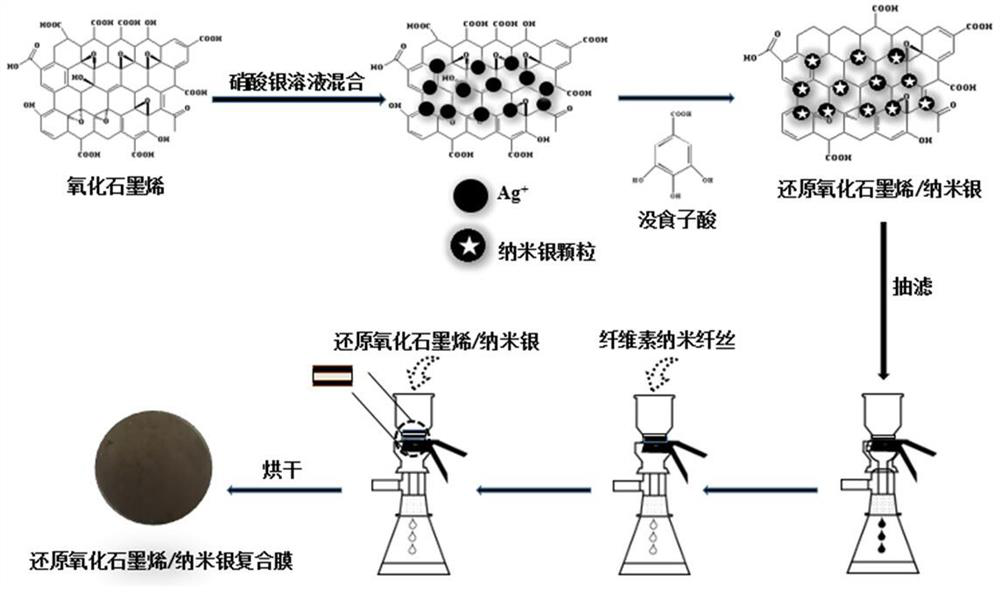

Preparation method of reduced graphene oxide/nano-silver composite film

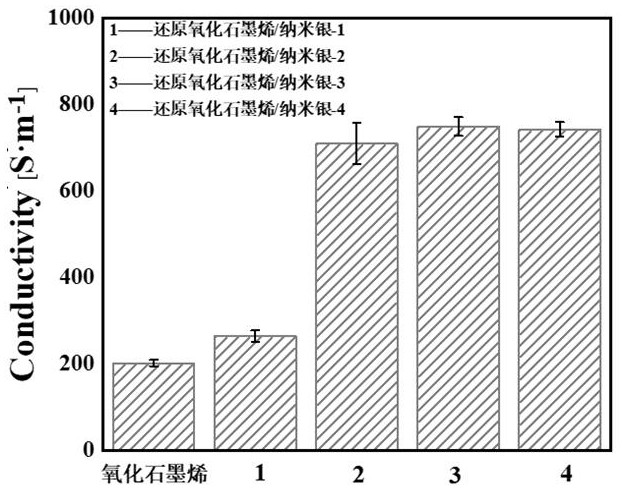

A graphene and nano-silver technology, applied in the field of composite membranes, can solve problems such as environmental pollution, and achieve the effects of improving mechanical properties, improving electrical conductivity, and preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

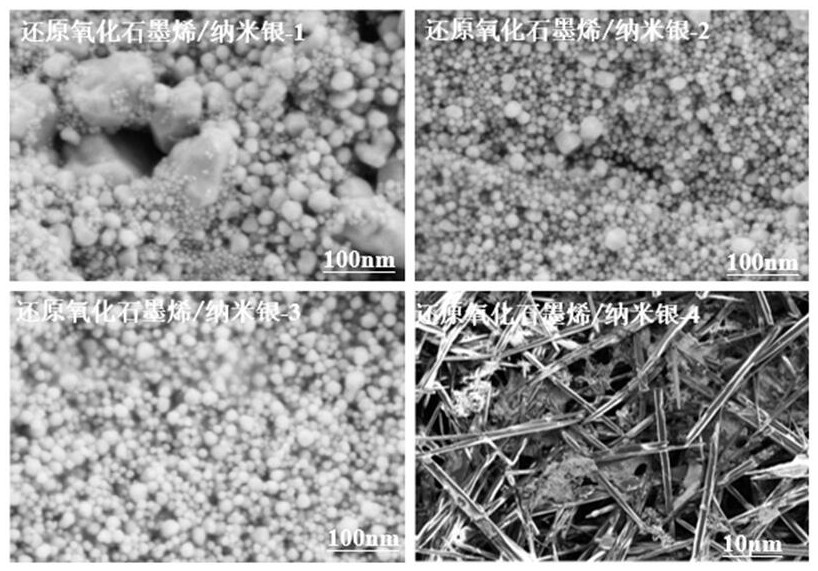

[0026] Example 1

[0027] First, add an ammonia solution to the graphene oxide / silver nitrate mixed solution, adjust the pH to 11, add a certain weight of reducing agent gallic acid (the mass ratio of gallic acid to silver nitrate is 0.25:1), and heat it in a water bath until it is in a water bath. Heating to 35° C. and reacting for 2.5 h to obtain the reduced graphene oxide / nano-silver mixed solution. Then put a layer of filter membrane in the sand core funnel, pour the uniform reduced graphene oxide / nanosilver mixture into the sand core funnel, and filter for 1h to dry state; pour the uniform cellulose nanofibril solution, Suction filtration for 4h to a dry state; pour into a uniform reduced graphene oxide / nano-silver mixture, suction filtration for 2h to a dry state (the absolute dry mass ratio of the mixture poured in three suction filtrations is 1:1:1). Finally, the composite membrane and filter membrane obtained by suction filtration were placed on a polytetrafluor

Example Embodiment

[0028] Example 2

[0029] First, add an ammonia solution to the graphene oxide / silver nitrate mixed solution, adjust the pH to 11, add a certain weight of reducing agent gallic acid (the mass ratio of gallic acid to silver nitrate is 0.5:1), and heat it in a water bath until the Heating to 45° C. and reacting for 1.5 h to obtain the reduced graphene oxide / nano-silver mixed solution. Then put a layer of filter membrane in the sand core funnel, pour the uniform reduced graphene oxide / nanosilver mixture into the sand core funnel, and filter for 1h to dry state; pour the uniform cellulose nanofibril solution, Suction filtration for 4h to a dry state; pour into a uniform reduced graphene oxide / nano-silver mixture, suction filtration for 2h to a dry state (the absolute dry mass ratio of the mixture poured in three suction filtrations is 1:1:1). Finally, the composite membrane and filter membrane obtained by suction filtration were placed on a polytetrafluoroethylene plate, and

Example Embodiment

[0030] Example 3

[0031] First, add an ammonia solution to the graphene oxide / silver nitrate mixed solution, adjust the pH to 11, add a certain weight of reducing agent gallic acid (the mass ratio of gallic acid to silver nitrate is 0.75:1), and heat it in a water bath until the Heating to 40° C. and reacting for 2 h to obtain the reduced graphene oxide / nano-silver mixed solution. Then put a layer of filter membrane in the sand core funnel, pour the uniform reduced graphene oxide / nanosilver mixture into the sand core funnel, and filter for 1h to dry state; pour the uniform cellulose nanofibril solution, Suction filtration for 4h to a dry state; pour into a uniform reduced graphene oxide / nano-silver mixture, suction filtration for 2h to a dry state (the absolute dry mass ratio of the mixture poured in three suction filtrations is 1:1:1). Finally, the composite membrane and filter membrane obtained by suction filtration were placed on a polytetrafluoroethylene plate, and

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap