Bonding pad layer system, gas sensor and method for manufacturing a gas sensor

a gas sensor and bonding pad technology, applied in the direction of instruments, fluid speed measurement, coatings, etc., can solve the problem of system lack of process stability, achieve the effects of reducing material consumption, reducing material consumption, and preventing the diffusion behavior of atoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]Identical reference numerals in the figures refer to identical or functionally identical elements.

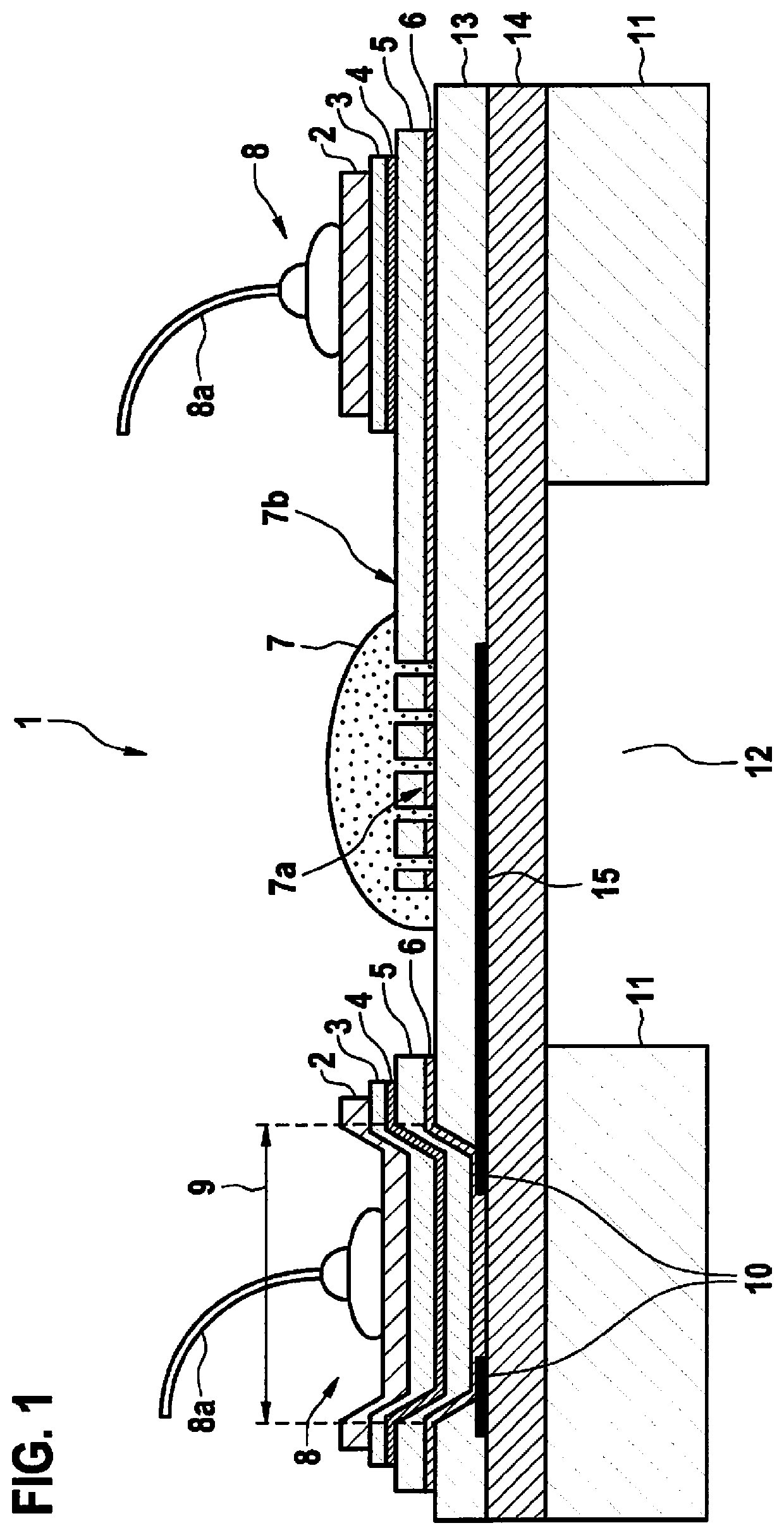

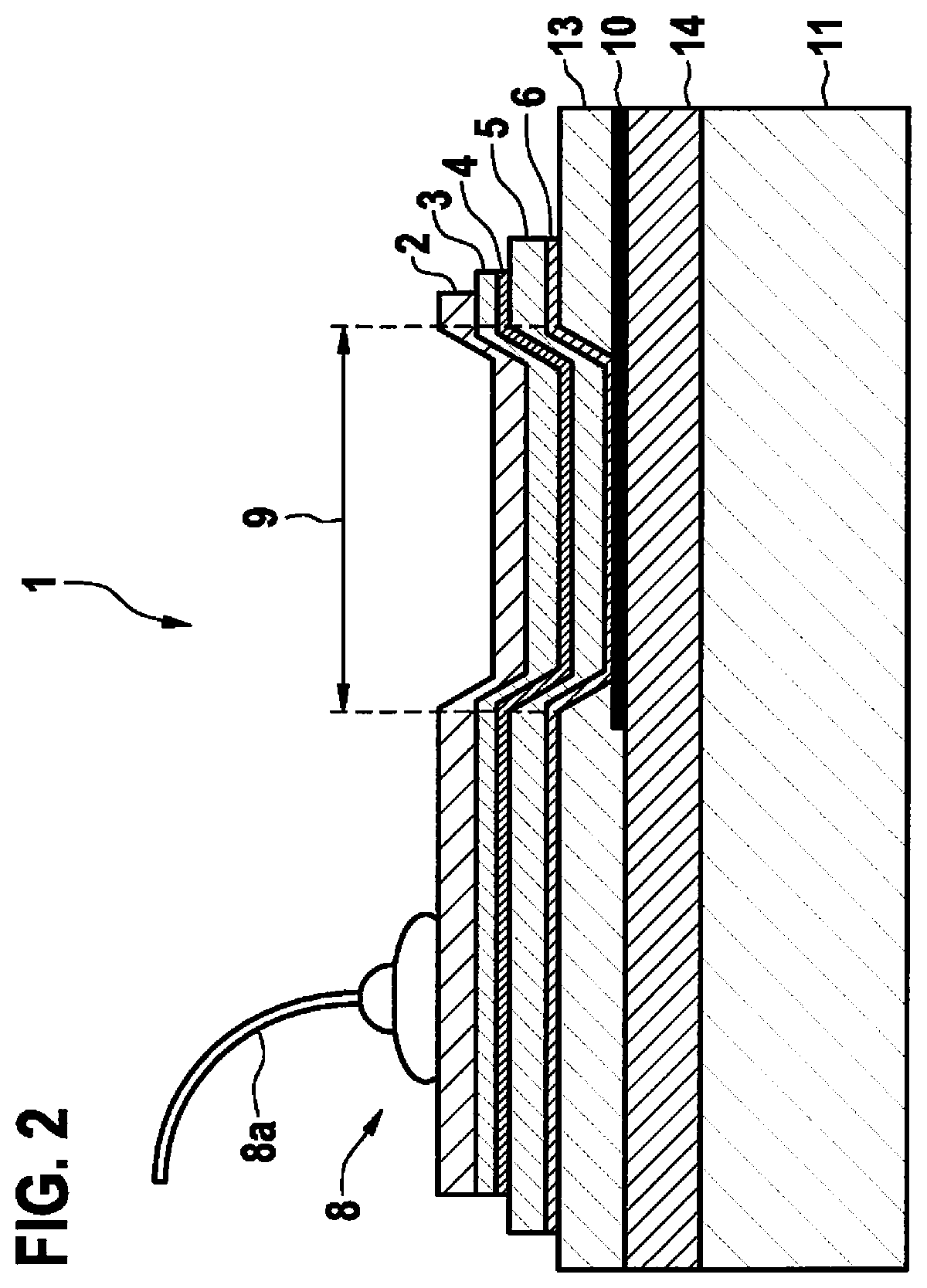

[0030]FIG. 1 is a schematic representation of a gas sensor according to a first specific embodiment of the present invention.

[0031]One possible implementation of a gas sensor according to the present invention is shown, including a bonding path layer system 1, including a micromechanical semiconductor chip 11 having a cavern 12 as a base, two dielectric layers 13 and 14, a platinum conductor track 10 to heater 15 in cavern area 12, a tantalum layer 6, upon which a first platinum layer 5 is deposited, upon that a tantalum nitride layer 4 is deposited, upon that a second platinum layer 3 is deposited, upon that a gold layer 2 is deposited, the individual layers being deposited over the entire area, even over a contact hole 9 and the individual layers subsequently being structured with the aid of standard methods. A bonding pad 8, a bonding wire 8a, a paste dot 7 and schematically an el

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap