Recombinant chondroitinase AC and preparation method and application thereof

A technology of chondroitin sulfate enzyme and construction method, which is applied in the field of recombinant chondroitin sulfate AC and its preparation, can solve the problems of increasing the production cost of ChSase AC, the low expression level of ChSase AC, and the slow growth of Flavobacterium chondroitin sulfate, etc., and achieve the improvement of technology Level, good stability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

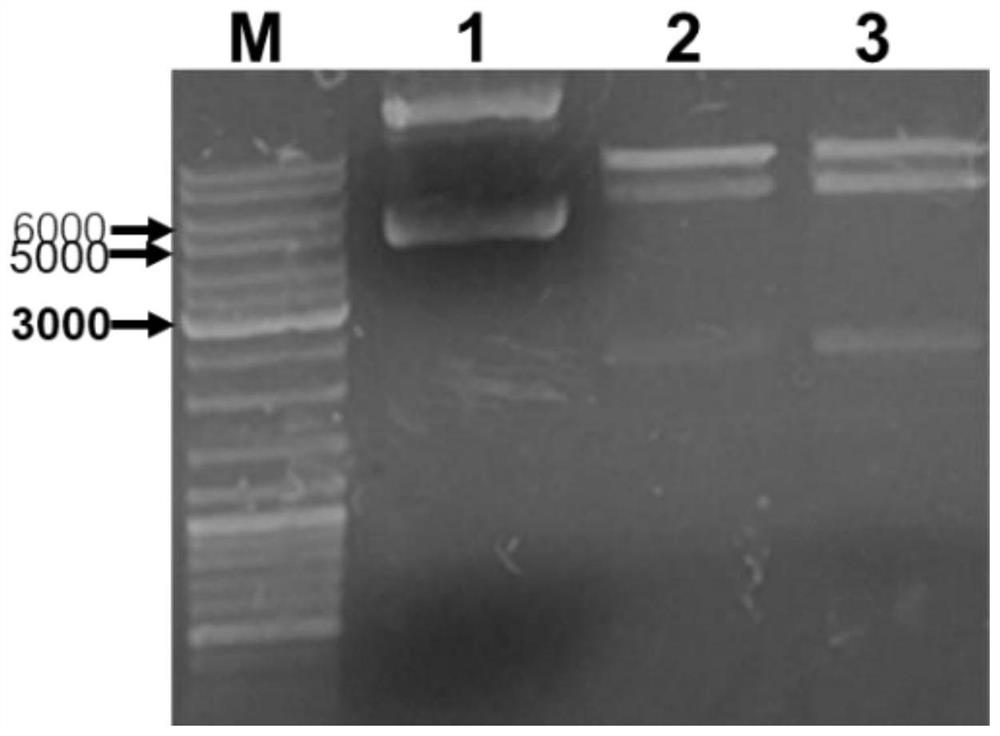

[0029] Embodiment 1: the cloning of a kind of chondroitin sulfate AC gene

[0030] (1) Pedobacter sp. ok626 Genomic DNA extraction

[0031] 1) will activate the Pedobacter sp. ok626 The strain was inoculated into a 250 mL Erlenmeyer flask containing 100 mL of peptone-yeast-glucose (PYG) medium in 10 % CO 2 Cultivate at 37°C for 18 hours, and centrifuge at 5866×g to obtain bacterial cells.

[0032] 2) Wash the bacterial cells collected by centrifugation in step 1) with 5 times the volume of distilled water, shake the sediment and mix well, then centrifuge at 5866×g at 4°C for 8 minutes, discard the supernatant; repeat this step once; add no Water alcohol, fully burn, eliminate RNase that may exist in the mortar; add the bacteria obtained by centrifugation into the liquid nitrogen pre-cooled mortar, and fully grind;

[0033] 3) Use the plasmid extraction kit to extract the plasmid from the centrifuged cells to obtain Pedobacter sp. .ok626 Genomic DNA, stored at -80°C.

[0

Embodiment 2

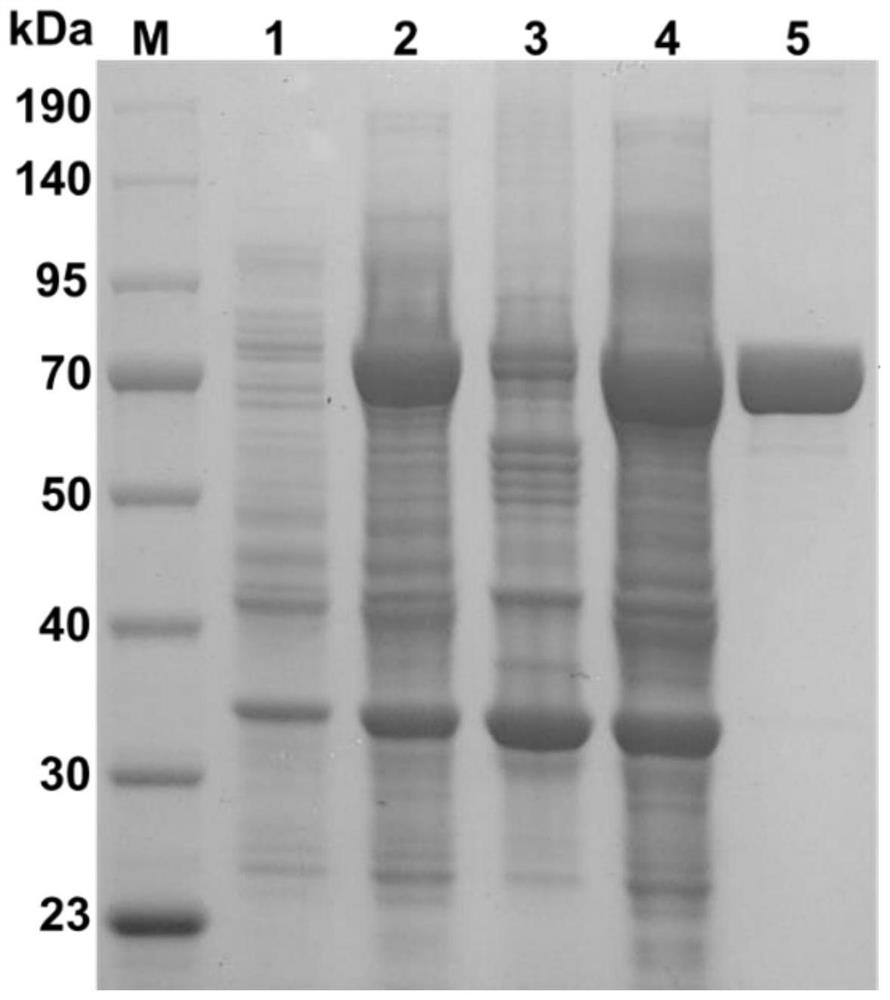

[0039] Example 2: Expression and purification of chondroitinase AC

[0040] (1) The recombinant expression vector obtained in Example 1 was transformed into Escherichia coli BL21 (DE3), and the strain was cultivated. Then pick a single colony and inoculate it in LB liquid culture containing 5 mL kanamycin (50 μg / mL), and culture overnight at 37 °C.

[0041] (2) Take 5 mL of the overnight cultured bacterial liquid into 250 mL of LB liquid medium (containing 50 μg mL -1 Kanamycin) in a 500 mL Erlenmeyer flask, shake culture at 200 rpm to OD 600 Approximately equal to 0.7.

[0042] (3) Add IPTG to a final concentration of 0.1 mM, and induce at 25°C for 15 hours.

[0043] (4) Take all the culture solution and centrifuge at 5866×g for 5 minutes at 4°C; add 8 mL of Tris-HCl buffer solution (50 mM, pH 8.0) to the centrifuged cells, put them in ice water for ultrasonic disruption, and 4°C Centrifuge at 5866×g for 20 minutes to collect the supernatant to obtain recombinant chondroit

Embodiment 3

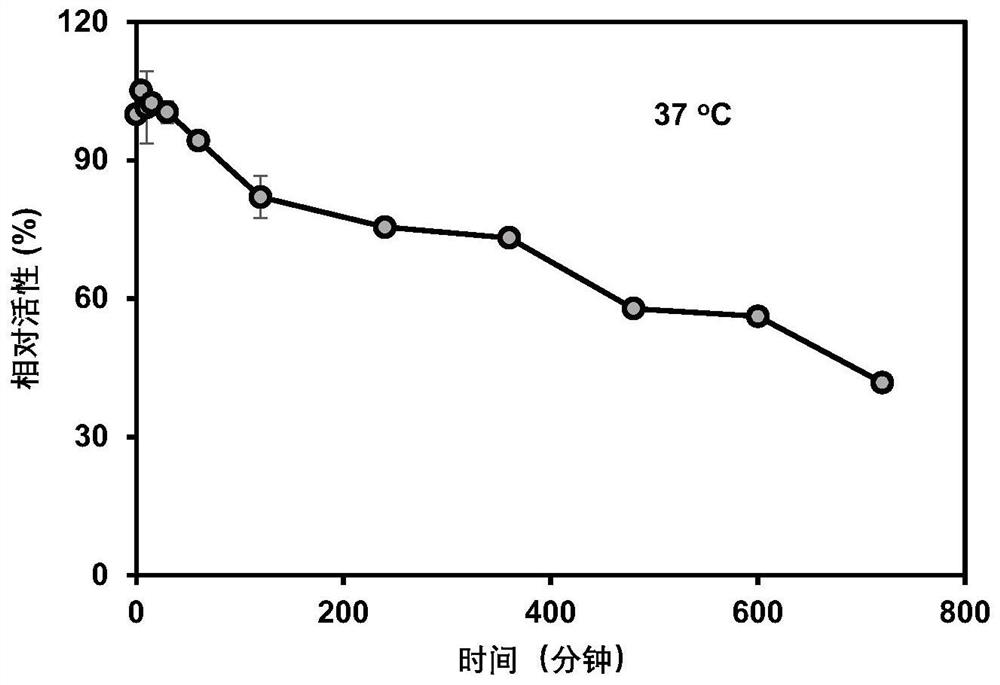

[0046] Embodiment 3: Enzyme activity analysis of recombinant chondroitinase AC

[0047] In this example, chondroitin sulfate A was used as a substrate, and the increase in absorbance of unsaturated disaccharides at 232 nm was measured to calculate the enzyme activity of chondroitin sulfate AC. The unit of enzyme activity is: the amount of enzyme that degrades chondroitin sulfate A to form 1 μmoL unsaturated oligosaccharide product per minute under the condition of 37°C. The molar extinction coefficient of the product unsaturated oligosaccharide at 232 nm is 5100M −1 cm −1 , Calculate the enzyme activity of recombinant chondroitinase AC according to the protein standard curve. Each experiment was determined independently three times, and the standard deviation was calculated. The calculated enzyme activity of recombinant chondroitinase AC is 325.2.6 U mg -1 -protein, K m Value is 0.5mg mL -1 , V max 509.43 U·mg -1 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap