Friction coating with light-emitting early-warning function and preparation method of friction coating

A friction coating and functional technology, applied in the field of friction coating with luminescent warning function and its preparation, can solve the problems of limiting the development and application of detection methods, interference, etc., and achieve the effects of low cost, elimination of interference, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Phosphor with double-layer luminescent effect and aluminum oxide (Al 2 o 3 ) Preparation of composite friction powder:

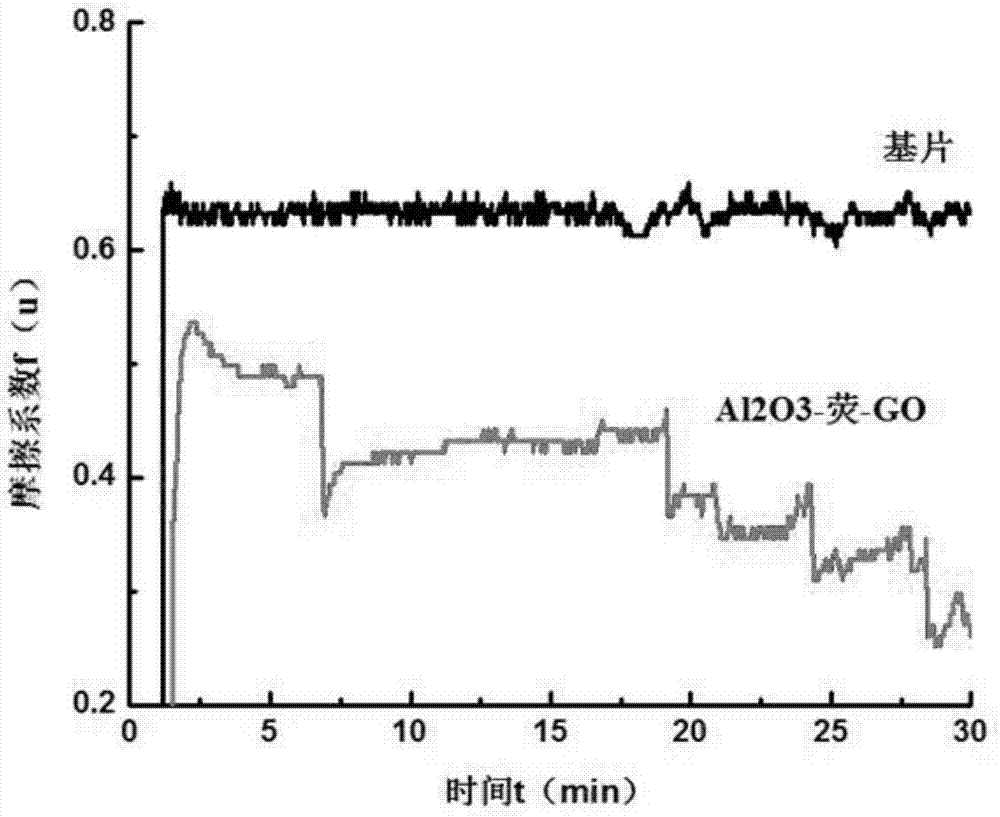

[0028] Take 20g of Al 2 o 3 With phosphors with different blue and green emission spectra, the phosphors of different colors and Al 2 o 3 According to the mass ratio of 1:4, add an appropriate amount of absolute ethanol to it, put it into a ball mill and stir it for 20 hours with a ball-to-material ratio of 500:1, and put it into an ultrasonic disperser for dispersion treatment to obtain uniformly dispersed Al 2 o 3 . In the above Al 2 o 3 Add 0.3% graphene to the mixture, continue to mix it with the oxide in a ball mill for 12 hours at a ball-to-material ratio of 500:1, and finally get Al 2 o 3 , phosphor and graphene composite powder.

[0029] (2) Preparation of composite film containing double-layer luminescent effect:

[0030] Prepare the epoxy resin-based film-forming system formula, with 45% epoxy resin, 15% polyamide resin, 15% ben

Embodiment 2

[0032] (1) Phosphors with a single green luminescence effect and titanium oxide (TiO 2 ) Preparation of composite friction powder:

[0033] Take 20g TiO 2 , add an appropriate amount of absolute ethanol to it, put it into a ball mill and stir it for 20h with a ball-to-material ratio of 500:1, then put the material into an ultrasonic disperser, open the suspension and agglomerate, so as to obtain uniformly dispersed TiO 2 , take out a part as a sample. Then add green phosphor powder to the remaining part, so that TiO 2 The mass ratio to the phosphor is 4:1, put it into a ball mill and stir for 12 hours at a ball-to-material ratio of 500:1 to obtain TiO 2 Composite powder with green phosphor.

[0034] (2) Preparation of composite films containing different luminous bodies:

[0035]Prepare the epoxy resin-based film-forming system formula, with 45% epoxy resin, 15% polyamide resin, 15% benzyl alcohol diluent, 10% OP-10 dispersant and 5% coupling agent, plus a small amount of di

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap