Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

17 results about "Blow out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

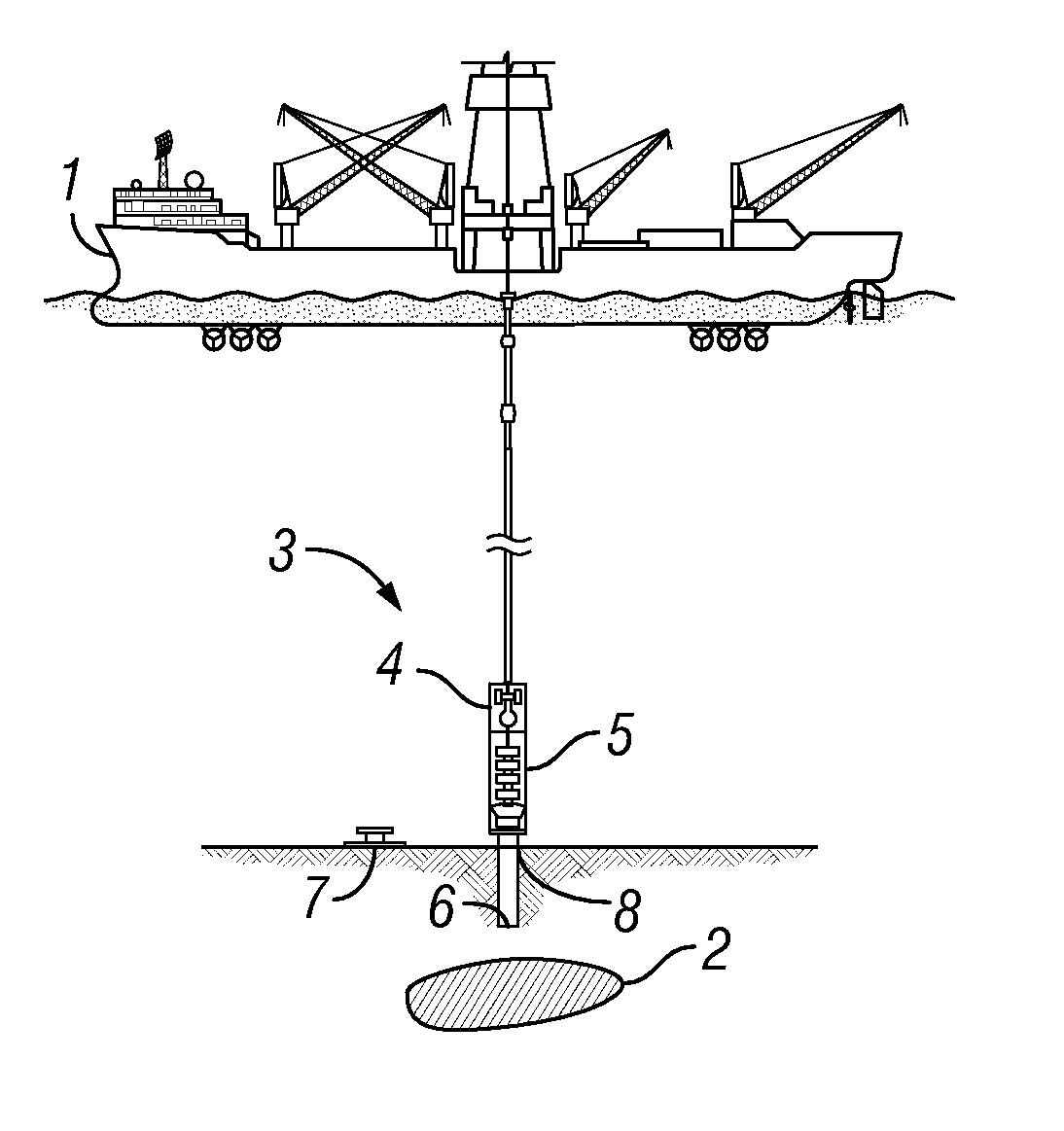

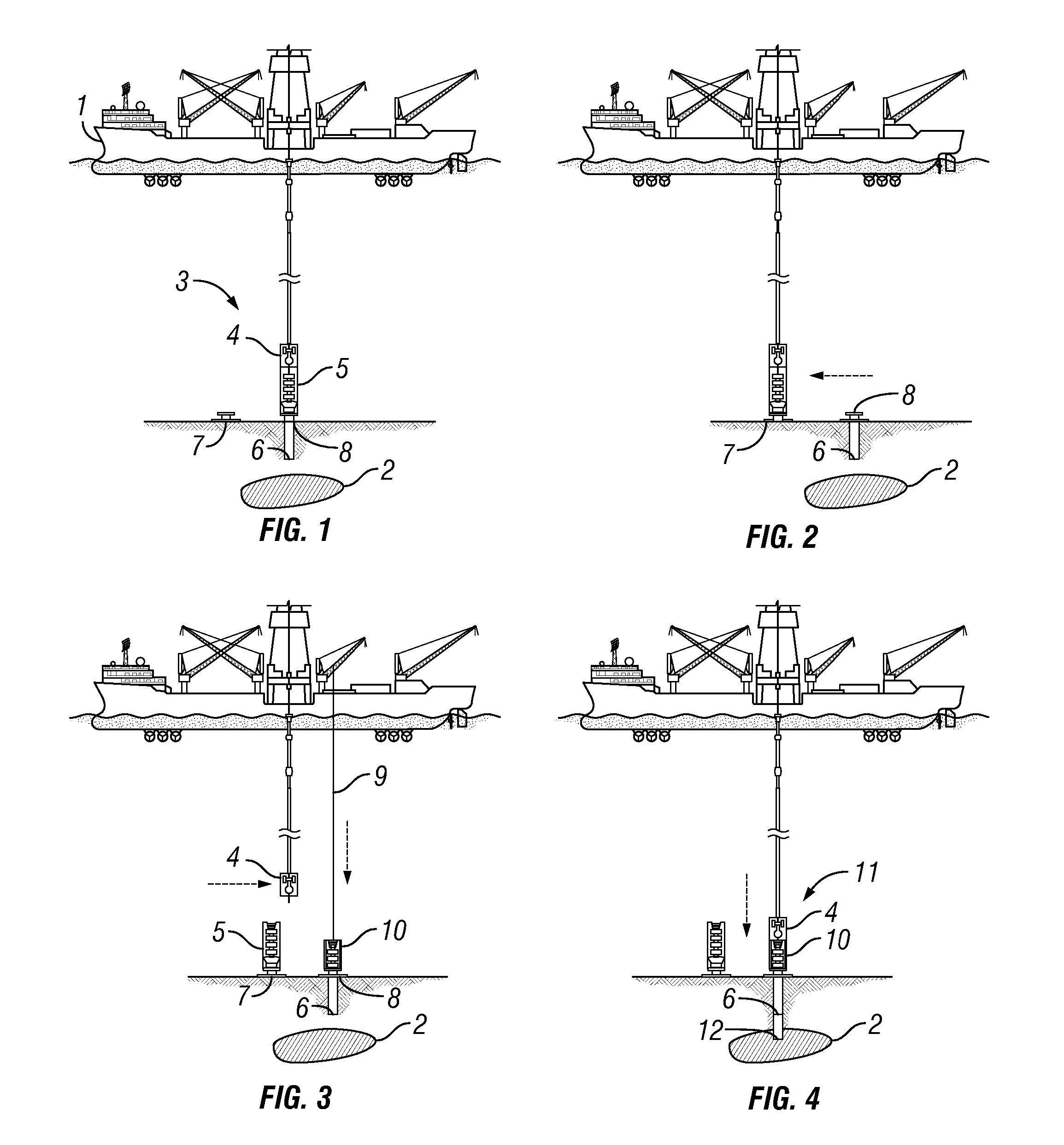

Dual-bop and common riser system

Owner:TRANSOCEAN OFFSHORE DEEPWATER DRILLING

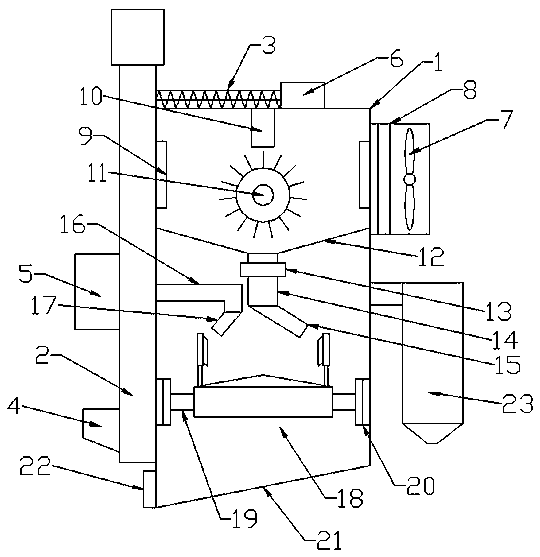

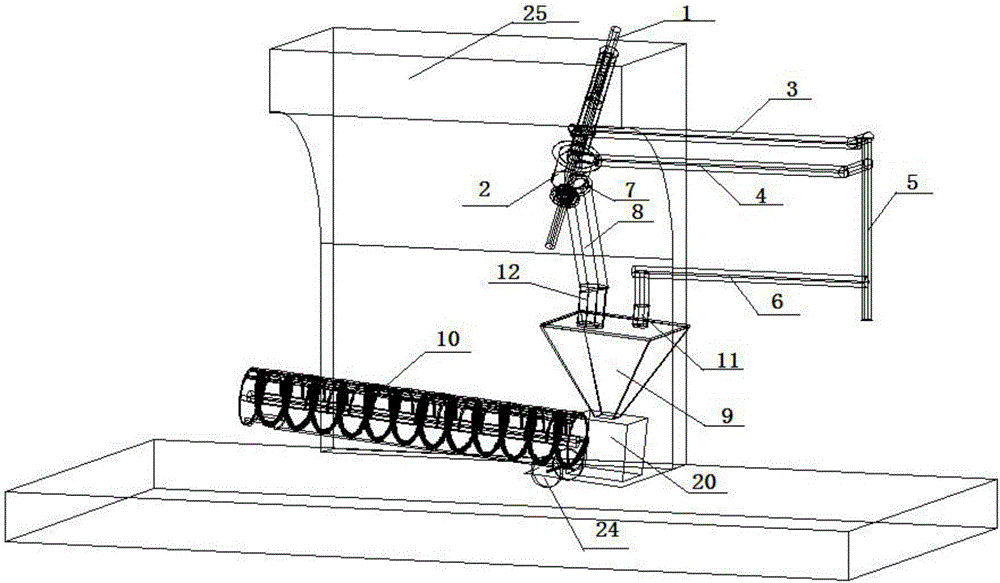

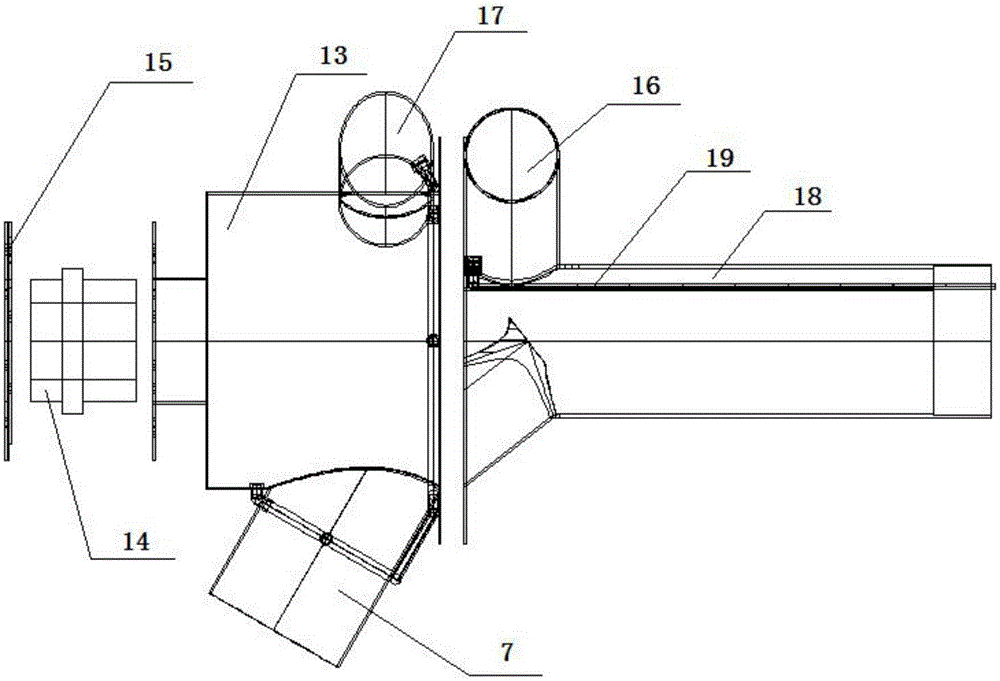

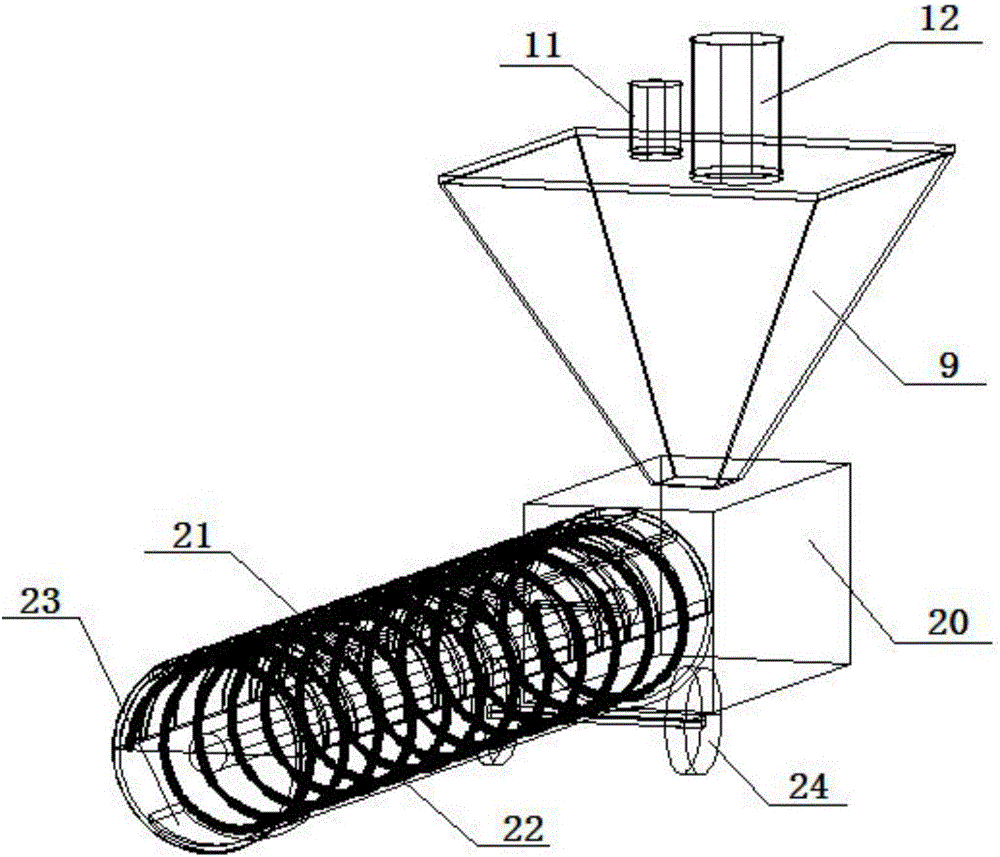

Impulse type food dryer

InactiveCN105494623AImprove drying efficiencyImprove product qualitySeed preservation by dryingAgricultural engineeringAir blower

Owner:刘操

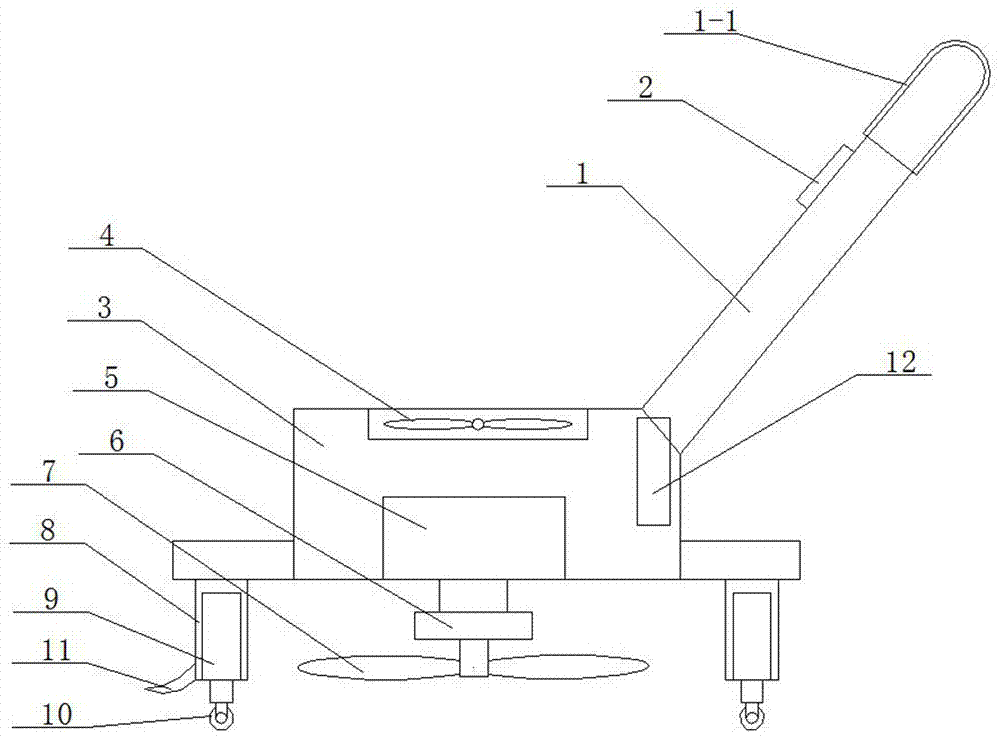

Novel mower

Owner:安徽富牧通生物科技有限公司

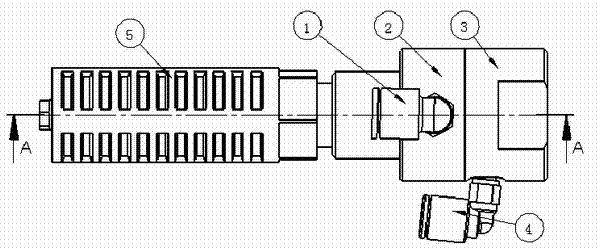

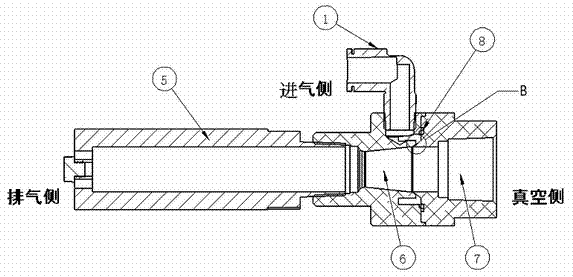

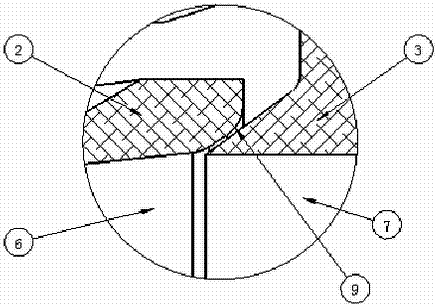

High-flow vacuum generator

InactiveCN104512012AIncrease the size of the acceleration zoneIncrease profitJet pumpsMachines/enginesLow noiseIndustrial equipment

Owner:STAR SEIKI XIANGYANG

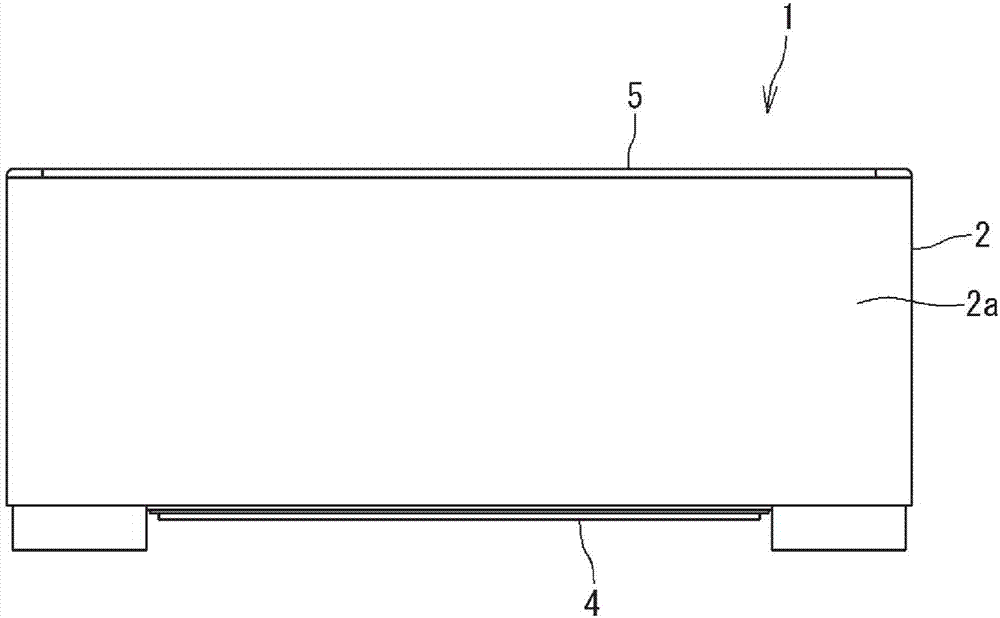

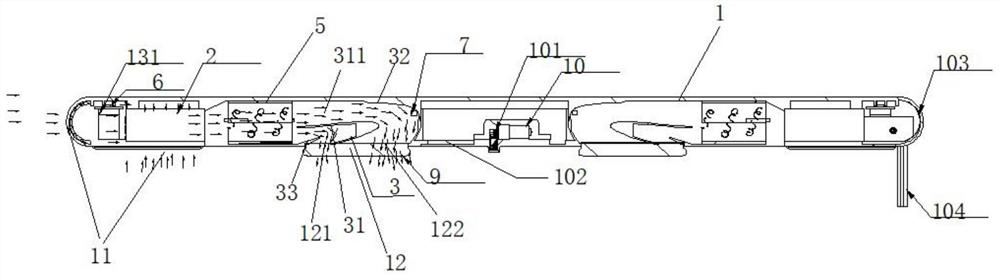

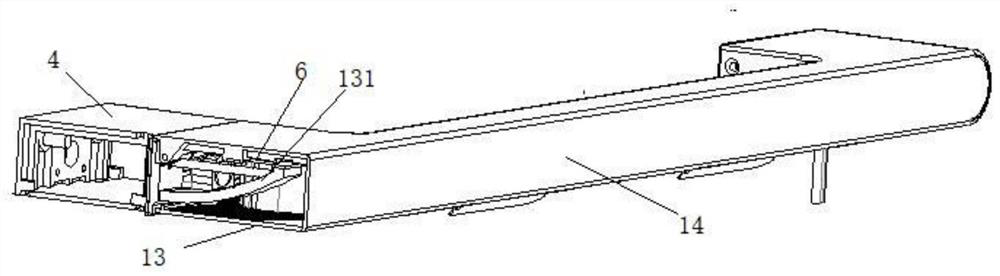

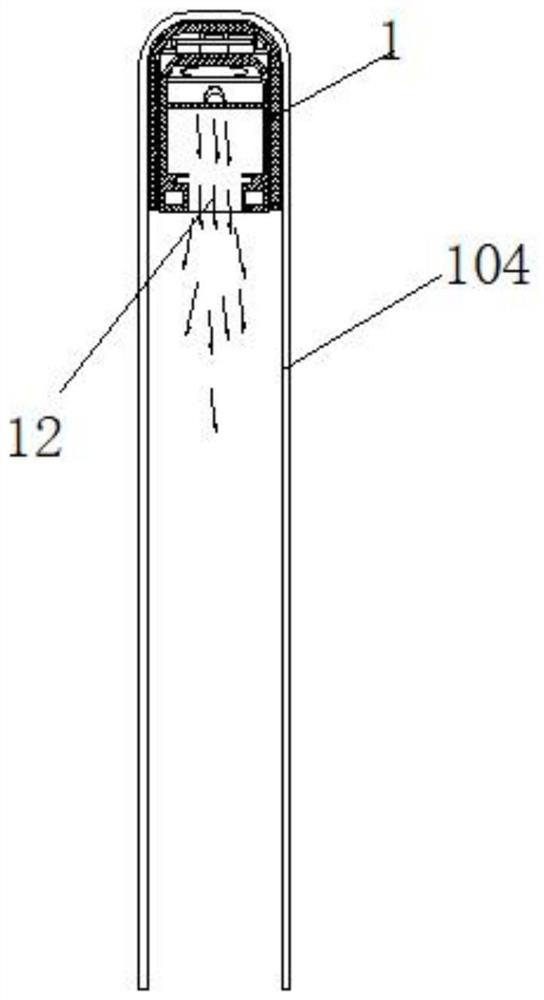

Indoor unit of air conditioning system

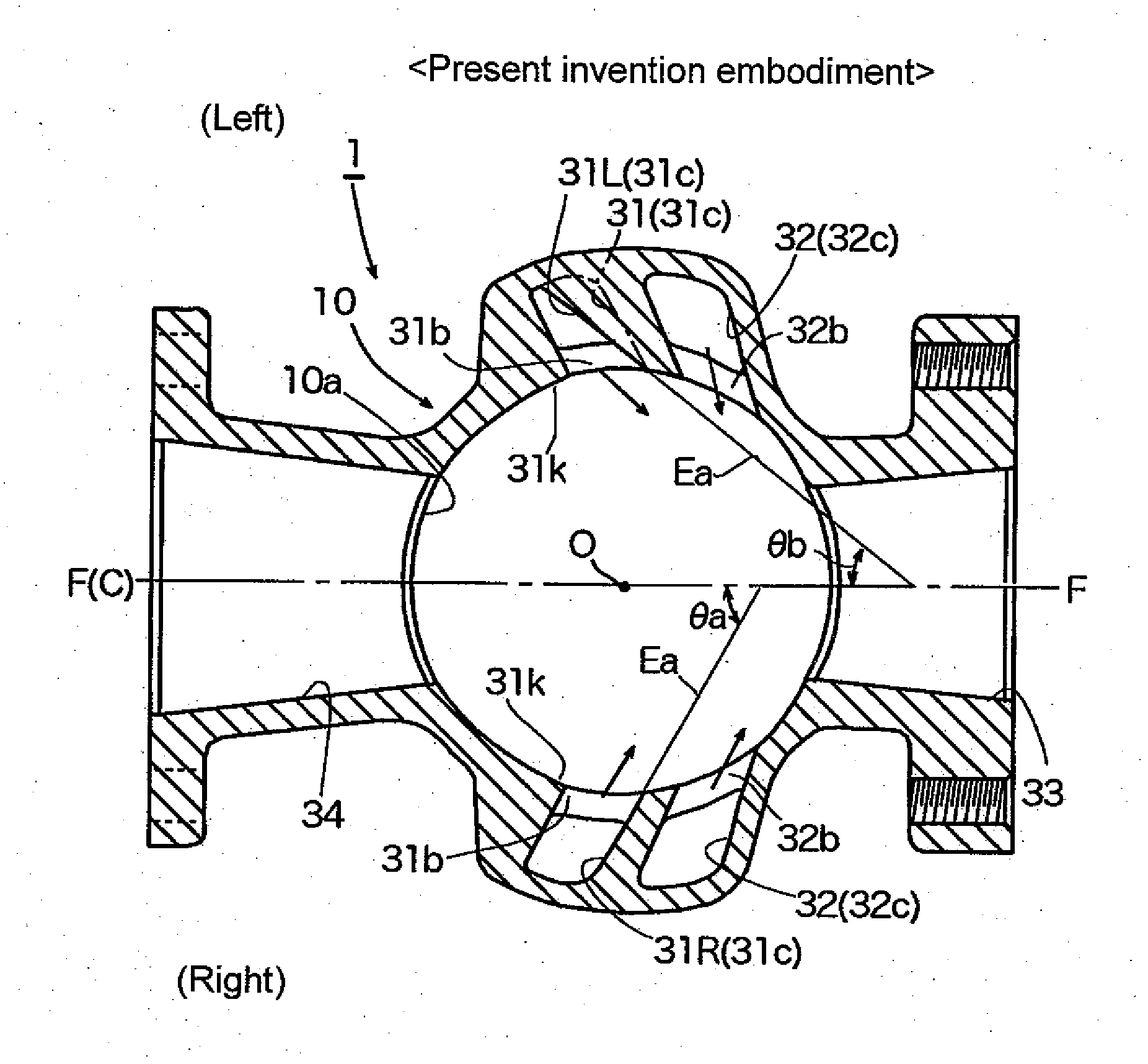

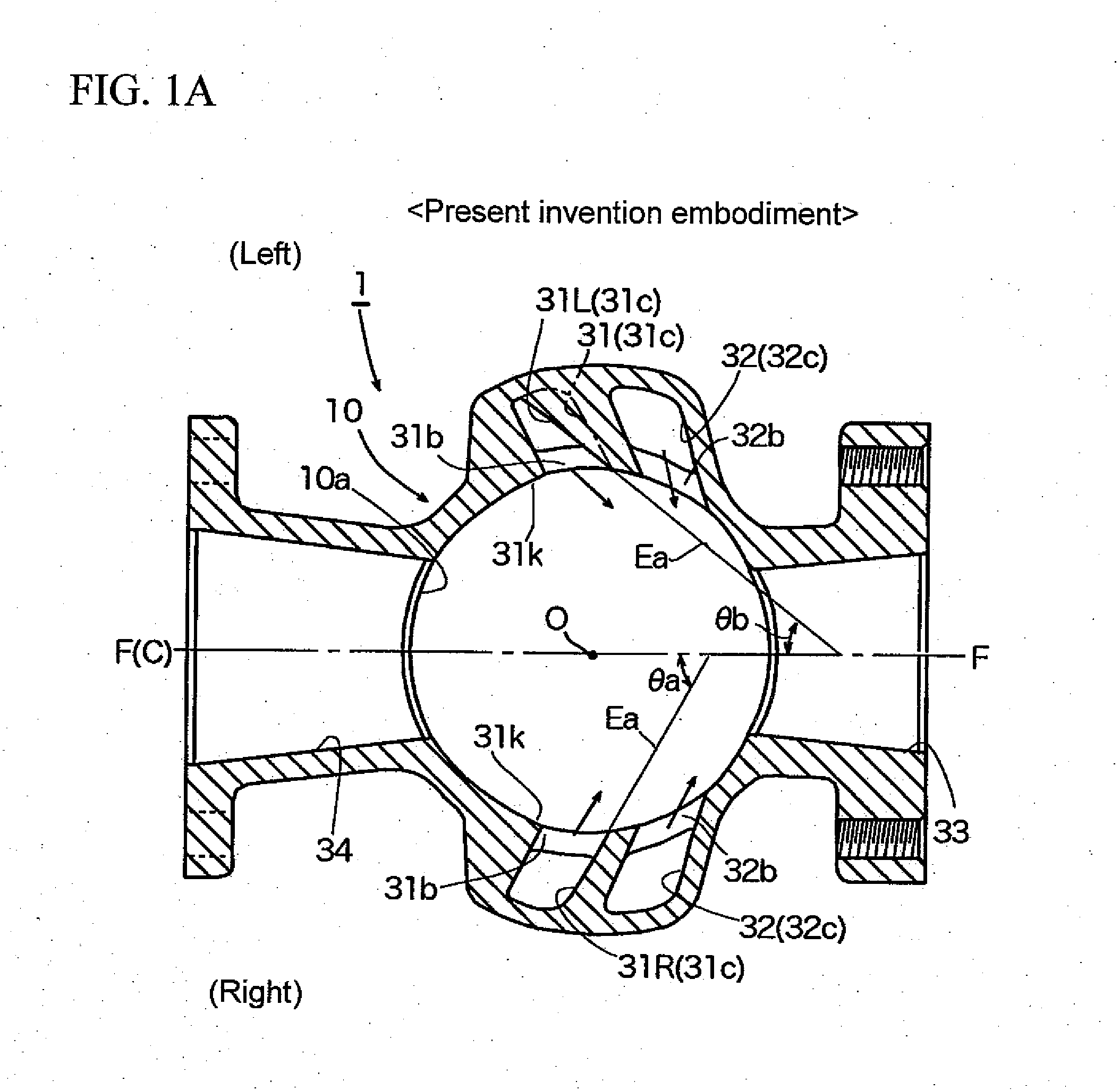

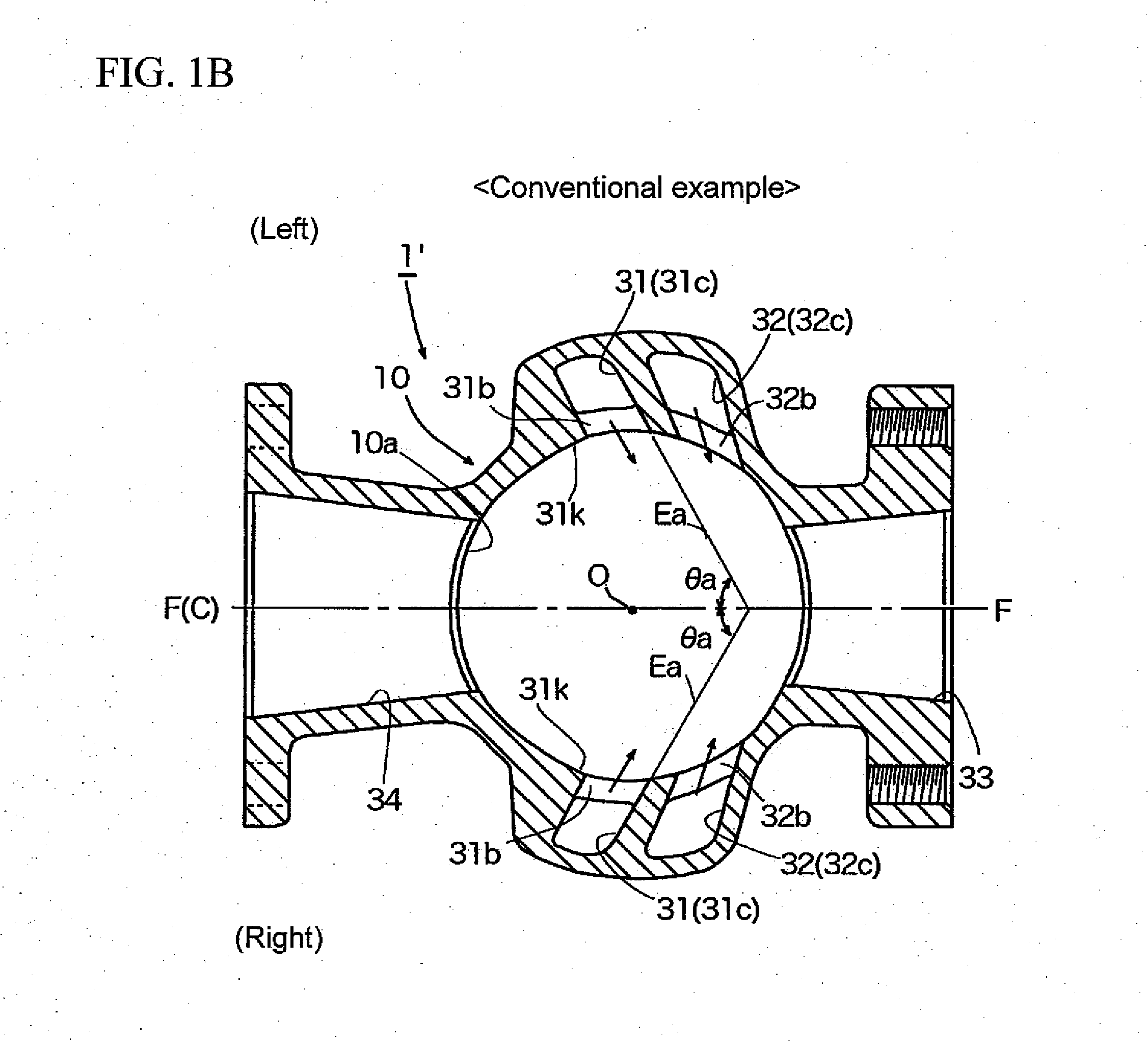

ActiveCN107407491AImprove diffusion abilityGuaranteed Diffusion EffectMechanical apparatusSpace heating and ventilation safety systemsEngineeringRefrigerant

Owner:DAIKIN IND LTD

Preparation method of gel bead

ActiveCN110404486ASmall size differenceEasy to operateGel preparationColloidal chemistry detailsLiquid storage tankThermostat

The invention relates to the fields of research and development of new materials and new structures, and concretely relates to a preparation method of a gel bead. A preparation device of the gel beadscomprises a cavity, an airflow cover, an air outlet pipe, a nozzle, a syringe pump, liquid storage tanks, an air inlet tube, a flow meter, a thermostat and a liquid conveying tube. A liquid raw material for gel beads to be prepared is placed in the first liquid storage tank, and the thermostat is turned on to maintain the temperature in the chamber at 30 DEG C; the flow rate of the flow meter isadjusted to 2 L / min to make air sequentially go through the second liquid storage tank and the air outlet tube from the air inlet tube and be downwards blown out from the airflow cover; a liquid in the first liquid storage pool is transported to the nozzle by the syringe pump, and the liquid forms a drop at the lower end of the nozzle; a part of air in the airflow cover enters a main tube throughfour slits at the nozzle, and generates a pulling force to the liquid drops at the lower end of the nozzle; and the liquid drop at the lower end of the nozzle is separated from the nozzle, drips intoan oily liquid in the third liquid storage tank, and moves downwards under the action of gravity, and the liquid drop gradually solidifies in the dripping process to form the gel bead.

Owner:JINHUA VOCATIONAL TECH COLLEGE

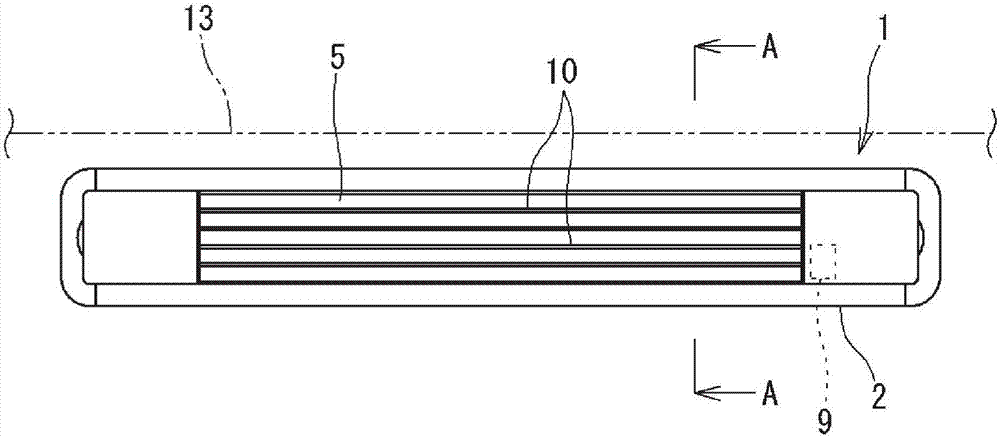

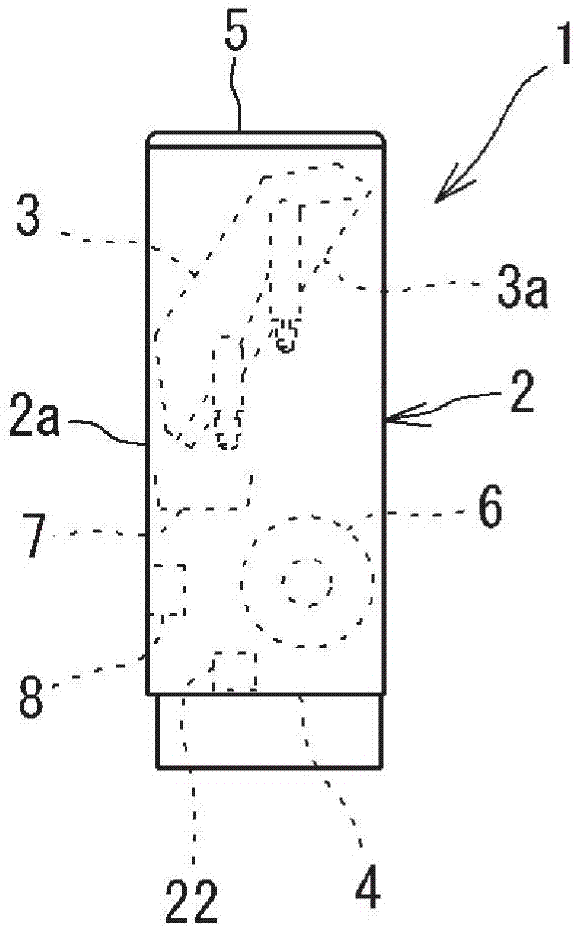

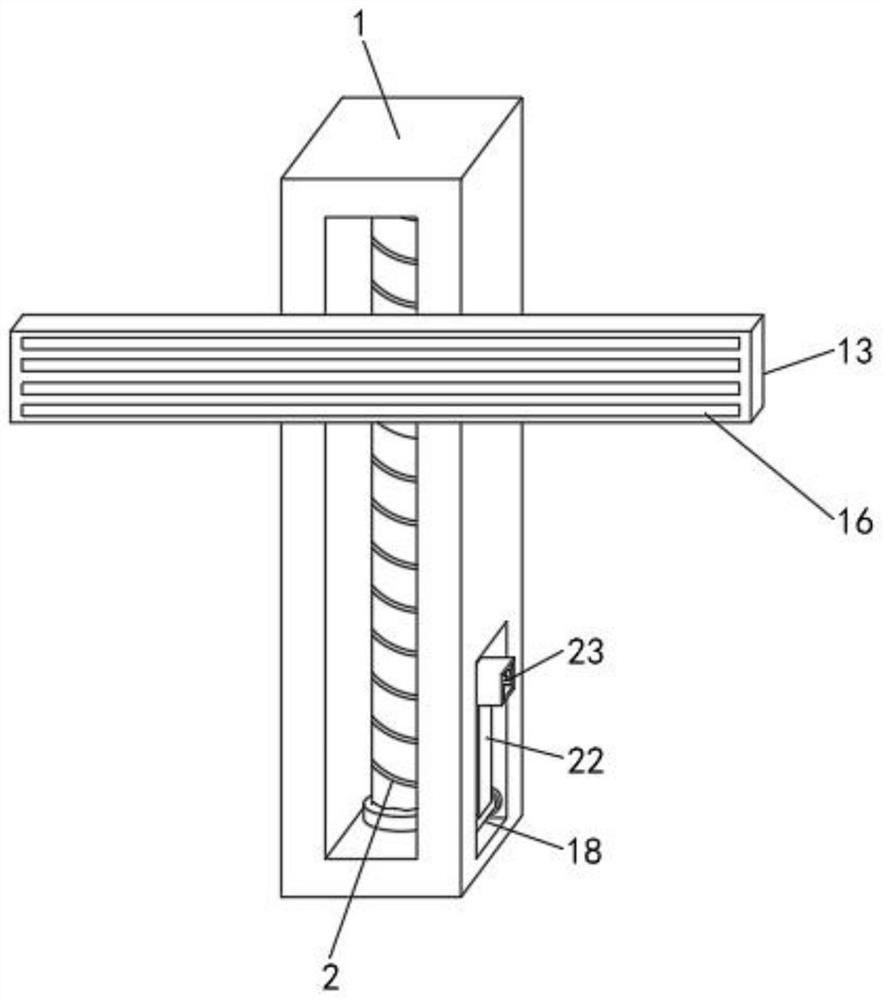

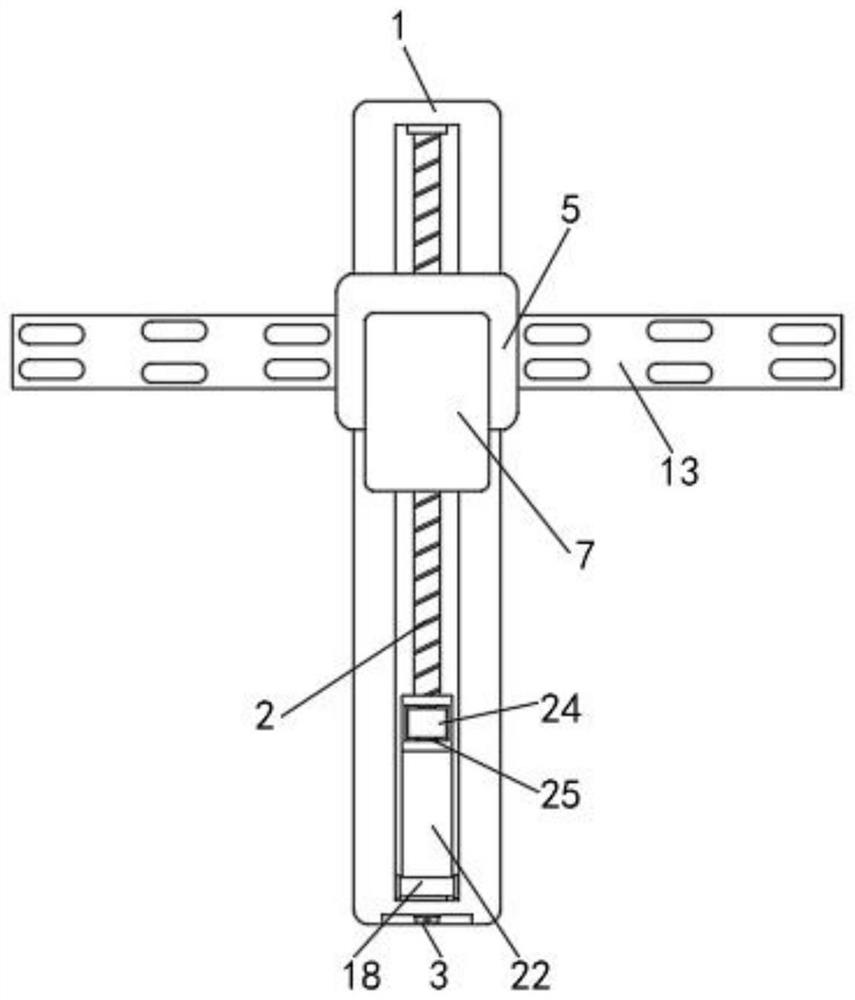

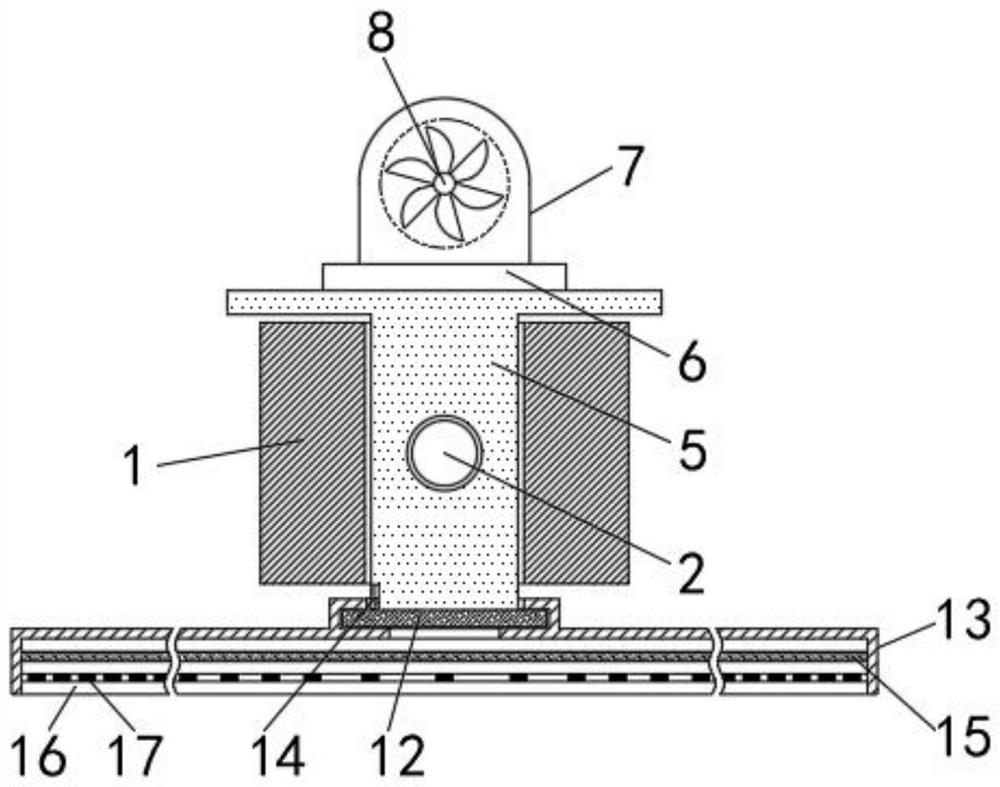

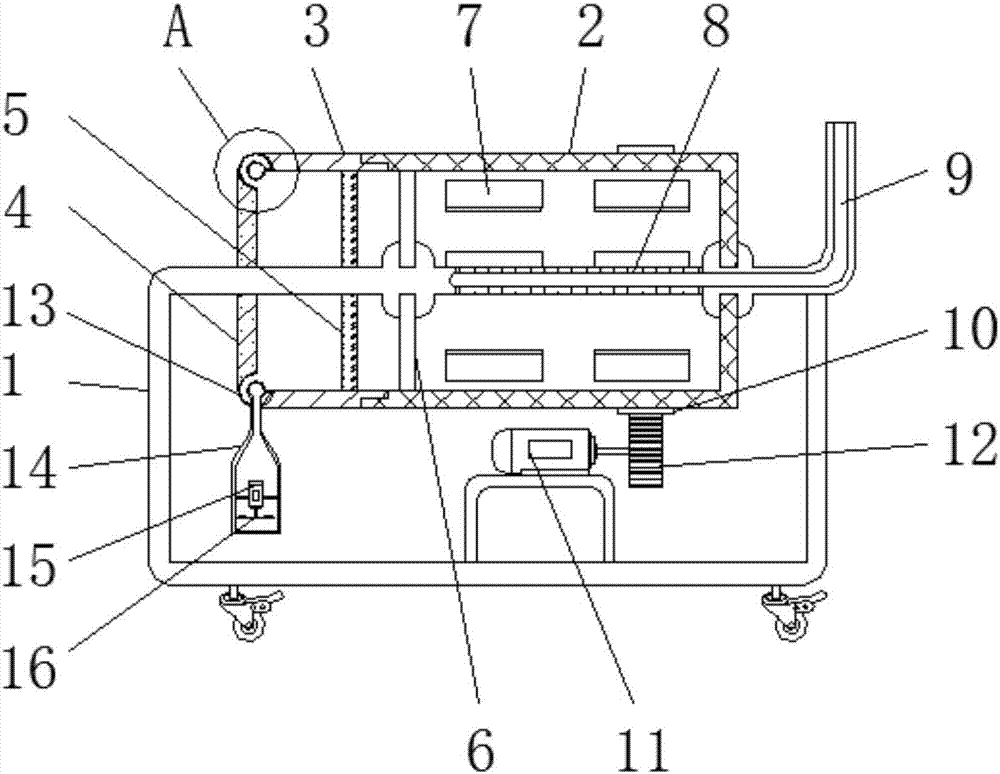

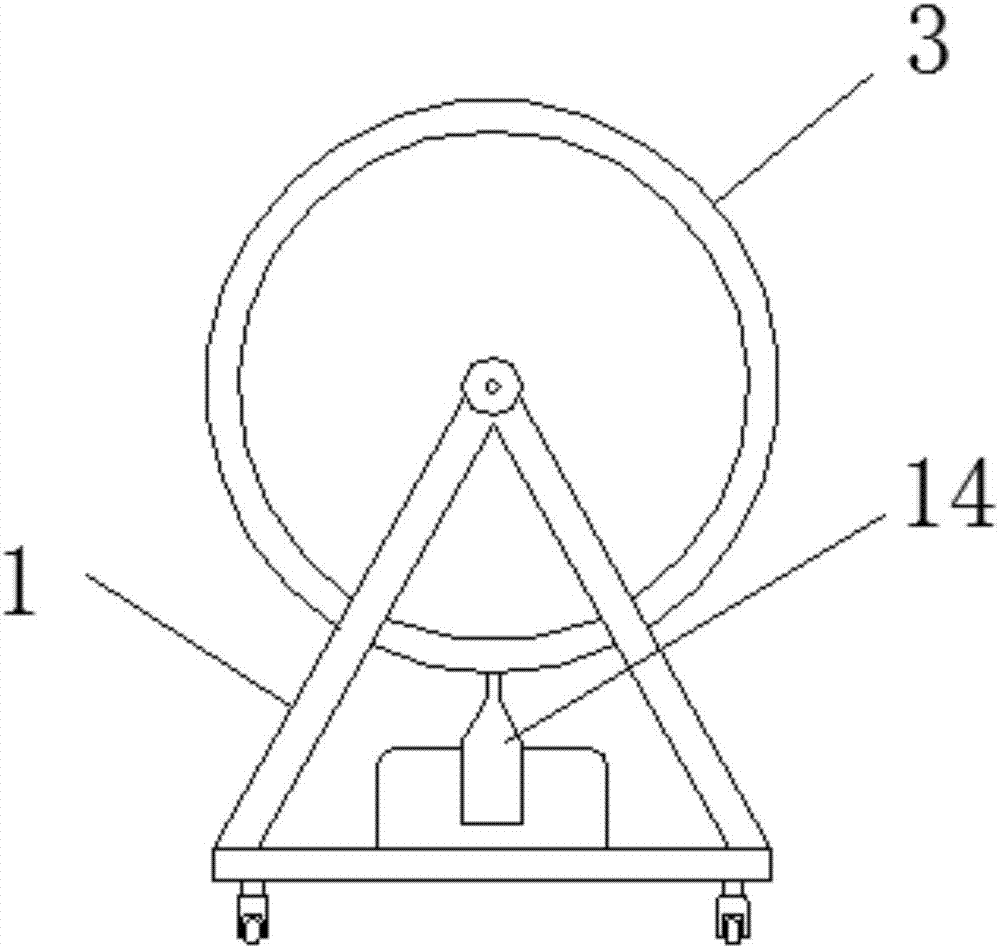

Direction-turning vertical warm air clothes dryer with single air outlet pipe

InactiveCN104328634AIncrease evaporation areaDry fastTextiles and paperLaundry driersControl systemBlow out

The invention relates to a warm air clothes dryer, and provides a direction-turning vertical warm air clothes dryer with a single air outlet pipe. The direction-turning vertical warm air clothes dryer comprises a bracket 1, a dryer body 6, a heating component 2, an air blowing device 3, a control system 4, an air outlet pipe 5 and clothes fixing equipment 9. The direction-turning vertical warm air clothes dryer is characterized in that the air outlet pipe 5 is connected with the dryer body 6, the dryer body 6 is arranged on the bracket 1, a bracket knob 10 is arranged on the bracket 1, and the direction of the air outlet pipe of the dryer body can be adjusted at 360 degrees by loosening and tightening the knob; and the air outlet pipe 5 is provided with an air outlet 7 and has a 90-degree angle with the clothes fixing equipment 9. The direction-turning vertical warm air clothes dryer provided by the invention can be used for adjusting the directions of the warm air clothes dryer body and the air outlet pipe at 360 degrees, can perform baking aiming at designated areas and linings of to-be-dried clothes, and is efficient and energy-saving; and warm air blown out from the air outlet can form a right angle with the to-be-dried clothes, the area of the to-be-dried clothes radiated by the warm air heat energy is relatively large, and the loss of the warm air heat energy is relatively low.

Owner:宋文学

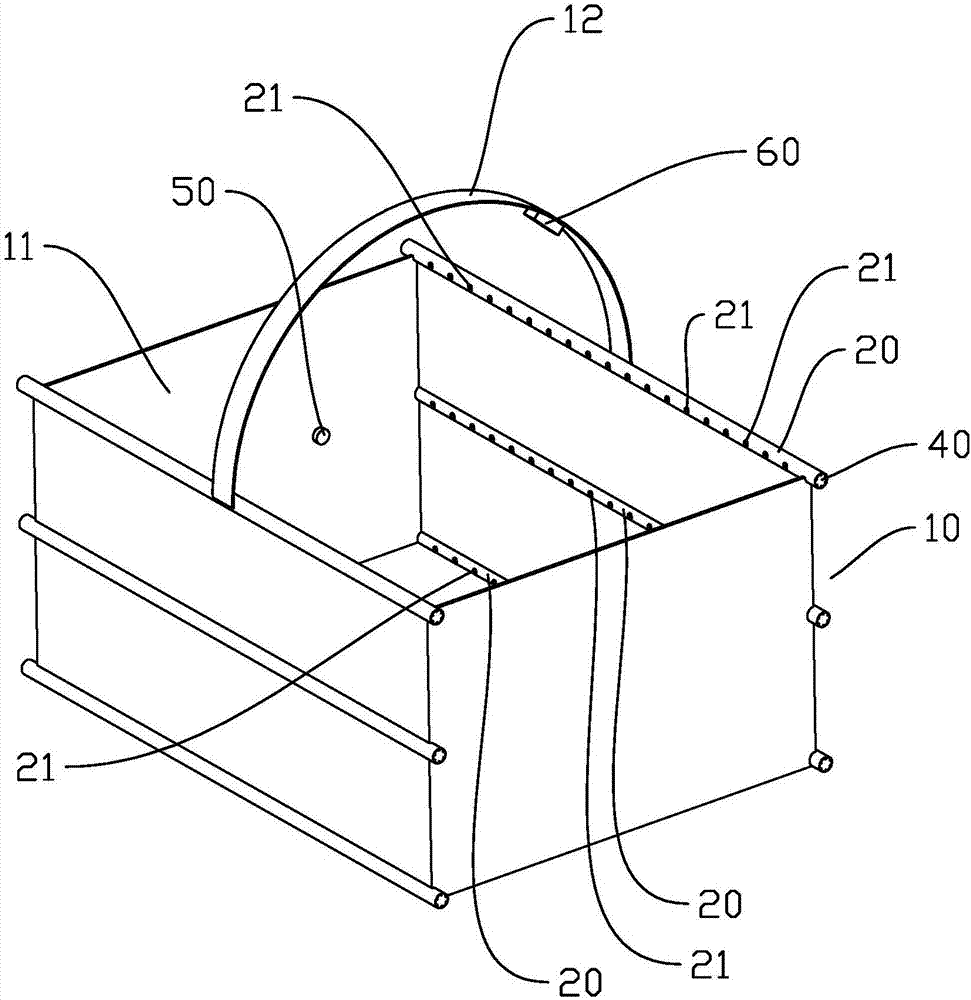

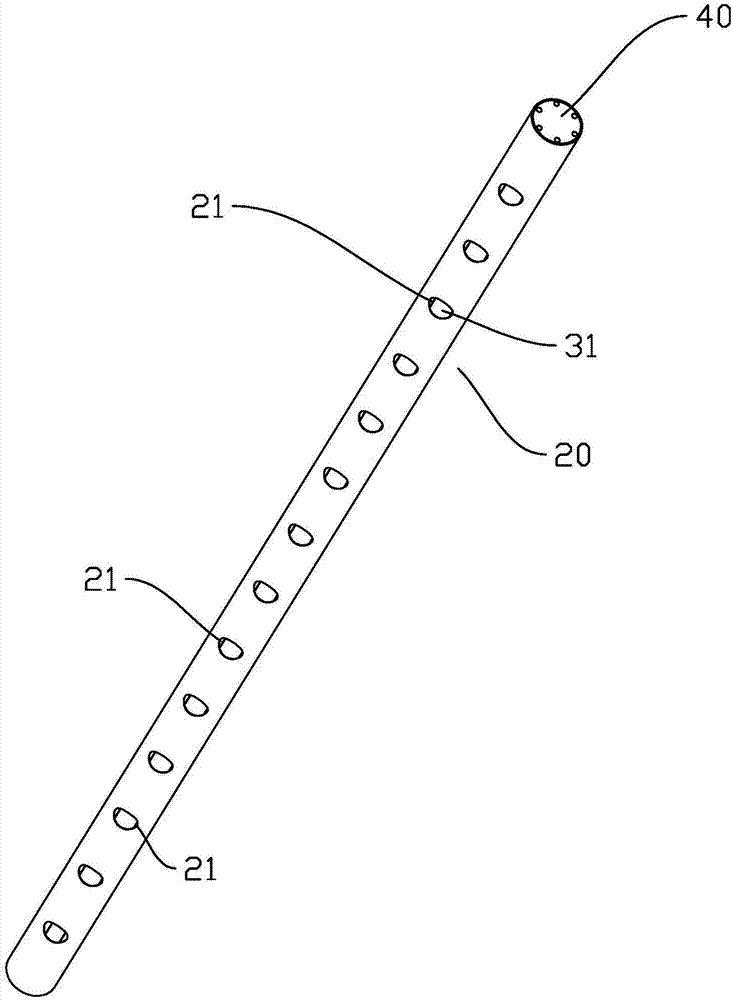

Bamboo basket with drying function

Owner:泰安市小利网络科技有限公司

Loop scavenged two-stroke internal combustion engine

Owner:YAMABIKO CORP

Energy-saving paper box drying equipment

InactiveCN112880329AIncrease the spray forceFreeze fastPretreated surfacesDrying gas arrangementsAdhesiveStructural engineering

The invention discloses energy-saving paper box drying equipment. The energy-saving paper box drying equipment structurally comprises a main body, a control panel and an alarm lamp, the control panel is arranged at the front end of the main body, the alarm lamp is fixedly embedded in the middle of the top of the main body, the main body comprises a rotating shaft, a conveying belt and a drying device, and the drying device comprises a ventilation groove, an air inlet, a rotating fan, a heat conduction piece and a side drying device; and the side drying device comprises an air storage tank, an air inlet, a corrugated sheet and an air outlet head, the air outlet head comprises an air outlet groove, a guide plate and an air spraying head, and the guide plate comprises a fixed block, an air guide groove and an air collecting block. According to the drying equipment, the position of the corrugated sheet in the side drying device is arranged to be aligned with the air outlet head, so that air flow can flow on the end face of the corrugated sheet back and forth, the jet force of the air flow is increased, the air flow can be transversely blown out from the side drying device, the air flow can enter gaps in a paper box to be in contact with an adhesive, and the adhesive can be rapidly solidified.

Owner:张顺妹

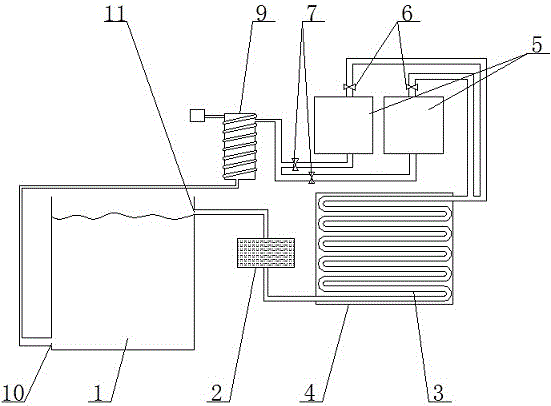

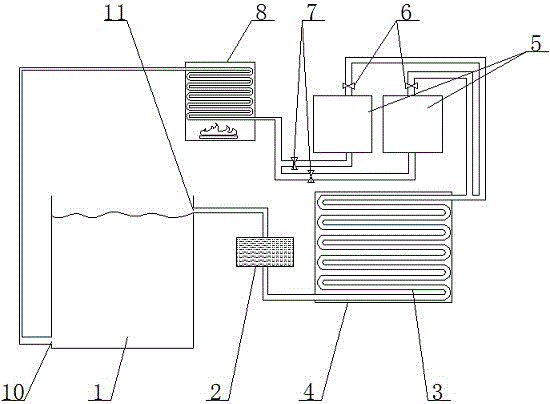

Circulating hot water system with preheating system and used for indoor swimming pool

InactiveCN107524325AAchieve recyclingReduce consumptionGymnasiumSwimming poolsThermal waterHeating system

Owner:NANJING LVZHICHENG PATENT TECH DEV CO LTD

Drying device for anti-corrosion thermal insulation coating

ActiveCN114308582AAdjust the rotation speedResistance adjustmentPretreated surfacesCoatingsThermal insulationHeater Rod

Owner:江苏丰辉环保科技有限公司

Air-drying machine

Owner:珠海三鲸科技有限公司

Cooling protection device for screen mesh wire production

InactiveCN111750610ACool evenlyImprove cooling efficiencyDomestic cooling apparatusLighting and heating apparatusCold airVentilation tube

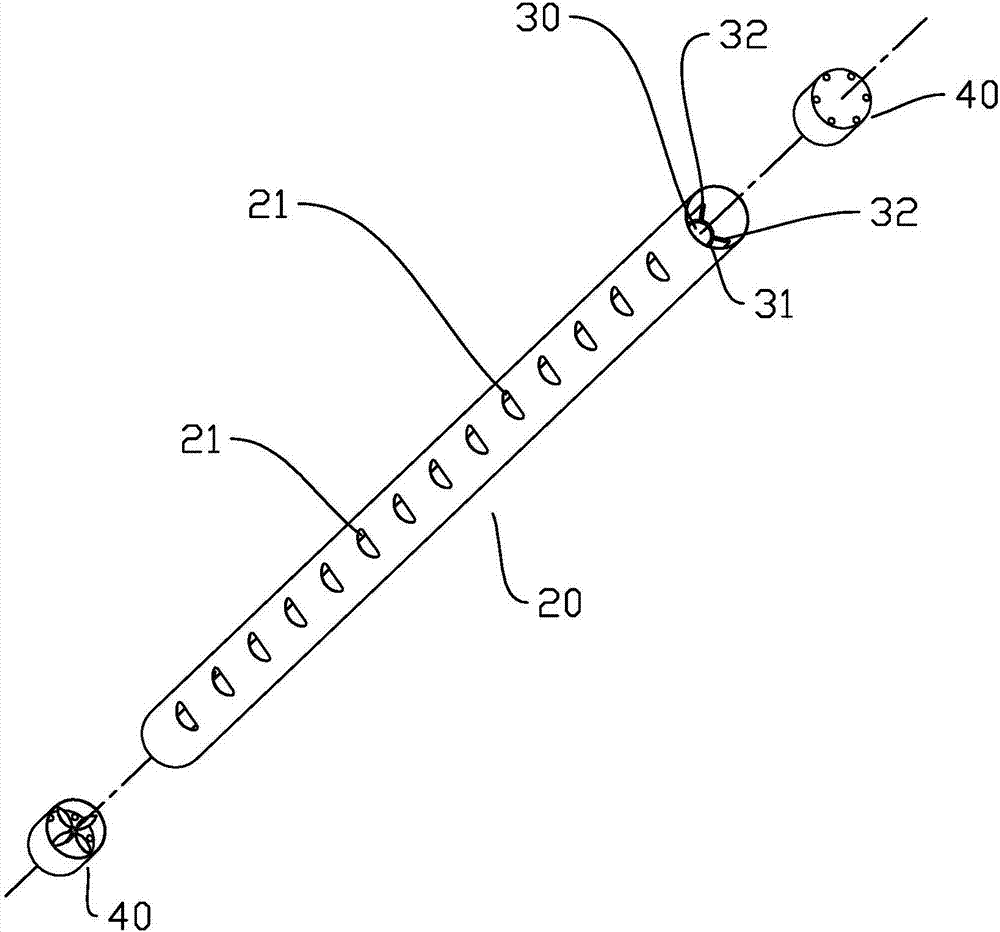

The invention provides a cooling protection device for screen mesh wire production. The cooling protection device comprises a top plate, supporting plates and a bottom plate; supporting legs are arranged on the two sides of the bottom of the bottom plate, the two sides of the top of the bottom plate are connected with the top plate through the supporting plates, a ventilation pipe is fixed to thebottom of the top plate, and a plurality of air outlets are formed in the bottom of the ventilation pipe. According to the cooling protection device, an air blower is arranged at the top to drive airto blow downwards, the air sequentially passes through a water pipe and a refrigeration plate in the downward blowing process, then passes through an air exhaust mechanism and finally reaches a rotating shaft wound with screen mesh wires, the refrigeration plate can refrigerate water in the water pipe, therefore cold air is generated, and the cold air descends; at the moment, air blown out by theair blower is changed into cold air through cold air treatment to be blown to the rotating shaft, and namely, the screen mesh wires can be cooled; and the cooled hot air rises at the moment and then is cooled through cold air again, therefore, it can be guaranteed that the screen mesh wires are rapidly cooled in the production process, and the cooling efficiency is higher.

Owner:ANHUI LANFEI CHEM FIBRE MFG CO LTD

Blowout preventing device for coal seam drilling

Owner:HUAIBEI MINING IND

Ceiling air conditioner indoor unit and air conditioner

ActiveCN110966678AImprove cooling effectImprove efficiencyLighting and heating apparatusAir conditioning systemsEngineeringIndoor air

The invention discloses a ceiling air conditioner indoor unit and an air conditioner. The air conditioner indoor unit comprises a shell, a heat exchanger and an air generating device, wherein the shell comprises a top cover and a cylinder body, an upper end of the cylinder body is connected with the top cover, the cylinder body comprises an inner cylinder body and an outer cylinder body which aresequentially arranged from inside to outside, a lower end of the inner cylinder body is connected with a lower end of the outer cylinder body, an air return port is formed on a wall of the inner cylinder body, an air outlet is formed on a wall of the outer cylinder body, and the heat exchanger and the air generating device are sequentially arranged between the outer cylinder body and the inner cylinder body and connected with the shell. The air conditioner comprises the air conditioner indoor unit, and the air conditioner indoor unit is the ceiling air conditioner indoor unit. The air conditioner indoor unit is advantaged in that the indoor air subjected to heat exchange through the heat exchanger can be blown out horizontally or obliquely, and downward direct blowing is avoided; the air conditioner improves the heat exchange effect and improves the comfort level.

Owner:GREE ELECTRIC APPLIANCE INC OF ZHUHAI

Tea leaf moisture removing device

InactiveCN107348022ASpeed up the flowImprove work efficiencyPre-extraction tea treatmentAudio power amplifierEngineering

Owner:余伟文

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap