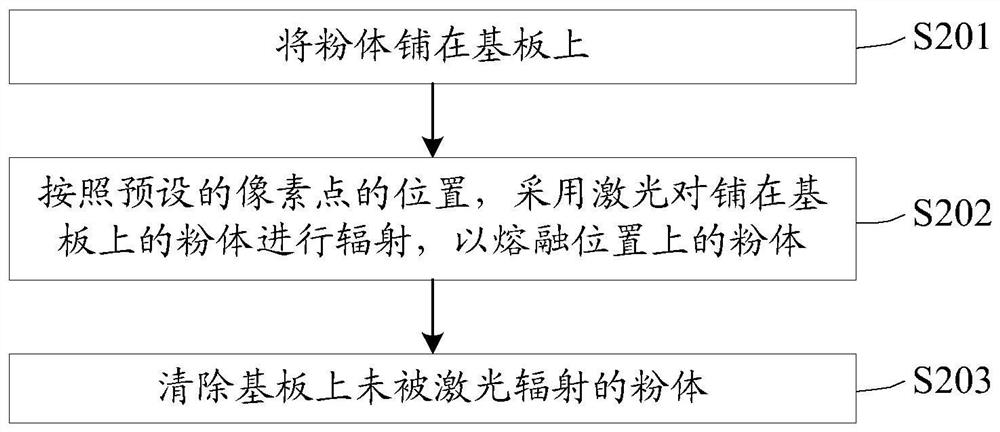

[0092] A method for preparing a color conversion layer according to an embodiment of the present invention, the method comprising:

[0093] subjecting the powder deposited on the substrate to at least one laser irradiation process to form a color conversion layer on the substrate;

[0094] Among them, the following steps are carried out in each laser irradiation process: combining figure 2 as shown,

[0095] Step S201: spread the powder on the substrate, wherein the powder is a polymer doped with quantum dots or phosphor;

[0096] Step S202: According to the preset pixel position, irradiate the powder on the substrate with laser to melt the powder at the position;

[0097] Step S203: remove the powder on the substrate that has not been irradiated by the laser.

[0098] In the above method, since the powder is a polymer doped with quantum dots or fluorescent powder, according to the preset pixel position, when the laser irradiates the polymer, the polymer will undergo a melting

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap