Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12 results about "Laser processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

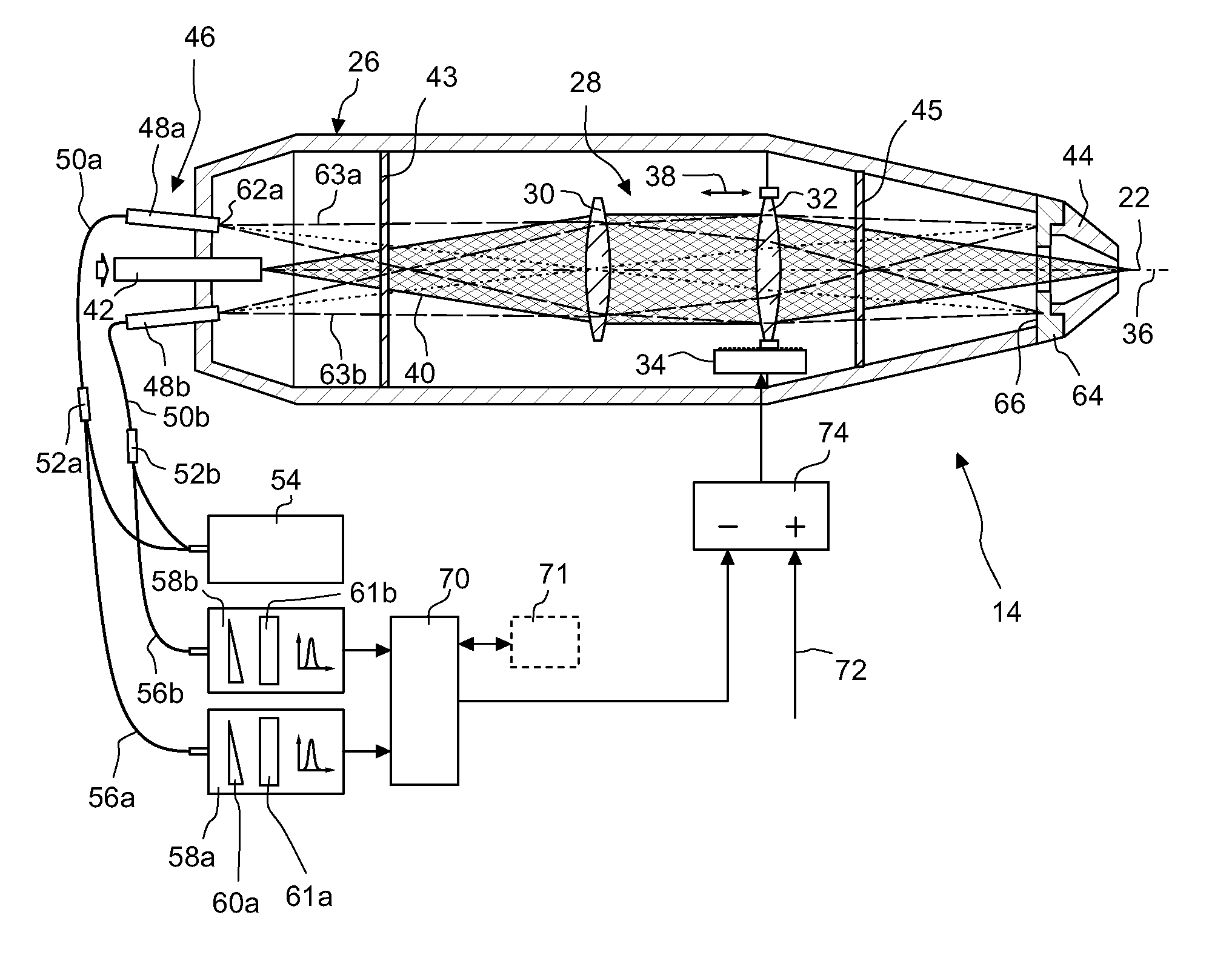

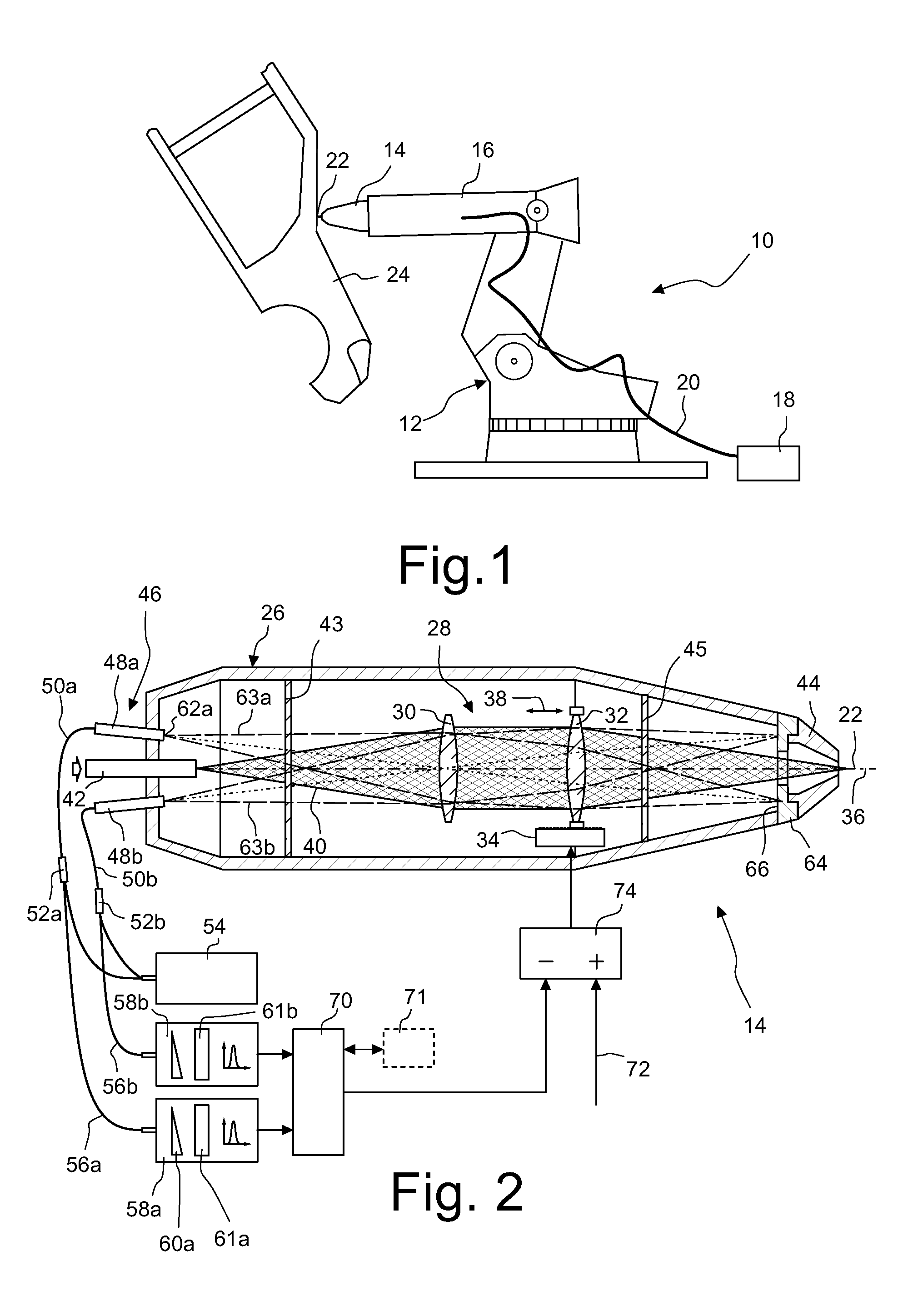

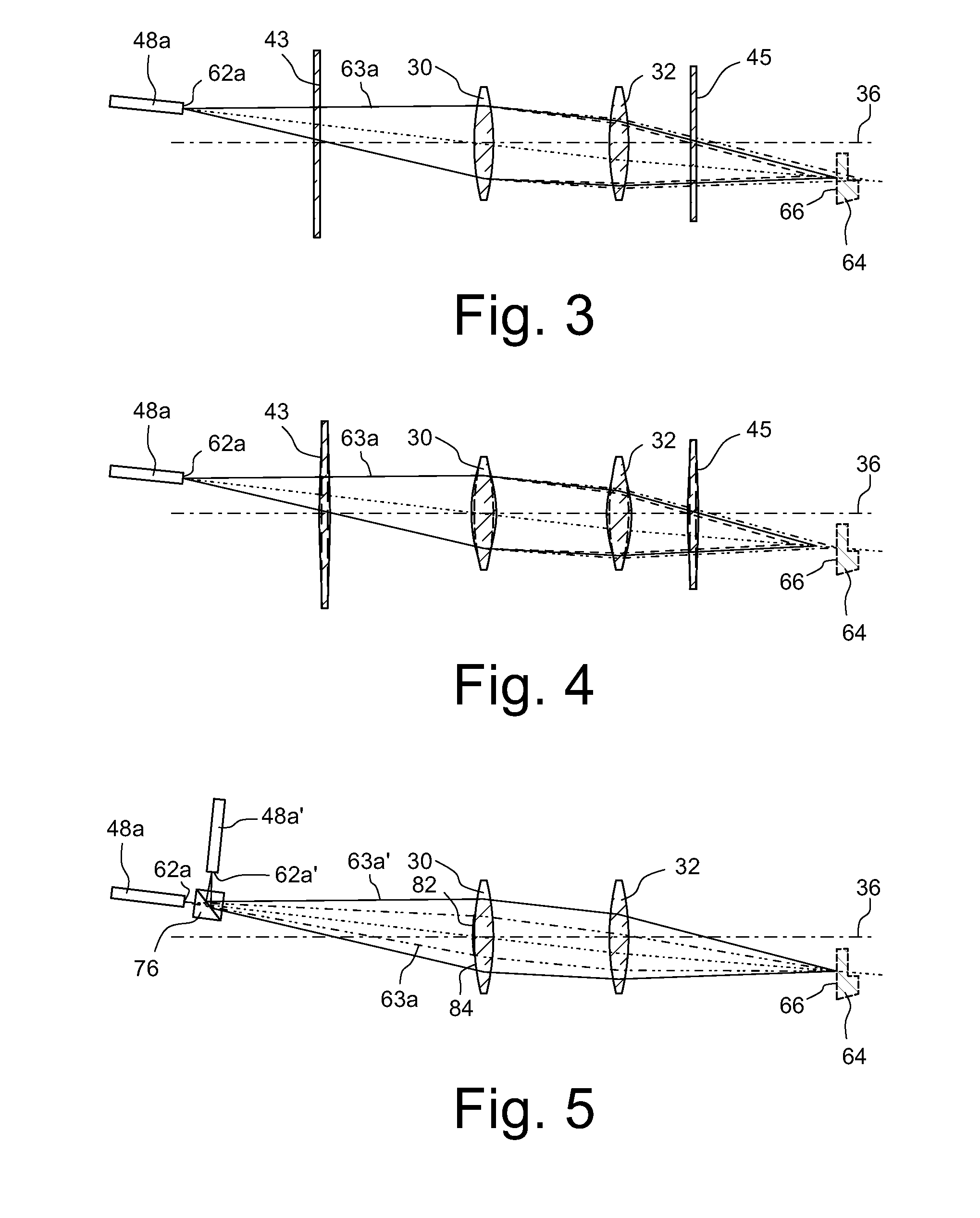

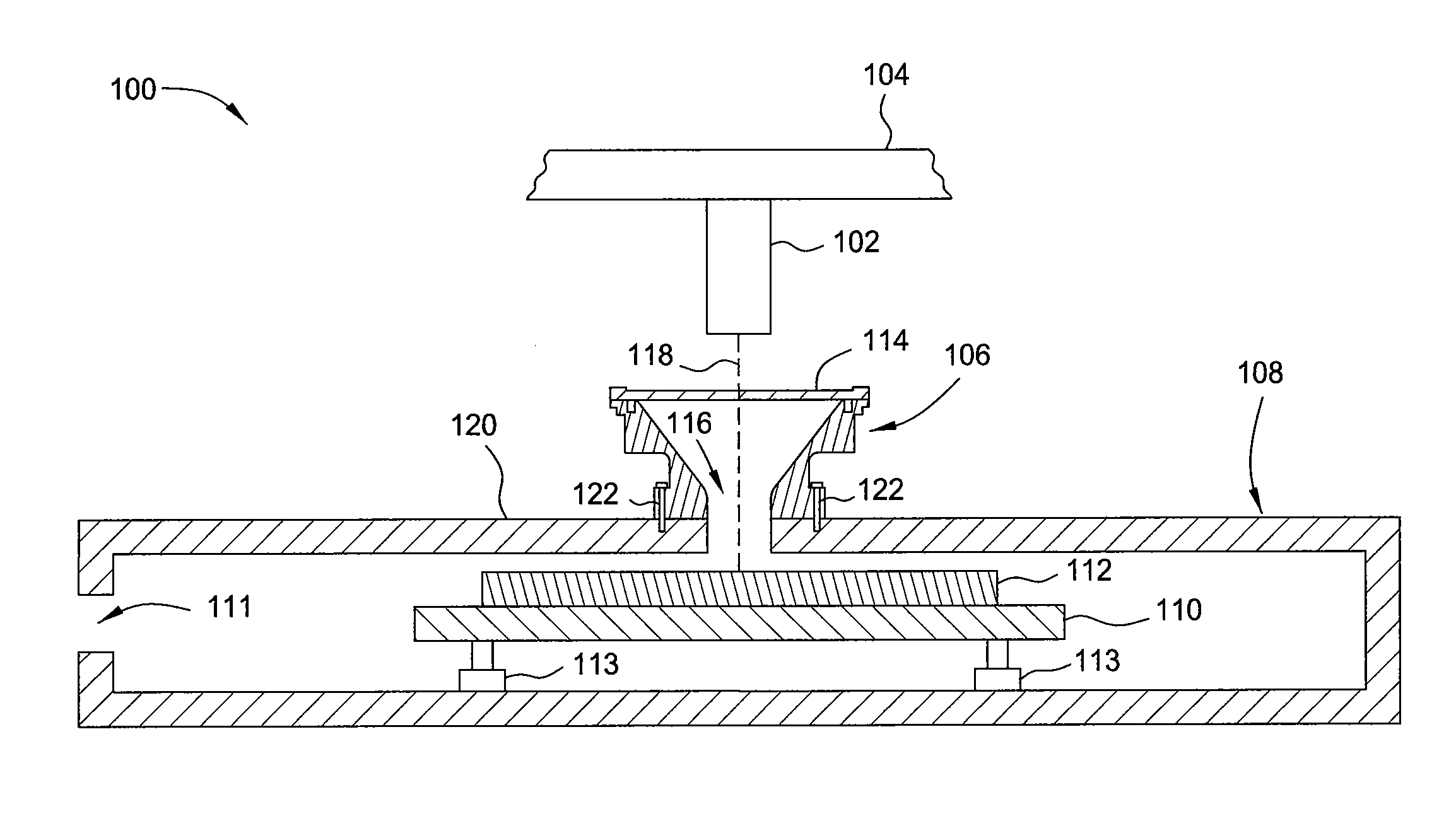

Laser Machining Apparatus with Adaptive Mirror

ActiveUS20140346155A1Stabilised betterSimple adaptationLaser beam welding apparatusOptoelectronicsInternal pressure

A laser machining apparatus comprises a laser radiation source that generates laser radiation. A first and a second adaptive mirror are provided each having a pressure chamber connected to a pressure source and a mirror substrate that bounds the pressure chamber. An internal pressure in the pressure chamber can be changed with the aid of the pressure source in such a way that the mirror substrate deforms if the internal pressure in the pressure chamber changes. The mirror substrate of the first adaptive mirror has a thickness which varies at least within a region of the mirror substrate that bounds the pressure chamber. The mirror substrate of the second adaptive mirror has a thickness which is constant over the entire region over which the mirror substrate is deformable.

Owner:LT ULTRA PRECISION TECH

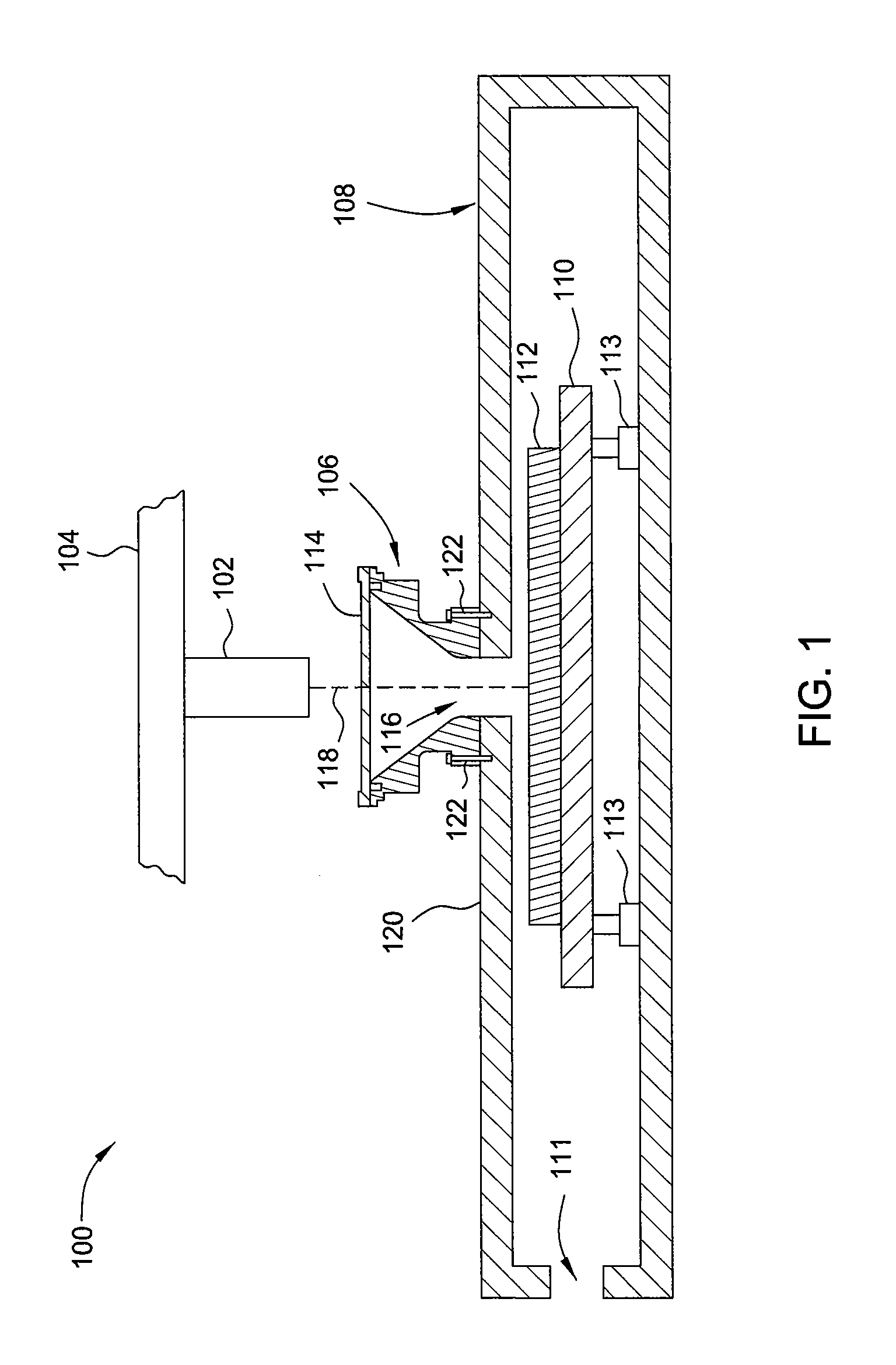

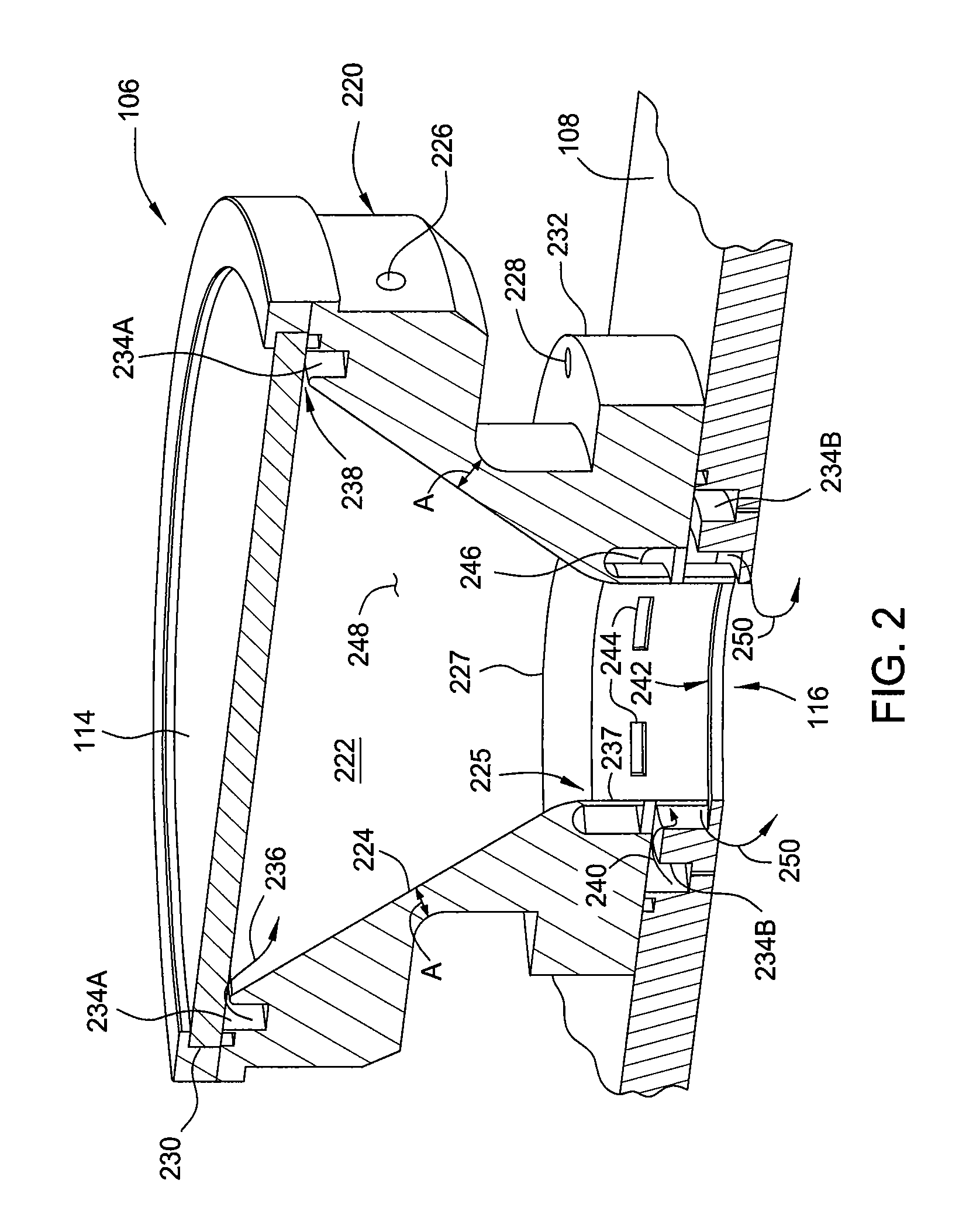

Particle control in laser processing systems

ActiveUS20130087547A1Reduce pollutionElectric heating for furnacesLaser beam welding apparatusLaser processingOxygen

Owner:APPLIED MATERIALS INC

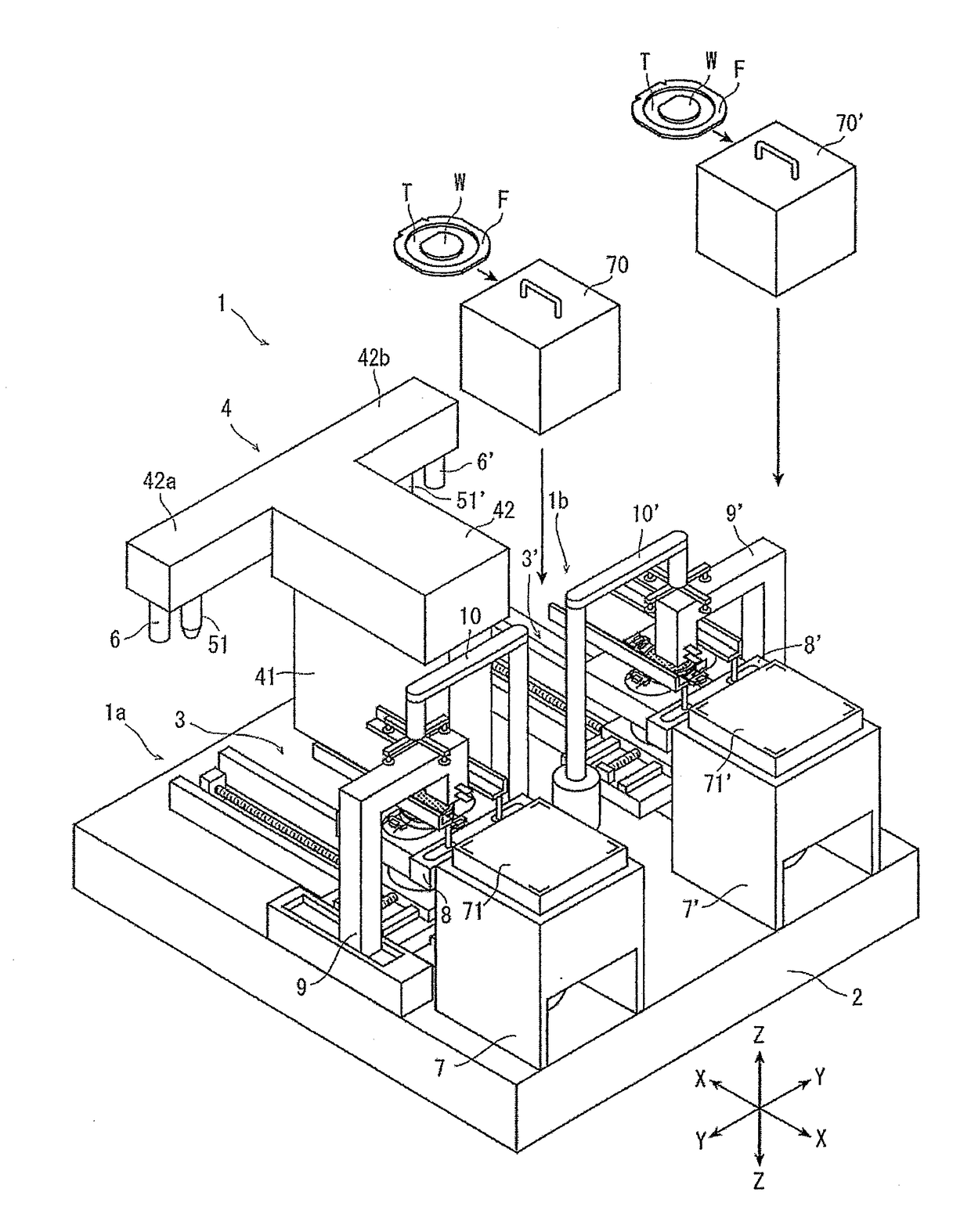

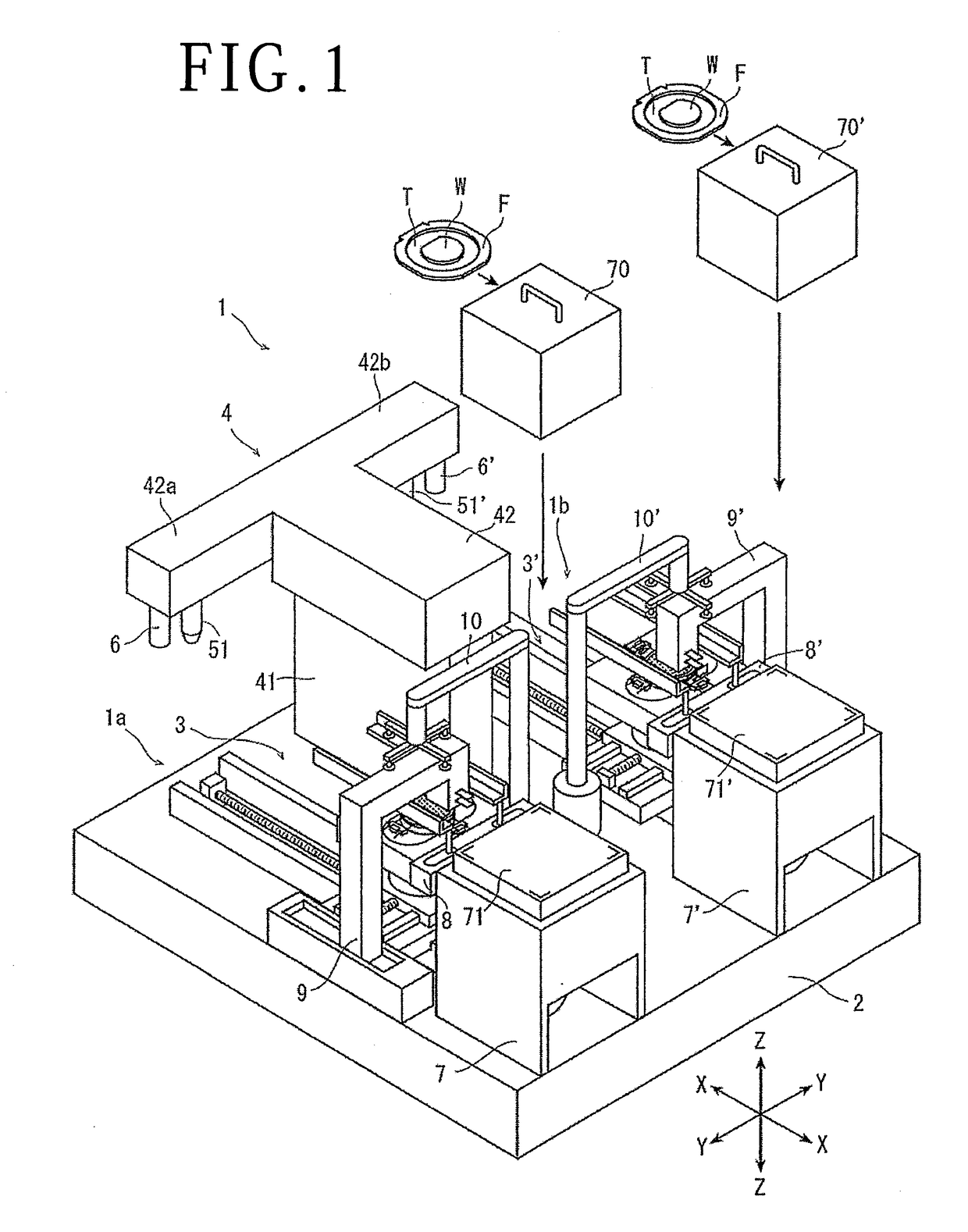

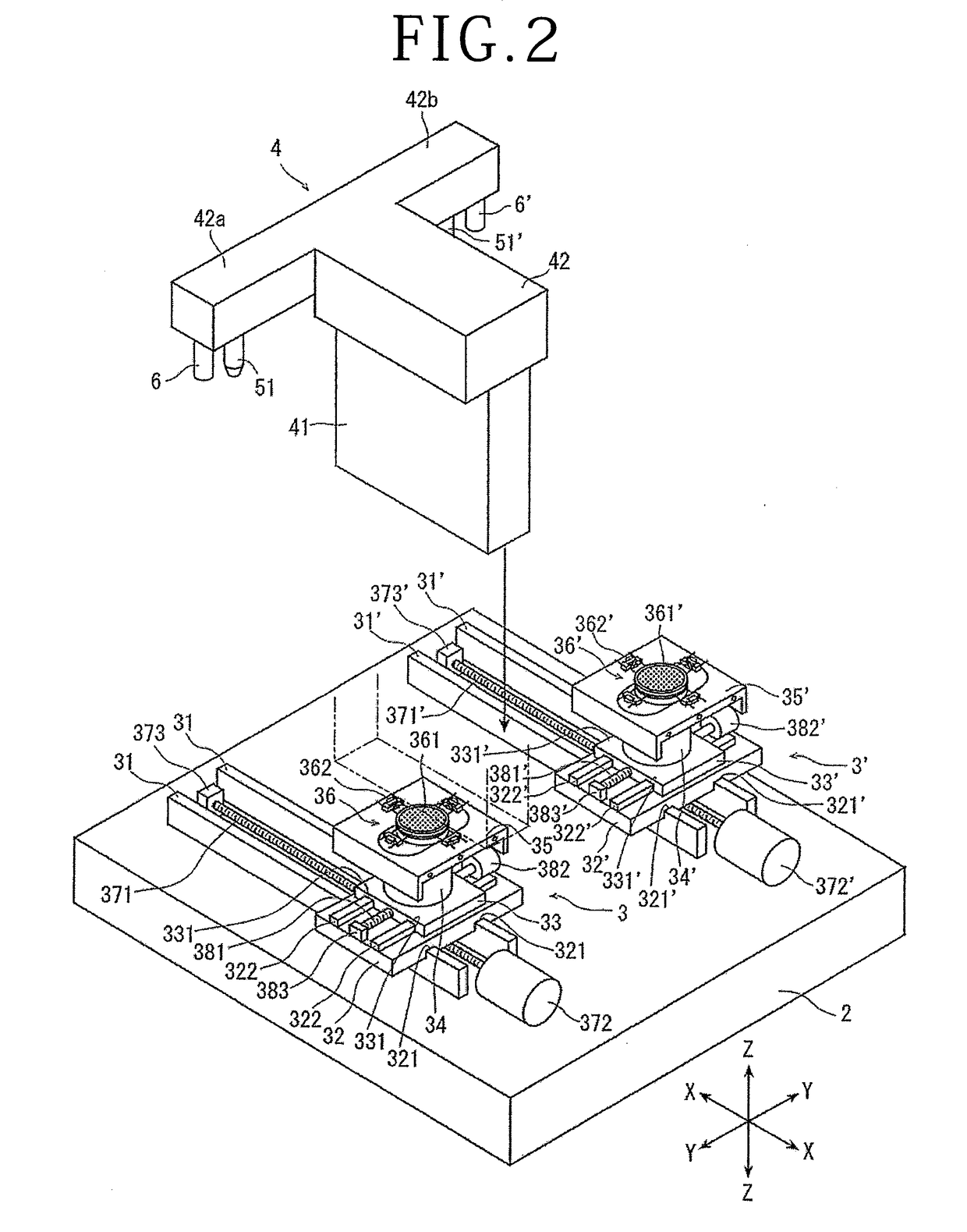

Laser processing apparatus

ActiveUS20170087671A1Improve economyLow costSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesLaser processingOptoelectronics

Owner:DISCO CORP

Laser marking method for random three-dimensional code

ActiveCN110348553AGuaranteed randomnessGuaranteed anti-counterfeiting functionRecord carriers used with machinesLaser beam welding apparatusColor imageLaser processing

The invention discloses a laser marking method for a random three-dimensional code, and belongs to the field of laser processing. The laser marking method comprises the following steps: changing a black region of a two-dimensional code image into a color to generate a three-dimensional code color image; generating marking paths according to the three-dimensional code color image, and classifying the marking paths according to colors to obtain classified storage information; and marking a random three-dimensional code on the multi-layer anti-counterfeiting module by adopting a laser according to the classified storage information, wherein the multi-layer anti-counterfeiting module is formed by superposing materials with different colors, and the colors of the materials include the color types in the three-dimensional code color image. According to the invention, the marking time is fixed; and the output power of the laser is modulated according to the received classified storage information, or when the output power of the laser is fixed, the marking time is adjusted according to the received classified storage information, and three-dimensional codes with different depths and a concave-convex feeling can be quickly marked on the multi-layer anti-counterfeiting module after one processing path is completed, so that the processing efficiency is greatly improved.

Owner:DONGGUAN EVER TECH LASER TECH LTD +1

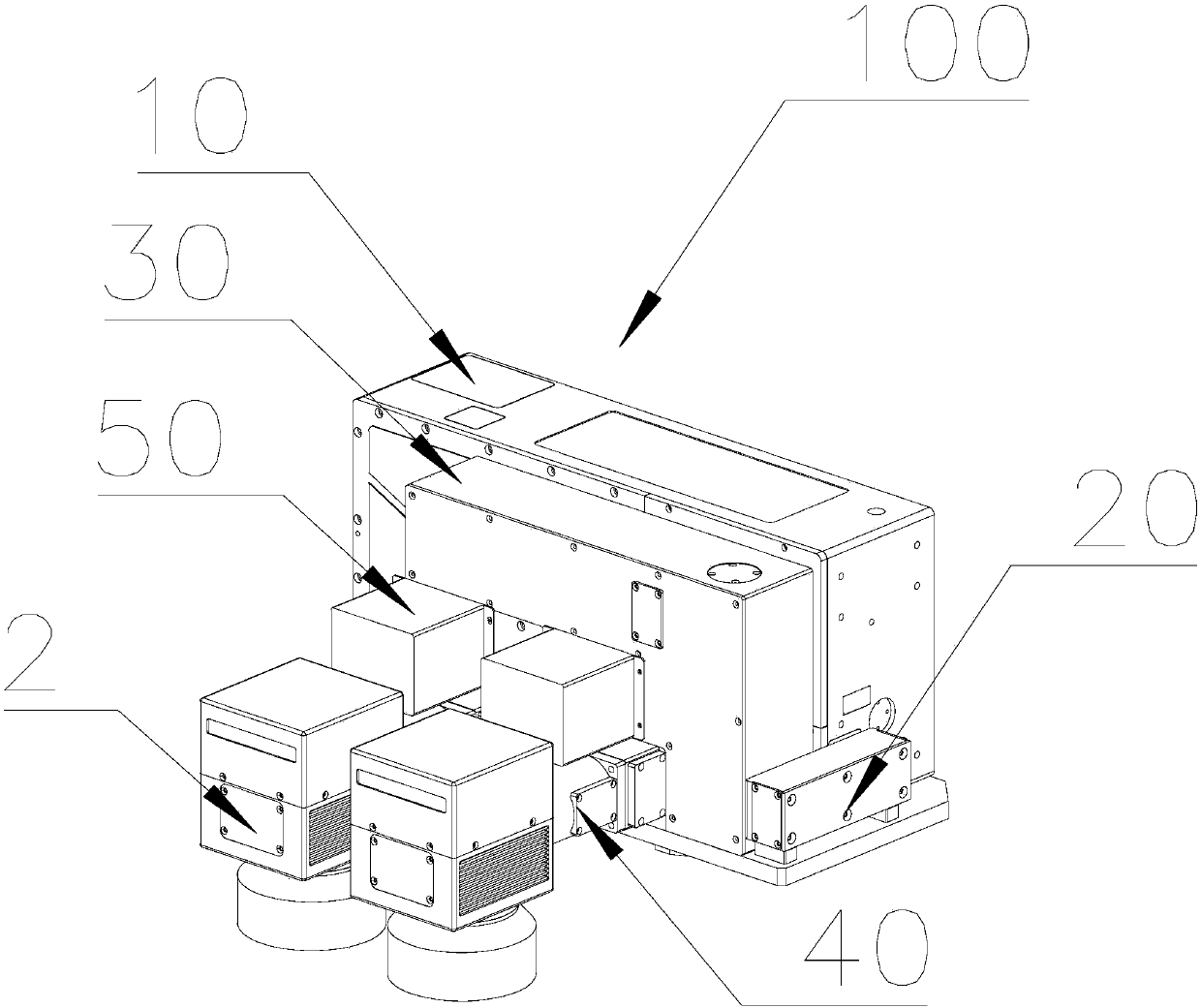

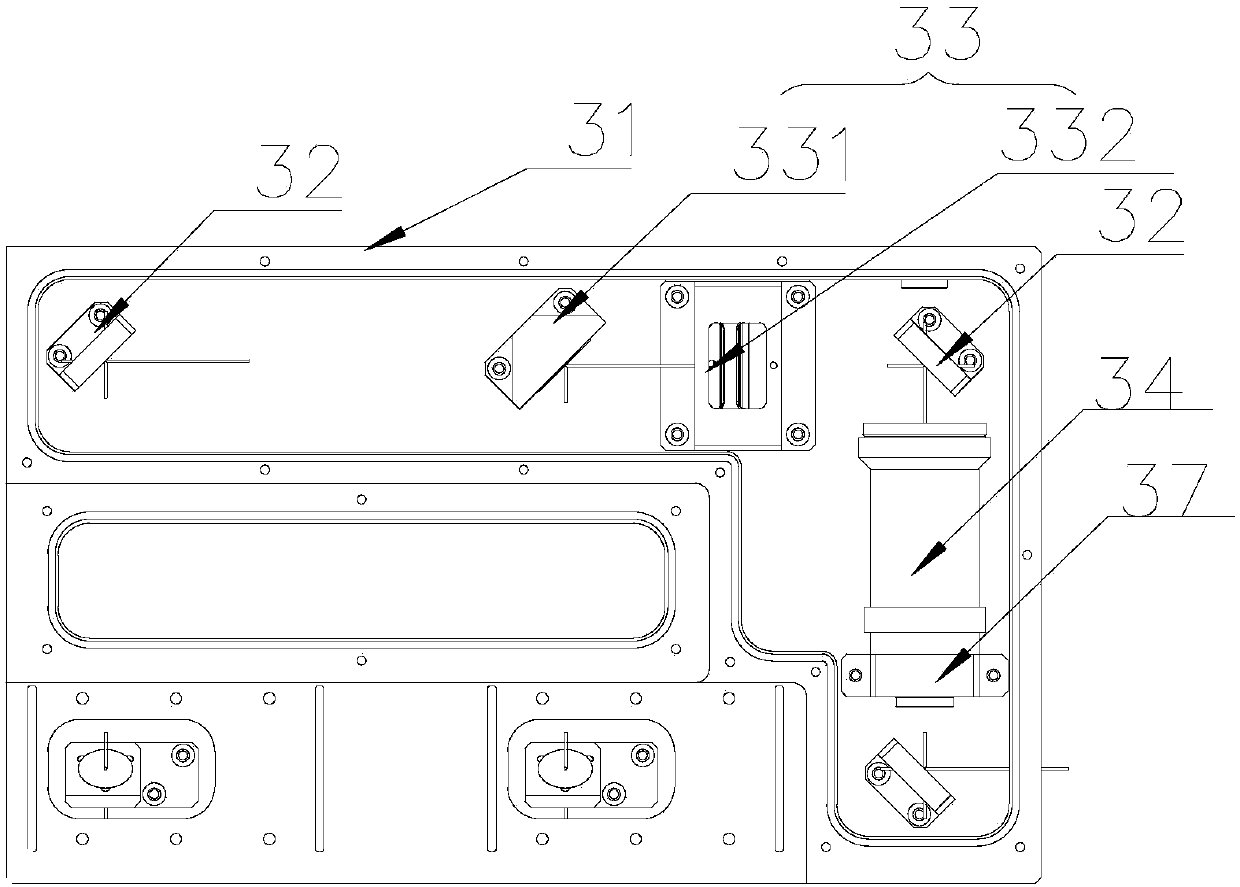

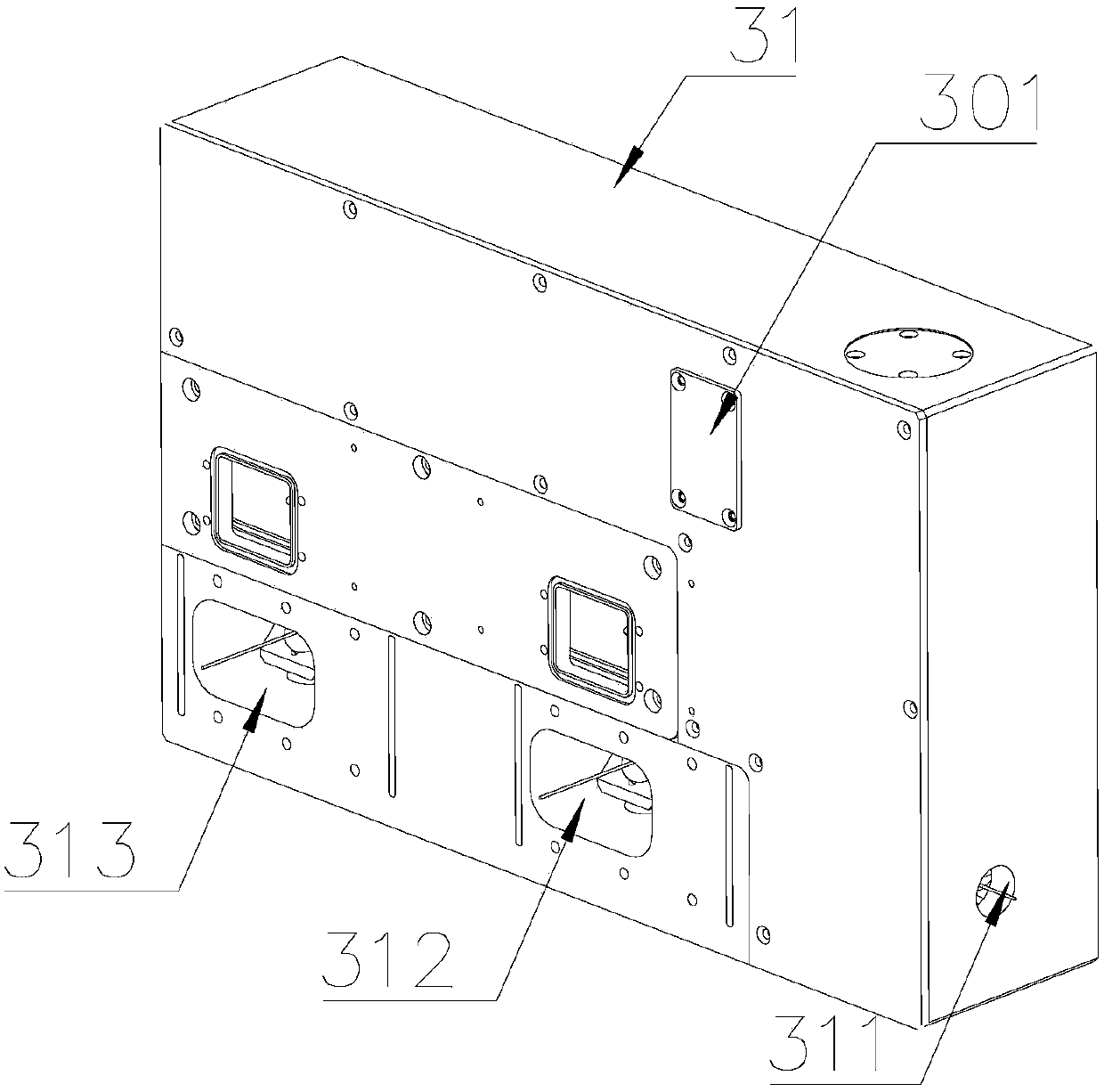

Laser light path system and double-head laser marking machine

ActiveCN110405338AImprove stabilityImprove qualityLaser beam welding apparatusLaser processingLight beam

Owner:HANS LASER TECH IND GRP CO LTD

Special water-cooling reflecting cover for laser processing

ActiveCN104175007AEnsure safetyDoes not affect processing qualityLaser beam welding apparatusLaser processingPhysics

Owner:重庆机电增材制造有限公司

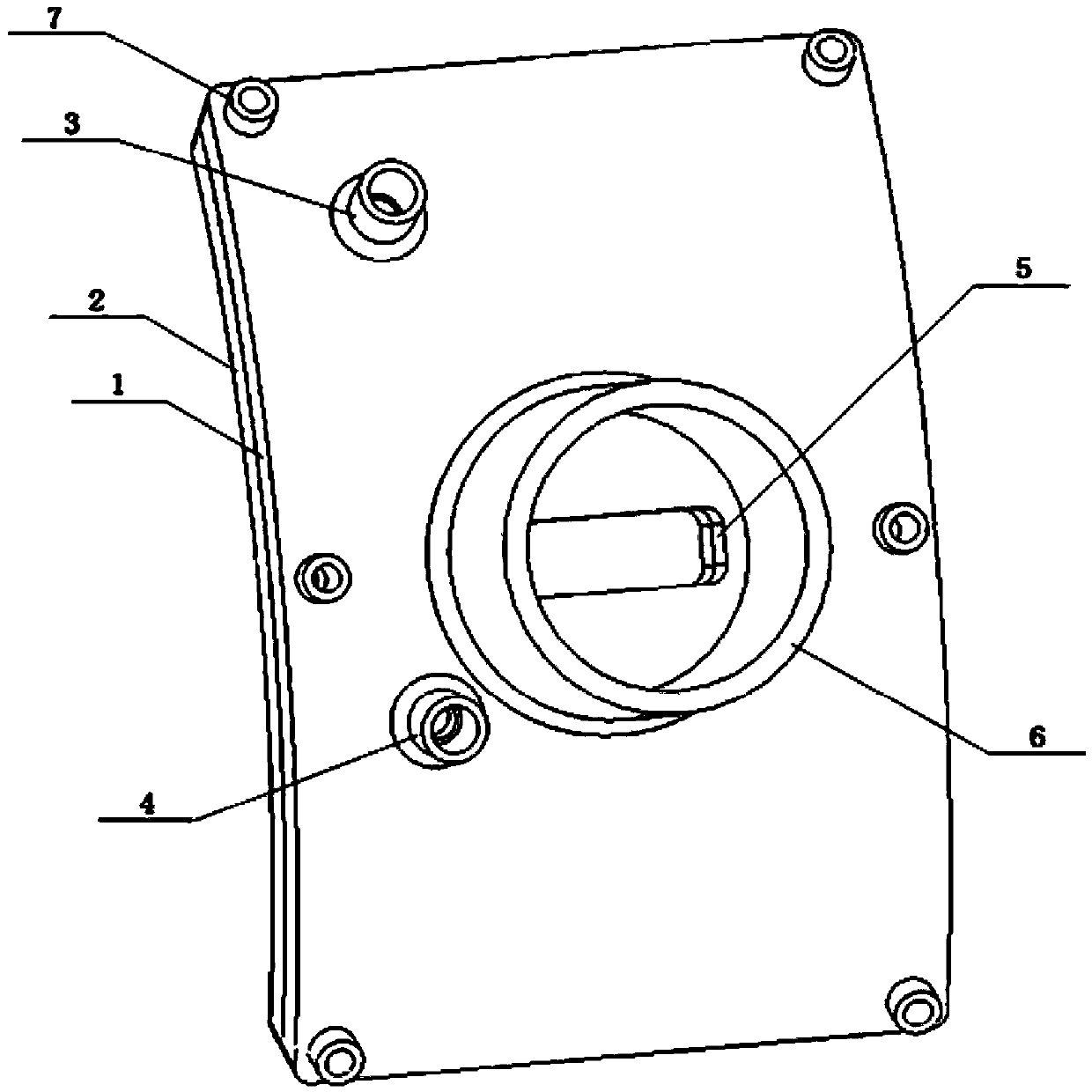

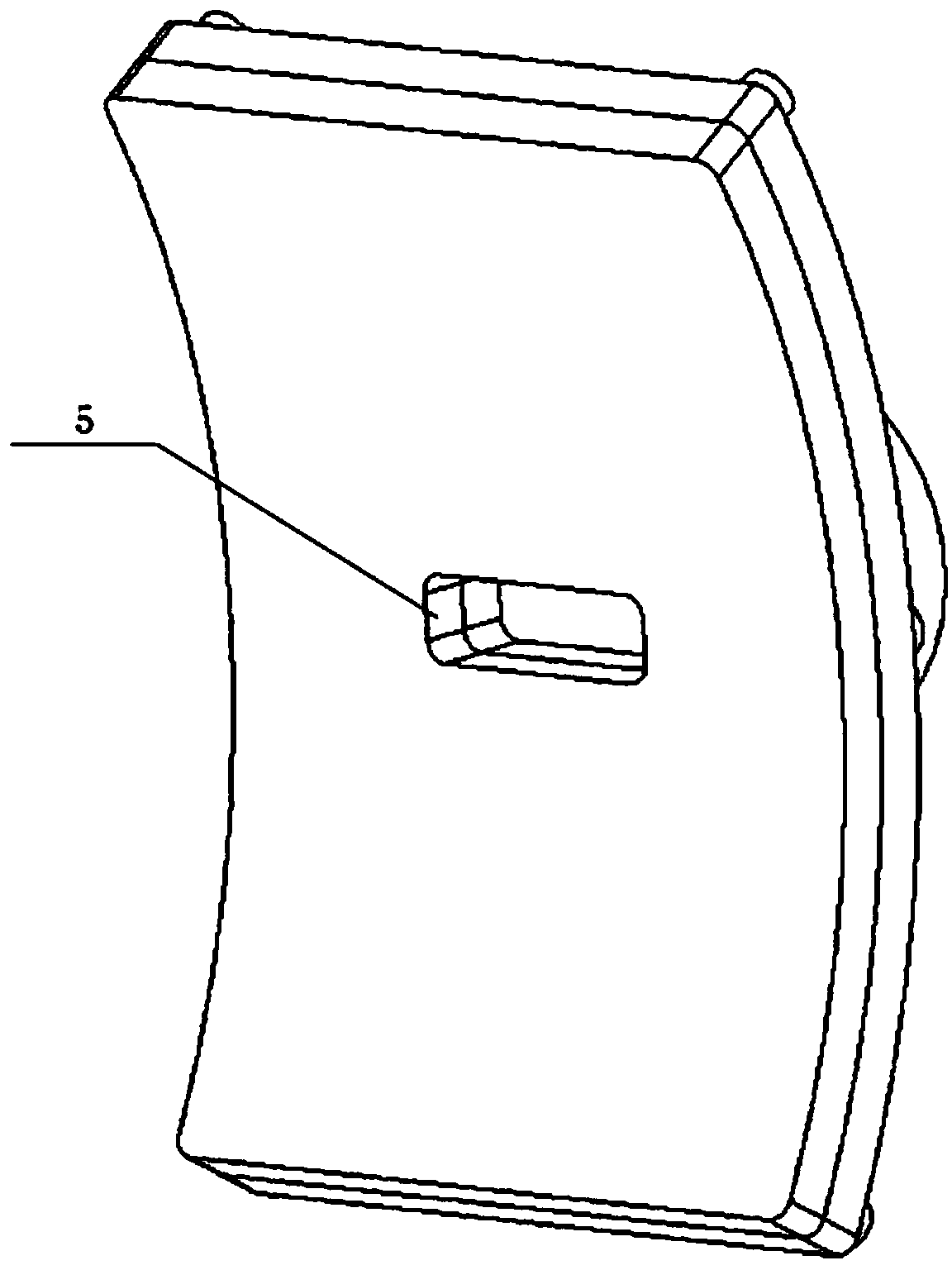

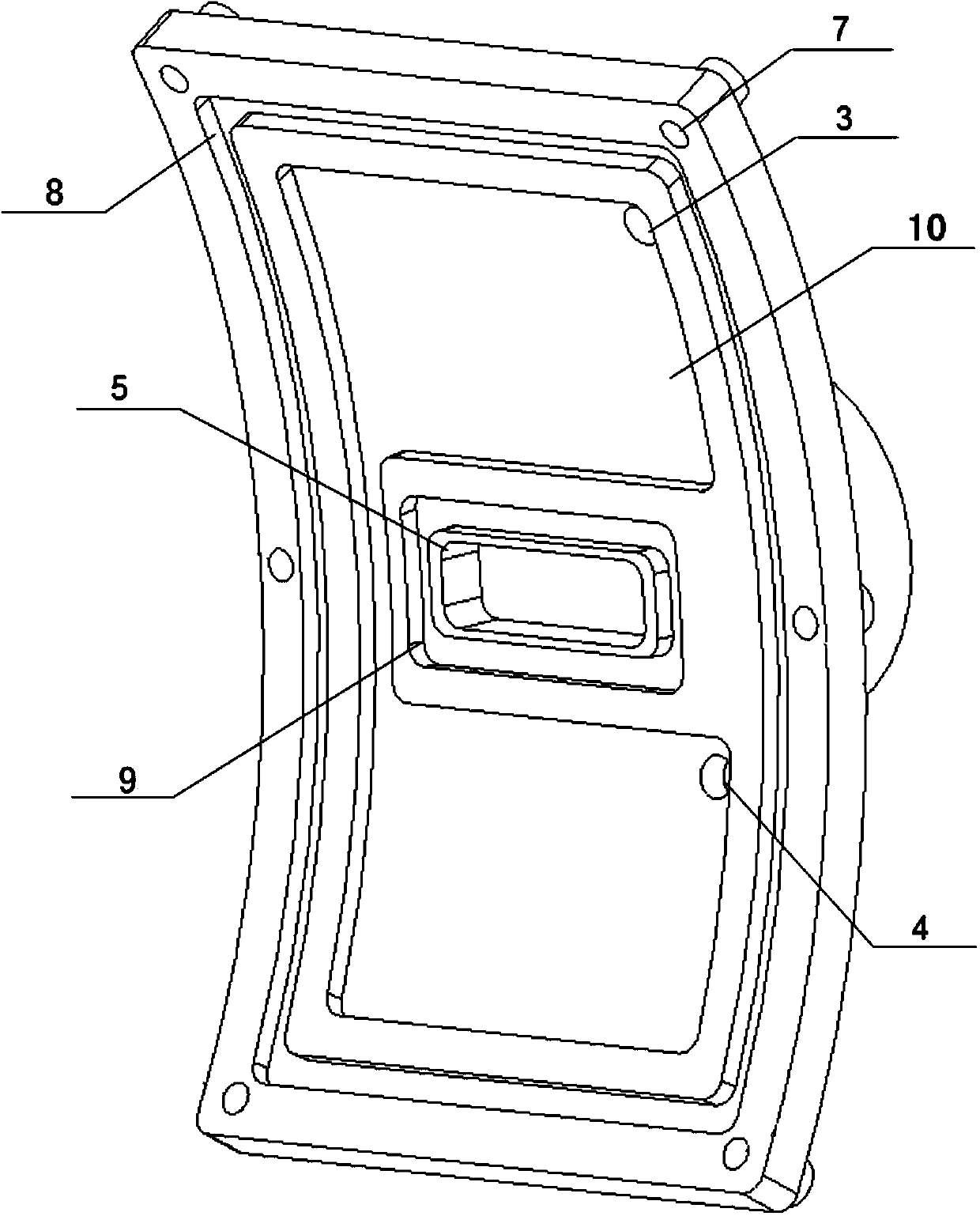

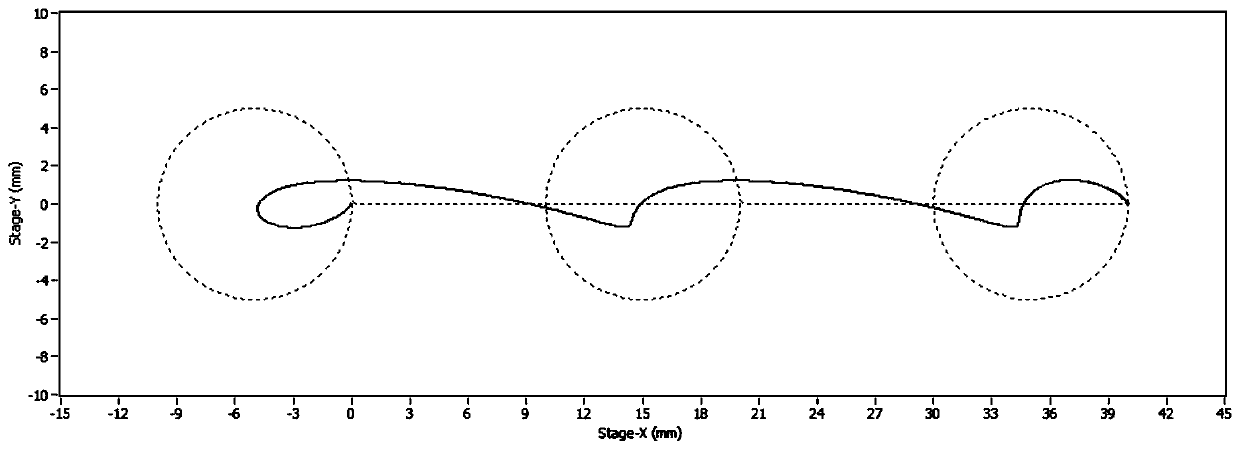

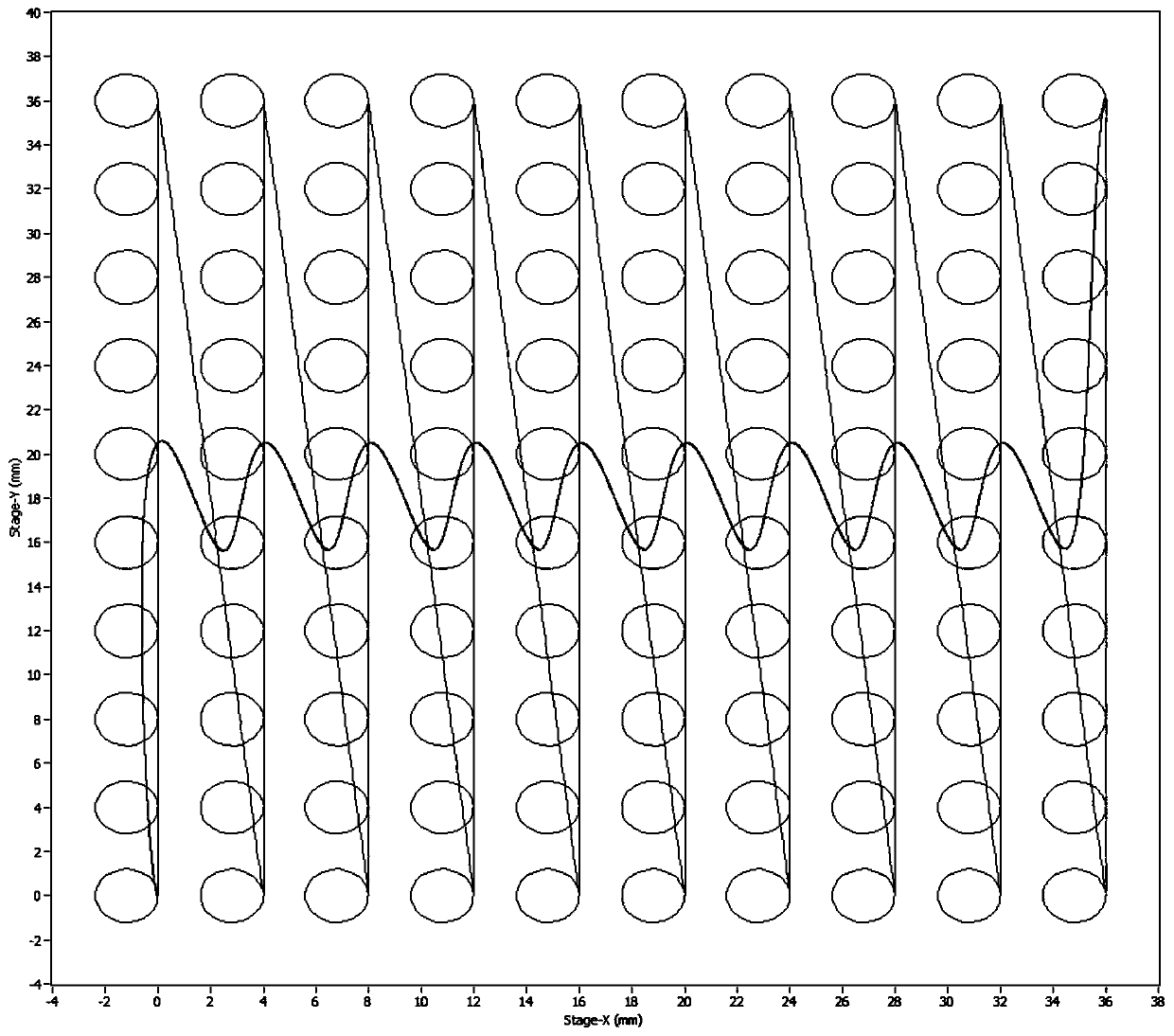

A filter for decomposing galvanometer and servo positions

PendingCN111049500AReduce shockImprove acceleration and decelerationDigital technique networkLaser beam welding apparatusLaser processingGalvanometer

Owner:XIAN MICROMACH TECH CO LTD

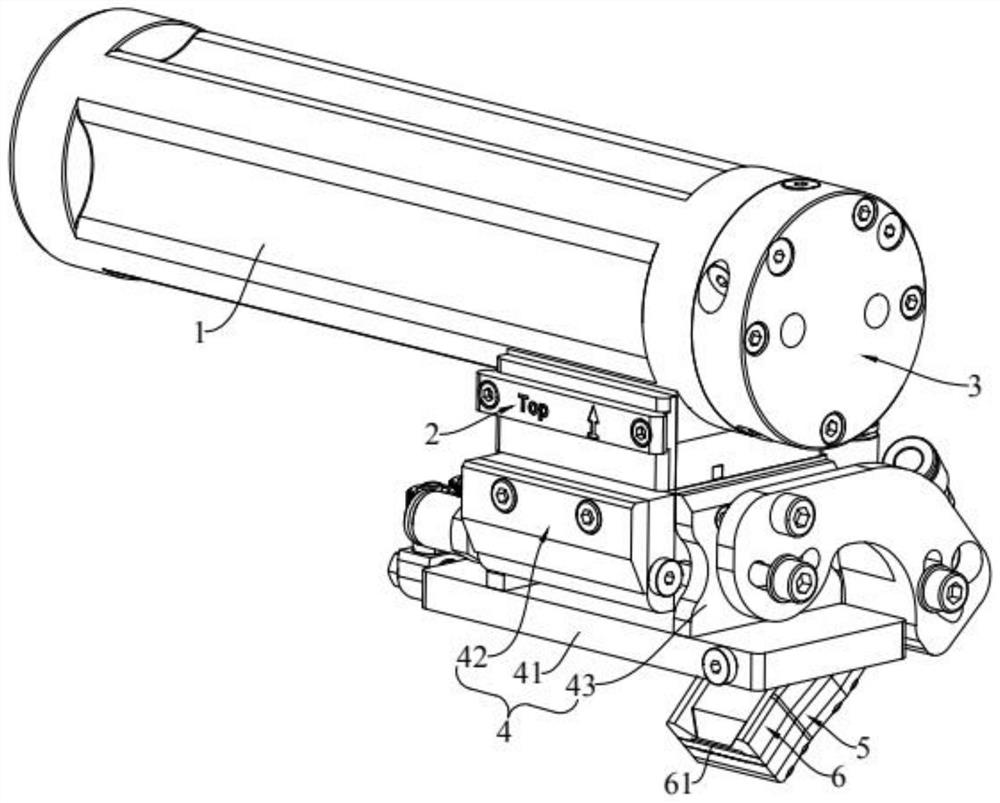

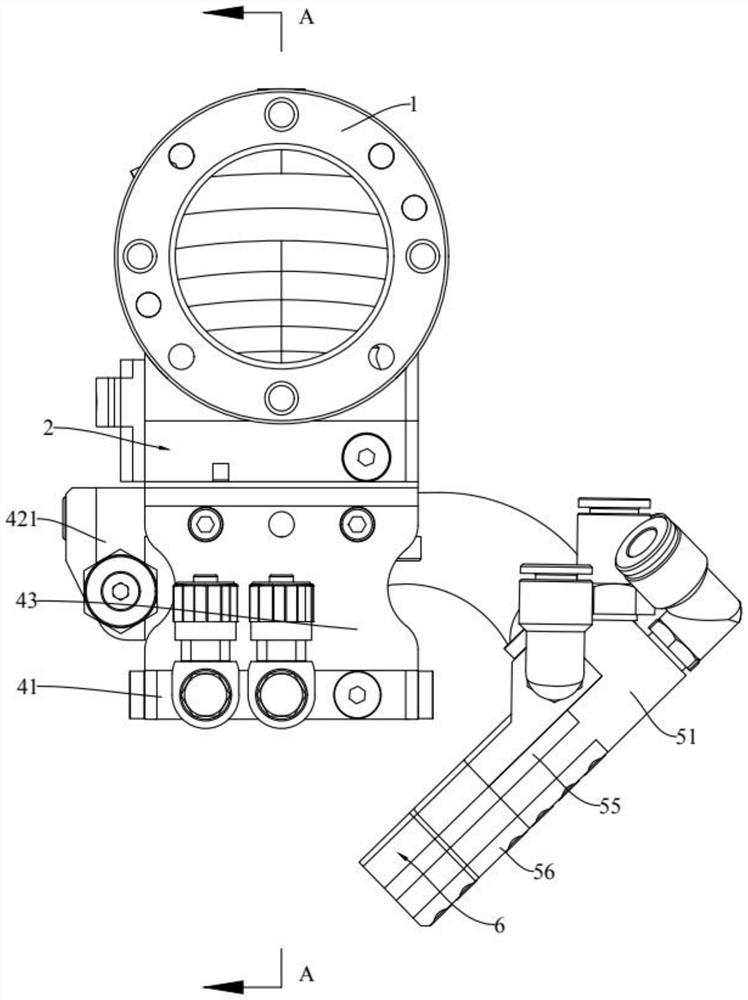

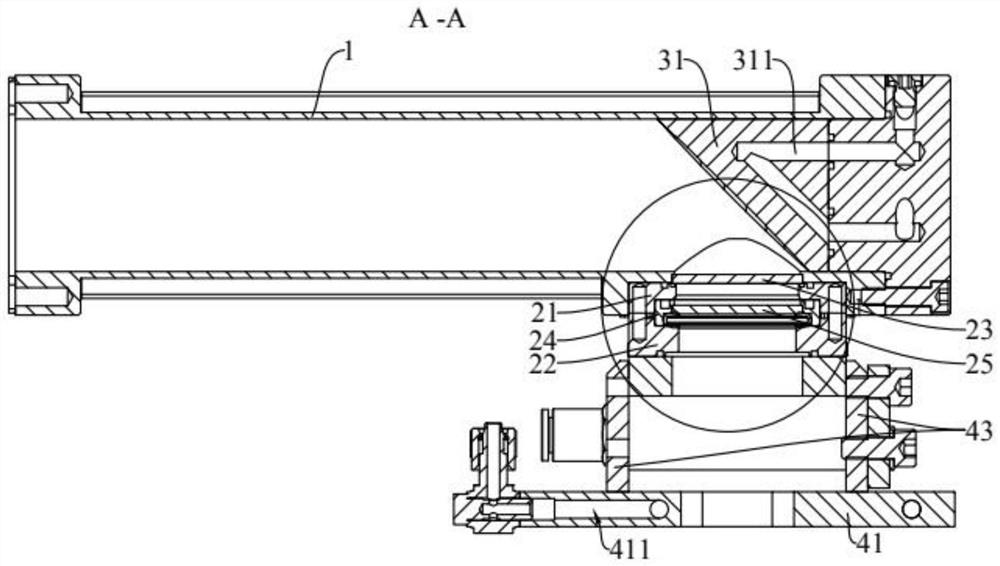

Inner hole cladding laser head

InactiveCN114107982AAvoid pollutionEven energy distributionMetallic material coating processesLaser processingLight spot

Owner:GANGCHUN LASER TECH (JIANGSU) CO LTD

Method for improving quality of inner wall of laser processing micropore based on dual cavitation effect

ActiveCN114589405AImprove inner wall qualityDecrease produces trendProcess efficiency improvementLaser beam welding apparatusUltrasonic cavitationLaser processing

Owner:SHANDONG UNIV OF TECH

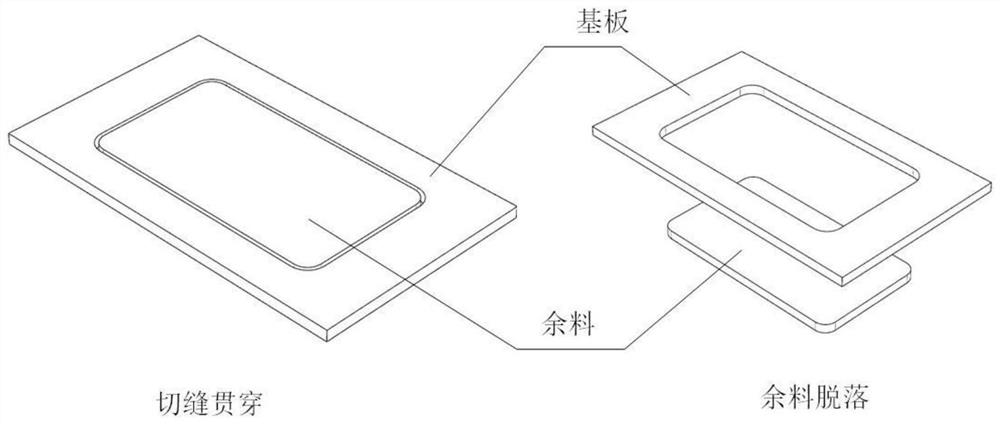

Strip coil laser machining method

ActiveCN113319437ARealize continuous processingImprove processing efficiencyMetal working apparatusLaser beam welding apparatusLaser processingLaser cutting

The invention relates to the field of machining, and discloses a strip coil laser machining method which comprises the steps that the machining contour of a workpiece is obtained; a path combination is planned according to the machining contour, wherein the path combination comprises at least two cutting paths; laser cutting parameters are calculated according to the conveying speed and path combination of a strip coil; and a laser cutting head is controlled to cut the strip coil according to the laser cutting parameters so as to obtain the workpiece cut and separated from the strip coil. According to the strip coil laser machining method, the path combination is flexibly planned based on the machining contour, then the laser cutting parameters are accurately calculated, a prefabricated cutting mold is not needed, continuous machining of the strip coil can be achieved, the machining efficiency of a metal plate is improved, and the production cost of the metal plate is reduced.

Owner:HANS LASER TECH IND GRP CO LTD +1

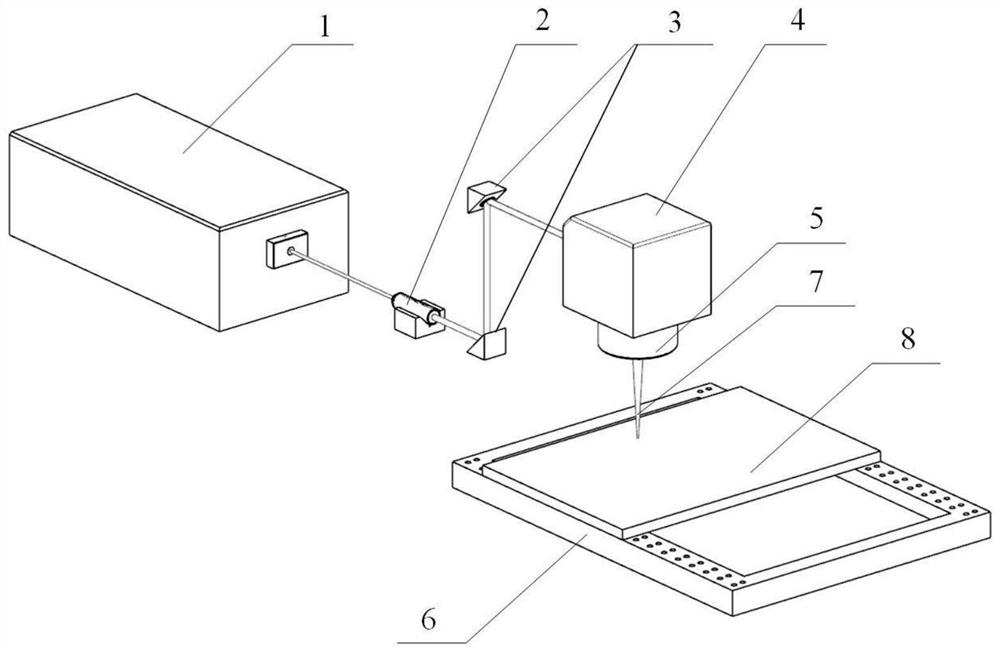

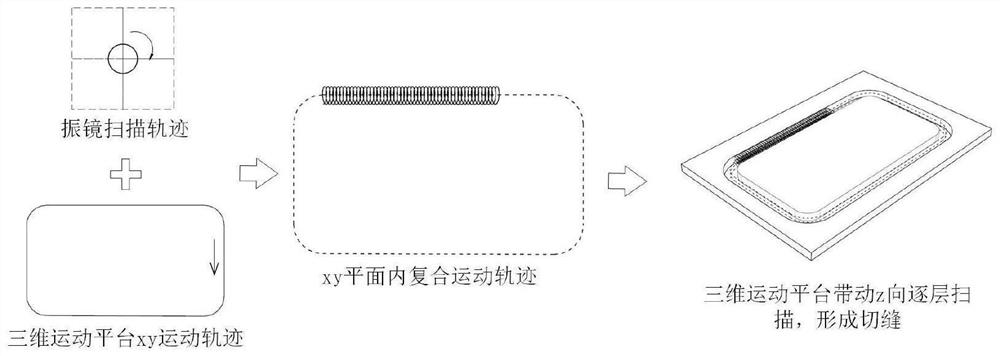

Large-breadth laser hole cutting method for glass

PendingCN114105466AIncrease the number of axesRich clampingGlass severing apparatusLaser processingLaser scanning

Owner:HUAZHONG UNIV OF SCI & TECH

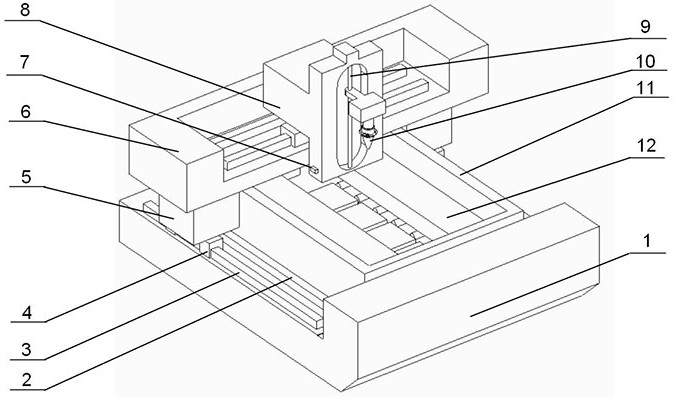

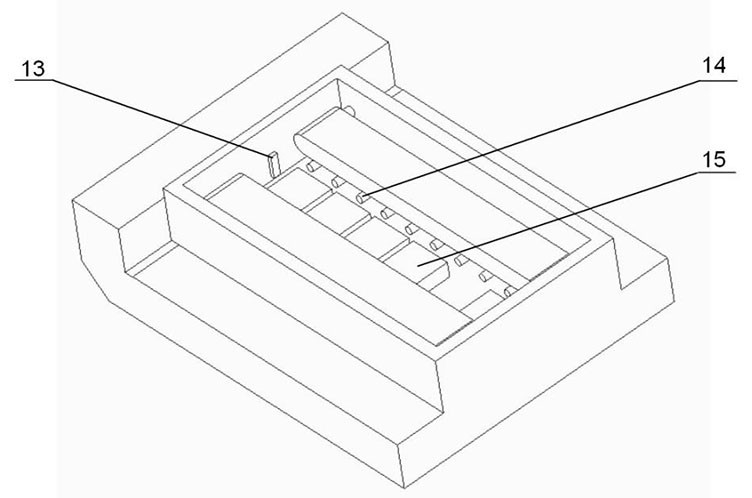

Laser processing equipment

The invention discloses laser processing equipment. The laser processing equipment comprises an object stage and a cutting device, wherein supporting frames are arranged on two sides of the object stage, and the supporting frames and the object stage are arranged in a split manner; the cutting device comprises a railcar and a cutting mechanism; a first sliding rail is arranged at the top of each supporting frame; the railcar is arranged on the first sliding rails; the cutting mechanism is arranged on the railcar; and a driving mechanism for driving the cutting mechanism to move in the railcarin the horizontal direction is arranged on the railcar. According to the laser processing equipment disclosed by the invention, the supporting frames and the object stage are arranged in a split manner, the cutting device is mounted on the supporting frames, the supporting frames are used for bearing the weight of the cutting device, the object stage only needs to bear the weight of a steel plate,and the bearing is separated, so that the problem that in the design of a single machine frame, when a large-scale steel plate is processed, the machine frame is liable to deform, and the processingaccuracy is influenced is solved.

Owner:PENTA CHUTIAN LASER (WENZHOU) CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap