Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Rocket engine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A rocket engine uses stored rocket propellants as reaction mass for forming a high-speed propulsive jet of fluid, usually high-temperature gas. Rocket engines are reaction engines, producing thrust in accordance with Newton's third law. Most rocket engines use the combustion of reactive chemicals to supply the necessary energy, but non-combusting forms such as cold gas thrusters and nuclear thermal rockets also exist. Vehicles propelled by rocket engines are commonly called rockets. Rocket vehicles carry their own oxidizer, unlike most combustion engines, so rocket engines can be used in a vacuum to propel spacecraft and ballistic missiles.

Anti-backfire nozzle for rocket engine

ActiveCN106762225AStop the spreadAnti-tempering functionRocket engine plantsCombustionThermal insulation

Owner:SHANGHAI INST OF SPACE PROPULSION

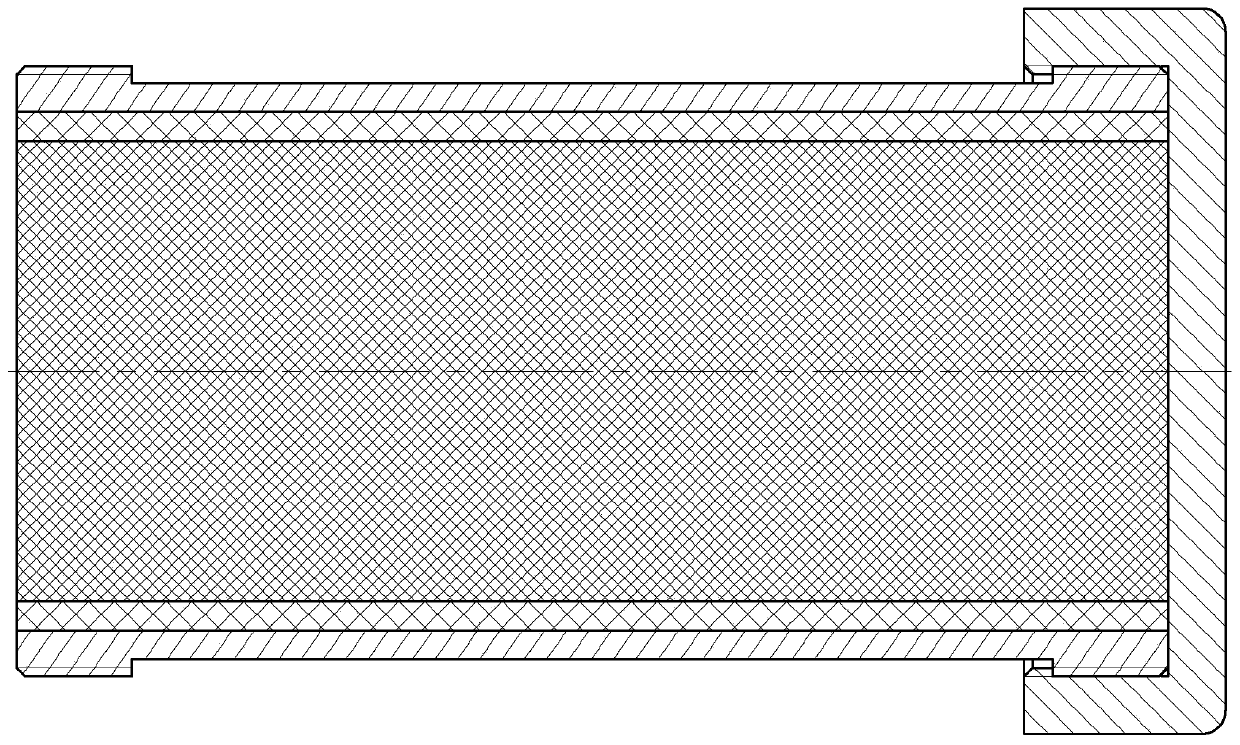

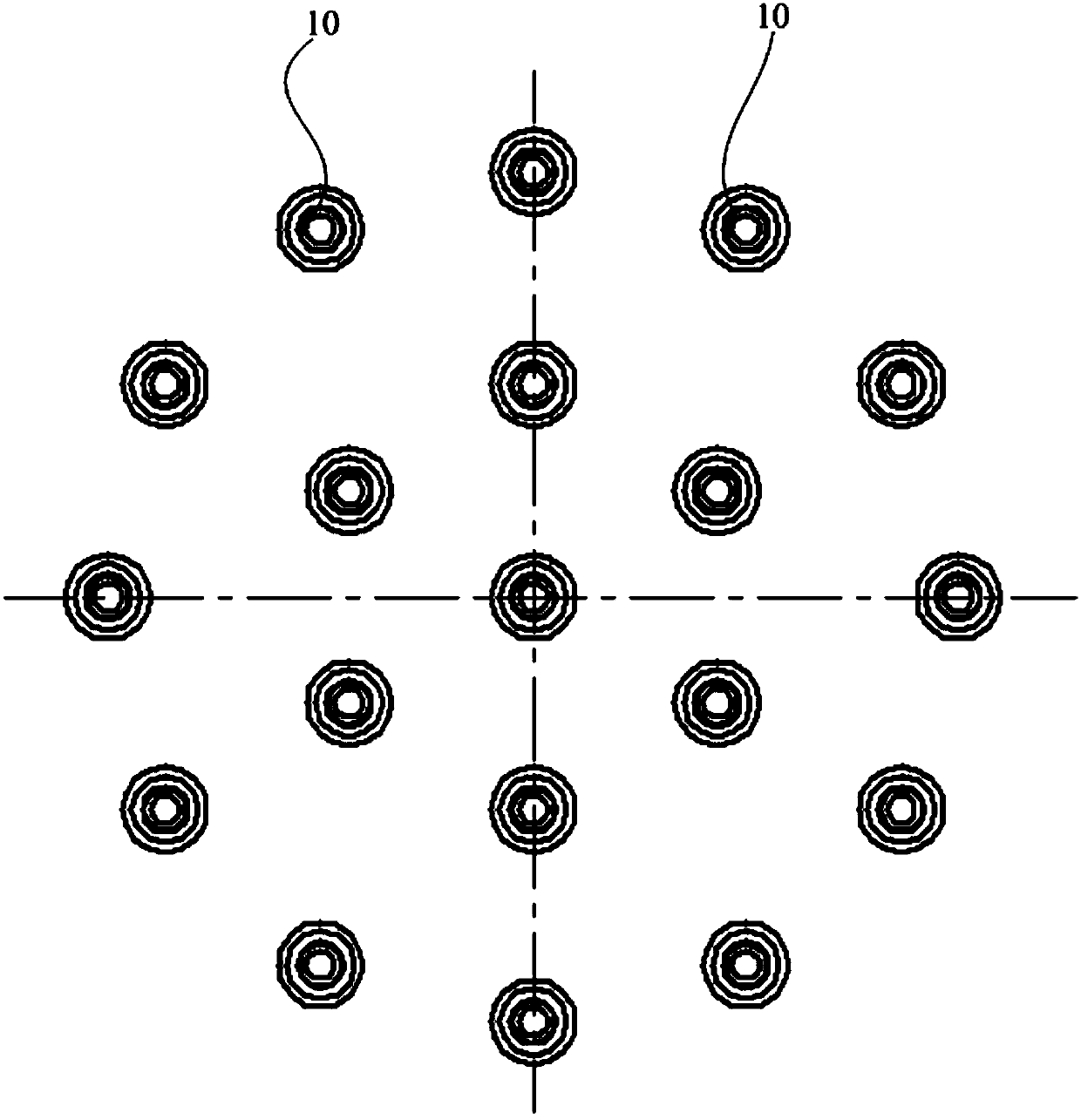

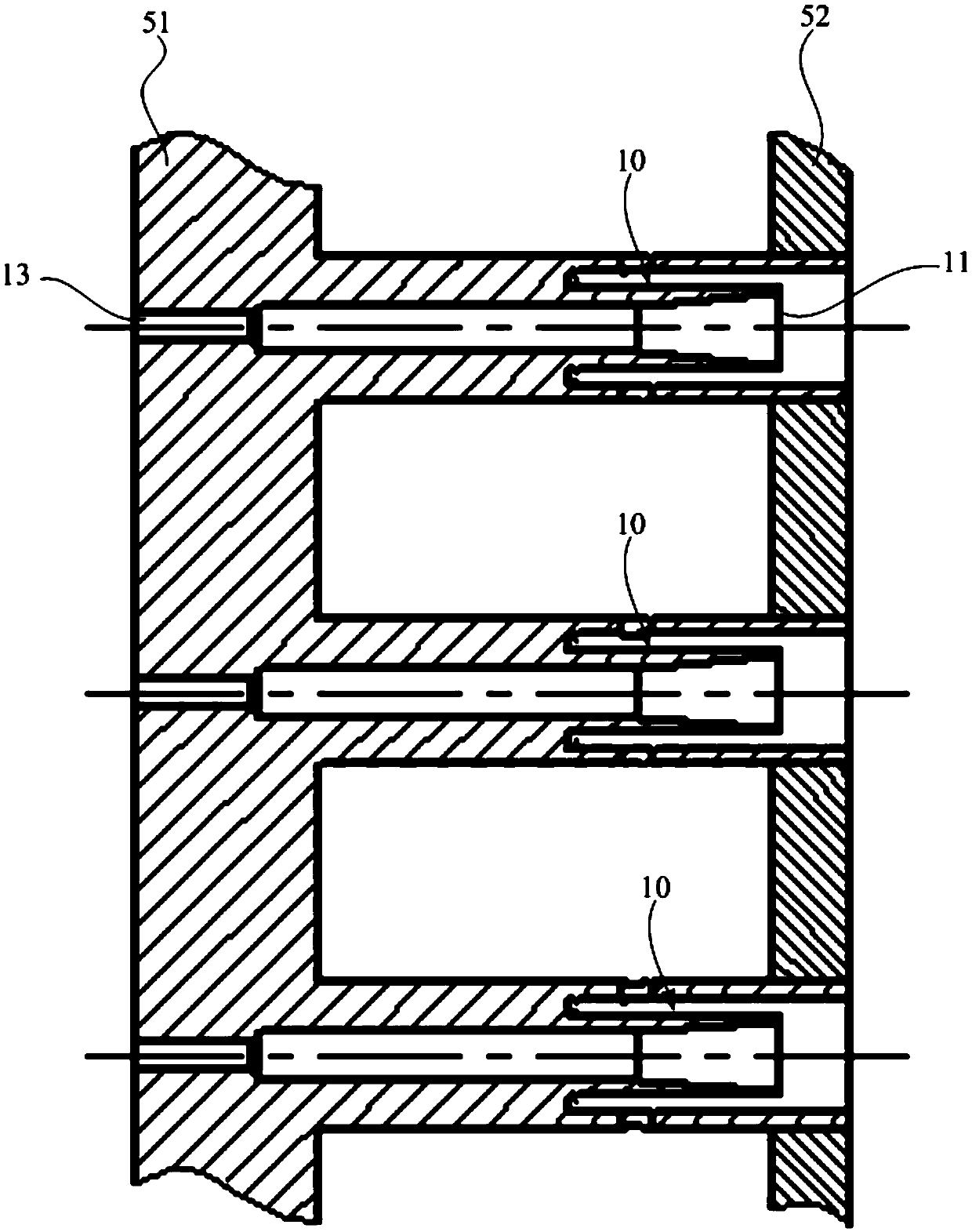

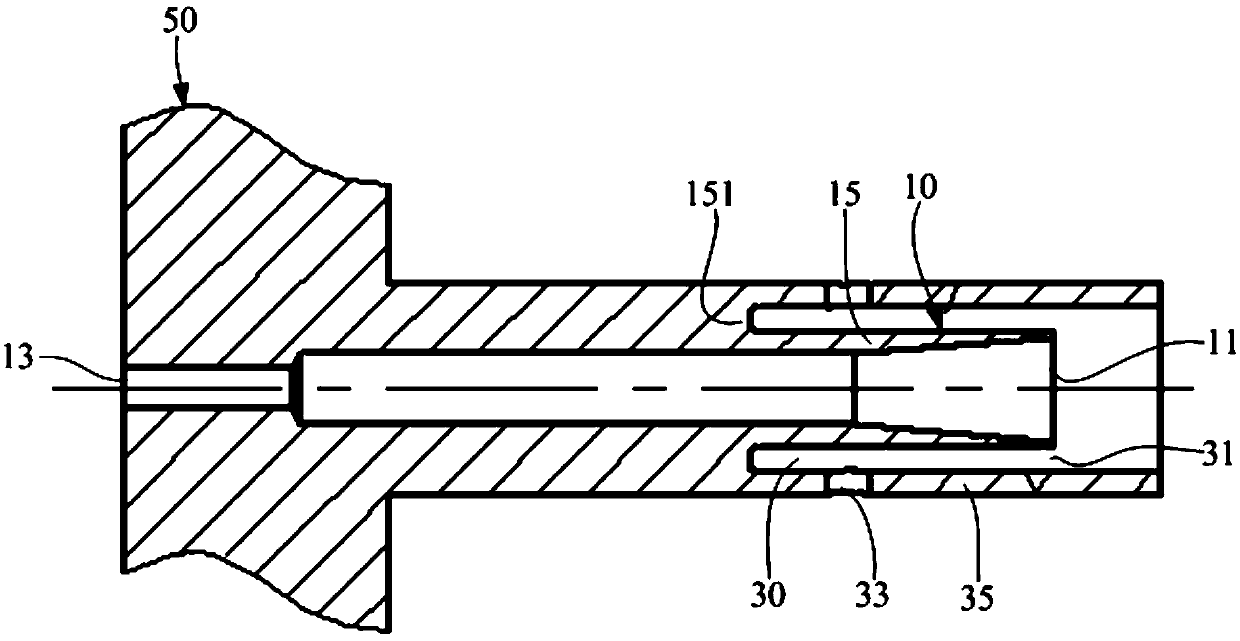

Dual-pulse solid rocket engine soft interlayer ablation test device

ActiveCN110425058ANo accelerationReal-time monitoring of flow fieldRocket engine plantsThroatCombustion

Owner:NANJING UNIV OF SCI & TECH

Rocket engine injection structure, injection device, rocket engine and rocket

InactiveCN109653902ASituations to Avoid WeldsReduce the use of weldingRocket engine plantsSpray nozzleInjection device

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD

Processing method of zirconium oxygen-free copper forging rod

InactiveCN111408632ABreak through the problem that ultrasonic flaw detection cannot be performedNon-destructive monitoring of internal qualityMetal-working apparatusFurnace typesSolution treatmentEngineering

The invention discloses a processing method of a zirconium oxygen-free copper forging rod. A rod material adopts zirconium oxygen-free copper casting billets. After forging and blanking, the casting billets are produced by hot forging, upsetting and stretching, solid solution treatment, cold forging, machining, aging and machining again. The specification can reach Phi (100-300)*(500-1500) mm. Theimportant thing to note that after the rod material is subjected to cold forging and machining, ultrasonic flaw detection is needed for nondestructive testing of internal quality. The processing method can successfully realize the feasibility of nondestructive flaw detection and avoid the problem that no echo exists or echo is weak in the ultrasonic flaw detection process of the rod material, sothat the detection requirement cannot be met. The product is applied to inner wall shrinkage parts of a power chamber groove of a rocket engine, the tensile strength and yield strength are still above150MPa at 500 DEG C, and the elongation rate is also above 15%.

Owner:SHENYANG TONGXING IND

Laser propelled engine

ActiveCN102062019BReduce heat resistance requirementsStable jobRocket engine plantsCombustion chamberHeat resistance

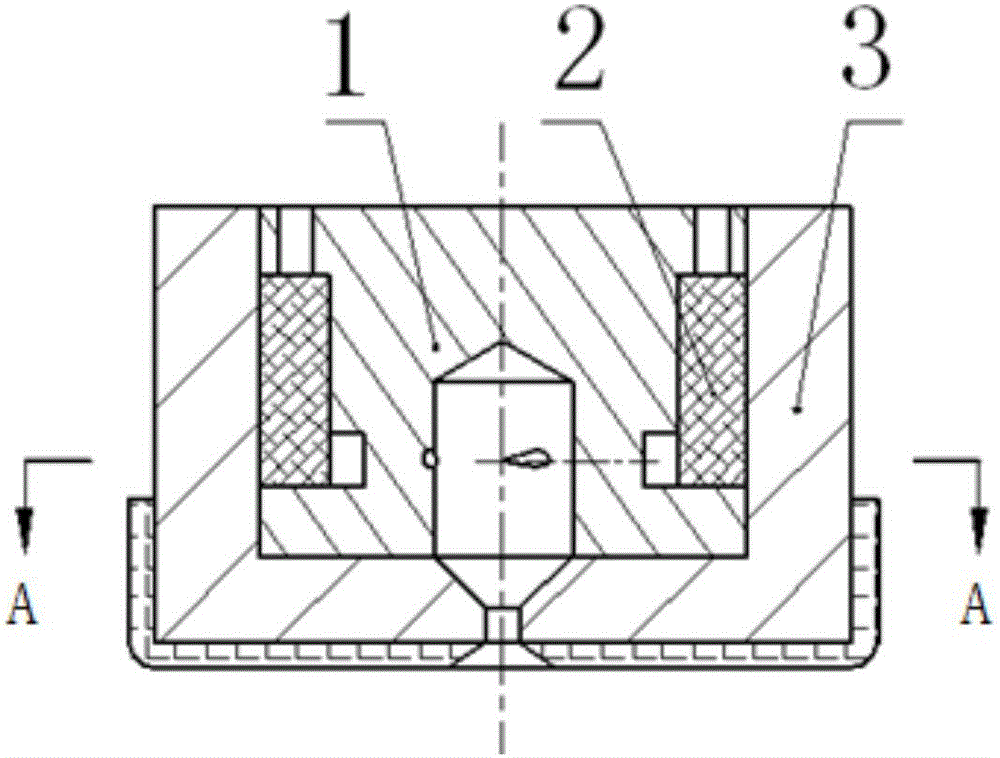

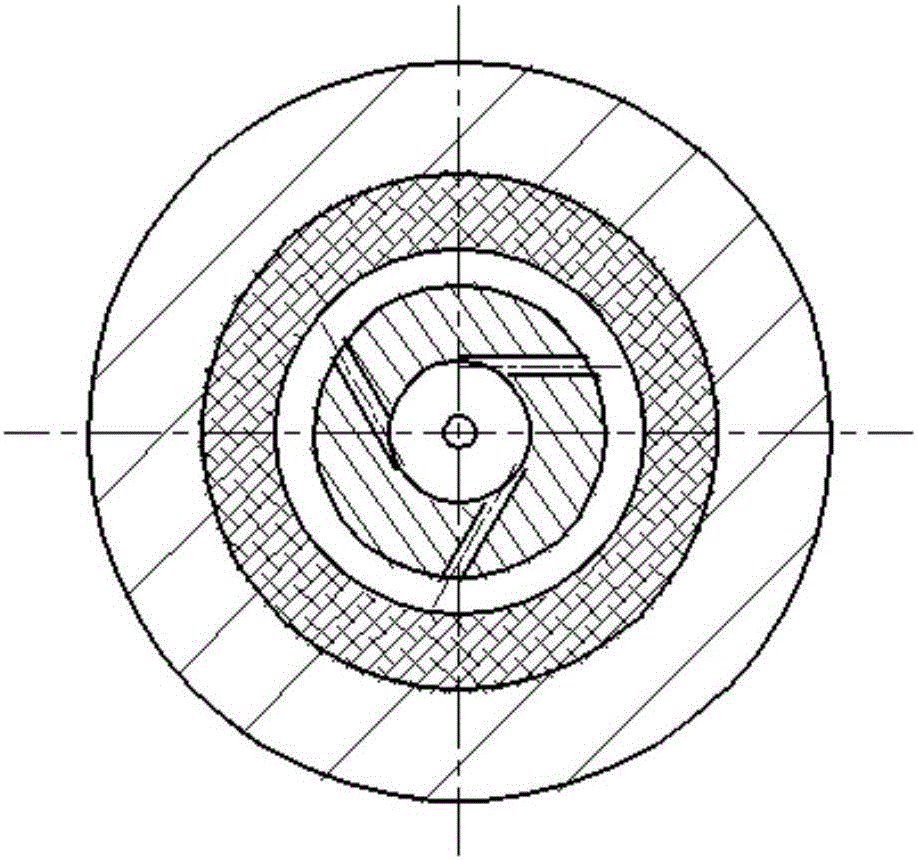

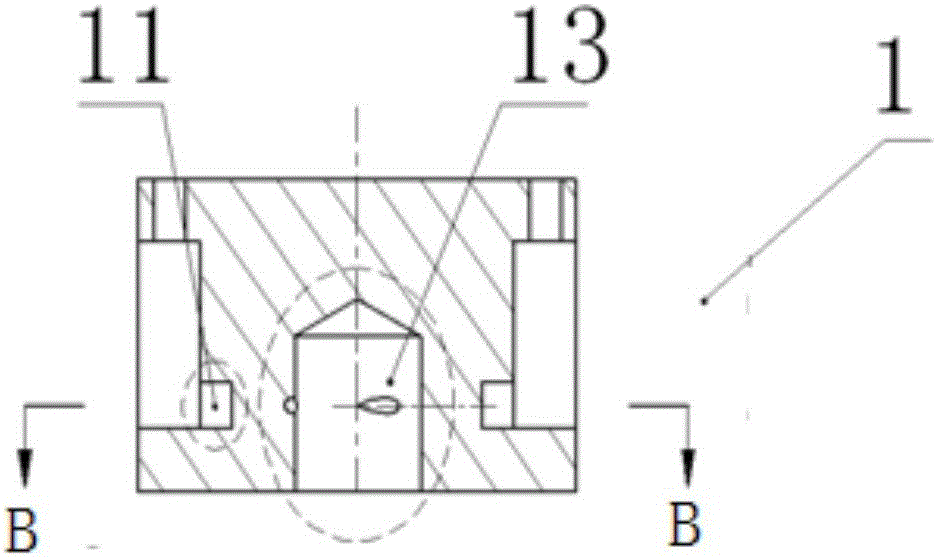

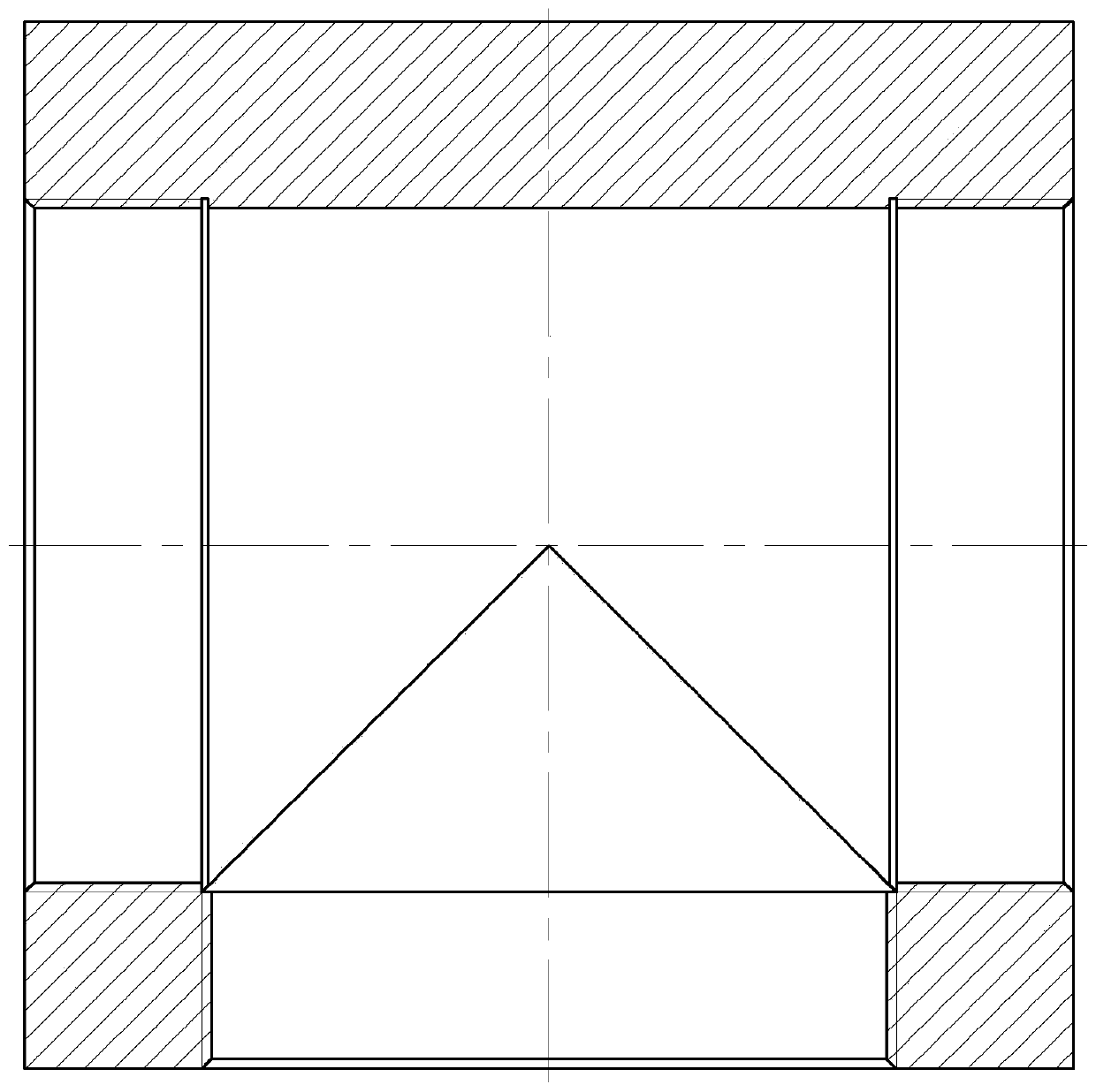

The invention relates to a laser propelled engine. The laser propelled engine comprises a plane lens (1), a conical parabolic reflector (2), a convex reflector (3) and a spray pipe (5). The appearance of the laser propelled engine is similar to that of the traditional liquid rocket engine. The size of a combustion chamber can be amplified or reduced in proportion as required, and the size of the plane lens (1) can be adjusted along with adjustment of the size of the combustion chamber, therefore, the requirement on the heat resistance of the material of the plane lens (1) is reduced. The bottom of the conical parabolic reflector (2) is positioned on the top of the spray pipe, can prevent a high-temperature plasma from refluxing to the combustion chamber and has favorable protecting effecton all optical devices. A laser focus point is always arranged nearby the throat part of the spray pipe, and the spray pipe works stably and is free from upstream influence.

Owner:SHENZHEN XUNTIAN SPACE TECH CO LTD

Solid-liquid engine grain burning surface uniform retreating control method

The invention belongs to the technical field of solid-liquid rocket engines, and aims to provide a solid-liquid engine grain burning surface uniform retreating control method in order to solve the technical problem that in the prior art, retreating of a burning surface in the length direction of a grain is not uniform. The method specifically comprises the following steps that (1) a grain injection channel is established, specifically, a sandwich grain base body and sandwich structure blades communicate with each other to form the injection channel; (2) a gas inlet manner is controlled, specifically, firstly, a gas oxidizing agent is fed along a hollow axial gas cavity, and then the gas oxidizing agent is fed into a combustion chamber along a hollow radial gas cavity; and (3) internal uniform injection is carried out, specifically the oxidizing agent is uniformly injected into the combustion chamber from the inside along an internal combustion channel. Uniform retreating of a grain burning surface is achieved through the constant flux of the oxidizing agent in the grain combustion channel direction, in addition, the turbulence effect on fuel gas is enhanced through injection of the oxidizing agent in the fuel channel and the blades, the turbulence combustion intensity can be improved, and the grain retreating speed and the engine combustion efficiency are improved.

Owner:INST OF MECHANICS CHINESE ACAD OF SCI

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap