Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Water gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water gas is a mixture of carbon monoxide and hydrogen produced from synthesis gas. Synthesis gas is a useful product, but requires careful handling due to its flammability and the risk of carbon monoxide poisoning. The water-gas shift reaction can be used to reduce the carbon monoxide while producing additional hydrogen, resulting in water gas.

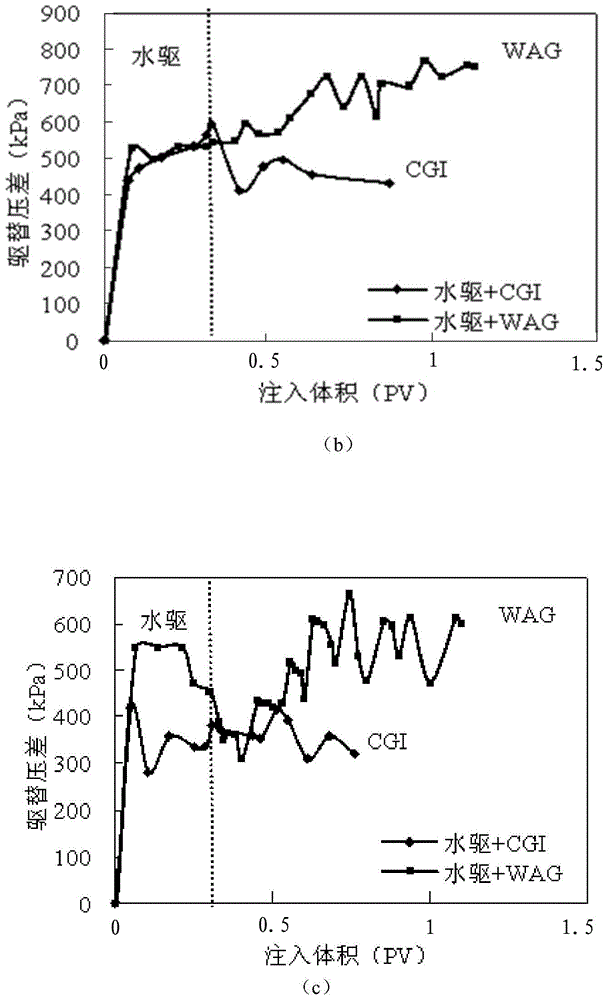

Carbon dioxide drive oil reservoir production method capable of realizing stage control on fluidity

ActiveCN104975829AExpand the affected volumeImprove mobility ratioFluid removalSealing/packingAliphatic amineProcess engineering

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

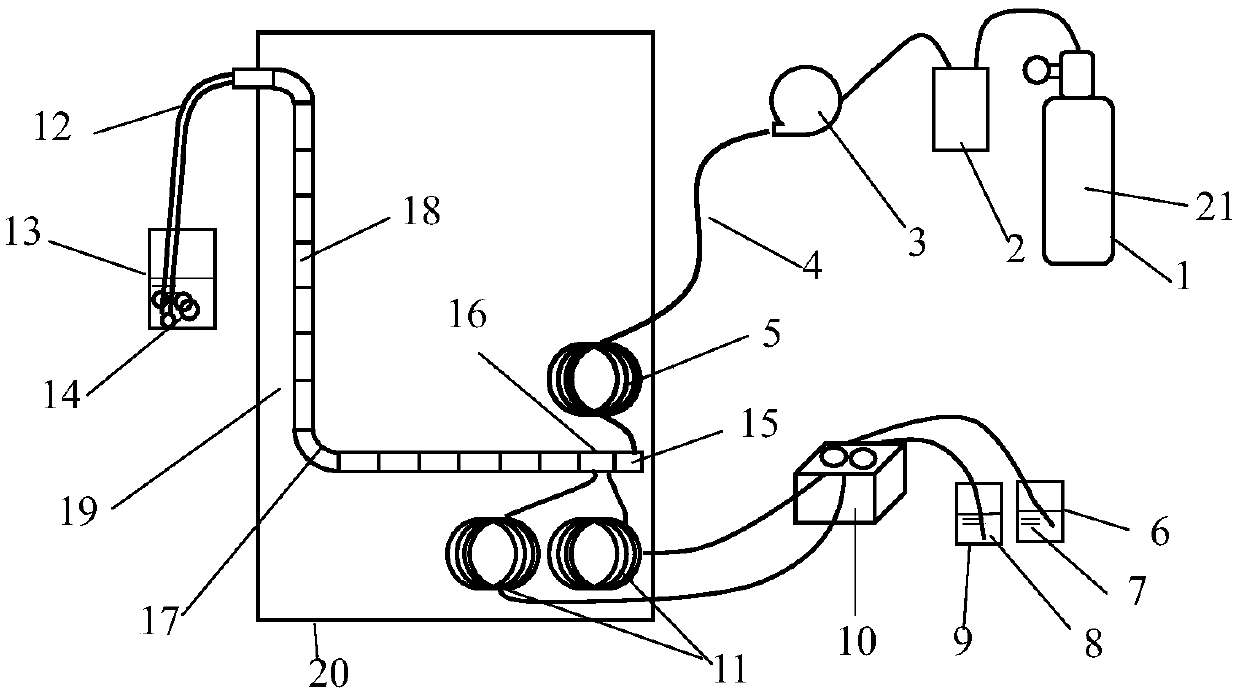

Experiment device for evaporating scaling risk of water production gas well shaft and method

ActiveCN108843314AEvaluation of foulingAssessing the risk of cloggingSurveySection planeCollection system

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

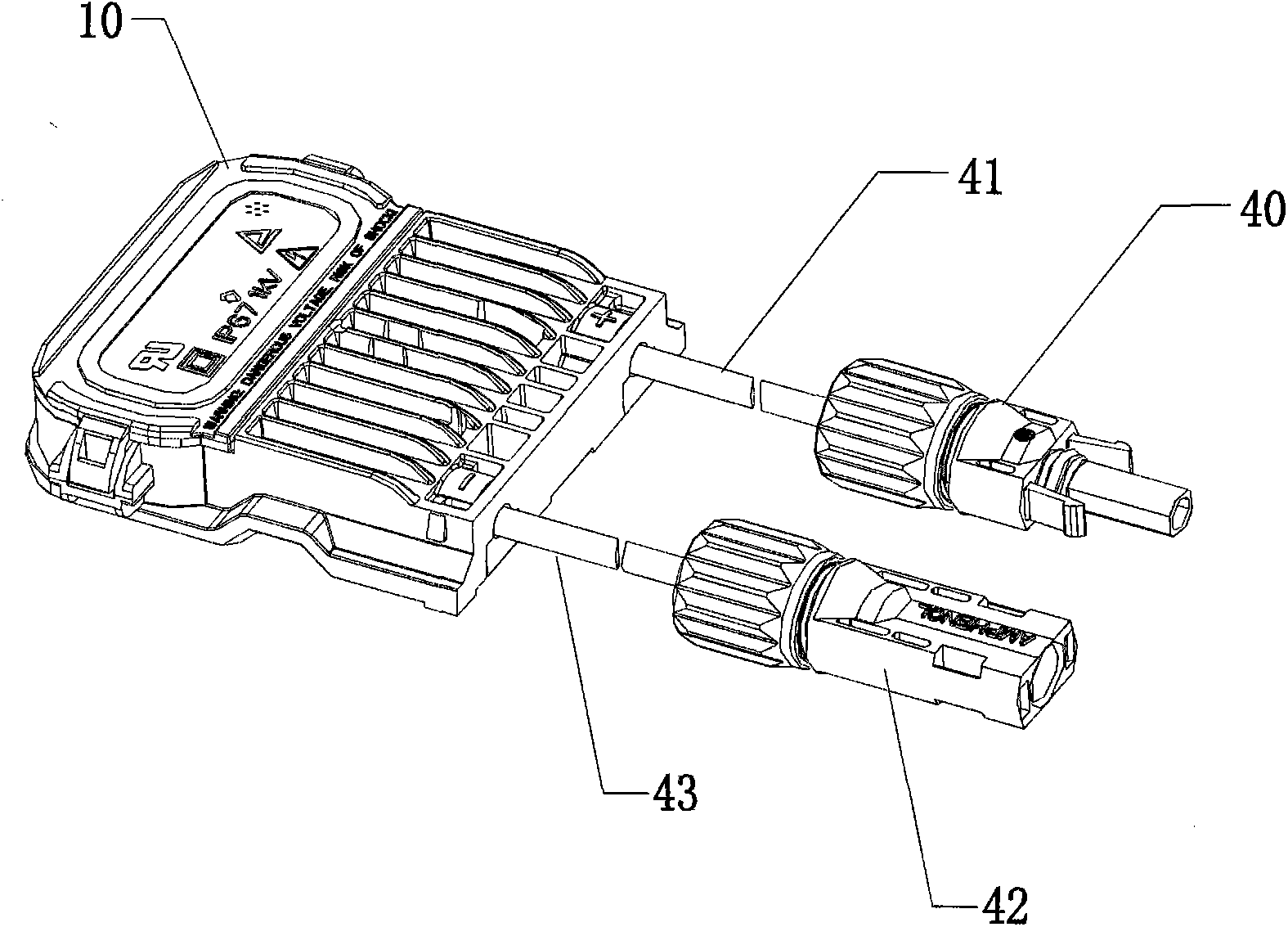

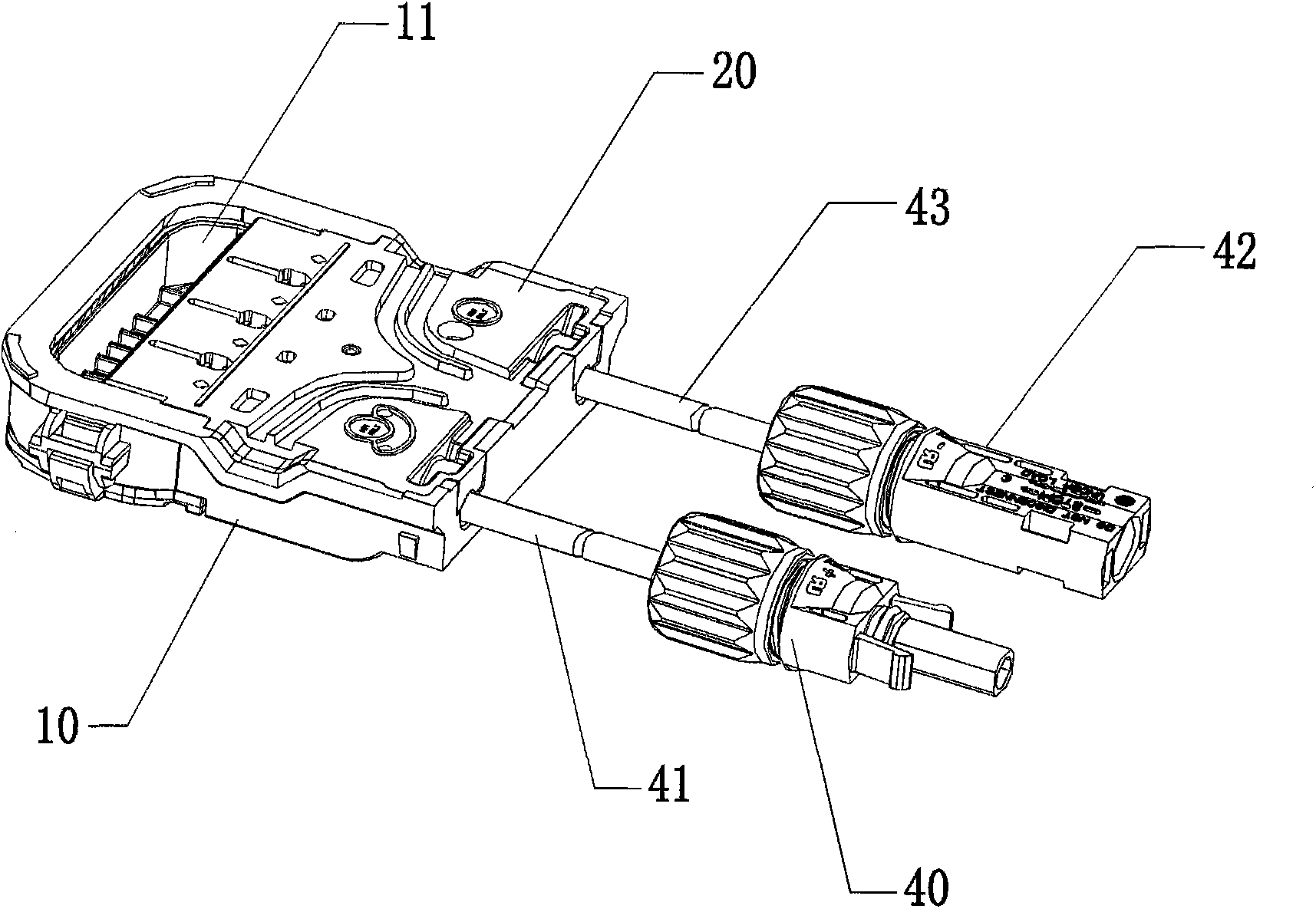

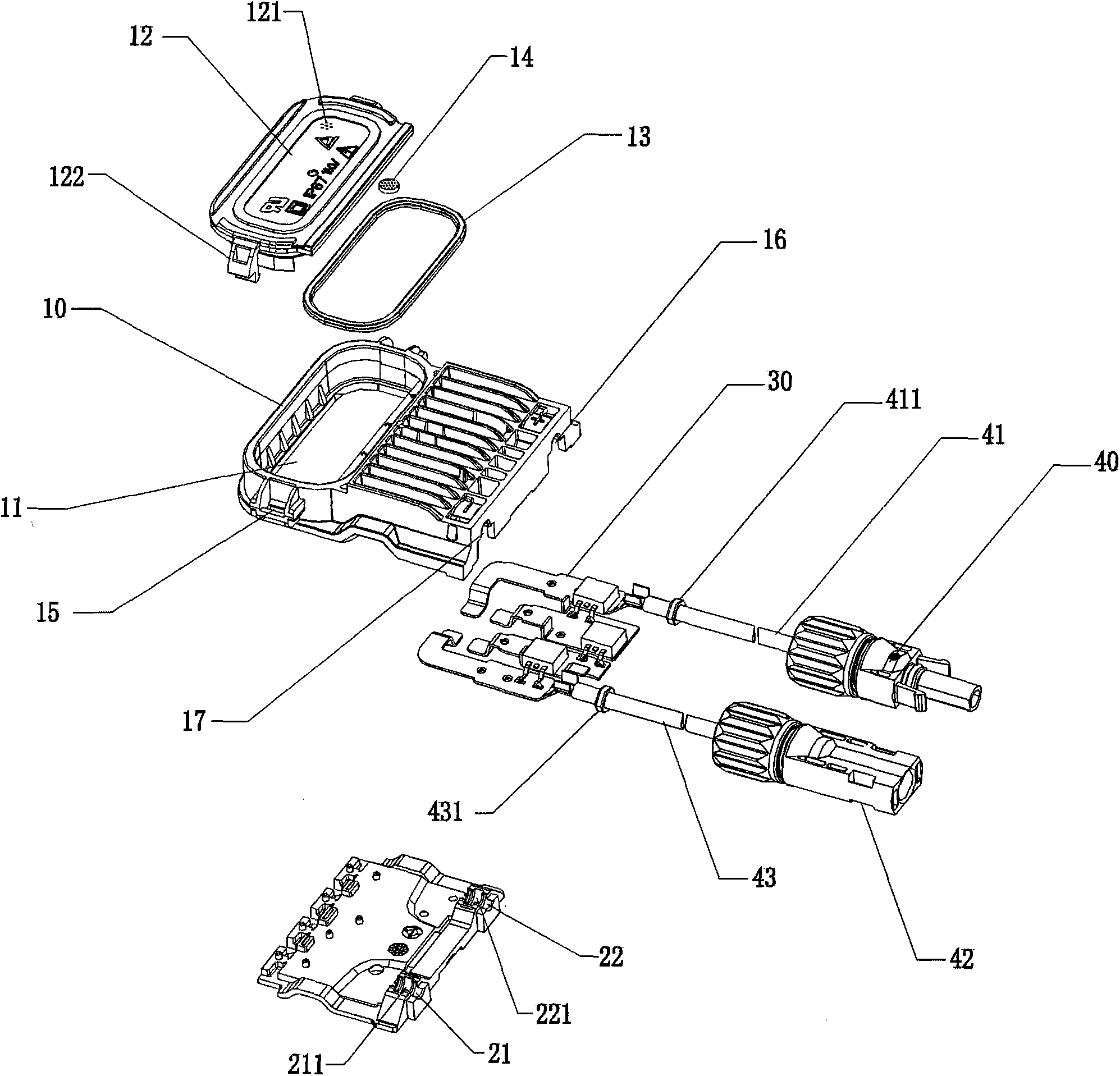

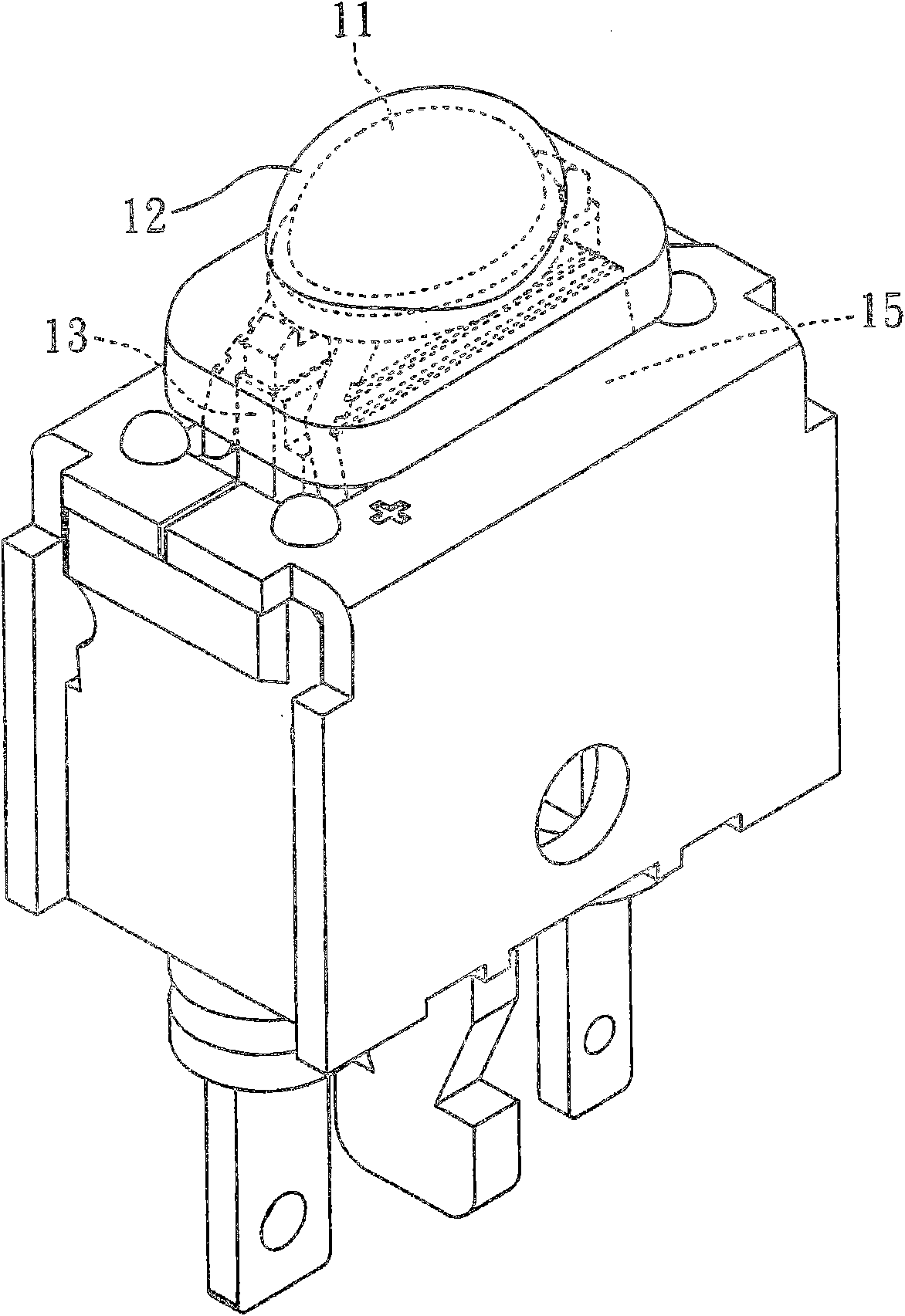

Waterproof and ventilating structure of solar junction box

InactiveCN103413853ANot prone to performance degradation issuesAvoid enteringClimate change adaptationPhotovoltaic energy generationEnvironment effectWater vapor

Owner:AMPHENOL TECH (SHENZHEN) LTD CO LTD

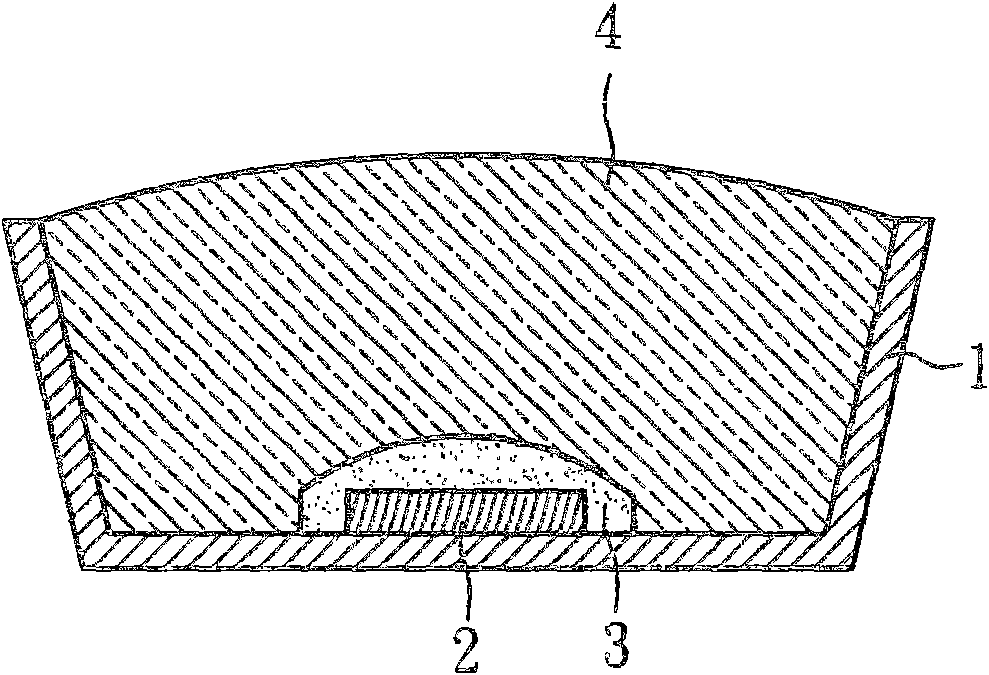

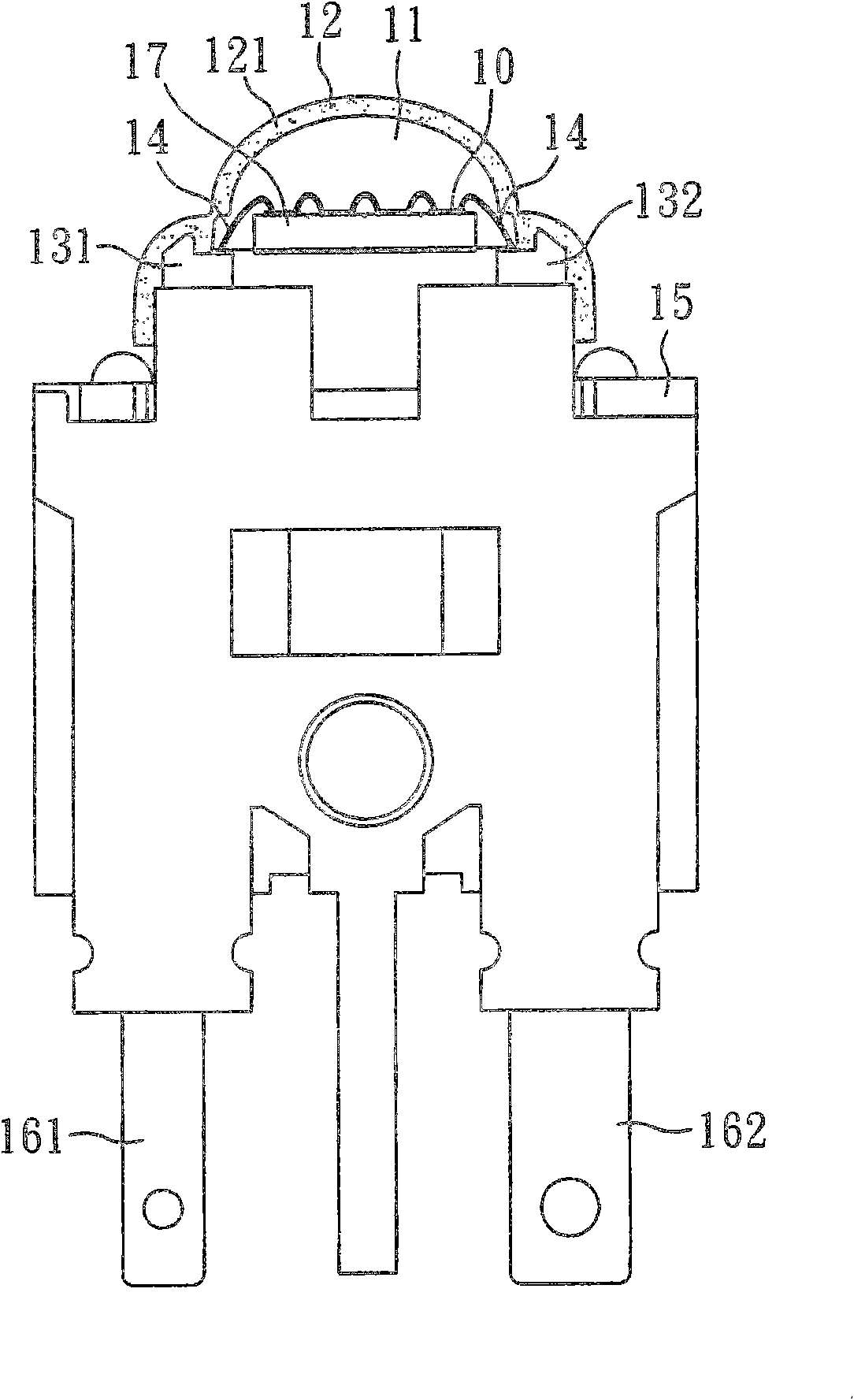

Light-emitting diode packaging structure

Owner:FORWARD ELECTRONICS CO LTD

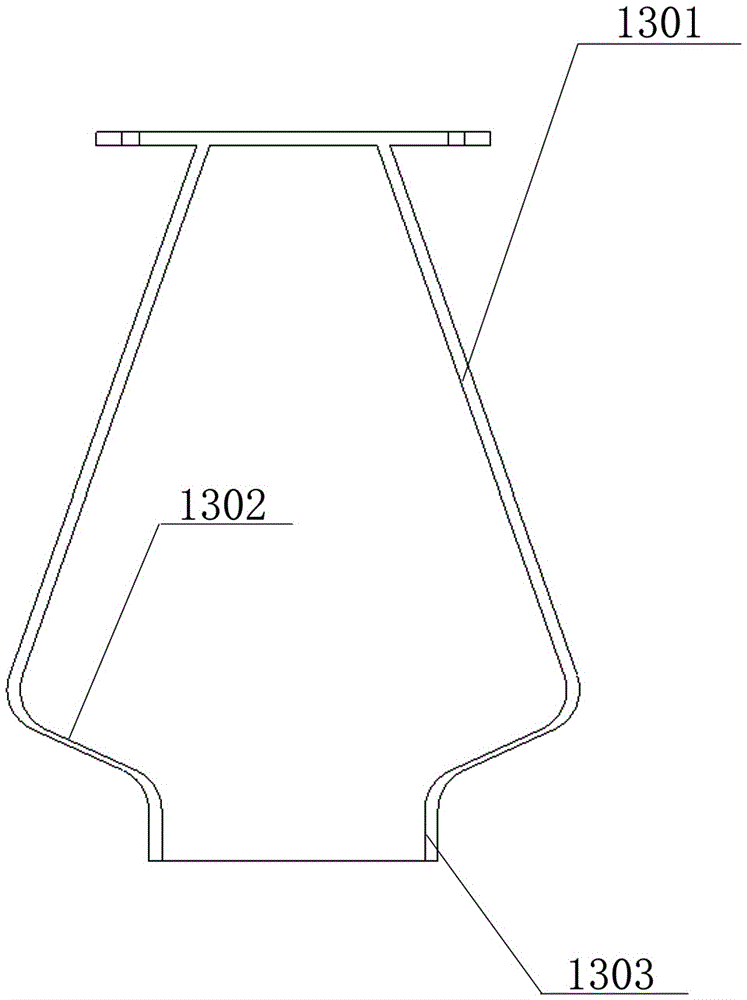

Self-heat balance laterite ore reduction method

InactiveCN113322362ASimple processReduce energy consumptionShaft furnaceCombustion chamberEngineering

The invention belongs to the technical field of nonferrous metallurgy, and particularly relates to a laterite ore self-heating balance reduction method. According to the laterite ore self-heating balance reduction method, coal is used as a reducing agent, on one hand, crystal water in laterite is evaporated at a high temperature and then is subjected to a water-gas reaction with the coal to generate coal gas, on the other hand, the coal gas and volatile components decomposed in the coal are also generated in the reduction process, and mixed coal gas is led out at a high temperature and returns to a combustion chamber to be combusted to serve as a heat source; and additional fuels such as the coal gas are not needed, process is simple, energy consumption is low, and energy conservation and environmental protection are achieved. The adopted coal is cheap and low-grade bituminous coal, self-heat-supply reduction is achieved, energy conservation and environmental protection are achieved, and production cost is low. A direct reduction shaft furnace can realize self-heating direct reduction, does not need or only needs a small amount of additional fuel gas, and can effectively reduce energy consumption and production cost.

Owner:SICHUAN LOMON MINING & METALLURGY

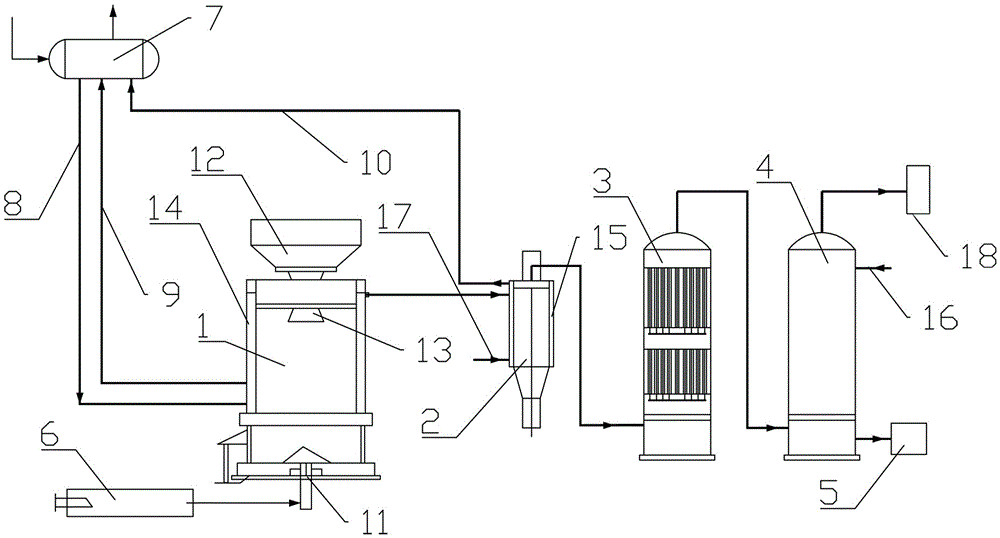

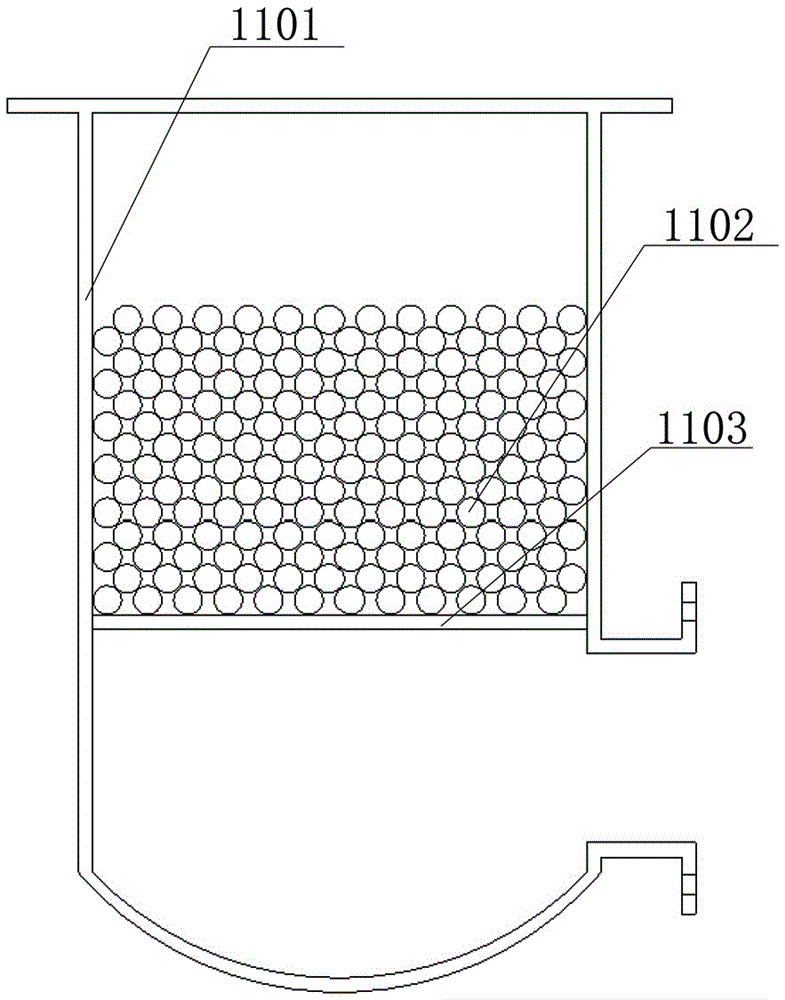

Fixed-bed pure-oxygen continuous gasification device and process adaptable to diversified coals

ActiveCN105542860AImprove decomposition rateHigh effective gas contentChemical industryGasification processes detailsAdditive ingredientFixed bed

Owner:河南顺达新能源科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap