Aqueous rubber polymer waterproof coating and preparation method thereof

A polymer waterproof and water-based polymer technology, applied in the field of architectural waterproof coatings, can solve the problems of short life of the waterproof layer, easy milk return, softening, waterproof performance decline, etc., and achieve the effect of high elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0090]Example 1

[0091]A water-based rubber polymer waterproof coating, which is characterized in that it comprises a water-based polymer composite emulsion and an inorganic filler, and the water-based polymer composite emulsion is prepared from the following parts by weight of raw materials:

[0092]Linear SBS 4%

[0093]Linear SIS 10%

[0094]SBR 7%

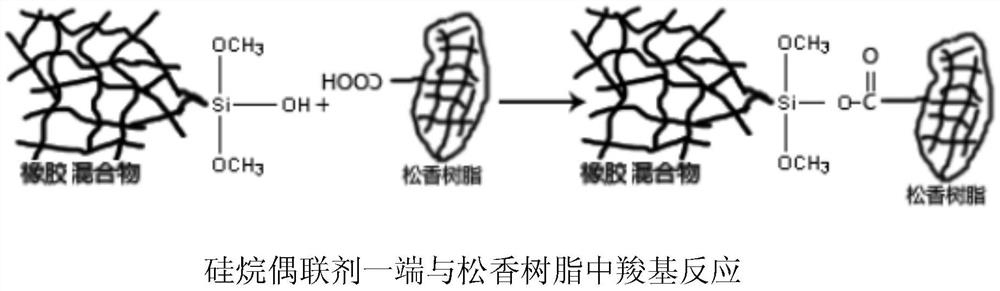

[0095]Rosin resin 10%

[0096]Naphthenic oil 13%

[0097]Vinyl triethoxysilane 0.2%

[0098]Alkylphenol polyoxyethylene ether 1.0%

[0099]Ammonia 0.7%

[0100]Zinc acetate 0.5%

[0101]Water 53.6%

[0102]A preparation method of water-based rubber polymer waterproof coating includes the following steps:

[0103](1) Preparation of polymer composite rubber

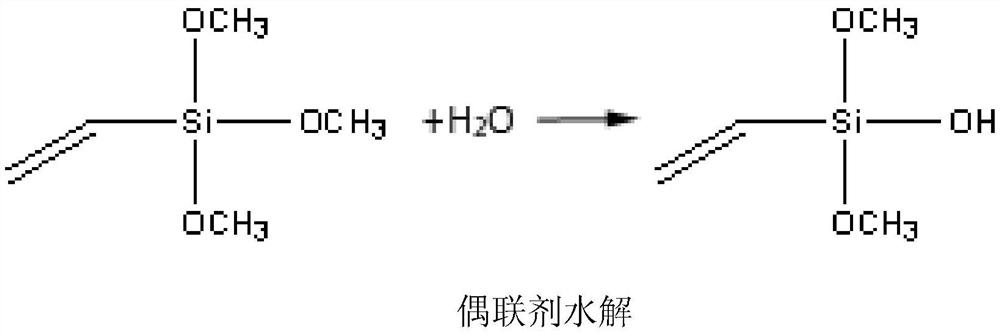

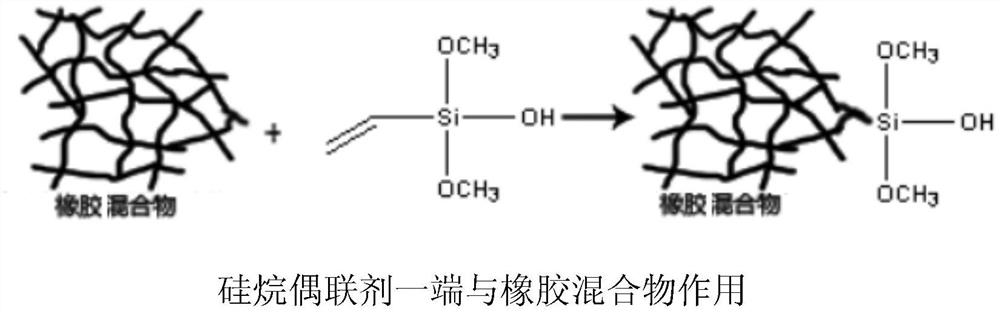

[0104]Put naphthenic oil, linear SBS, SBR, linear SIS, and rosin resin into the modification kettle, heat up to 170℃~200℃, mix and modify for 1h~4h; mix vinyl triethoxysilane and water according to weight After mixing evenly with a ratio of 1:1, pour it into the modification kettle and mix and stir for 0.5h-1h at 170℃~200℃

Example Embodiment

[0112]Example 2

[0113]A water-based rubber polymer waterproof coating, which is characterized in that it comprises a water-based polymer composite emulsion and an inorganic filler, and the water-based polymer composite emulsion is prepared from the following parts by weight of raw materials:

[0114]Linear SBS 12%

[0115]Linear SIS 13%

[0116]SBR 10%

[0117]Rosin resin 8%

[0118]Aromatic oil 15%

[0119]β—(3,4 epoxy cyclohexyl) ethyl trimethoxysilane 0.4%

[0120]Fatty alcohol polyoxyethylene ether 3.0%

[0121]Ammonia 1.3%

[0122]Zinc acetate 0.8%

[0123]Water 36.5%

[0124]A preparation method of water-based rubber polymer waterproof coating includes the following steps:

[0125](1) Preparation of polymer composite rubber

[0126]Put aromatic oil, linear SBS, SBR, linear SIS, rosin resin into the modification kettle, heat up to 170℃~200℃, mix and modify for 1h~4h; add β—(3,4 epoxy cyclohexyl) Ethyltrimethoxysilane and water are evenly mixed in a weight ratio of 1:1, then poured into the modification kettle, mixed and

Example Embodiment

[0134]Example 3

[0135]A water-based rubber polymer waterproof coating, which is characterized in that it comprises a water-based polymer composite emulsion and an inorganic filler, and the water-based polymer composite emulsion is prepared from the following parts by weight of raw materials:

[0136]Linear SBS 5%

[0137]Linear SIS 10%

[0138]SBR 6%

[0139]Rosin resin 9%

[0140]Naphthenic oil 30%

[0141]3-glycidylpropyltrimethoxysilane 0.3%

[0142]Alkylphenol polyoxyethylene ether 0.7%

[0143]Fatty alcohol polyoxyethylene ether 1.5%

[0144]Ammonia 2.0%

[0145]Zinc acetate 0.5%

[0146]Water 35%

[0147]A preparation method of water-based rubber polymer waterproof coating includes the following steps:

[0148](1) Preparation of polymer composite rubber

[0149]Put the naphthenic oil, linear SBS, SBR, linear SIS, and rosin resin into the modification kettle, heat up to 170℃~200℃, mix and modify for 1h~4h; combine the coupling agent and water according to the weight ratio of 1:1 After mixing uniformly, pour into the modifi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap