Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

21 results about "Laser cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser cutting is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications, but is also starting to be used by schools, small businesses, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the material or the laser beam generated. A commercial laser for cutting materials involved a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials.

Laser device for cutting

Owner:HANS CNC SCI & TECH

Array flexible curved surface self-sensing driver based on IPMC and preparation method thereof

ActiveCN105789429AEasy to controlPrecise control of surface deformation positionPiezoelectric/electrostrictive devicesPolyelectrolyteSelf sensing

Owner:HEFEI UNIV OF TECH

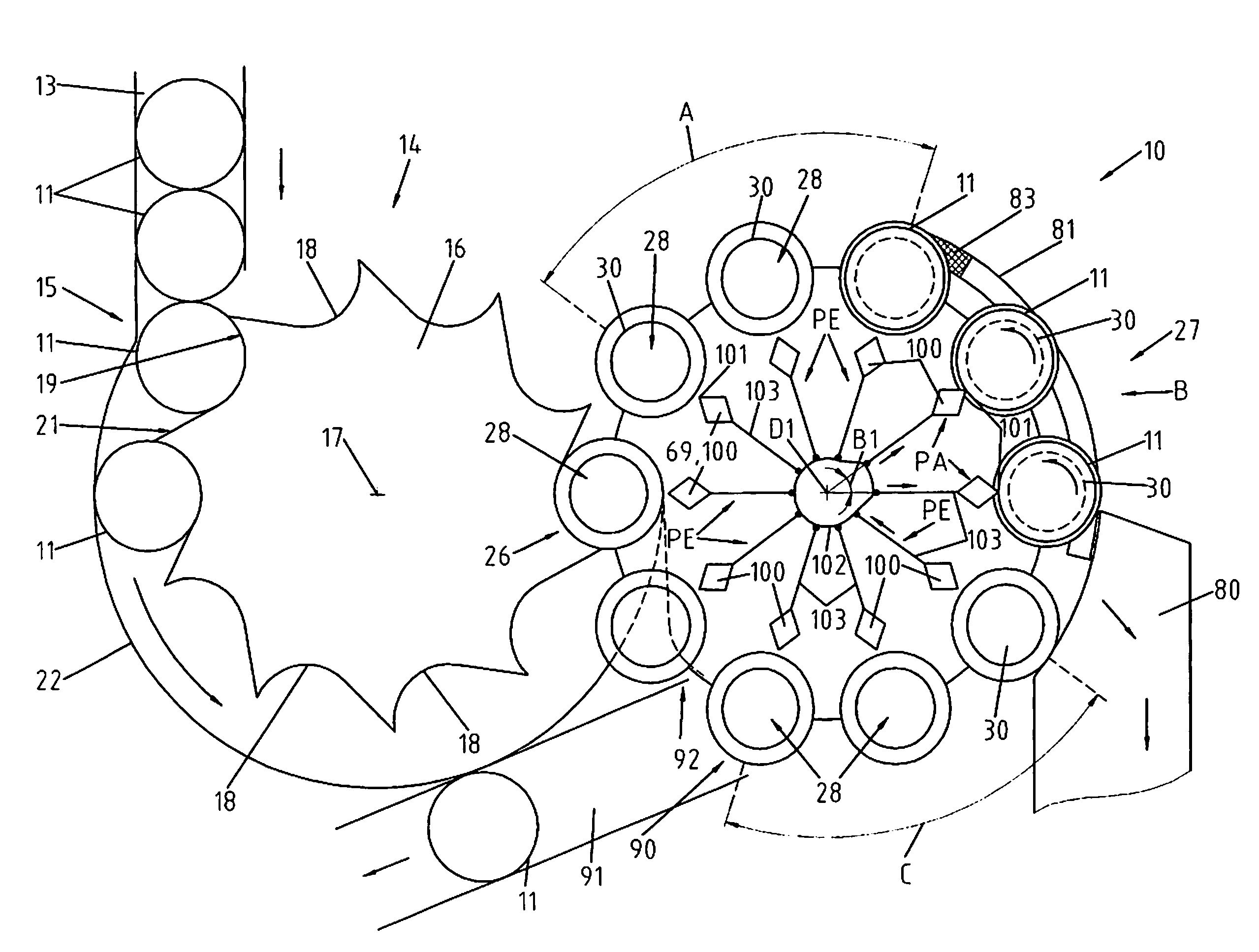

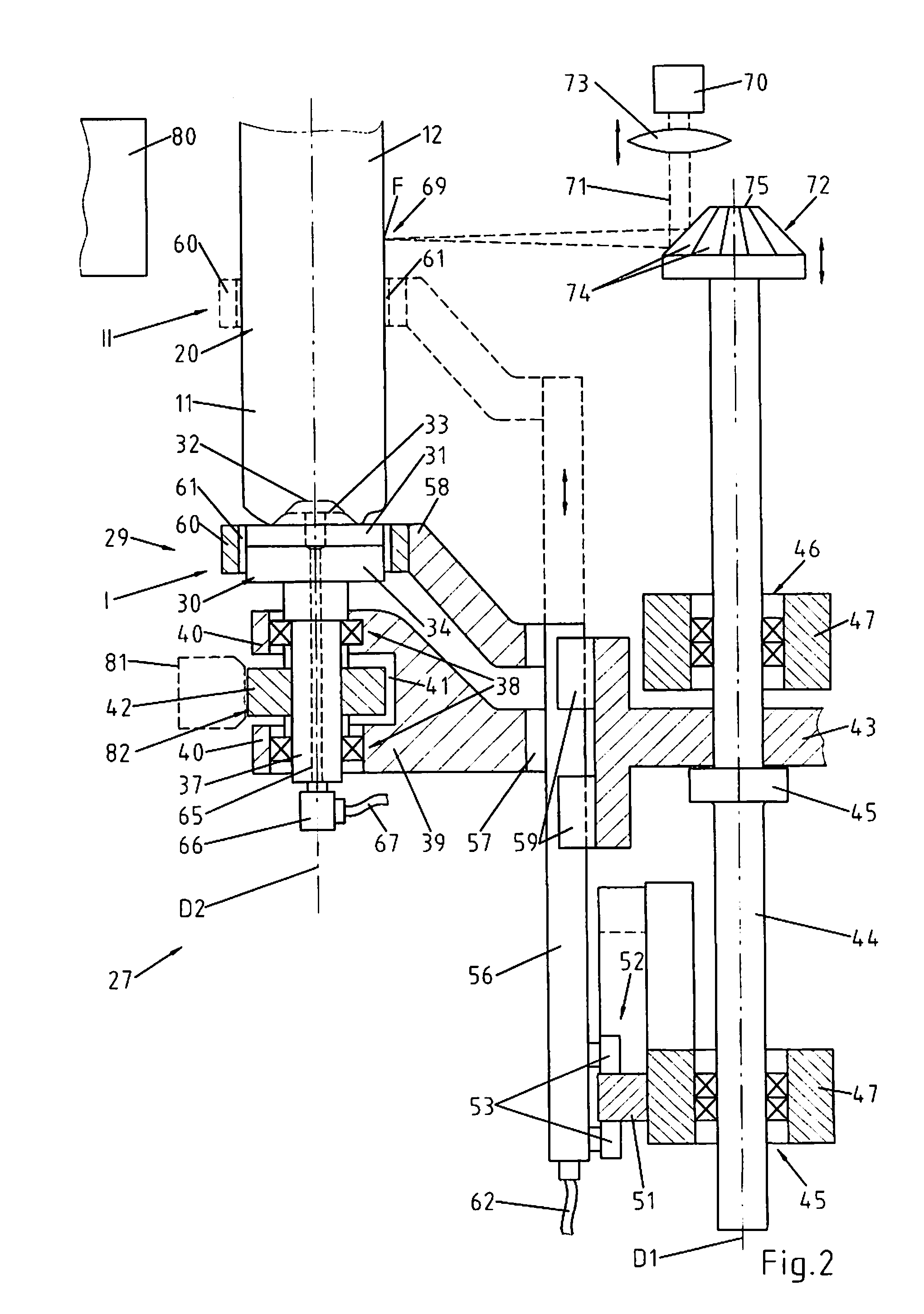

Device and method for cutting off an end section of a can blank

InactiveUS20140346154A1Sufficient time availableStock shearing machinesMetal working apparatusEngineeringLaser cutting

Owner:SCHULER PRESSEN GMBH & CO KG

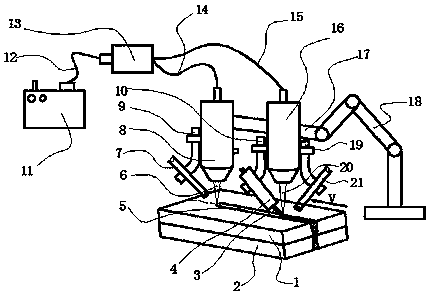

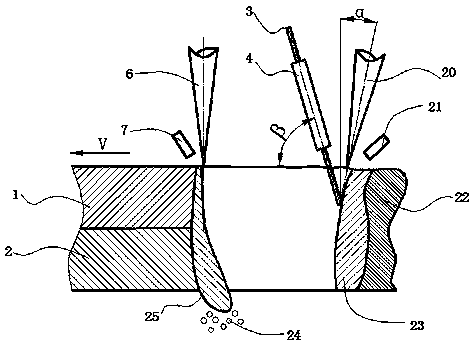

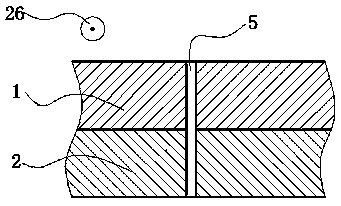

Car steel-aluminum splicing joint welding method and system

InactiveCN107971650AImprove connection strengthIncrease binding areaWelding/soldering/cutting articlesWelding apparatusLaser cuttingEngineering

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

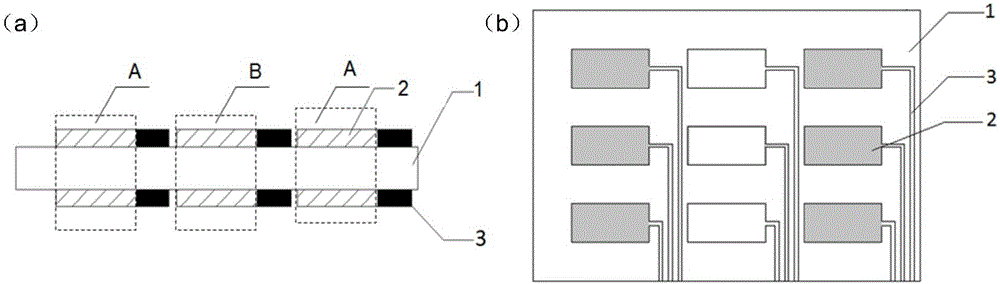

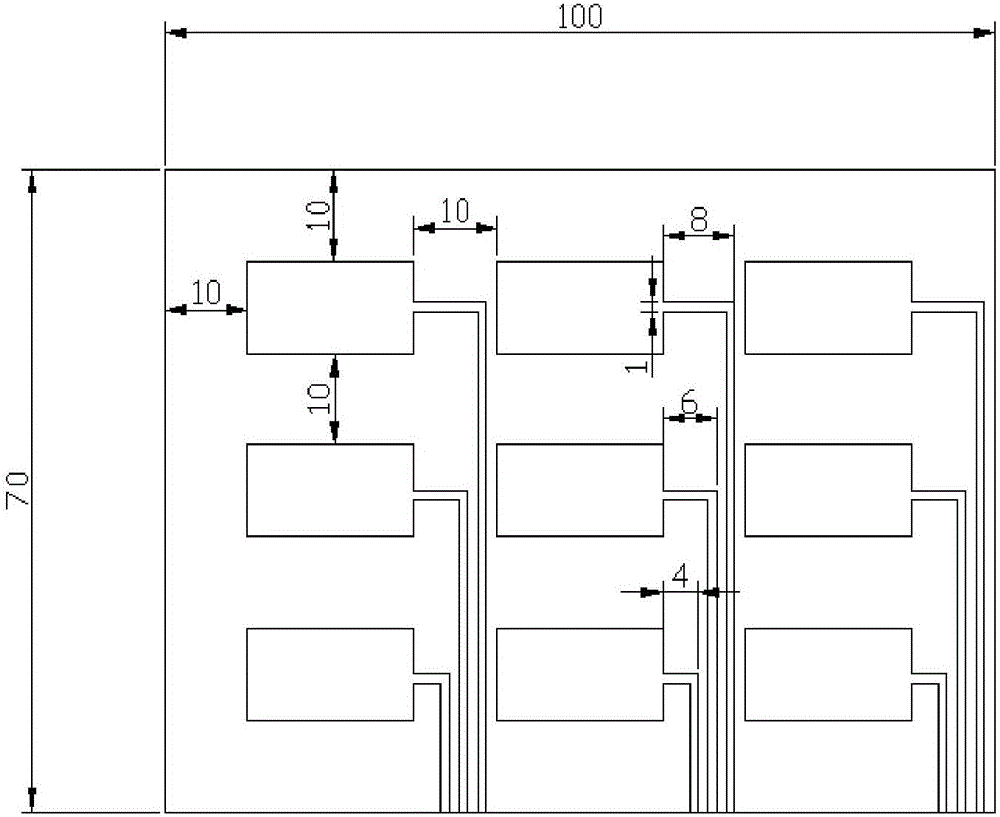

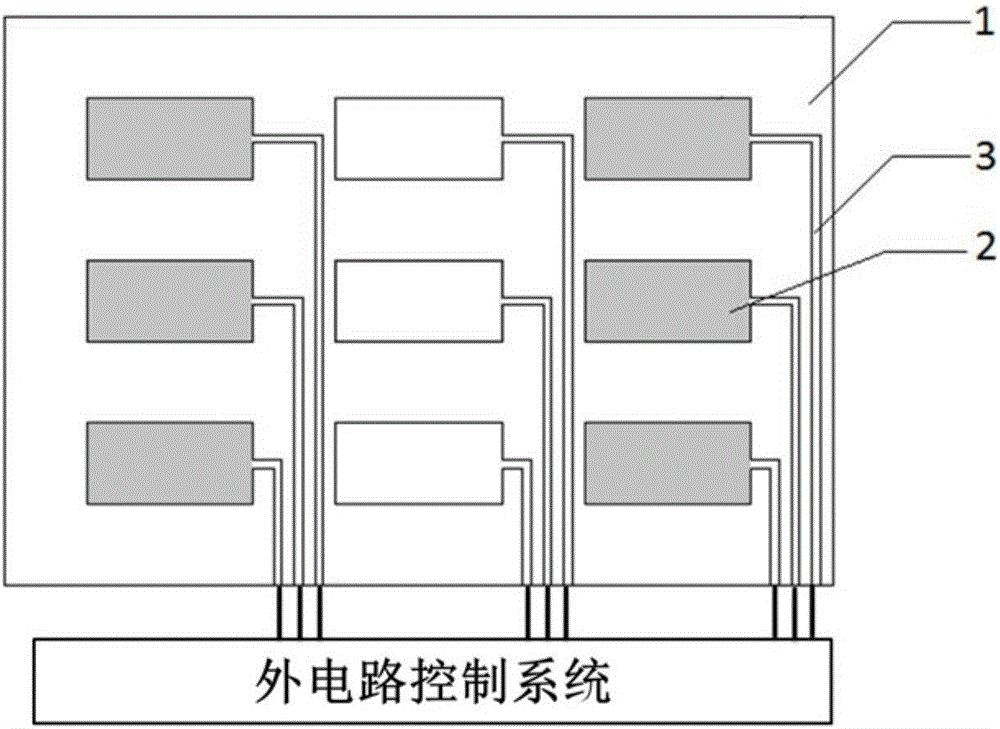

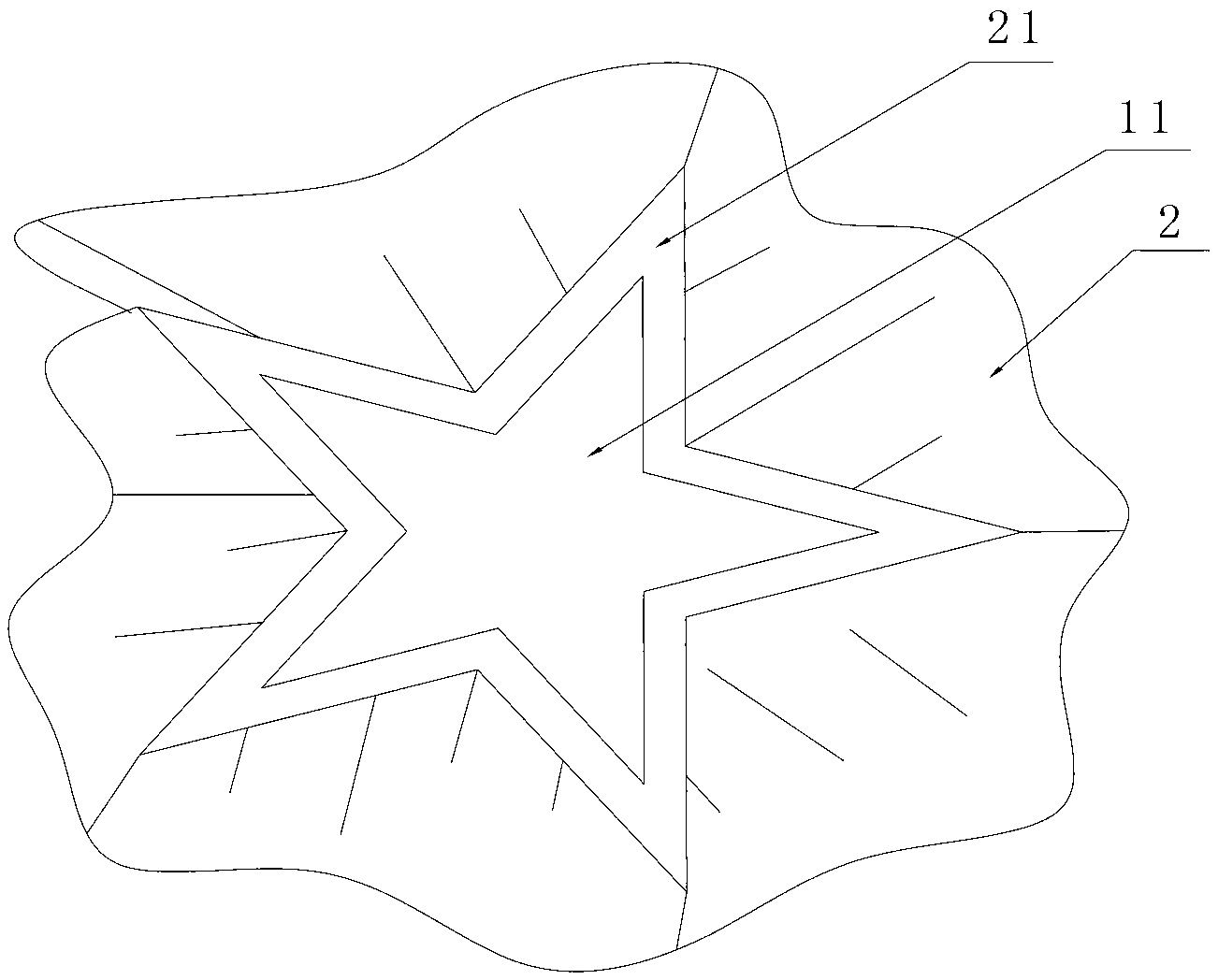

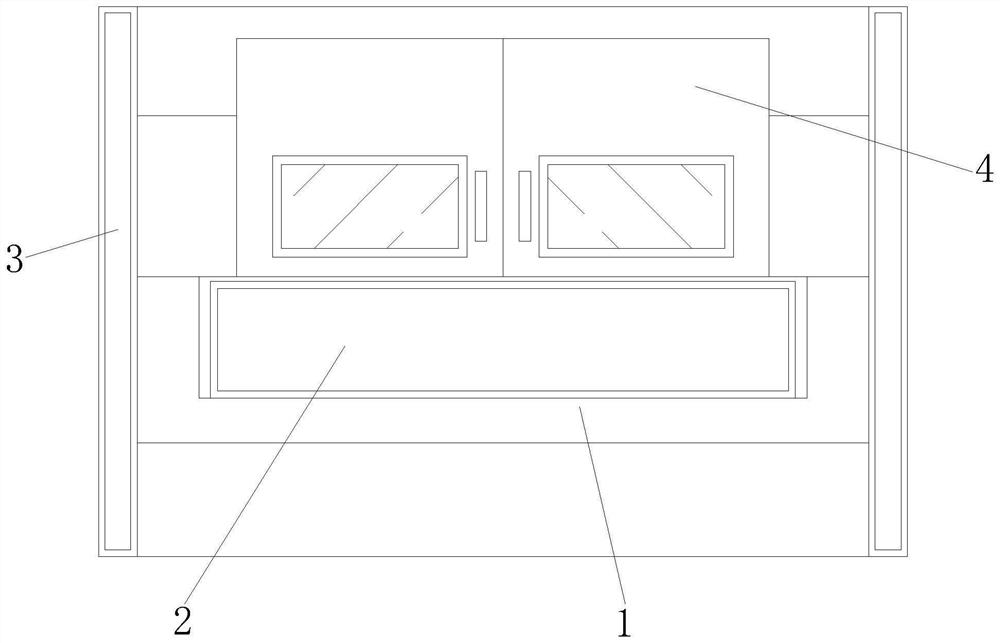

Display panel mother board, display panel and manufacturing method of display panel

ActiveCN109860208AEffective protectionImprove production yieldSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLaser cutting

The invention provides a display panel mother board, a display panel and a manufacturing method of the display panel. The display panel mother board comprises at least one display unit and a cuttablearea connected to the edge of the display unit. The display unit has a display area and a non-display area connected between the display area and the cuttable area. The cuttable area is provided witha cutting position. The display panel mother board comprises a substrate and a device layer arranged on the substrate, and the device layer comprises a TFT device area corresponding to the display area and an inorganic film layer wrapping the TFT device area. The inorganic film layer covers the non-display area and the cuttable area, hollowed-out patterns are arranged in the non-display area in the thickness direction of the non-display area in an up-and-down penetrating mode, and a groove which is not arranged in a penetrating mode is formed at a cutting position, thereby effectively avoidingthe heat radiation influence of laser cutting, and improving the production yield.

Owner:YUNGU GUAN TECH CO LTD

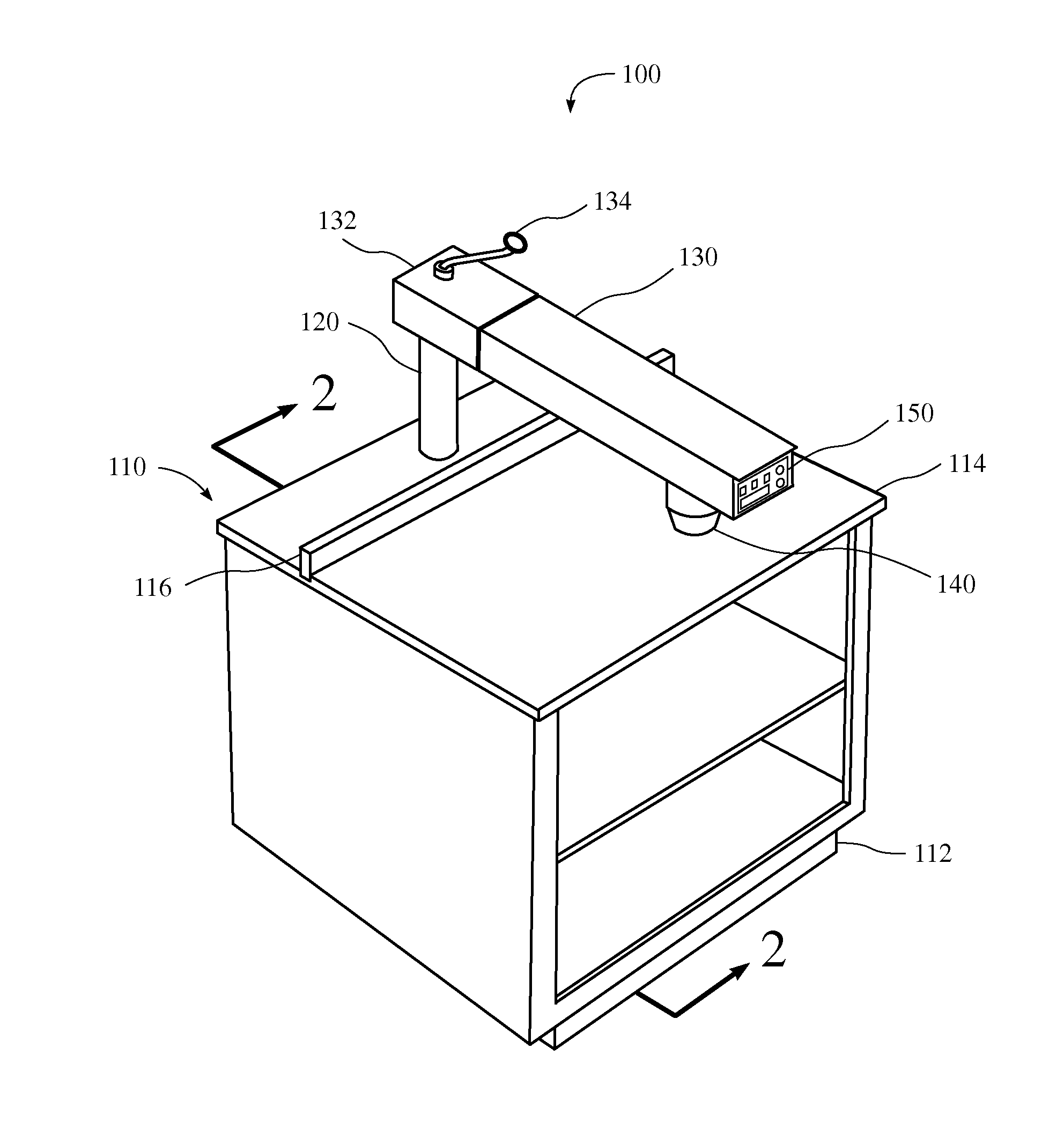

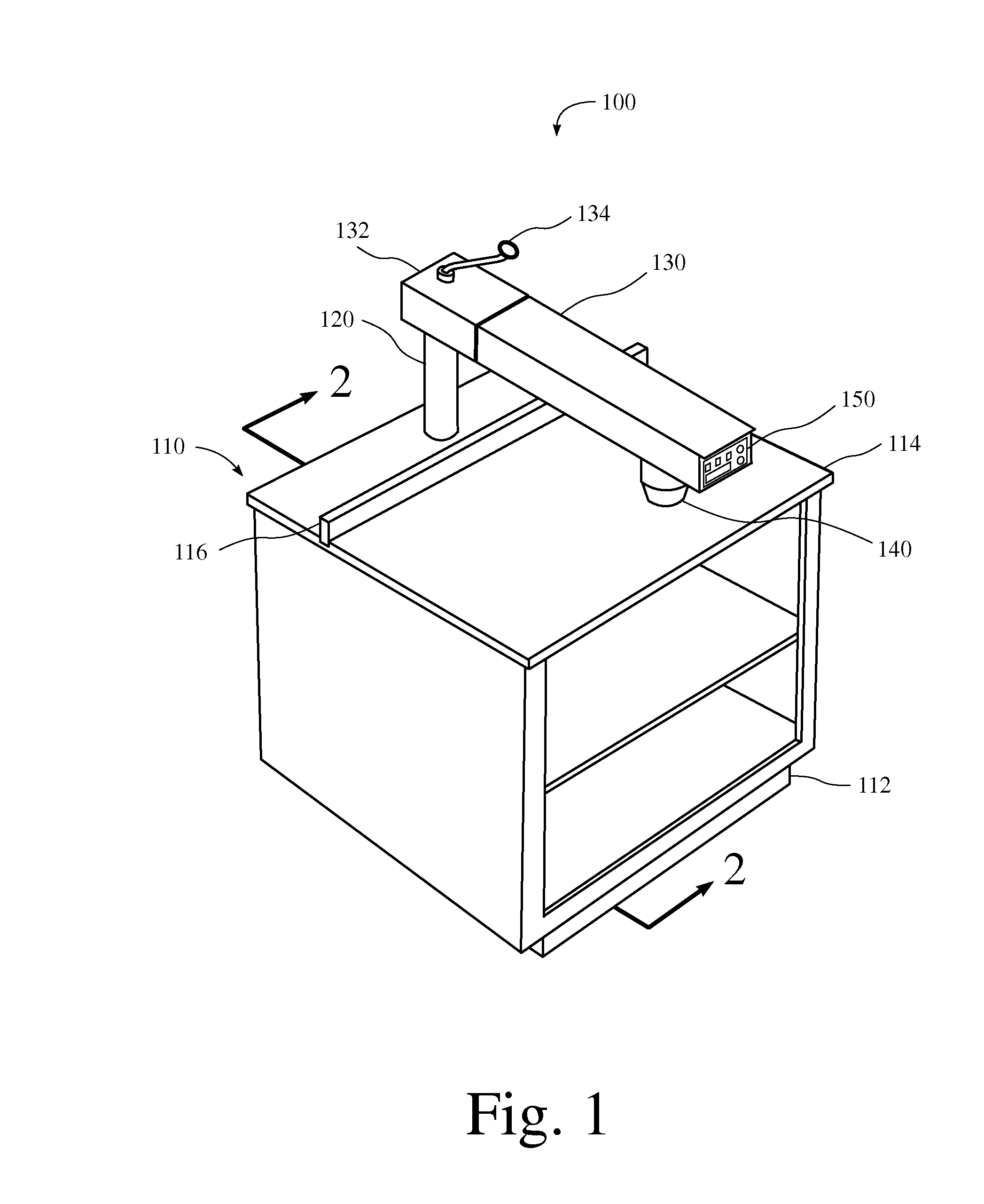

Laser Woodworking Machine

InactiveUS20120037274A1Reasonable space requirementImprove the security environmentWooden sticks manufactureMulti-purpose machinesEngineeringLaser cutting

Owner:HENDERSON CHARLES L

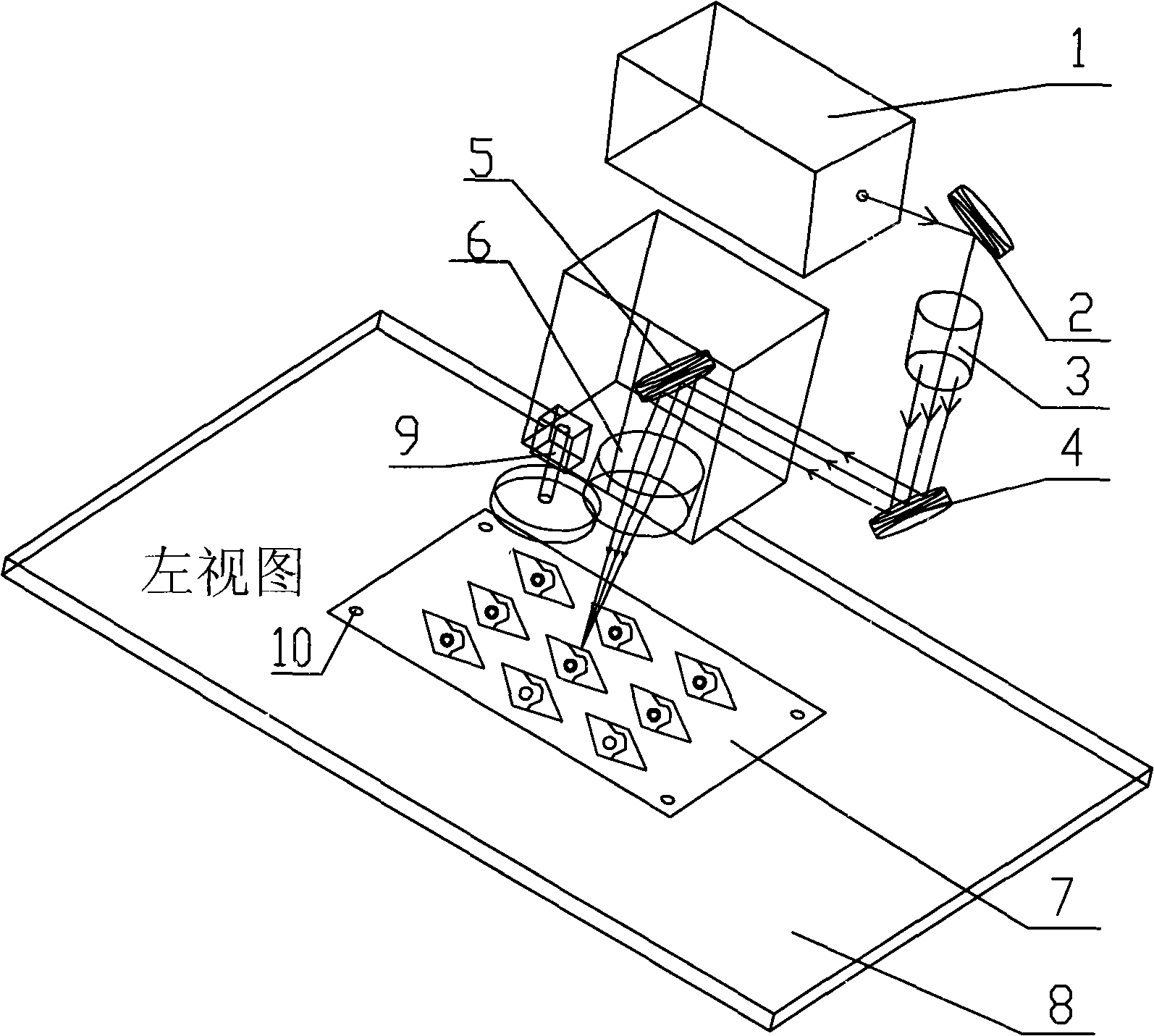

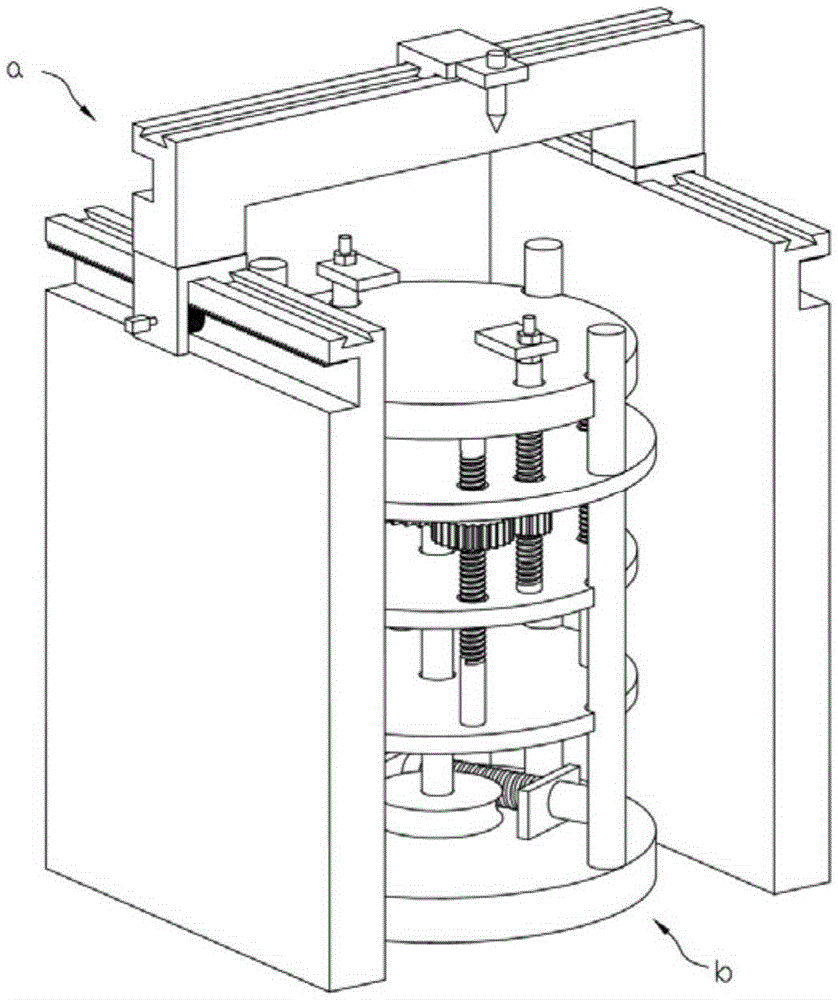

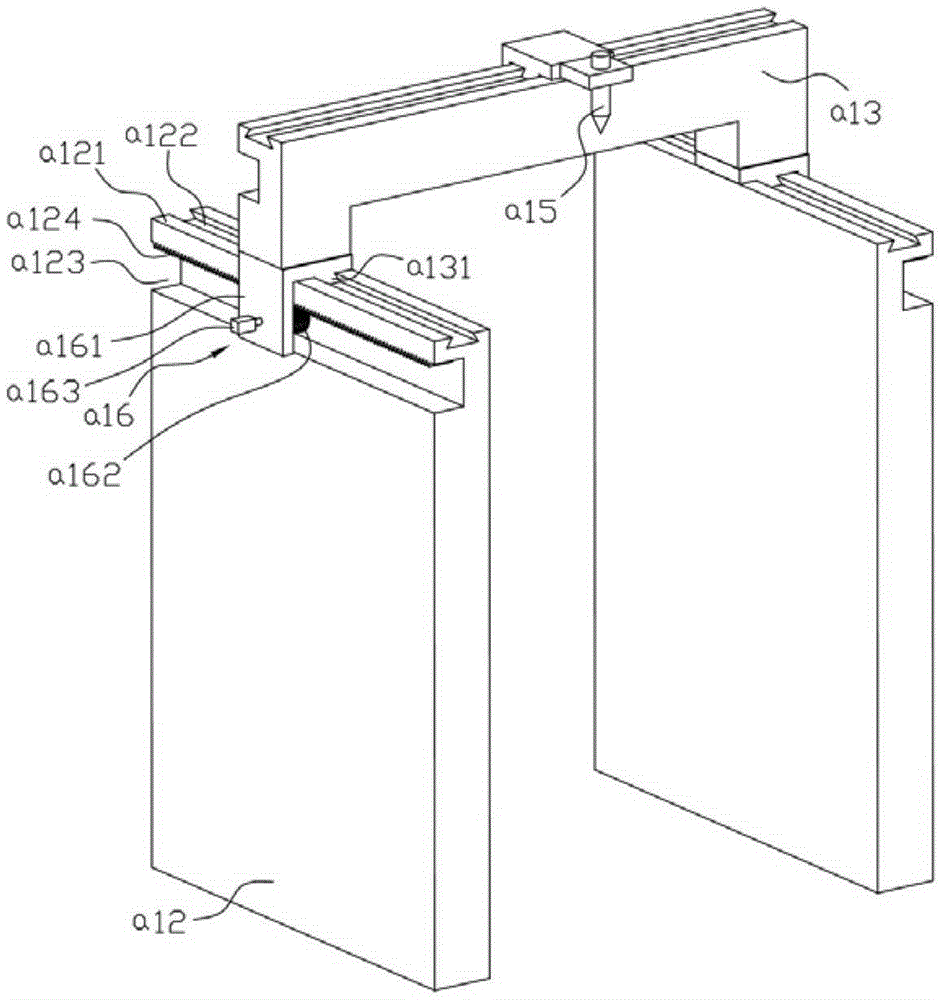

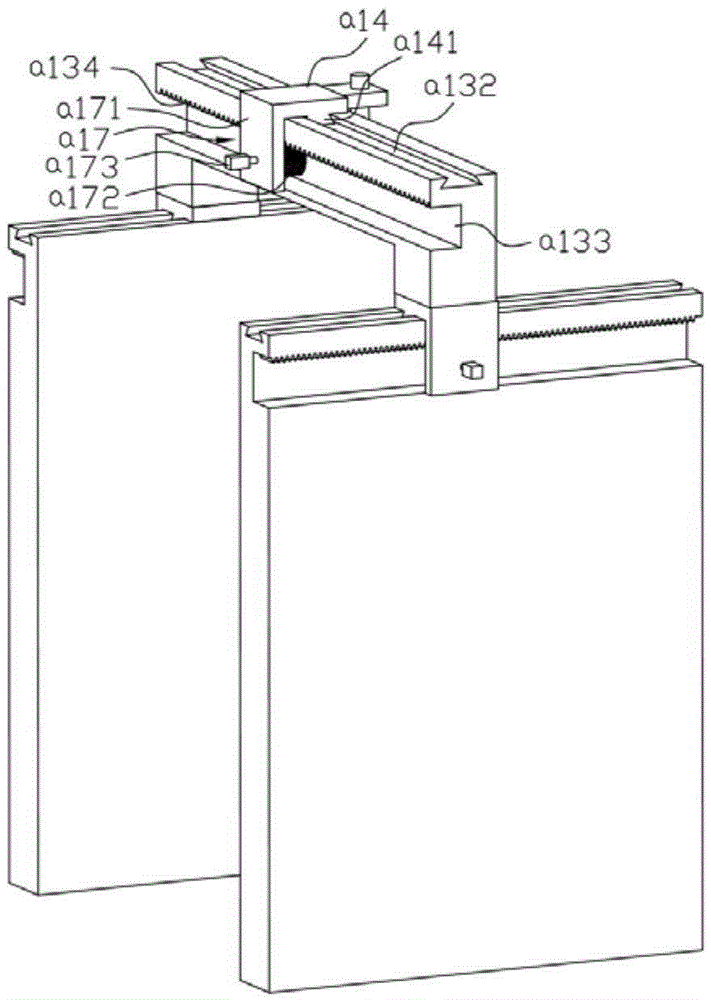

Template laser cutting equipment provided with template fixture

InactiveCN105414750AWelding/cutting auxillary devicesAuxillary welding devicesLaser cuttingLaser beams

Owner:DONGGUAN QINZHI IND DESIGN CO LTD

Method for applique on fabric

InactiveCN103266512AFast bondingCause sewing inconvenienceTextile decorationLaser cuttingBiomedical engineering

Owner:广州衍才烫花工艺有限公司

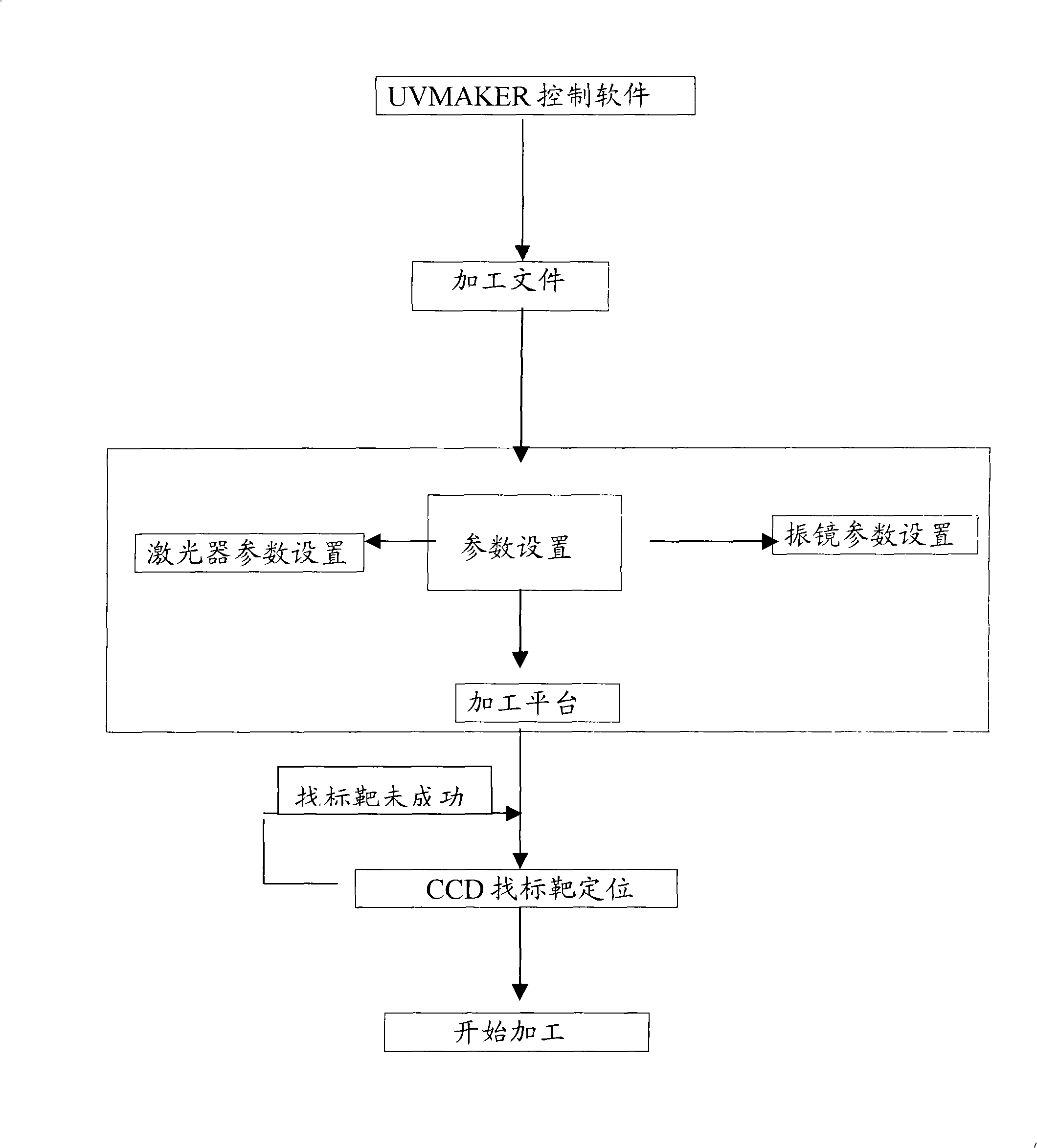

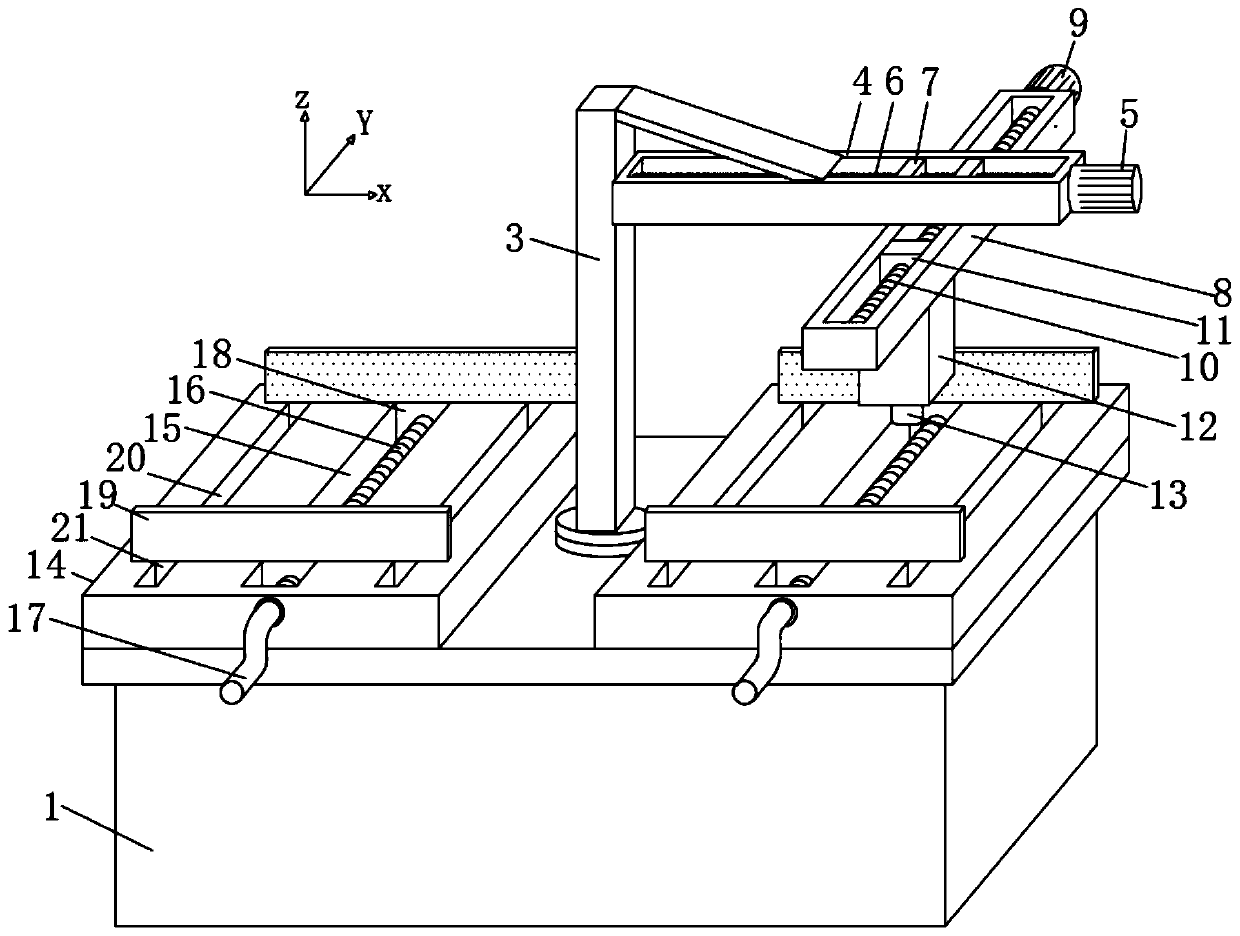

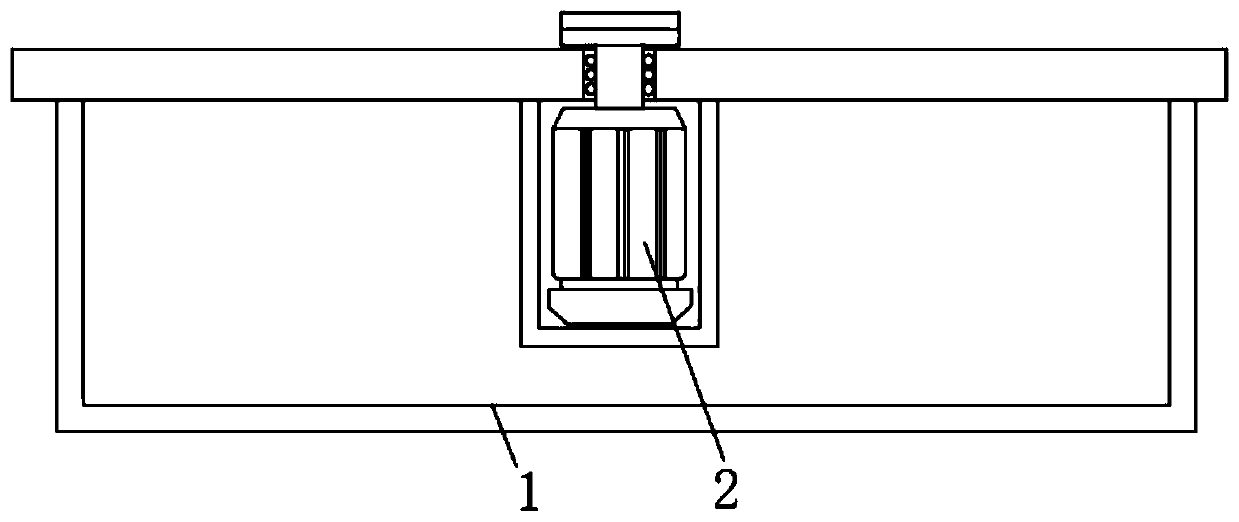

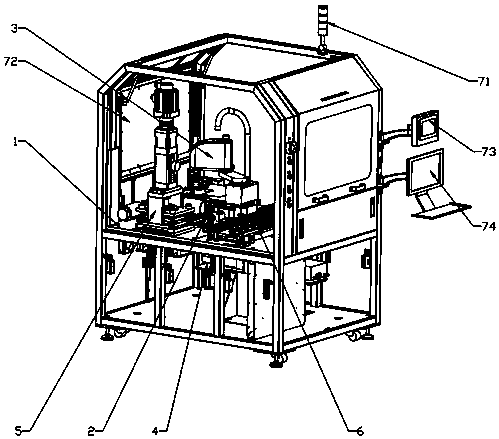

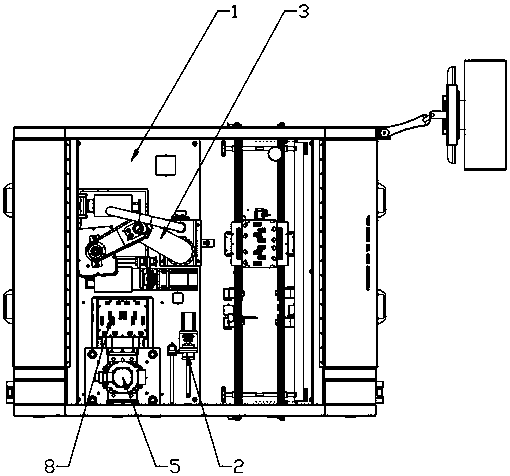

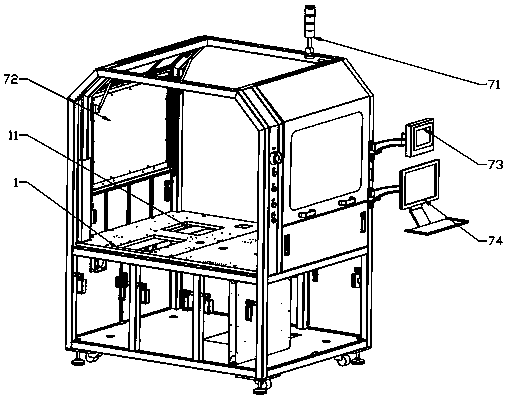

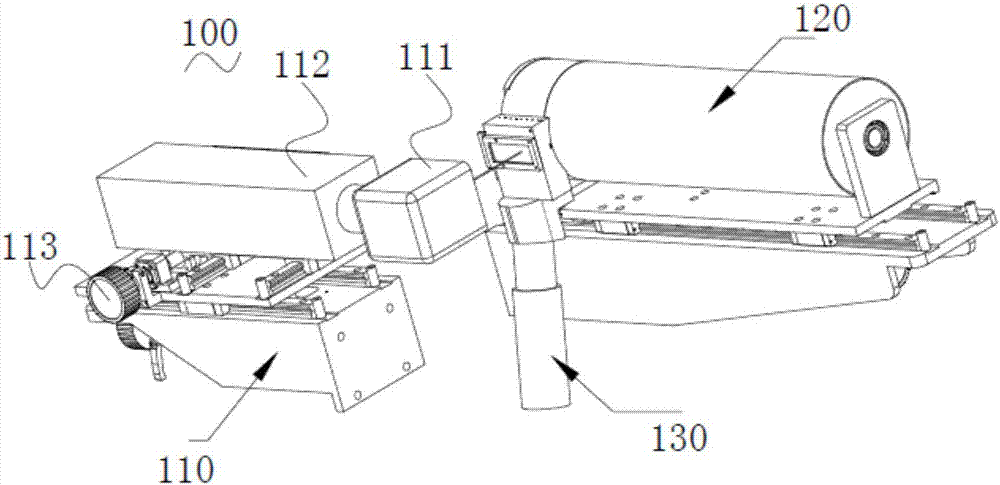

Fiber laser cutting equipment

Owner:NINGBO HANTU MACHINERY DESIGN CO LTD

Laser cutting machine for precision ceramic

InactiveCN110125537AAvoid driftingImprove work efficiencyLaser beam welding apparatusMotor driveLaser cutting

Owner:SUZHOU GENFU MACHINERY SCI & TECH

Automatic circuit board film pasting machine

PendingCN107645845ARealize automatic glue sticking film workGreat practicabilityNon-metallic protective coating applicationProduction lineAdhesive

Owner:深圳市芬能自动化设备有限公司

Anti-spatter laser die-cutting device and method

PendingCN107350638AQuality improvementPrevent adhesionLaser beam welding apparatusEngineeringLaser cutting

Owner:GUANGDONG YI XINFENG INTELLIGENT EQUIP CO LTD

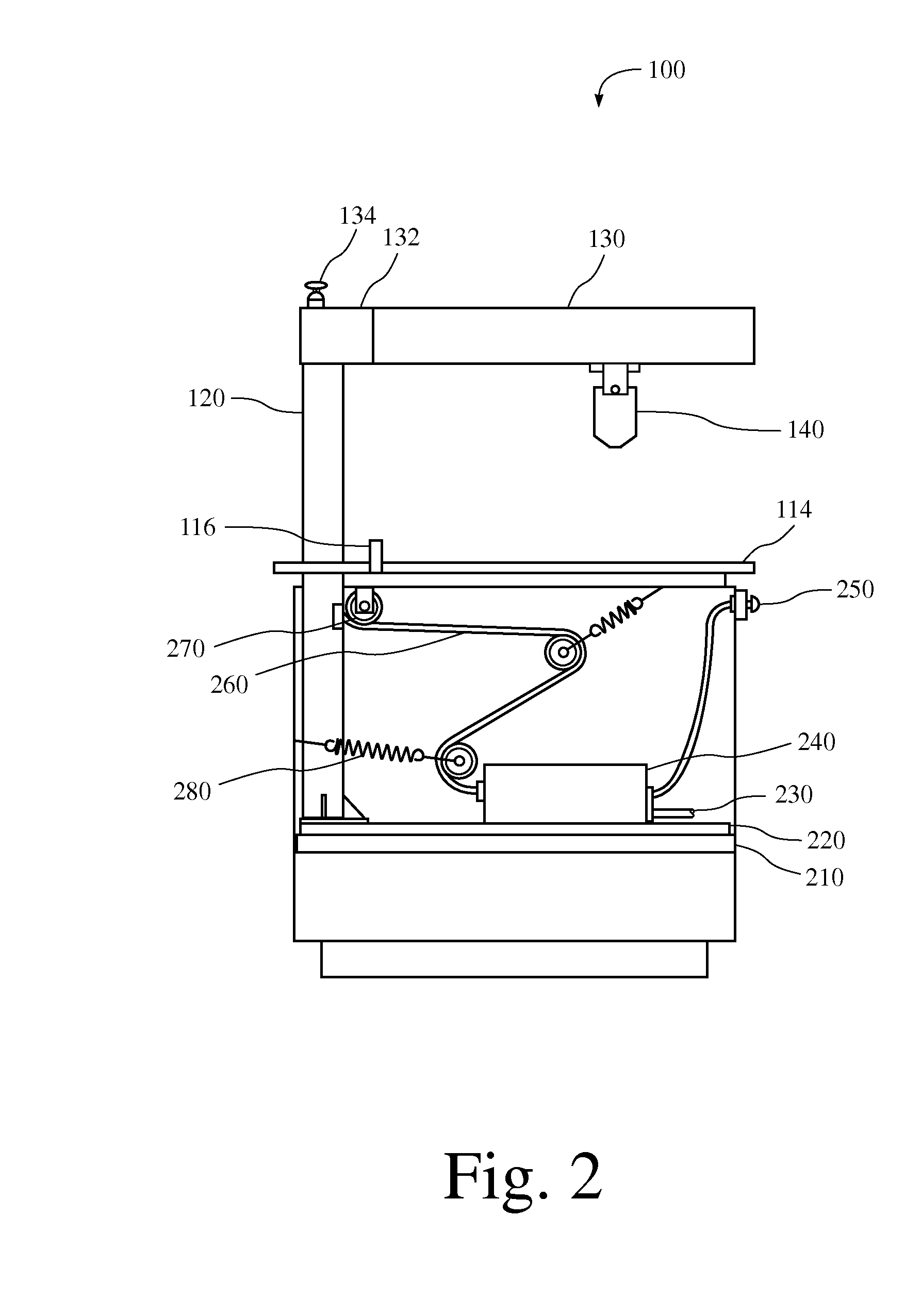

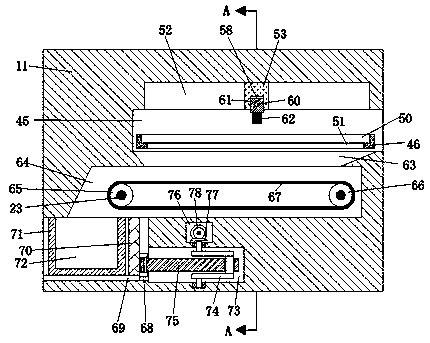

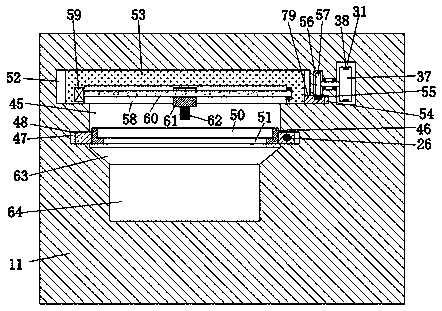

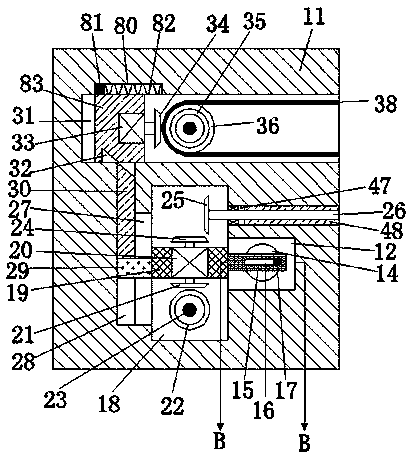

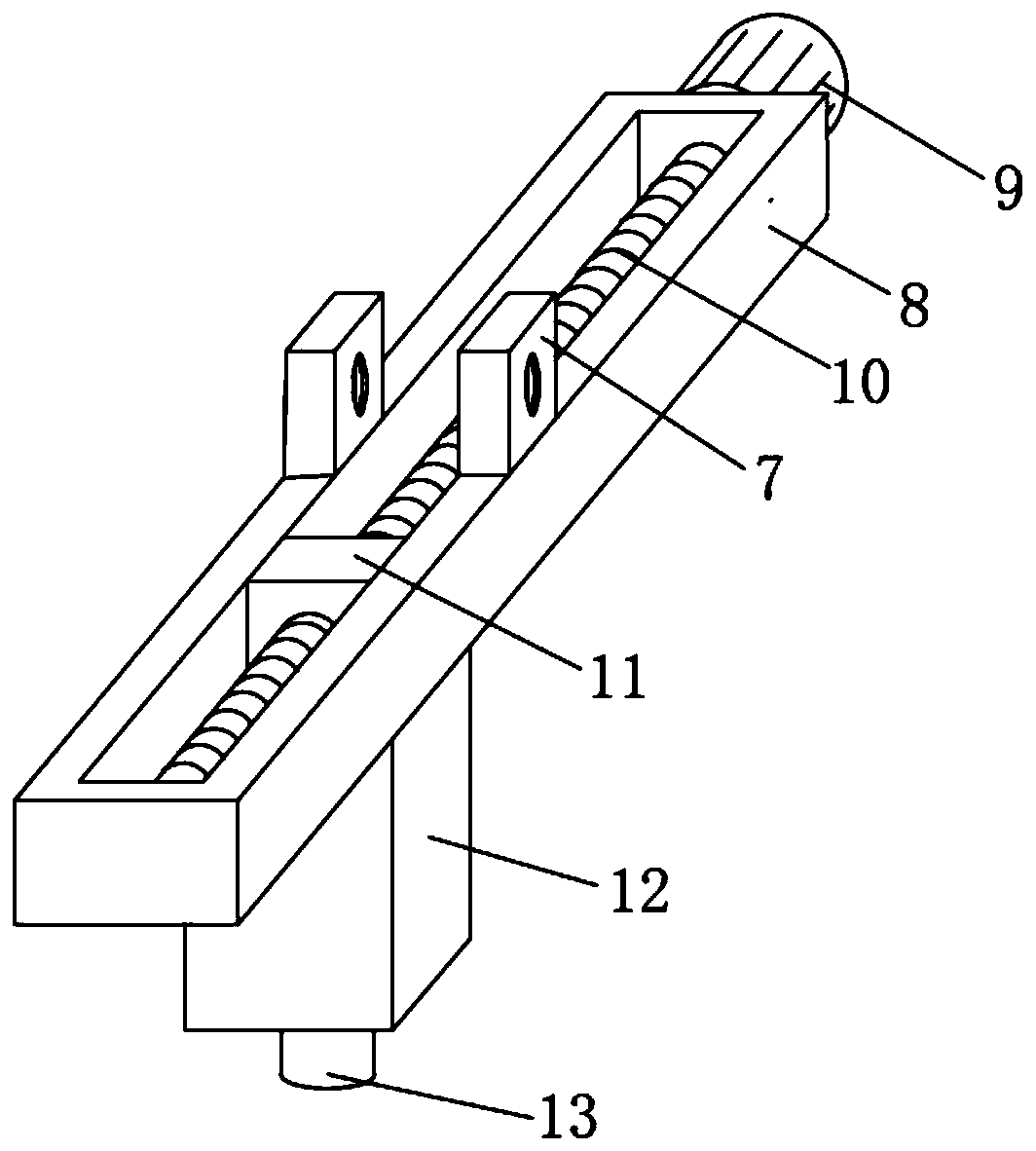

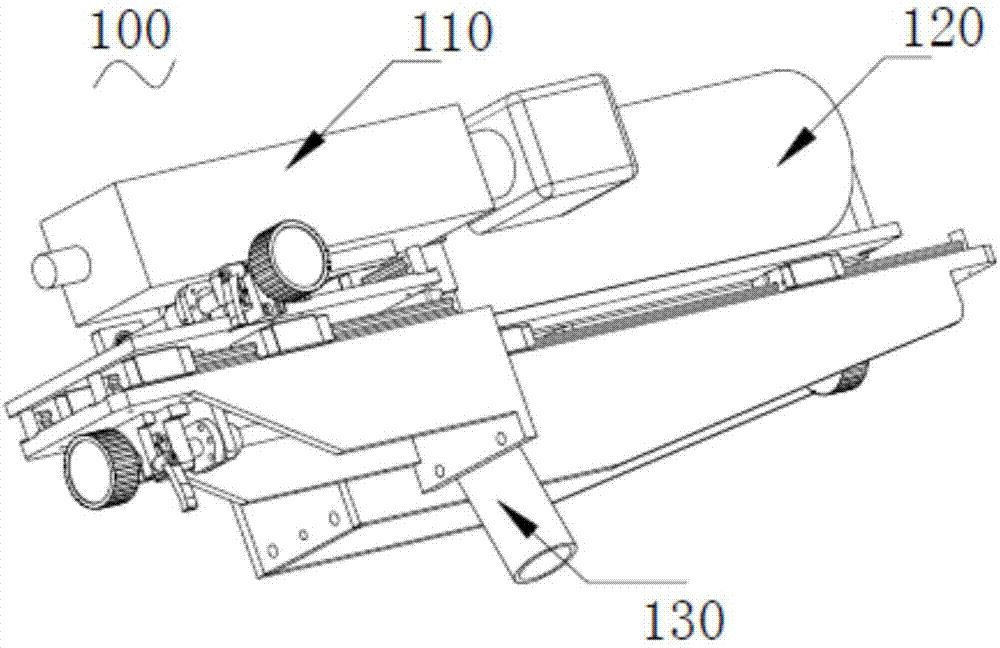

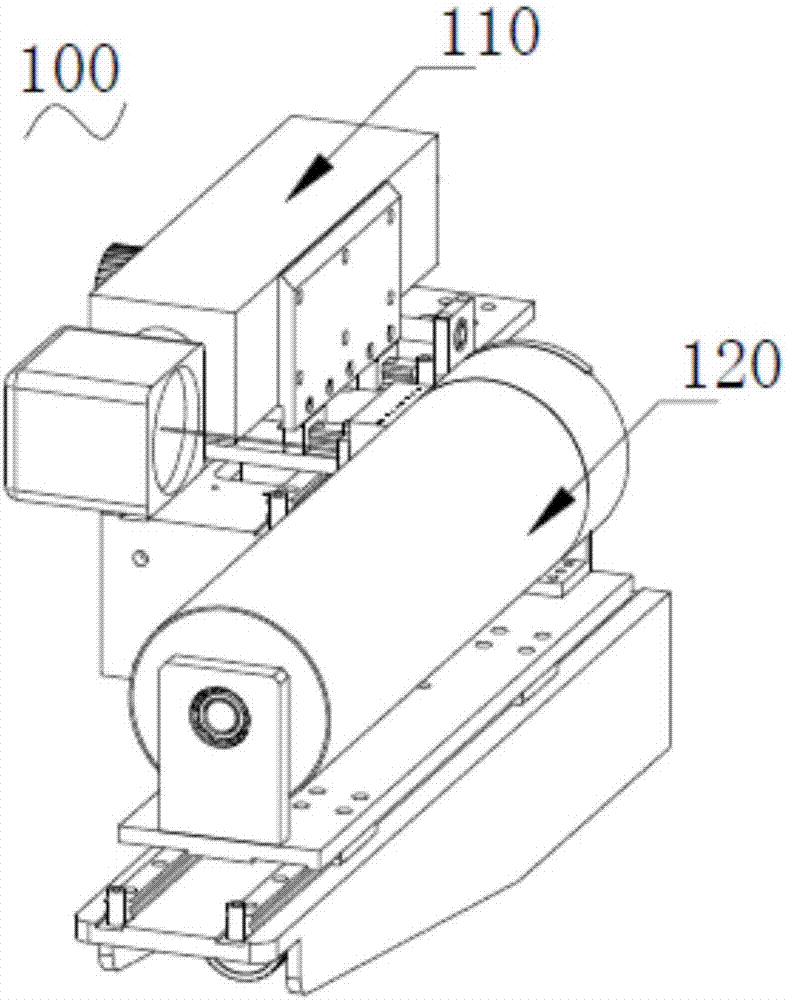

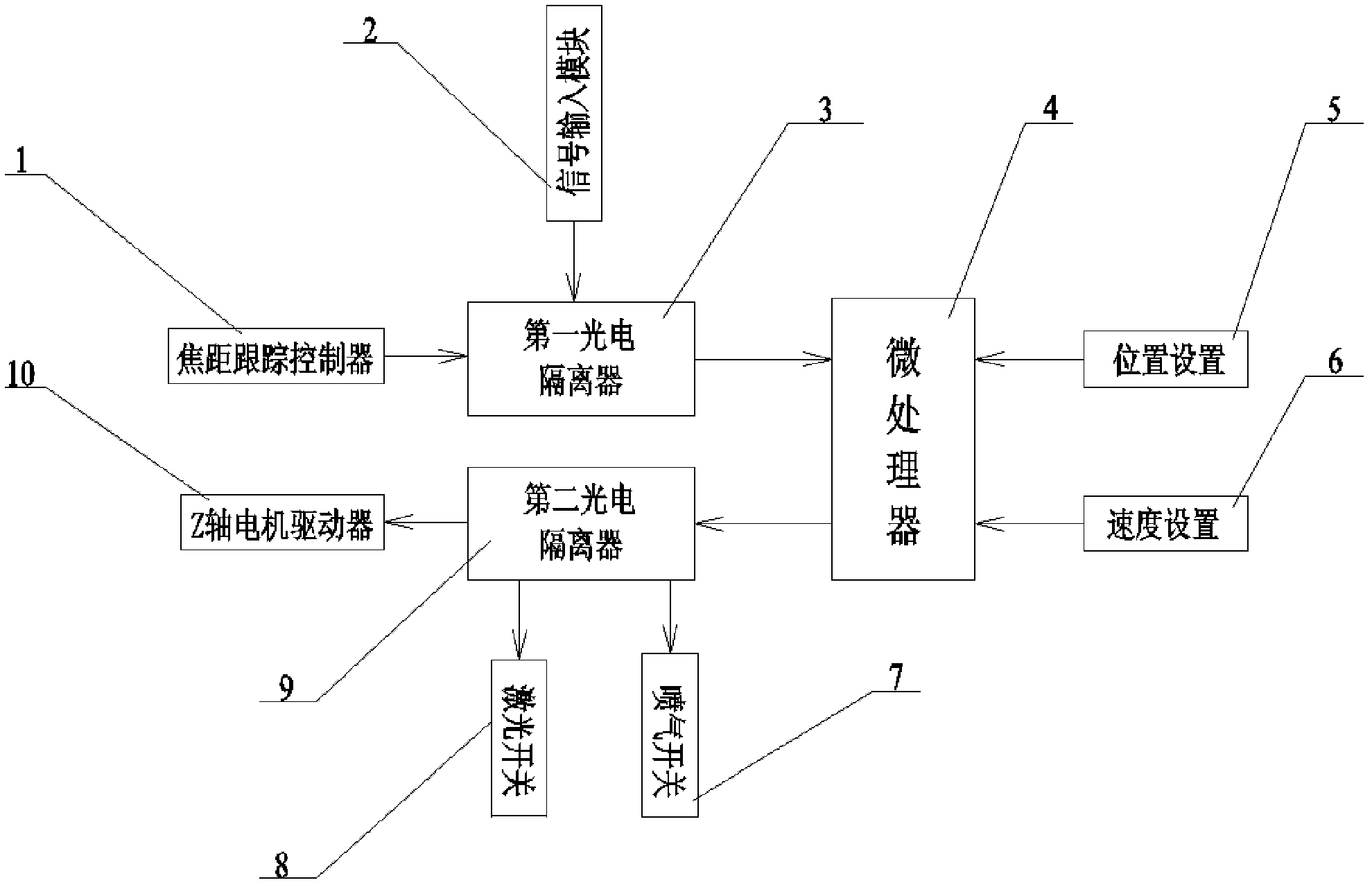

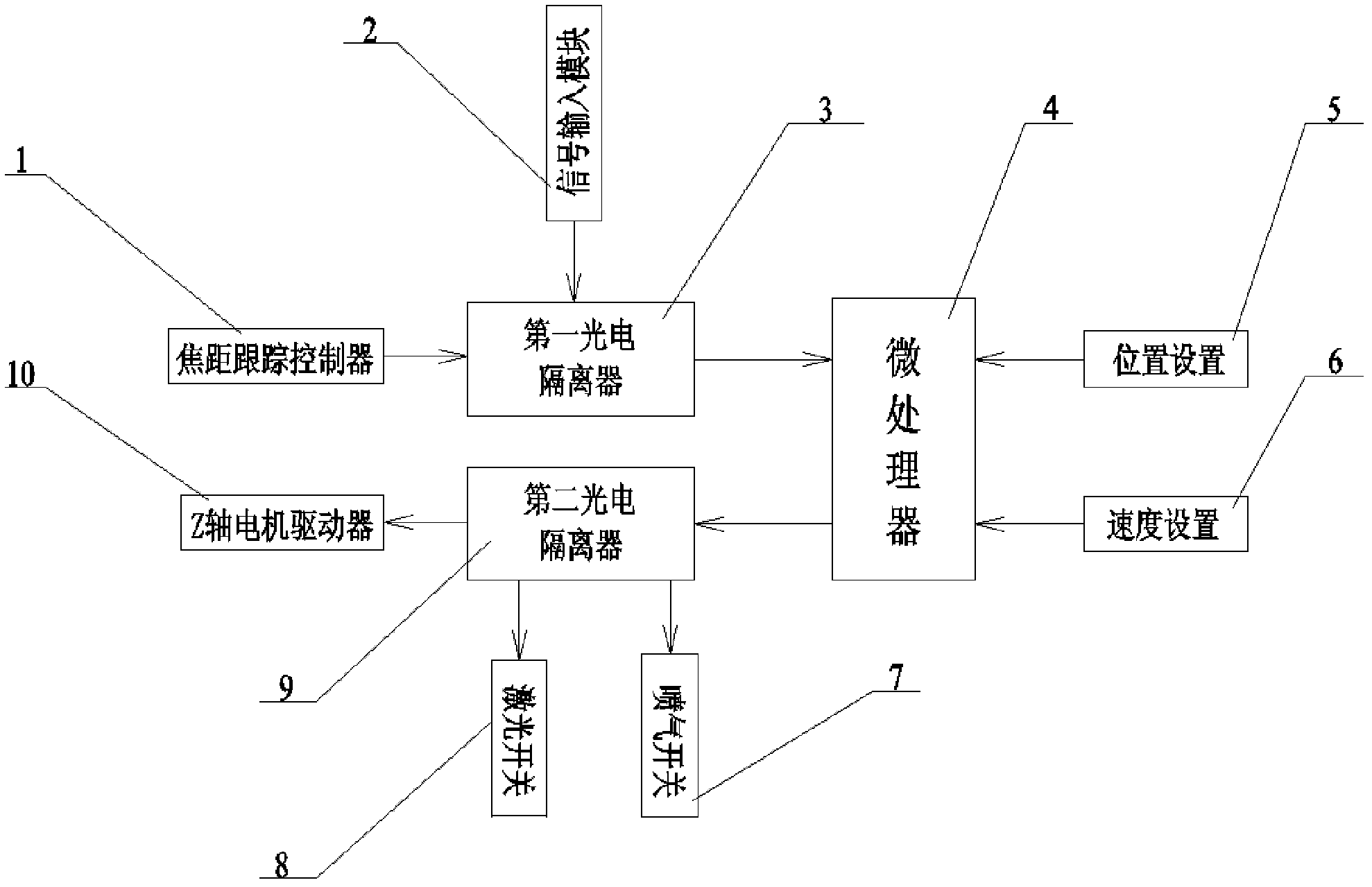

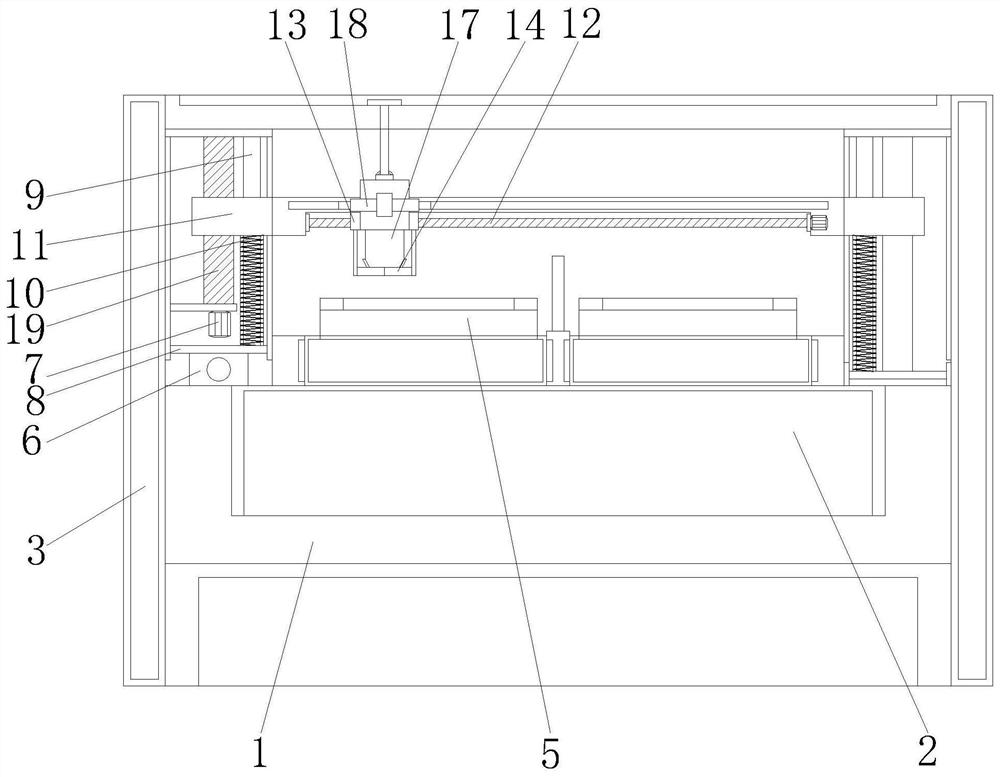

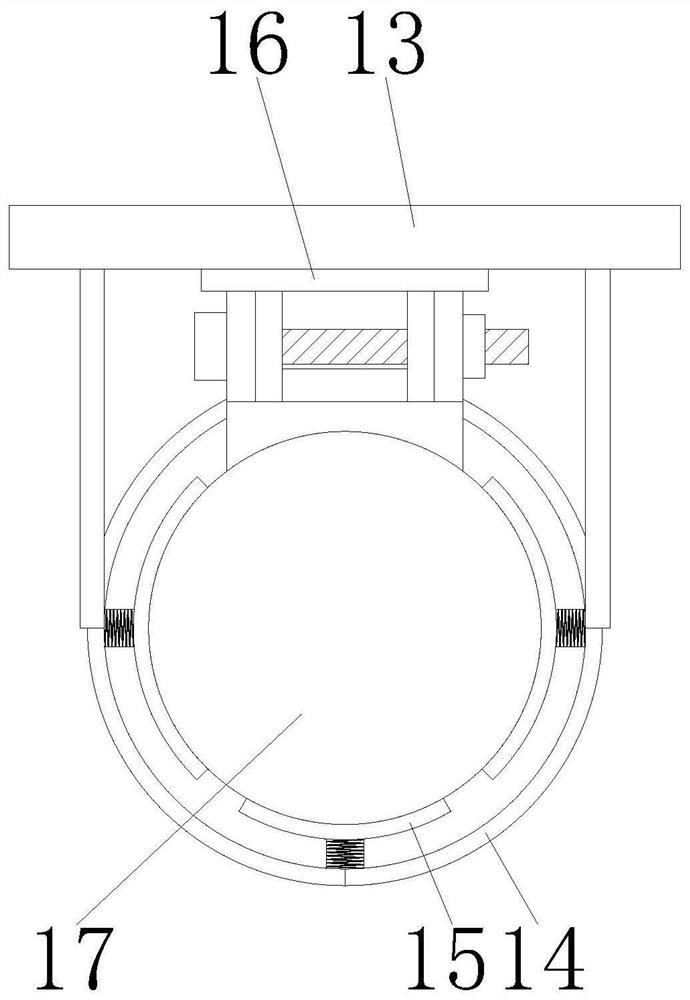

Z-shaft independent controller for planar laser cutting machine

InactiveCN102205461ASimple structureHigh movement reliabilityLaser beam welding apparatusControl systemElectric machinery

Owner:江苏亚威创科源激光装备有限公司

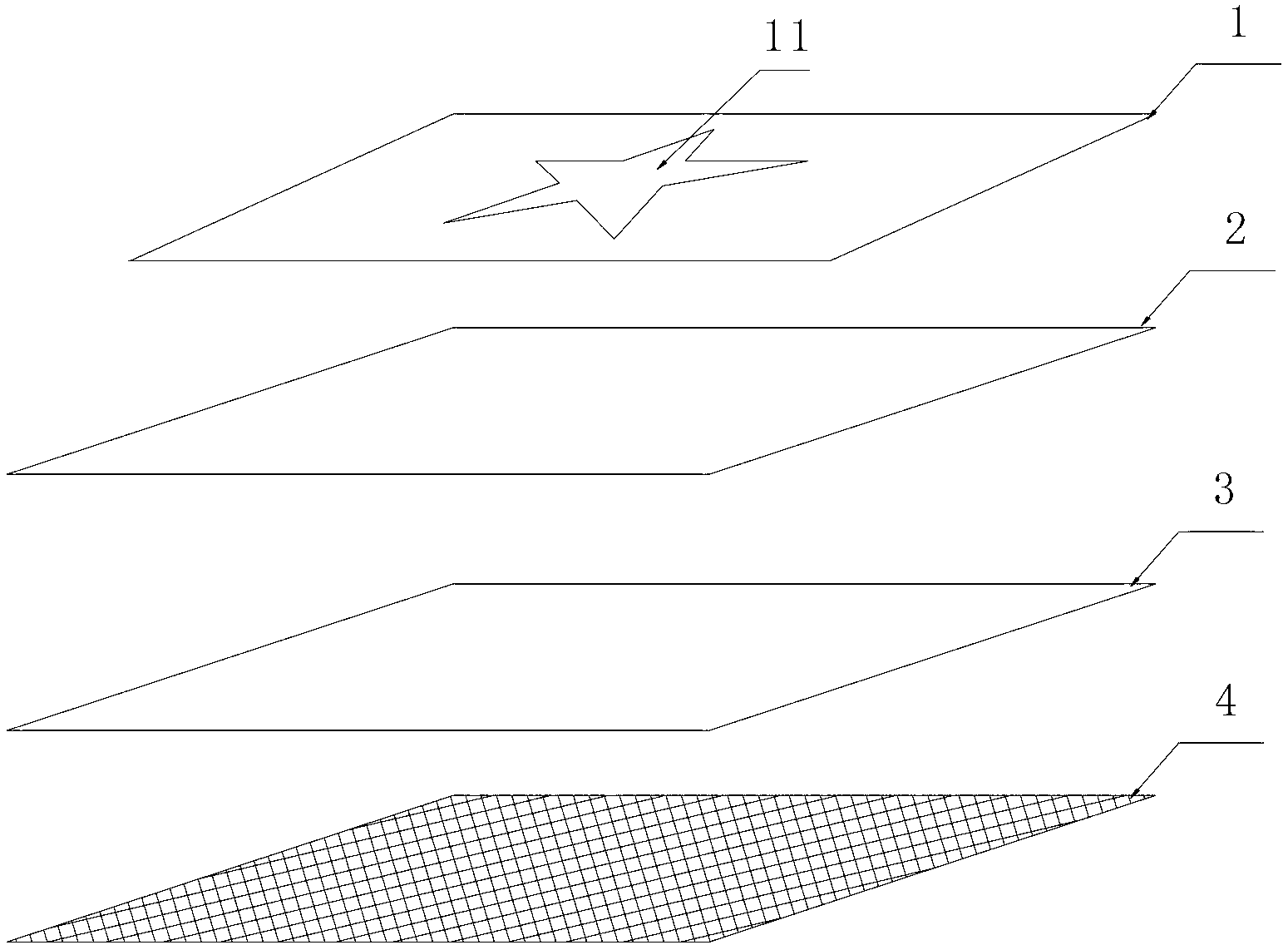

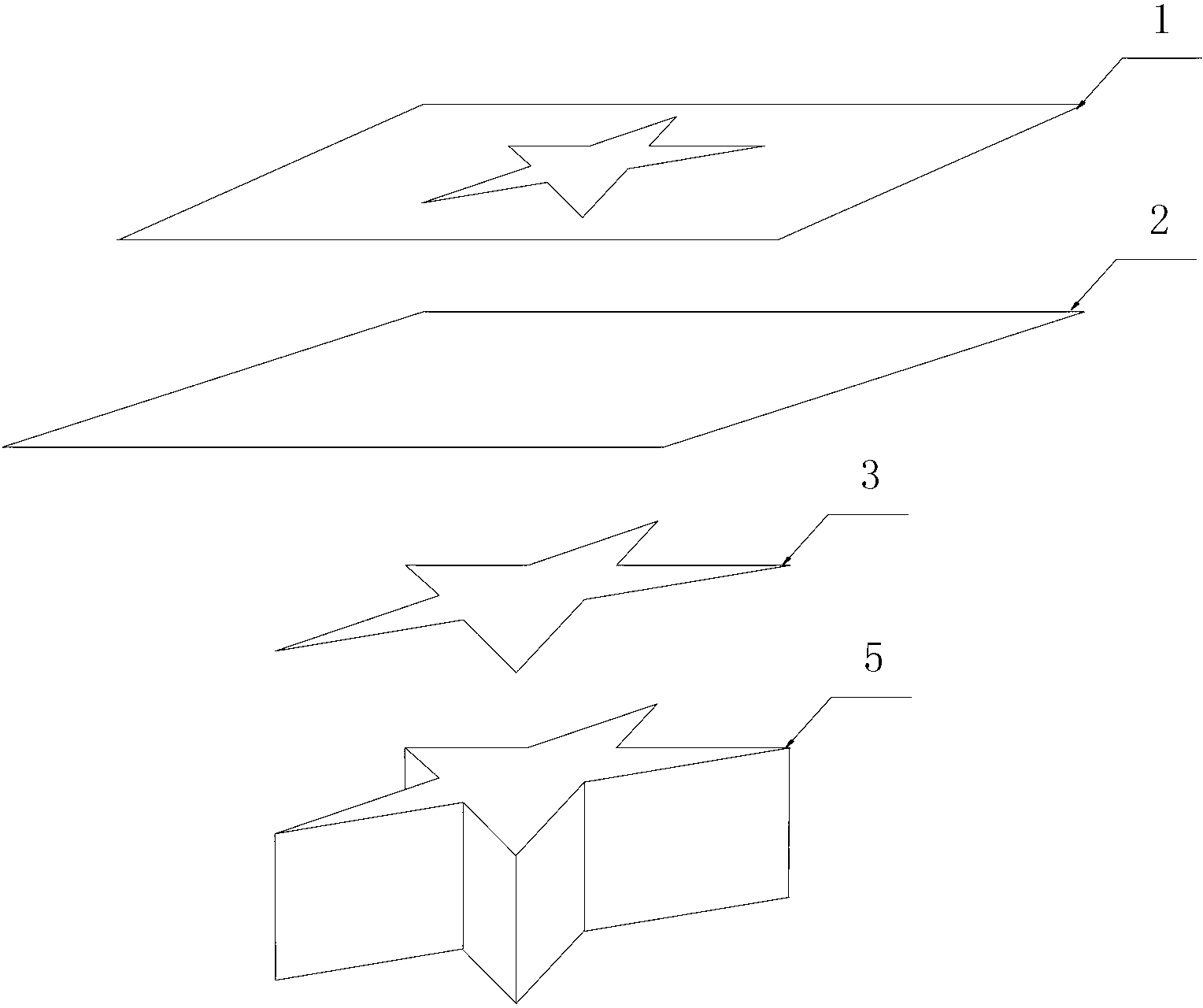

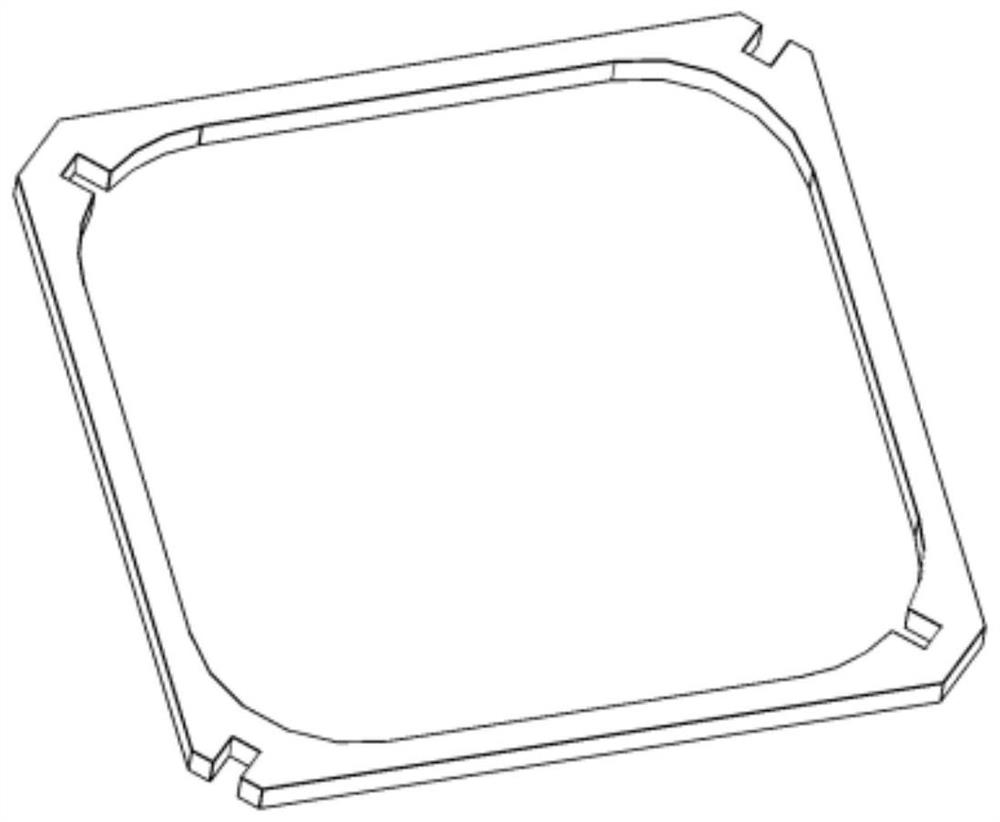

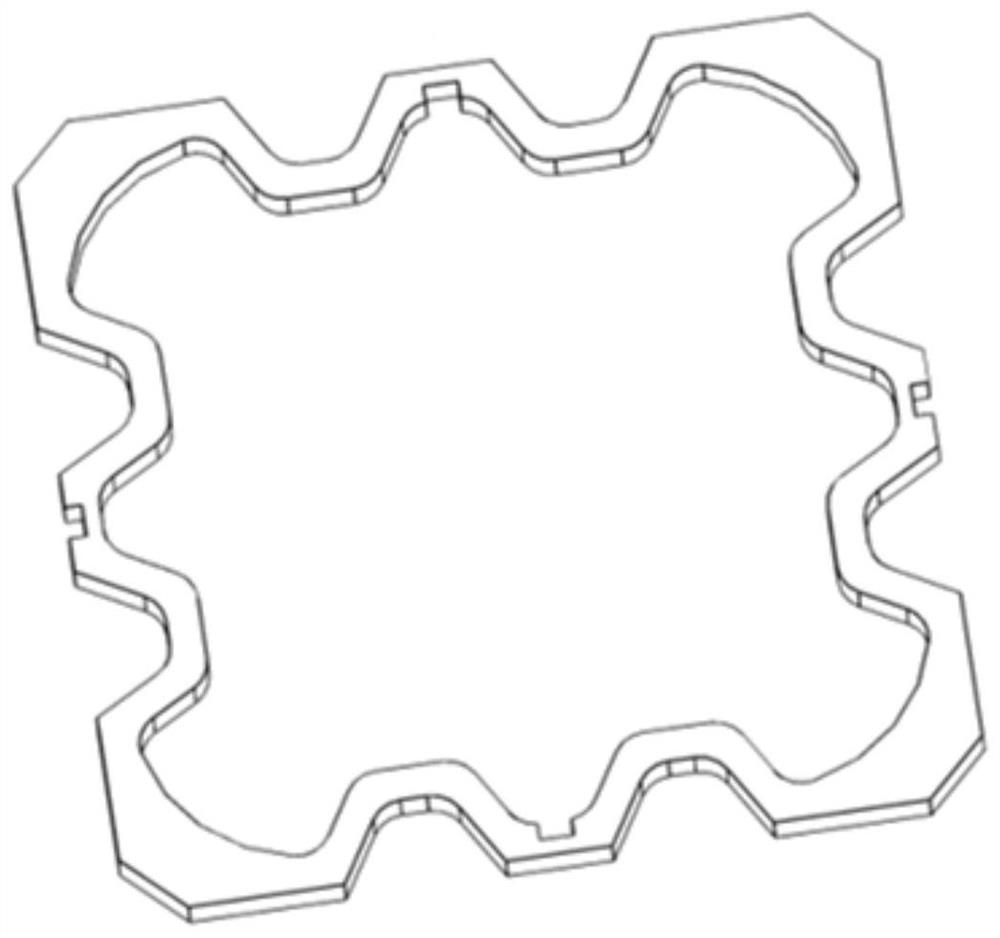

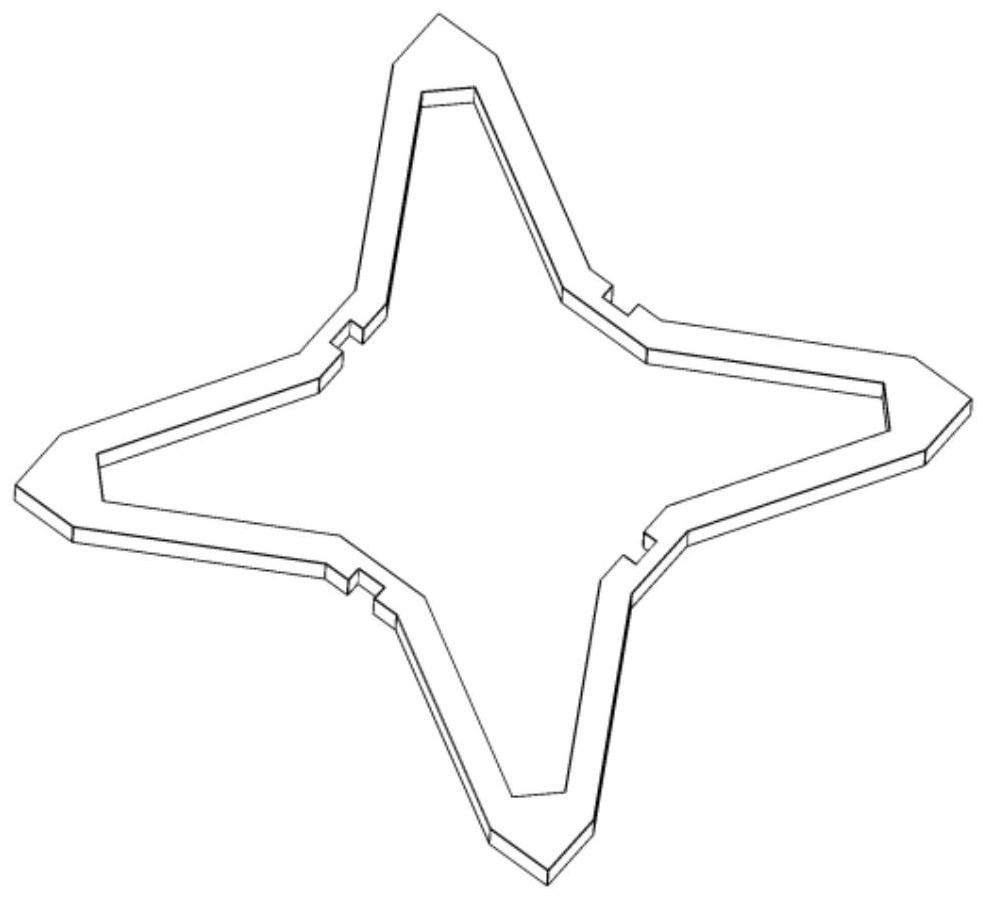

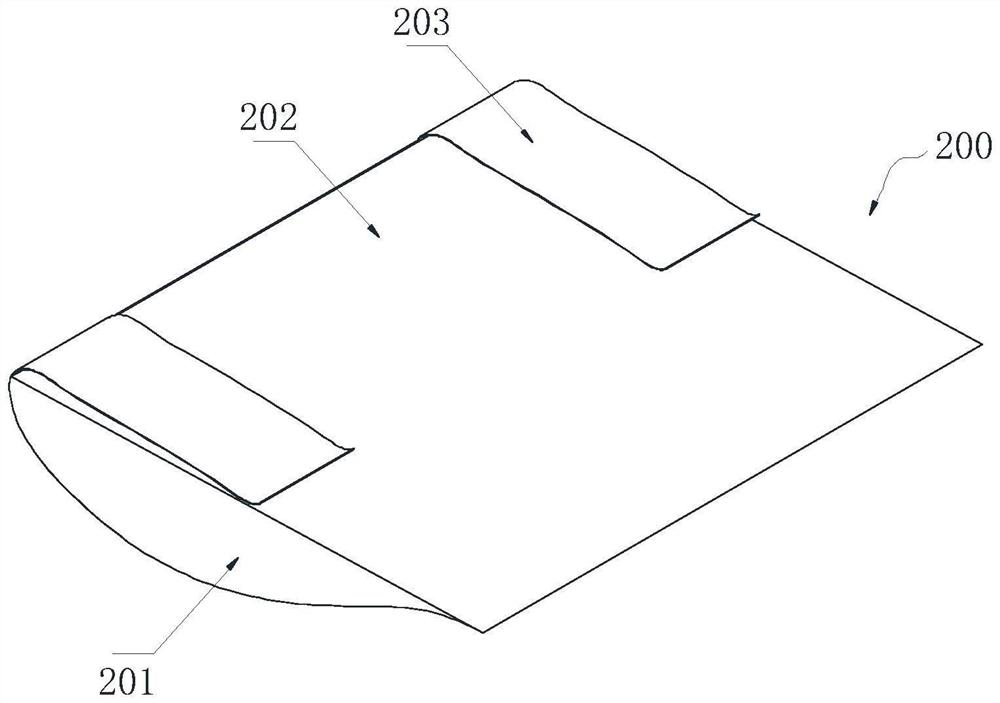

Three-dimensional metamaterial functional component and manufacturing method thereof

ActiveCN114523662ARealize structural deformationSimple structureIncreasing energy efficiencyAdditive manufacturing processesStructural deformationLaser cutting

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Anti-collision device of laser cutting machine

Owner:苏州法那科智能装备有限公司

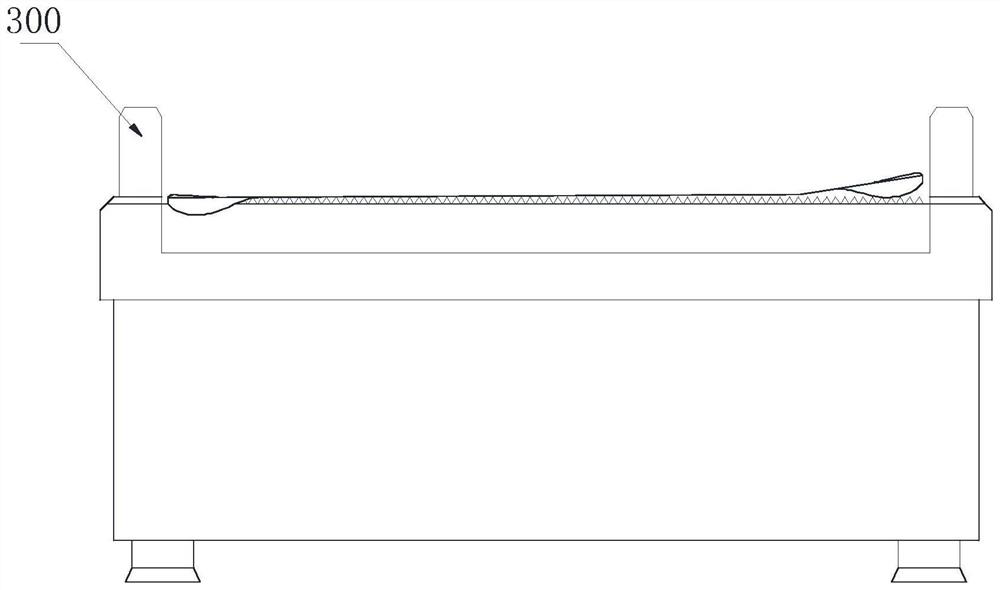

Strip coil laser machining method

ActiveCN113319437ARealize continuous processingImprove processing efficiencyMetal working apparatusLaser beam welding apparatusLaser processingLaser cutting

The invention relates to the field of machining, and discloses a strip coil laser machining method which comprises the steps that the machining contour of a workpiece is obtained; a path combination is planned according to the machining contour, wherein the path combination comprises at least two cutting paths; laser cutting parameters are calculated according to the conveying speed and path combination of a strip coil; and a laser cutting head is controlled to cut the strip coil according to the laser cutting parameters so as to obtain the workpiece cut and separated from the strip coil. According to the strip coil laser machining method, the path combination is flexibly planned based on the machining contour, then the laser cutting parameters are accurately calculated, a prefabricated cutting mold is not needed, continuous machining of the strip coil can be achieved, the machining efficiency of a metal plate is improved, and the production cost of the metal plate is reduced.

Owner:HANS LASER TECH IND GRP CO LTD +1

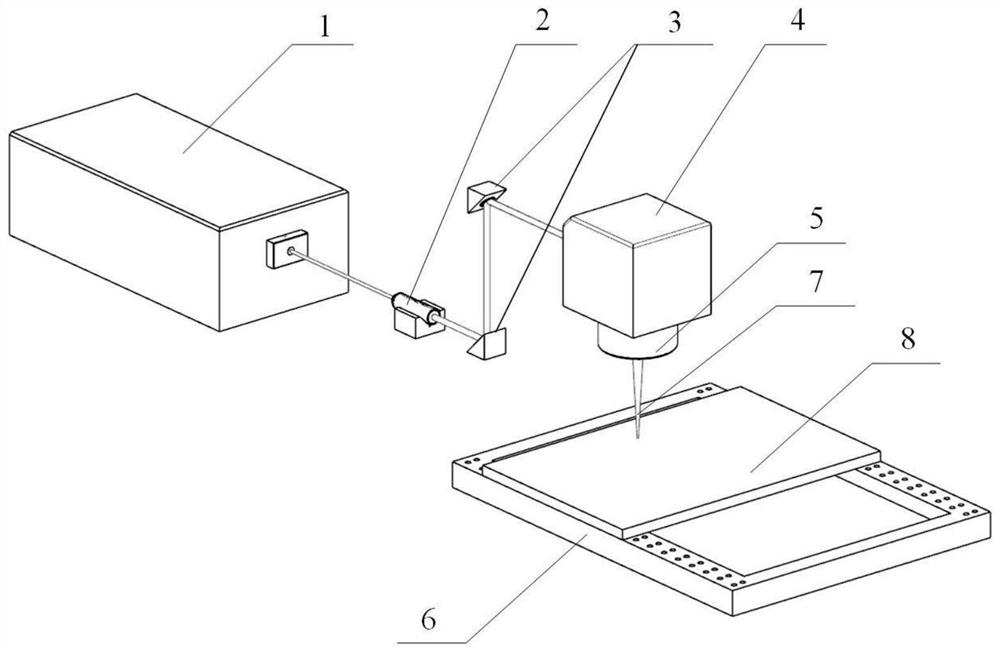

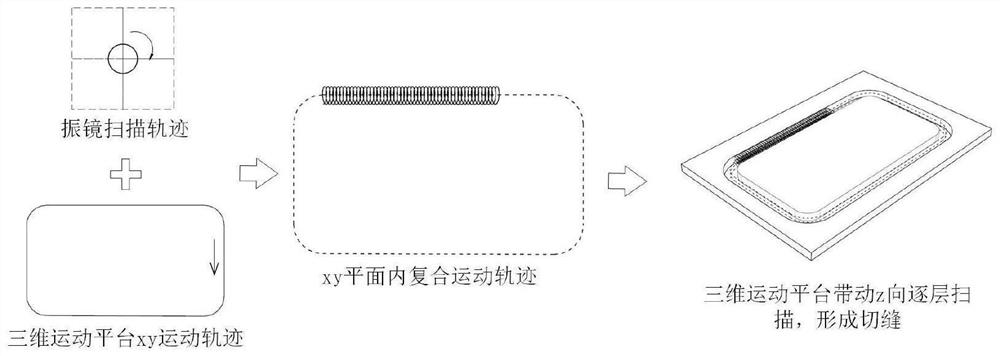

Large-breadth laser hole cutting method for glass

PendingCN114105466AIncrease the number of axesRich clampingGlass severing apparatusLaser processingLaser scanning

Owner:HUAZHONG UNIV OF SCI & TECH

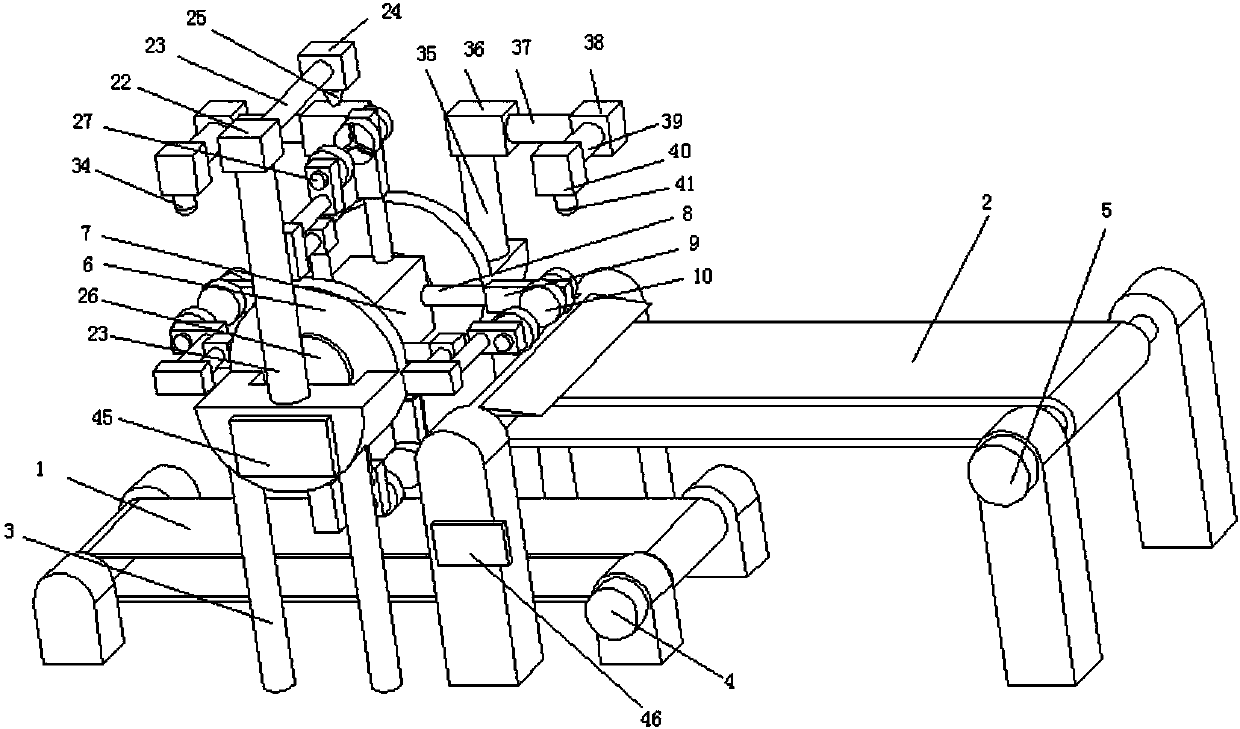

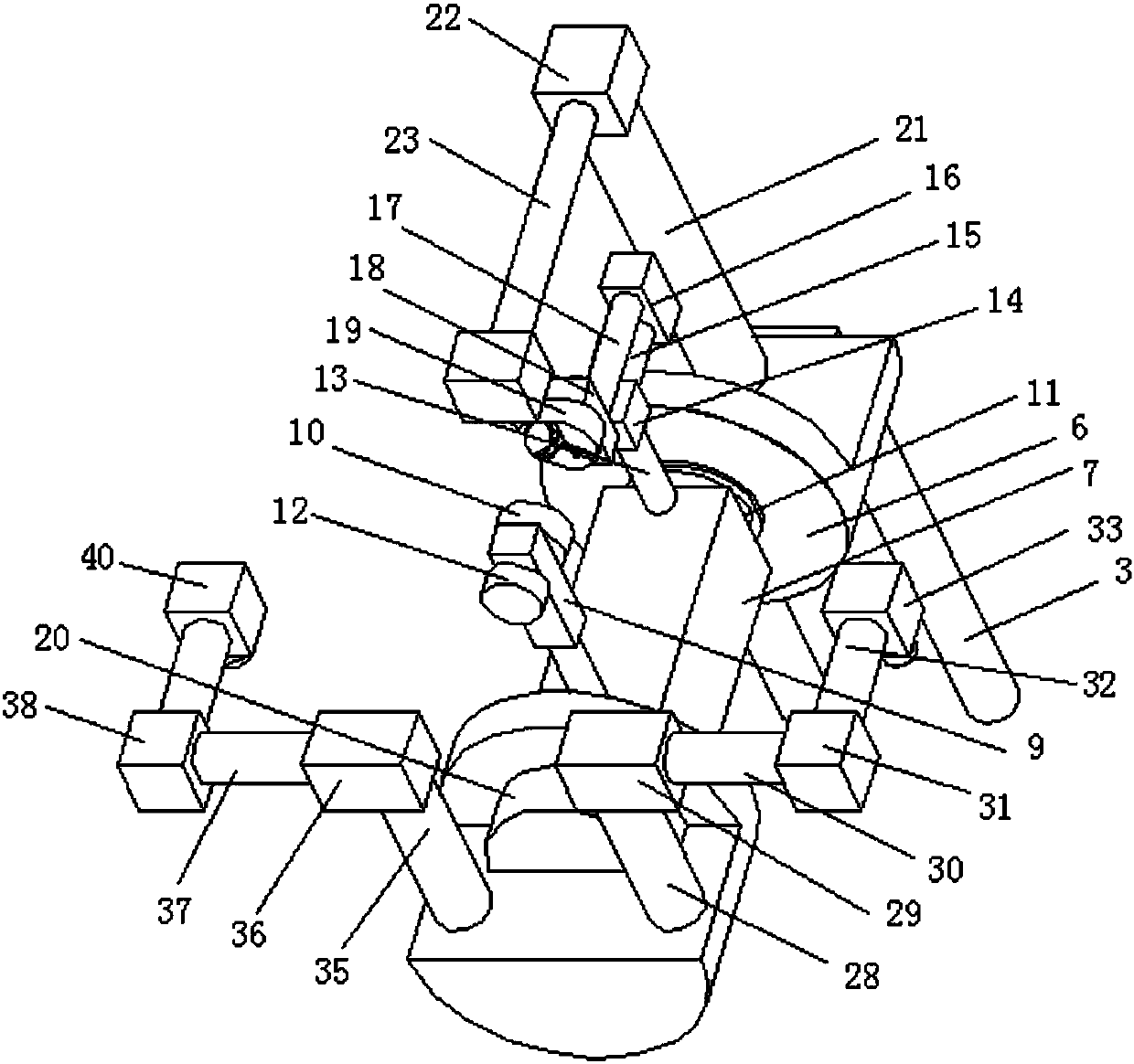

Laser cutting machine for precious metal processing

PendingCN114043099ALess likely to cause damageReduce lossLaser beam welding apparatusMetal machiningEngineering

The invention provides a laser cutting machine for precious metal processing, and belongs to the technical field of precious metal processing. The laser cutting machine for precious metal processing comprises a laser cutting machine body, a feeding assembly and a collecting assembly. The laser cutting machine body is provided with an operation table; the feeding assembly comprises a cutting table, a lifting part, a rotating shaft, a feeding wheel, a driving part and a feeding rod, the cutting table is mounted on the upper side of the operation table, the lifting part is mounted on the cutting table, the rotating shaft is mounted on the lifting part, the feeding wheel is in key connection with the rotating shaft, the driving part is mounted on the cutting table, the feeding rod is in transmission connection with the driving part, and the feeding rod is rotationally connected to the cutting table; and the collecting assembly comprises a collecting plate and a collecting tank, and the collecting tank is located on one side of the collecting plate. According to the laser cutting machine for precious metal machining, precious metal is clamped and fixed, damage is not likely to be caused, meanwhile, precious metal powder is collected, and loss is reduced.

Owner:GUANGZHOU DEYUFU JEWELRY CO LTD

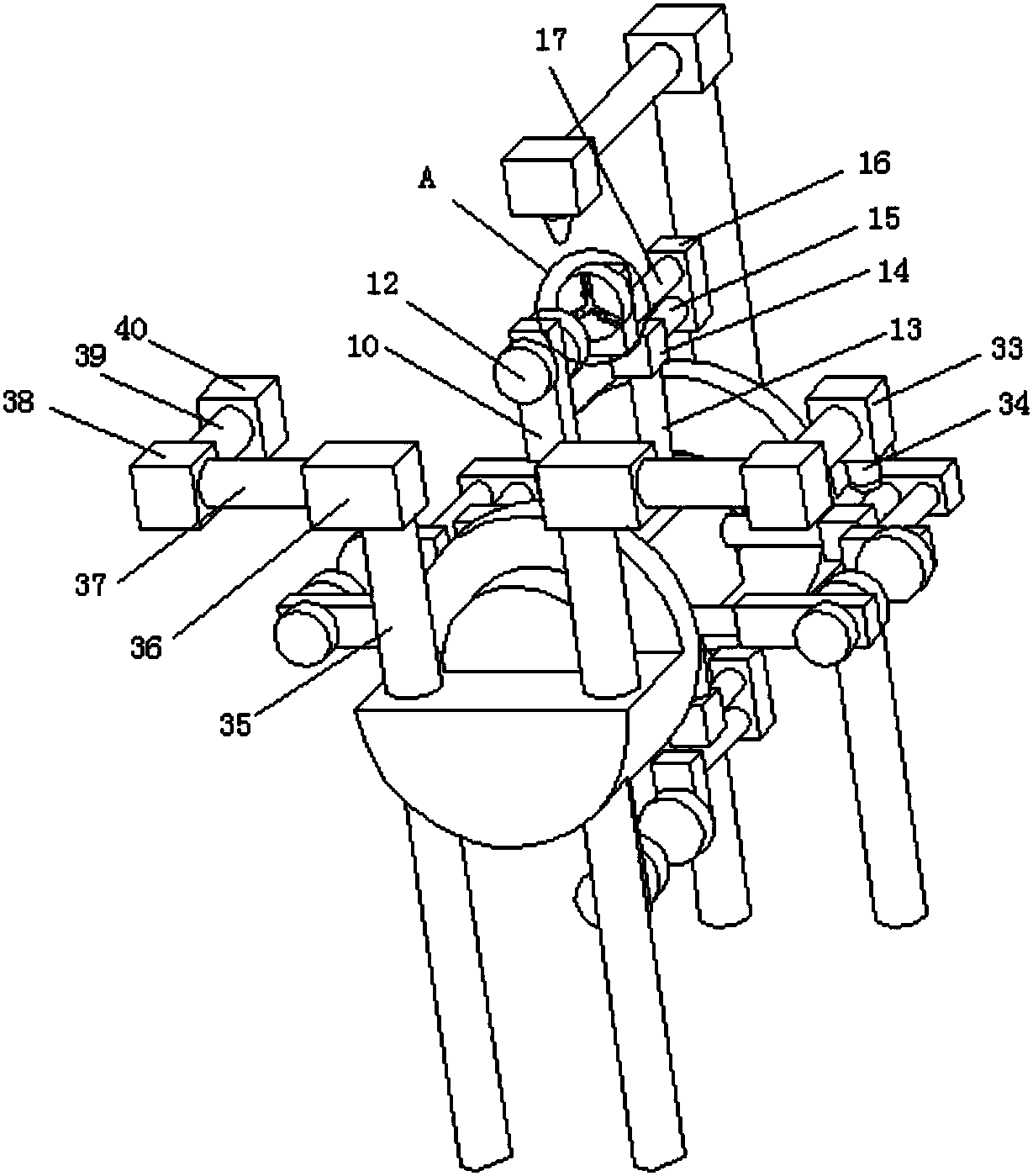

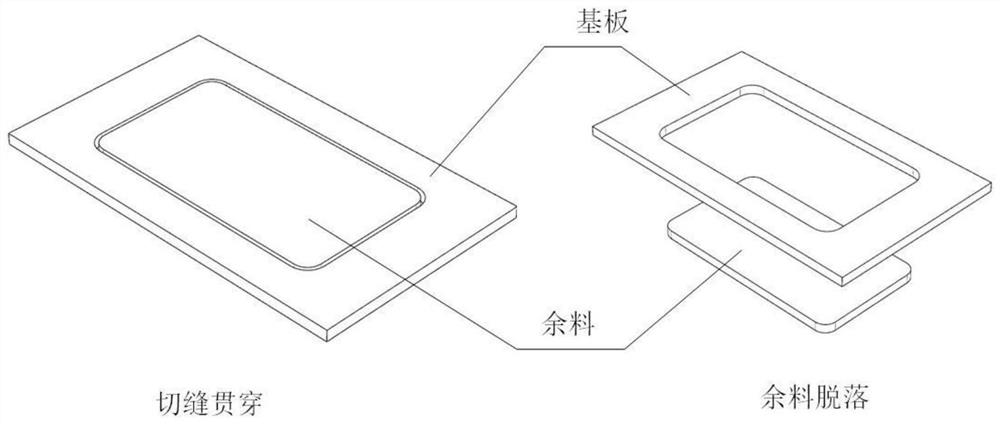

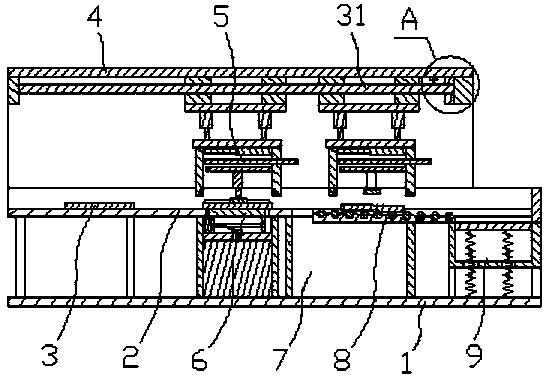

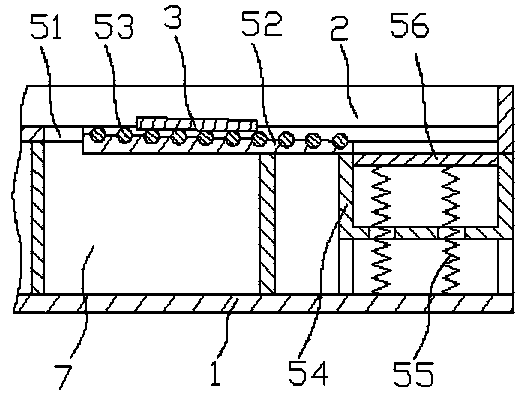

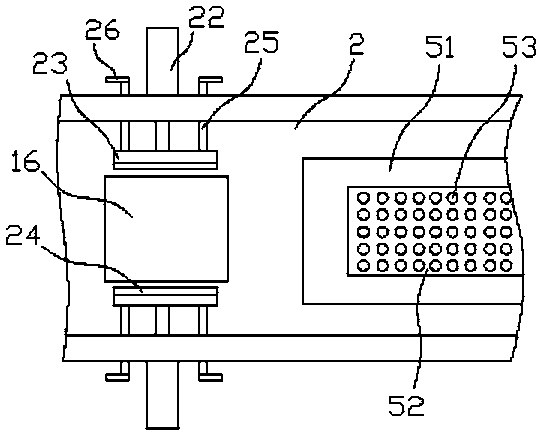

Tile laser cutting equipment capable of separating waste

InactiveCN110802333AAchieve separationWill not affect the delivery of genuine productsWelding/cutting auxillary devicesAuxillary welding devicesCeramic tilesLaser cutting

The invention relates to tile laser cutting equipment capable of separating waste. A rack and an upper frame are included. A conveying groove is formed in the rack. A feeding device matched with tilesin the conveying groove is arranged below the upper frame. A laser cutting matching port is formed in the middle portion of the conveying groove. The rack is provided with a laser cutting device matched with the laser cutting matching port. The side, located at the output end of the laser cutting device, of the conveying groove is provided with a separation port. The separation port is matched with a separation device. The separation device comprises a waste collecting box arranged on the rack and matched with the separation port, a separation inclined block is arranged on the waste collecting box, the end, close to the output end, of the separation inclined block is a low end, separation balls are embedded in the separation inclined block, the separation ball at the highest point is flush with the bottom face of the conveying groove, the distance between the separation inclined block and the three side edges of the separation port is 20-50 mm, and the rack is further provided with astacking collecting device matched with the low end of the separation inclined block.

Owner:东莞市史雷帝三维数控科技有限公司

Laser cutting machine with plate fixing device

PendingCN114799505ASolve the cutting accuracySolve the problem of the yield rate of cutting finished productsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser cutting

Owner:安徽同兴科技发展有限责任公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap