Manganese oxide supported catalyst, preparation method thereof and preparation method of formic acid

A supported catalyst, manganese oxide technology, applied in the preparation of organic compounds, physical/chemical process catalysts, molecular sieve catalysts, etc. problems, to achieve the effects of low cost, high yield and selectivity, and simple preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

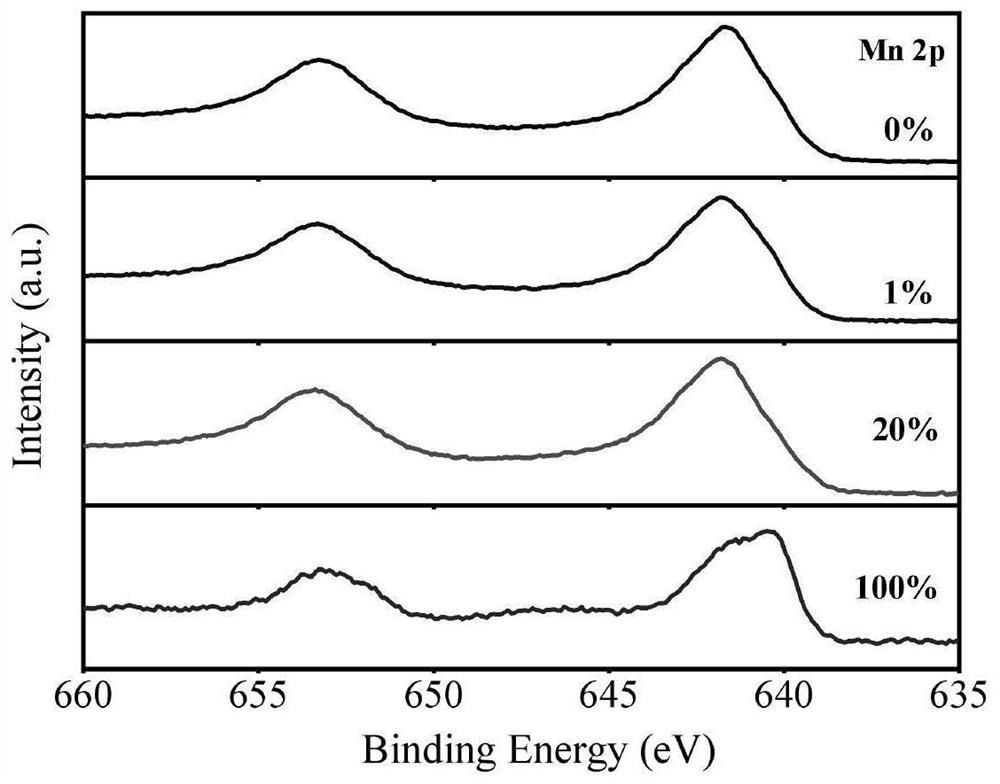

[0029] The present invention also provides a preparation method of the manganese oxide supported catalyst described in the above scheme, comprising the following steps:

[0030] The mixed aqueous solution of the manganese source and the precursor of the metal oxide auxiliary agent is mixed with the carrier, and then evaporated to dryness and calcined in sequence to obtain the manganese oxide supported catalyst.

[0031]In the present invention, the molar ratio of the manganese source to the metal oxide auxiliary agent precursor is preferably 1:(0.025~0.080), more preferably 1:(0.030~0.070), further preferably 1:(0.045~0.055 ); the molar ratio of the manganese source and water is preferably 1:(0.8~2.8), more preferably 1:(1.0~2.2), more preferably 1:(1.4~1.9); the manganese source preferably includes KMnO 4 , (CH 3 COO) 2 Mn and Mn(NO 3 ) 2 One or more of them; the metal oxide additive precursor preferably includes Fe(NO 3 ) 3 , (CH 3 COO) 2 Zn, Ce(NO 3 ) 3 , (NH 4 ) 2

Embodiment 1

[0038] Take 0.31g KMnO 4 , 0.01g (NH 4 ) 2 MoO 4 Dissolve in 30mL deionized water, add 0.2g ZSM-5, stir at room temperature for 4h, then transfer to 90°C oil bath and heat until the water evaporates to dryness, place the material in a muffle furnace and calcinate at 500°C for 3h to obtain Mn - Mo / ZSM-5 supported catalyst.

Embodiment 2

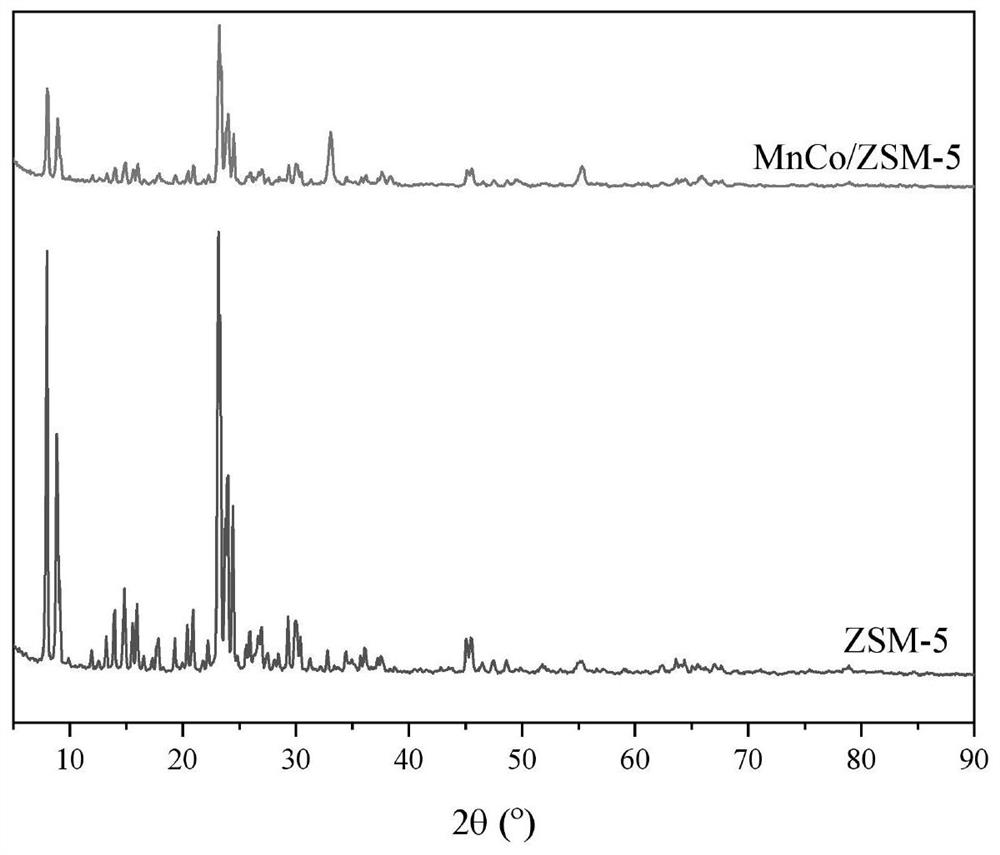

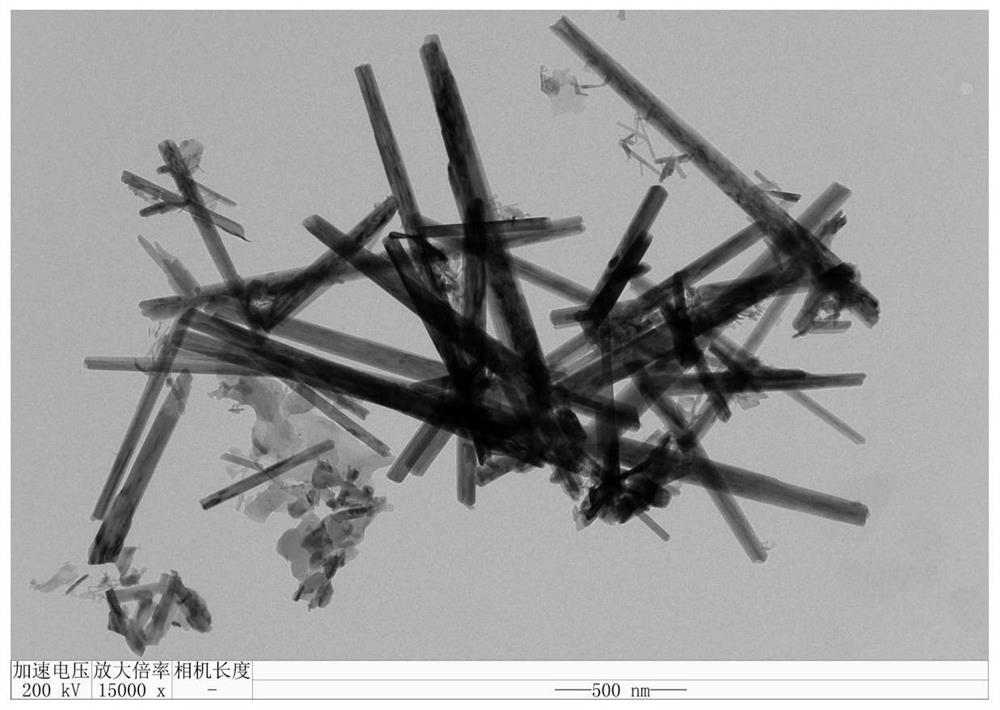

[0040] Take 0.35g KMnO 4 , 0.02g Co(NO 3 ) 2 Dissolve in 50mL deionized water, add 0.2g ZSM-5, stir at room temperature for 5h, then transfer to 90°C oil bath and heat until the water evaporates to dryness, place the material in a muffle furnace and calcinate at 600°C for 3h to obtain Mn - Co / ZSM-5 supported catalyst.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap