Spot welding robot workstation

A technology of robots and workstations, applied in the direction of manipulators, manufacturing tools, welding equipment, etc., to achieve the effects of good flexibility, injury prevention, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

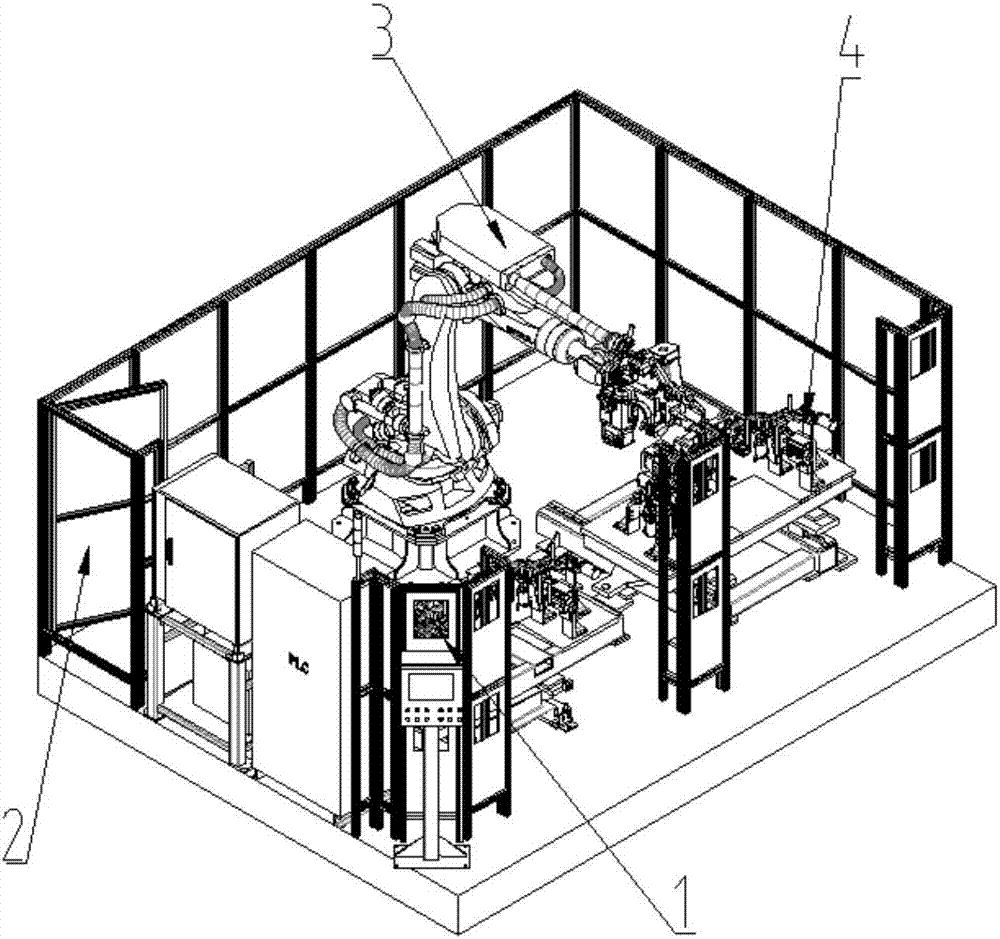

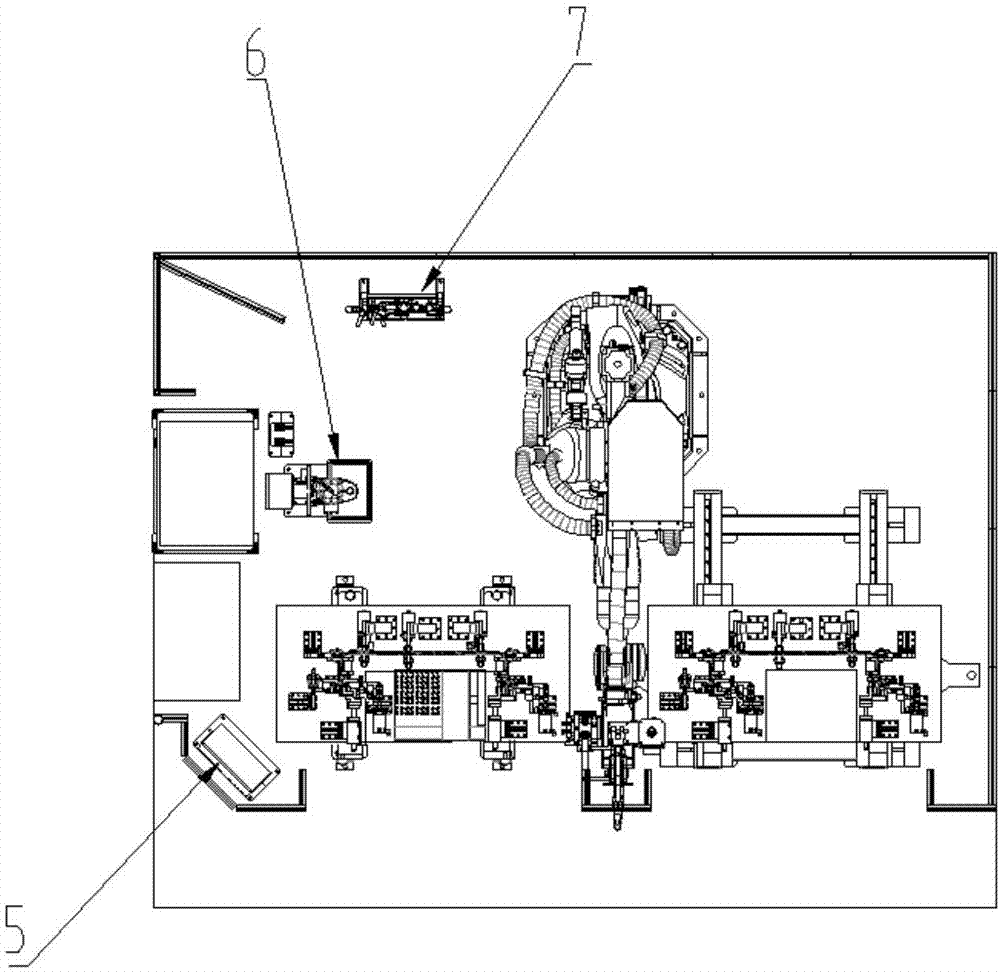

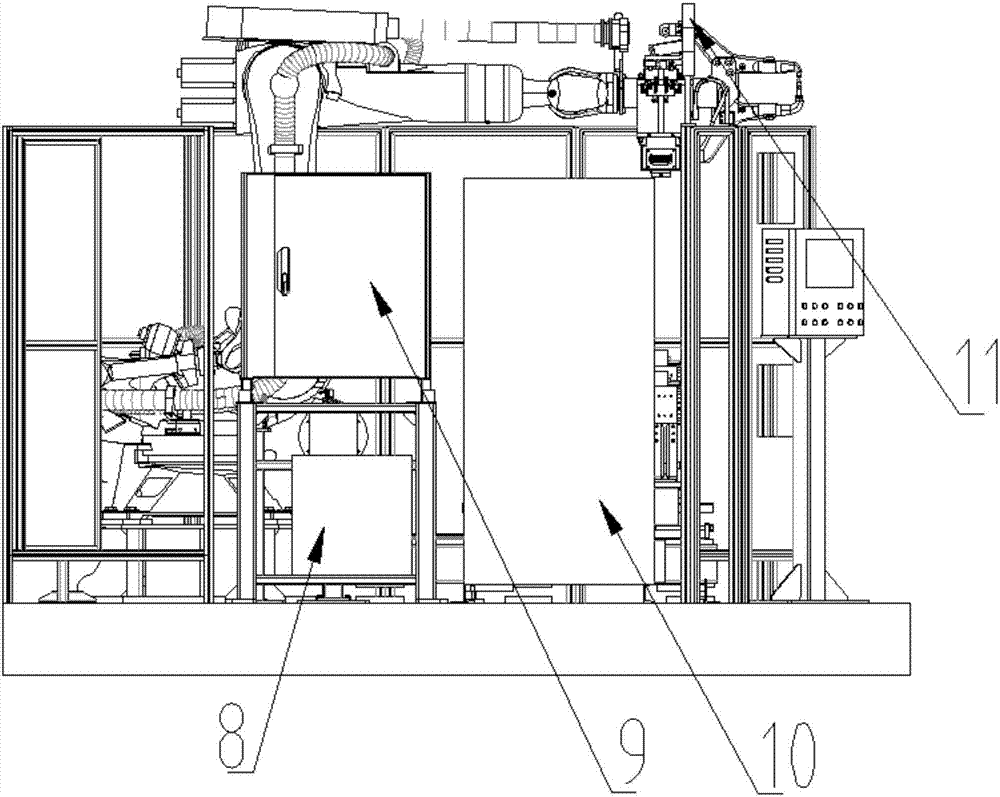

[0026] Combine below Figure 1~3 The present invention will be described in detail.

[0027] Such as Figure 1~3 As shown, a spot welding robot workstation includes a robot 3, a welding system 4, an integrated system 1 and a safety system 2:

[0028] The robot 3 includes a robot body, a robot controller 9, a pipeline package and a robot base, the robot body is located on the robot base, and the robot controller 9 is connected to the robot body by a pipeline package;

[0029] The welding system 4 includes a servo welding tongs, a welding controller 8, a mold trimmer 6 and a water and air unit 7, the servo welding tongs are located on the robot body, and the repair welding controller 8 is respectively connected to the servo welding tongs, the mold repairing Device 6 and water gas unit 7;

[0030] Described integrated system 1 comprises system control cabinet 10, PLC and touch screen 5, and described PLC is positioned at system control cabinet, and described touch screen 5 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap