Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Silicon alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon alloys are metallic or semiconductor alloys with silicon as a significant element. Silicon is an important alloying addition in metallurgy, particularly for a range of aluminium-silicon alloys, even though it only forms a minor proportion of the alloy.

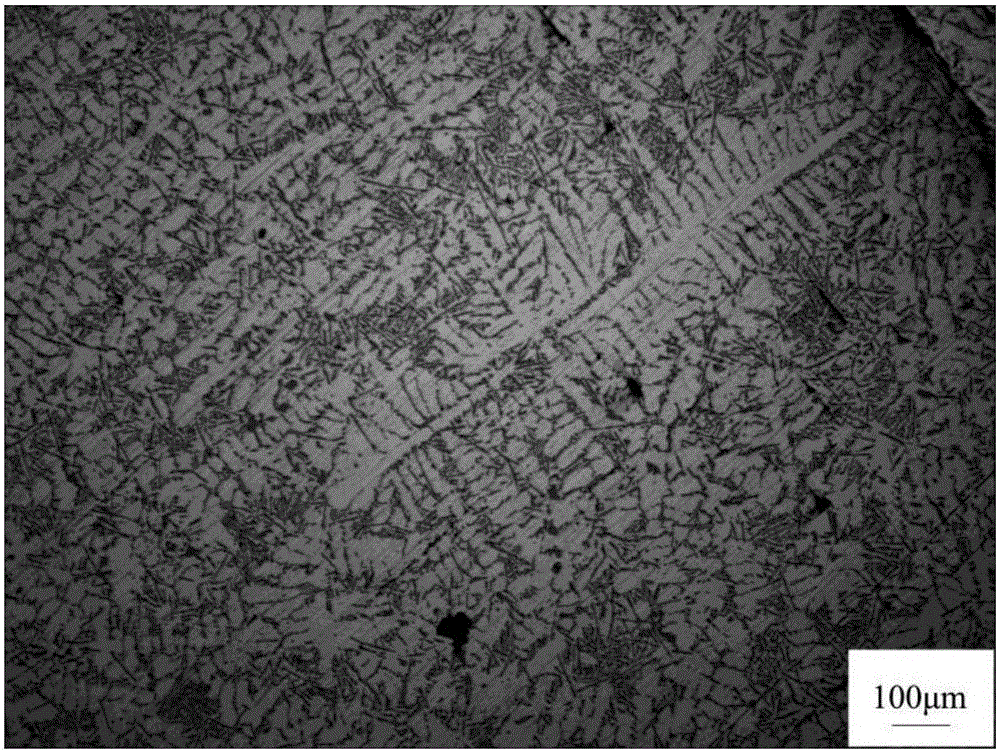

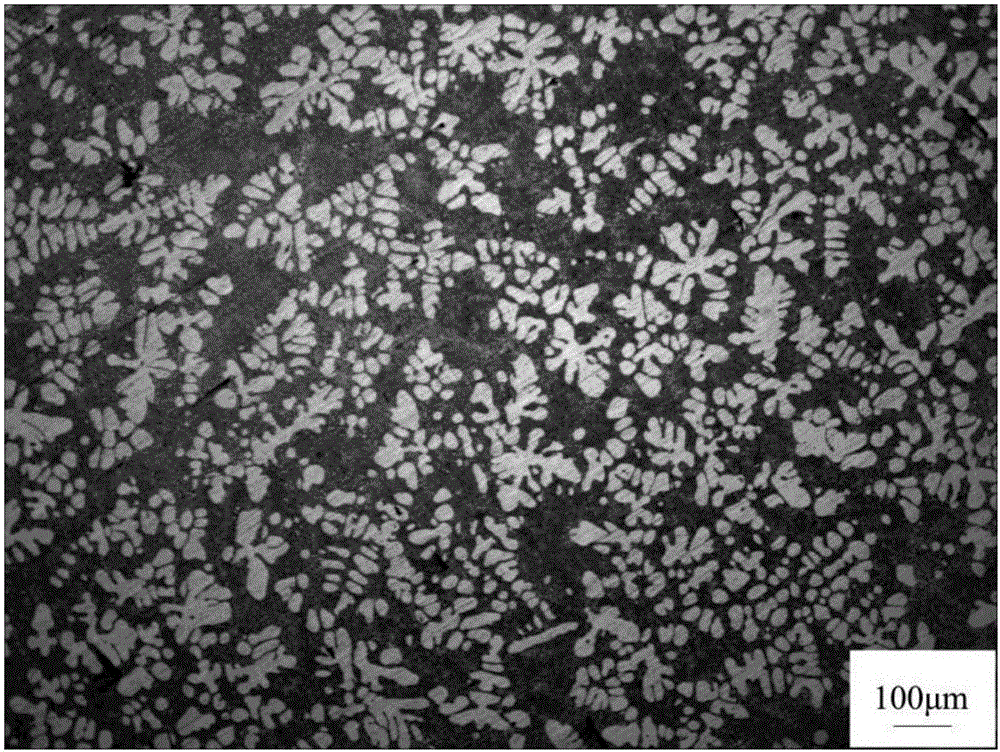

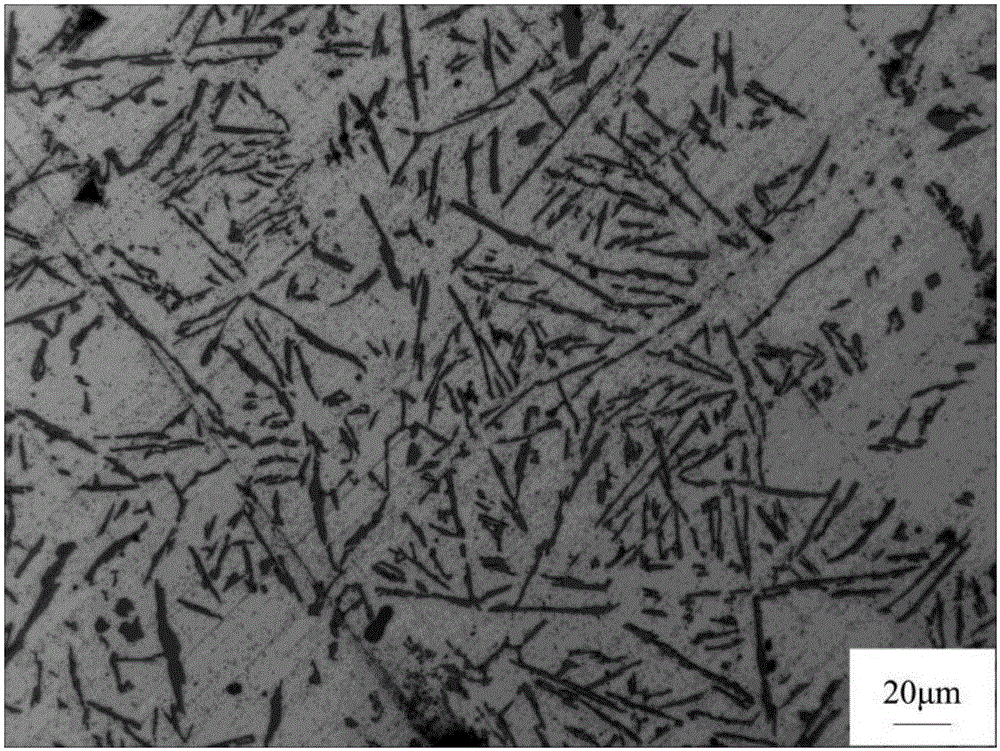

Aluminum-lanthanum-boron-strontium intermediate alloy for cast aluminum-silicon alloy and preparation method of aluminum-lanthanum-boron-strontium intermediate alloy

InactiveCN106191490AGood metamorphic effectAvoid reactionSilicon alloyCastability

Owner:SOUTHEAST UNIV

Electromagnetic shielding method and product

InactiveCN102950828ANo pollution in the processElectromagnetic shielding method is simple and fastVacuum evaporation coatingSputtering coatingInsulation layerSilicon oxygen

The invention provides an electromagnetic shielding method comprising the steps that: a substrate is provided; a vacuum plating method is adopted, wherein an aluminum-silicon alloy target is adopted as a target material, oxygen is adopted as a reaction gas, and an insulation layer is formed on the substrate, wherein the insulation layer is an aluminum-silicon-oxygen layer; and a vacuum plating method is adopted, wherein a nickel-copper alloy target is adopted as a target material, and a conductive layer is formed on the insulation layer, wherein the conductive layer is a nickel-copper alloy layer. The invention also provides a product obtained with the provided electromagnetic shielding method.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Casting aluminum-silicon alloy and preparation method thereof

Owner:成都慧腾创智信息科技有限公司

Ceramic alloy material and preparation method thereof

The invention relates to a ceramic alloy material and a preparation method thereof. The nanometer ceramic alloy material is prepared from raw materials including nanometer materials and a gelatinizingagent; and the nanometer materials comprise nanometer aluminum oxide, complex fibers and nanometer silicon alloys with the mass ratio being (0.05-0.8):(0.05-0.1):(0.1-0.85). According to the ceramicalloy material, the nanometer aluminum oxide, the complex fibers and the nanometer silicon alloys are combined in a proper ratio to form a specific nanometer material formula. The nanometer ceramic alloy material composed of the nanometer materials and the gelatinizing agent has the advantages of being good in corrosion resistance, good in fire resistance and high in strength, and being able to use in high temperature or humid environment.

Owner:HUNAN YIXING CONSTR CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap