Integrated automobile manufacturing line

An automobile manufacturing, integrated technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as difficulty, poor mobility, and high demand for automobiles, achieve a small footprint, a high degree of integration, and solve travel problems. difficult effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] The following will be described in detail in conjunction with the embodiments of the present invention with reference to the accompanying drawings.

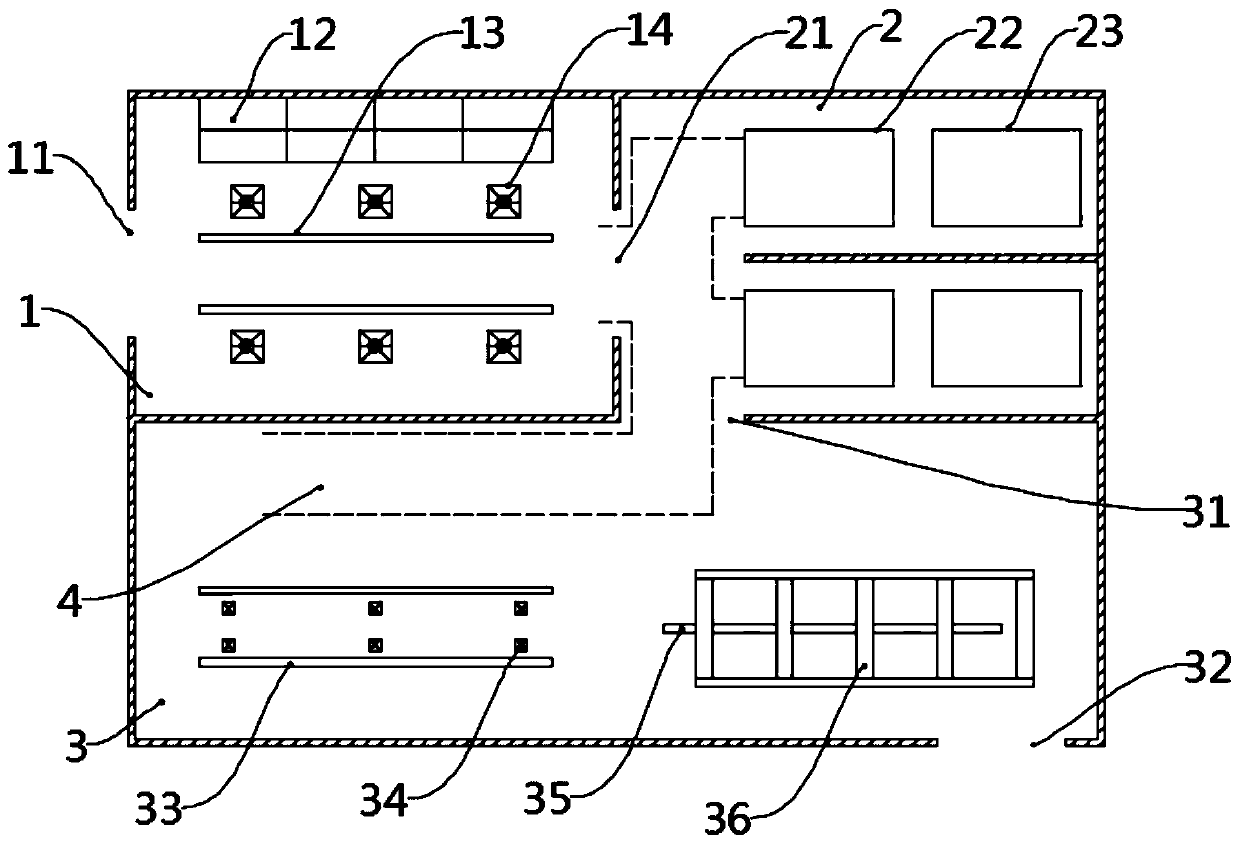

[0020] Integrated automobile manufacturing line, including welding workshop 1, painting room 2 and final assembly workshop 3;

[0021] The left side of the welding workshop 1 is provided with a general entrance 11, and the interior of the welding workshop 11 is provided with a parts storage area 12, and the inner bottom surface of the welding workshop 11 is provided with two first rails arranged in parallel in front and back 13. A number of welding machines 14 are installed on the top of the welding workshop 1 on the first track 13;

[0022] The painting room 2 is located on the right side of the welding workshop 1; a No. 1 entrance and exit 21 is set between the painting room 2 and the welding workshop 1, and there are left and right painting booths 22 arranged side by side in the painting room 2 and paint bit 23;

[0023]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap