Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Iron alloys" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron alloy, as the name suggests, is an alloy that have iron as the principal component. Iron is used as a constituent in most of the commercial alloys. For example, iron is the major component of wrought and cast iron and wrought and cast steel.

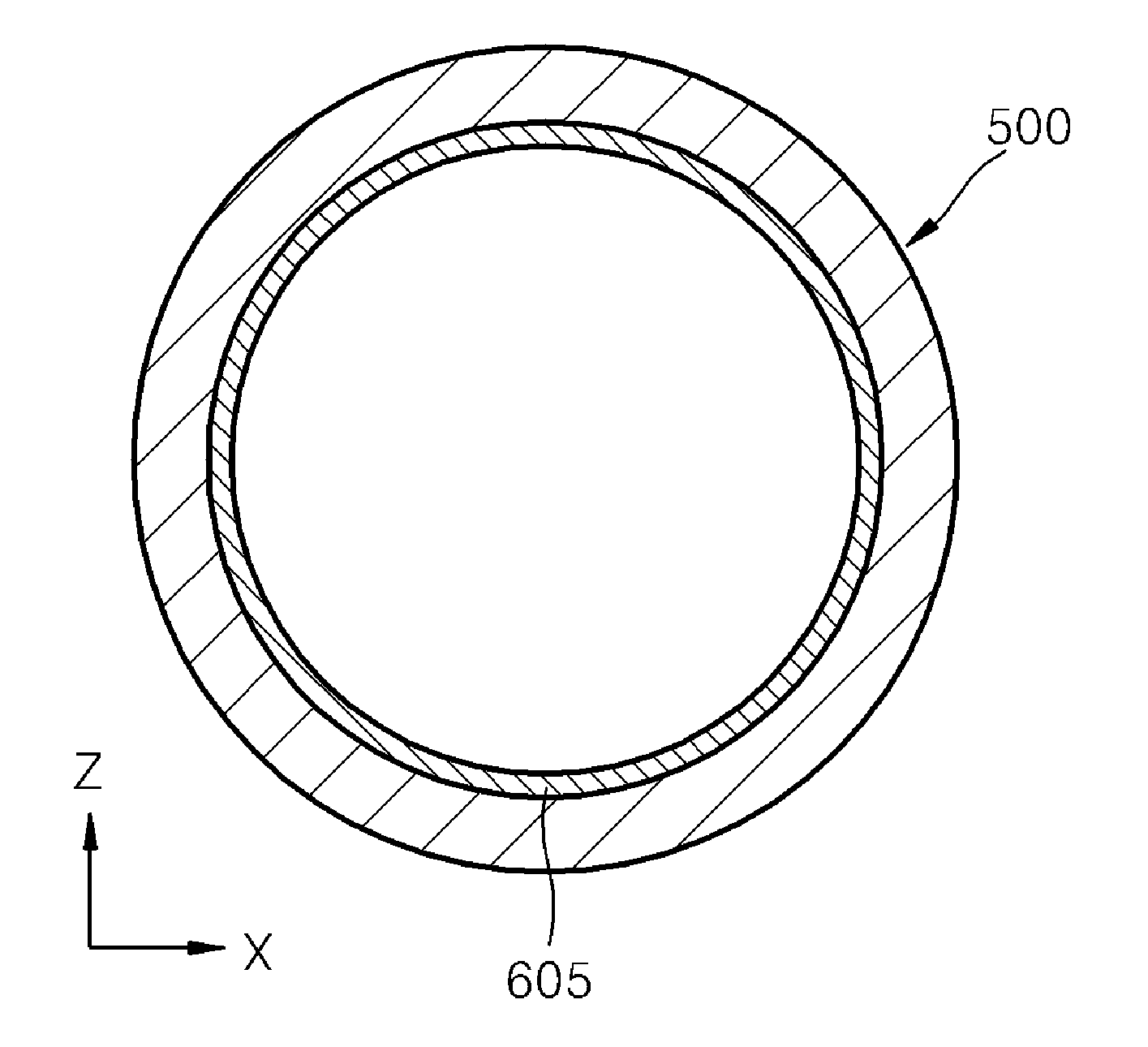

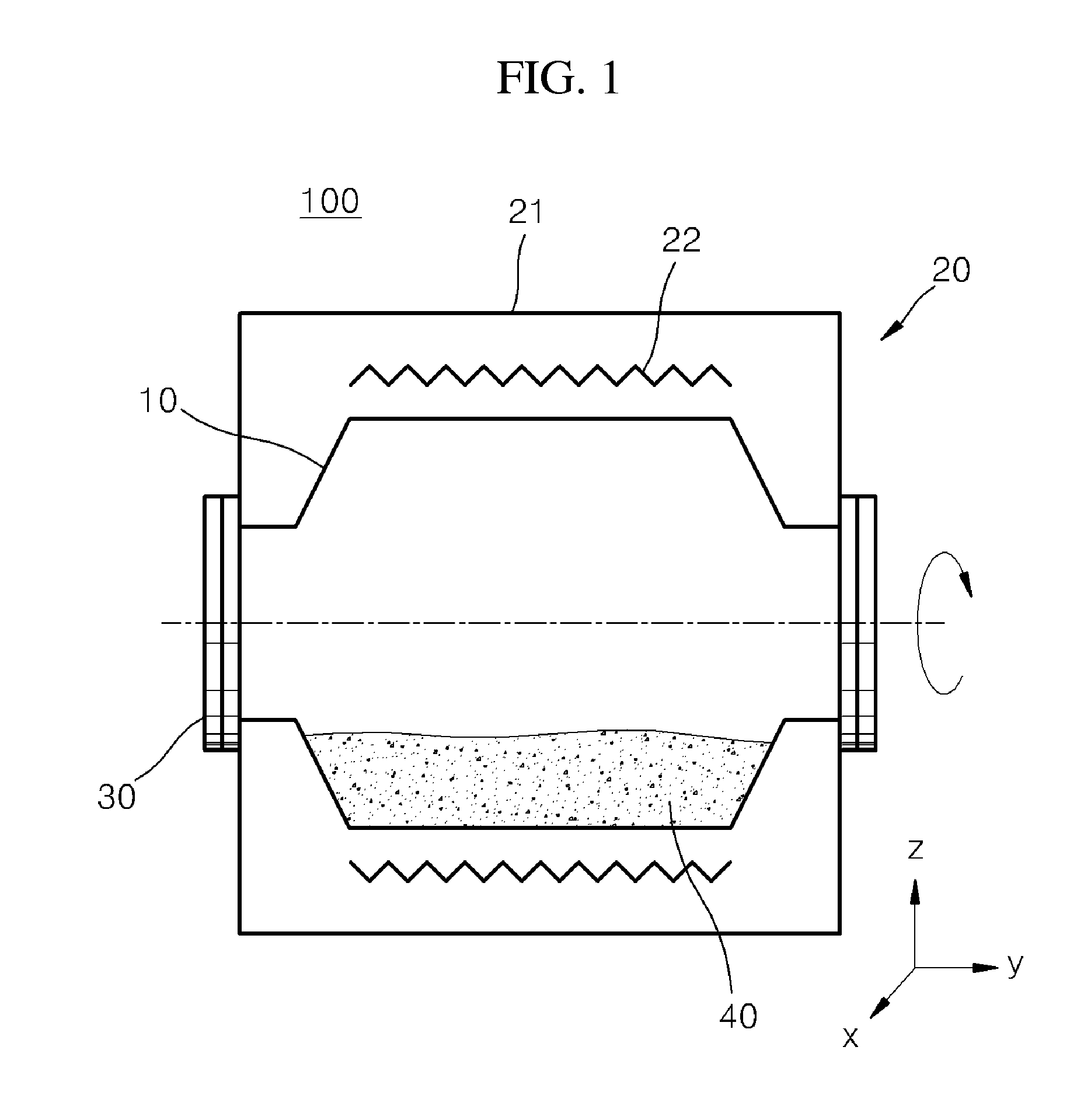

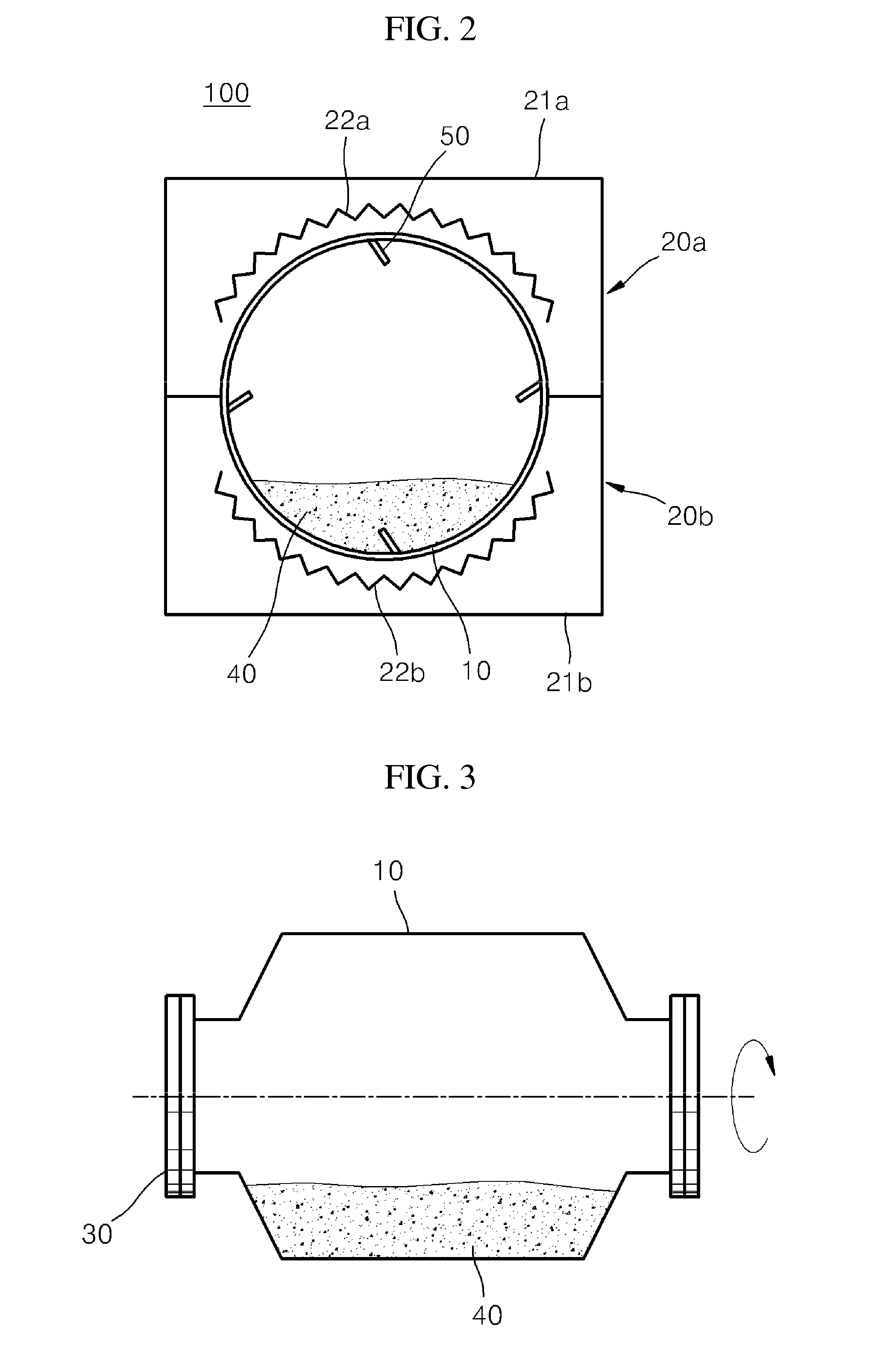

Apparatus for manufacturing compound powder, method of manufacturing iron-boron compound powder by using the apparatus, boron alloy powder mixture, method of manufacturing the boron alloy powder mixture, combined powder structure, method of manufacturing the combined powder structure, steel pipe, and method of manufacturing the steel pipe

ActiveUS20140096858A1High hardnessLow melting pointHeat treatmentsLiquid surface applicatorsPowder mixtureAlloy

Owner:KMT CO LTD

Alloy material with high temperature coefficient of resistance and preparation method thereof

The invention provides an alloy material with high temperature coefficient of resistance. The alloy material is prepared by adding six metal components as the additives to nickel-ferrum alloy, and smelting same to obtain the product, wherein the six metal components are respectively germanium, zirconium, cerium, titanium, aluminum and ferrum; and the alloy material comprises the following components in percentage by weight: 50-65% of component Ni, 14-21% of component Cr, 0.1-0.9% of component Ge, 0.15-0.5% of component Ce, 0.2-1% of component Zr, 1.1-3.5% of component Ti, 0.5-2% of component Al, and the balance of component Fe. The invention also provides a preparation method of the alloy material. The alloy material prepared by the preparation method provided by the invention is of 8.2g / cm<3> based on the density, and has the resistivity of 1.53 (microhm.megabyte.20 DEG C); and the alloy material has temperature coefficient of resistance of 240aR / *10<-6>DEG / C under 100-800 DEG C; and the temperature is in good linear relation to the resistivity.

Owner:WUHAN XINYUAN TUOER TECH CO LTD

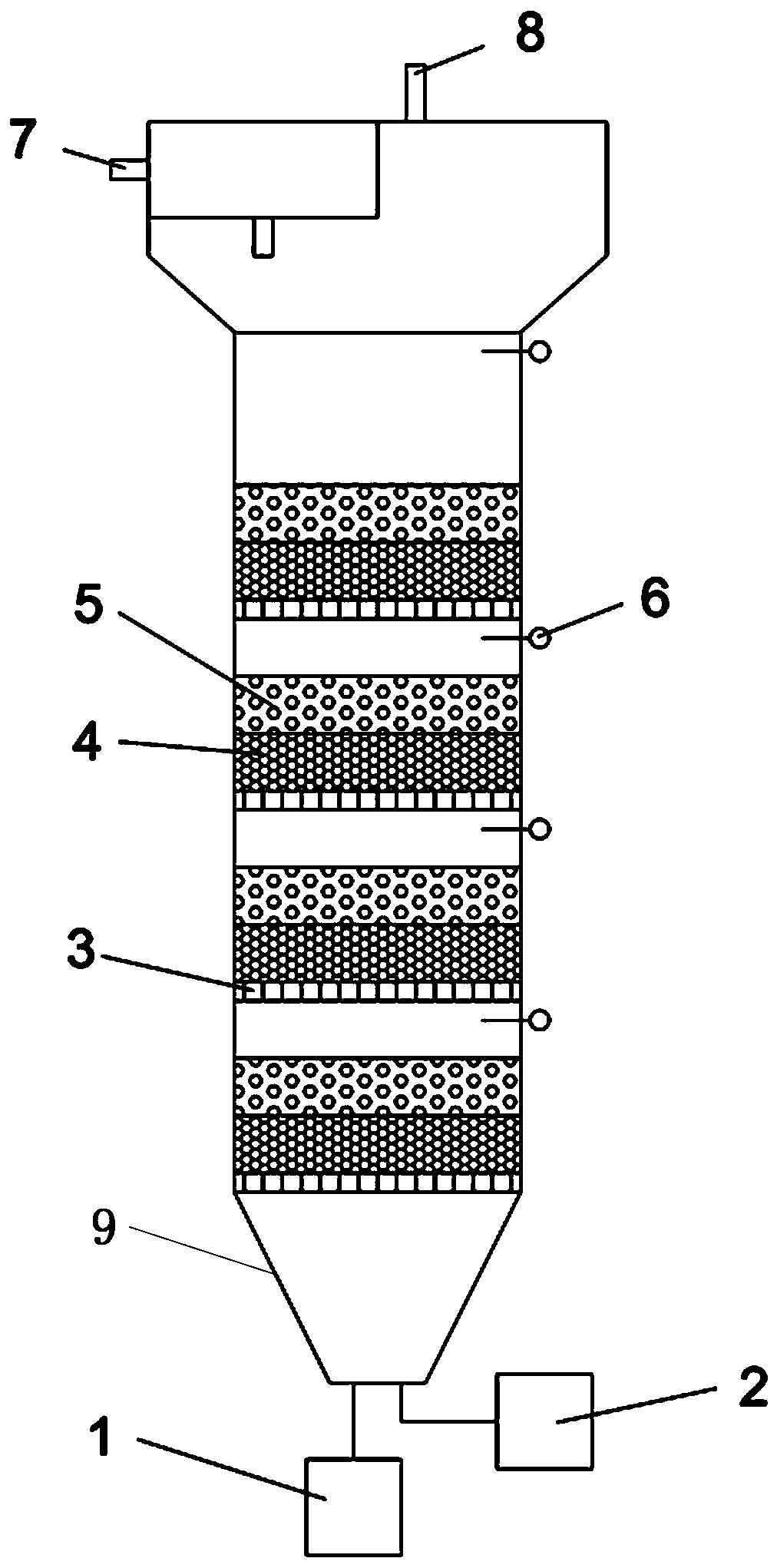

Efficient alloy baking device and baking method thereof

The invention discloses an efficient alloy baking device and a baking method thereof in the field of alloy baking. The efficient alloy baking device comprises a hot-blast stove, the hot-blast stove isconnected with an air inducing mechanism through a hot-blast pipeline, a temperature adjusting mechanism is further arranged between the air inducing mechanism and the hot-blast stove, the air inducing mechanism is connected with a baking bin, and the baking bin is arranged on a rack. The hot-blast stove is arranged on one side of the rack, a weighing and discharging mechanism is arranged below the baking bin, the baking bin is further provided with a feeding mechanism in a matched mode, and the hot-blast stove is controlled by an intelligent detection control system. The hot-blast stove andthe baking bin are of a separated structure, coal gas can be fully combusted, carbon monoxide poisoning accidents are avoided, safety measures are complete, the hot-blast stove is controlled by the intelligent detection control system, the hot-blast stove and the baking bin can be monitored in real time, and the heat energy utilization efficiency is greatly improved through the air inducing mechanism and the temperature adjusting mechanism. The efficient alloy baking device and the baking method thereof can be used for iron alloy baking.

Owner:JIANGSU EURASIA ENVIRONMENTAL PROTECTION TECH CO LTD

Device and method for treating oxidation-state nitrogen wastewater by using combination of iron alloy and anaerobic ammonium oxidation bacteria

ActiveCN111517591AEnsure complete removalWater treatment parameter controlWater contaminantsNitrite ionSludge

Owner:BEIJING UNIV OF TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap