Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8 results about "GARLIC POWDER" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Garlic powder is ground, dehydrated garlic. It is a very common seasoning. Applications include pasta, pizza, ranch dressing and grilled chicken.

Deep-fried chicken steak filled with cheese and preparation method thereof

Owner:NEW HOPE LIUHE

Preparation method of tomato red sour soup

Owner:贵州王苗丫民族风味食品有限公司

Snowflake chicken meat bar and preparation method thereof

Owner:濮阳市东大食品有限公司

Feed capable of preventing swine brucellosis

InactiveCN106974096APrevention of porcine brucellosisImprove immunityAntibacterial agentsMetabolism disorderCodonopsisGARLIC POWDER

The invention relates to feed capable of preventing swine brucellosis. The feed is characterized by being prepared from raw materials in parts by weight as follows: 450-480 parts of corn, 120-140 parts of bean curd dregs, 120-150 parts of soybean meal, 50-70 parts of tapioca flour, 120-140 parts of rice bran, 10-20 parts of zeolite powder, 5-10 parts of betaine, 5-10 parts of garlic powder, 12-18 parts of herba lycopodii, 10-15 parts of herba taxilli, 8-12 parts of radix stephaniae tetrandrae, 8-12 parts of radix astragali, 5-8 parts of radix codonopsis pilosulae, 5-8 parts of cortex eucommiae, 8-12 parts of radix scutellariae and 5-8 parts of radix glycyrrhizae. The feed can well prevent the swine brucellosis, contribute to enhancement of immunity and promote growth and development.

Owner:CHANGSHA RUIDUOKANG BIOTECH CO LTD

Formula and production process of crispy meat

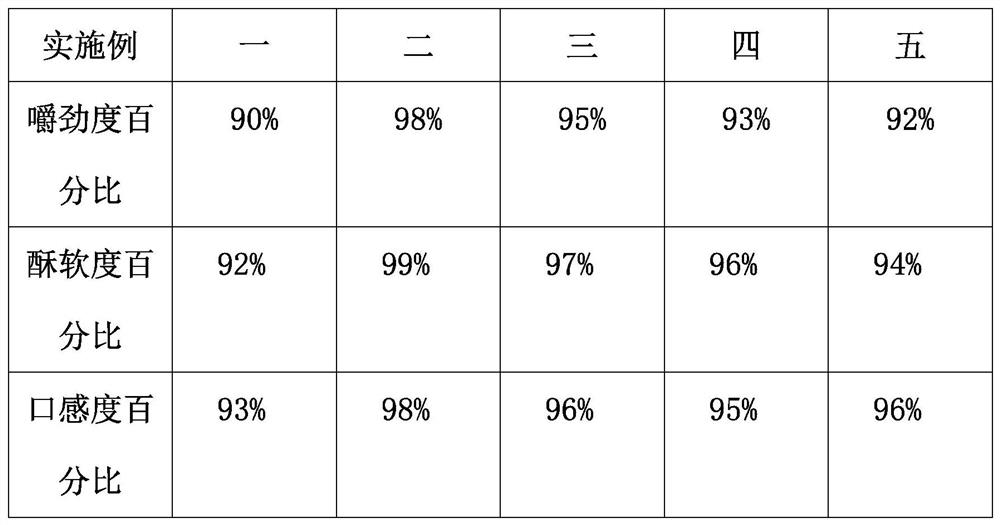

PendingCN112971055AImprove chewinessImprove crispnessFood mechanical treatmentBiotechnologyGARLIC POWDER

Owner:邓关成

Broiler feed and preparation method thereof

InactiveCN107712424AImprove meat qualityIncrease freshnessFood processingAnimal feeding stuffBiotechnologyPeanut meal

Owner:衡阳县福茂农林生态有限公司

Feed for preventing pig sarcosporidiosis

InactiveCN107048025APrevention of insect diseaseImprove immunityFood processingAnimal feeding stuffAnimal scienceBroken rice

Owner:CHANGSHA RUIDUOKANG BIOTECH CO LTD

Broken-peel pickled pepper red sour soup and manufacture method thereof

InactiveCN112753983ASave time and costLow pollution rateFood scienceBiotechnologyMonosodium glutamate

The invention discloses a broken-peel pickled pepper red sour soup, which comprises the following raw materials in parts by weight: 10-70% of Lycopersicon esculentum, 10-70% of broken-peel pickled peppers, 10-15% of colleseed oil, 1-4% of Zingiber officinale Roscoe, 1-4% of Allium sativum L. and 5-8% of added water. All the raw materials are grinded into a paste, and then, according to parts by weight of the raw material paste, 1-2% of chicken powder, 1-3% of monosodium glutamate, 0.5-2% of lactic acid, 0.5-1% of citric acid, 2-5% of white sugar, 0.5-1% of Litsea pungens Hemsl. oil and 0.1-0.5g / kg of sodium benzoate are added. The manufacture method of the broken-peel pickled pepper red sour soup comprises the following steps of: 1) taking food materials: breaking the Lycopersicon esculentum and the broken-peel pickled peppers for standby, and taking bruised ginger and minced garlic; 2) evenly mixing the food materials, adding the colleseed oil and the water, grinding into an even paste, and heating the even paste at the temperature of 80 DEG C for 7 minutes; 3) seasoning by adding the chicken powder, the monosodium glutamate, the lactic acid, the citric acid, the white sugar and the Litsea pungens Hemsl. oil in sequence; 4) adding the sodium benzoate for corrosion prevention; and 5) after filling is carried out, sterilizing by heating at the temperature of 75 DEG C for 15min, cooling to be 40 DEG C or below, and then, packaging in a box. The invention has a simple technology, waste resources are reasonably utilized, and cost is low.

Owner:GUIZHOU MEITAN FUYING FOOD DEV CO LTD

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap