Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

16 results about "Machine vision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Machine vision (MV) is the technology and methods used to provide imaging-based automatic inspection and analysis for such applications as automatic inspection, process control, and robot guidance, usually in industry. Machine vision refers to many technologies, software and hardware products, integrated systems, actions, methods and expertise. Machine vision as a systems engineering discipline can be considered distinct from computer vision, a form of computer science. It attempts to integrate existing technologies in new ways and apply them to solve real world problems. The term is the prevalent one for these functions in industrial automation environments but is also used for these functions in other environments such as security and vehicle guidance.

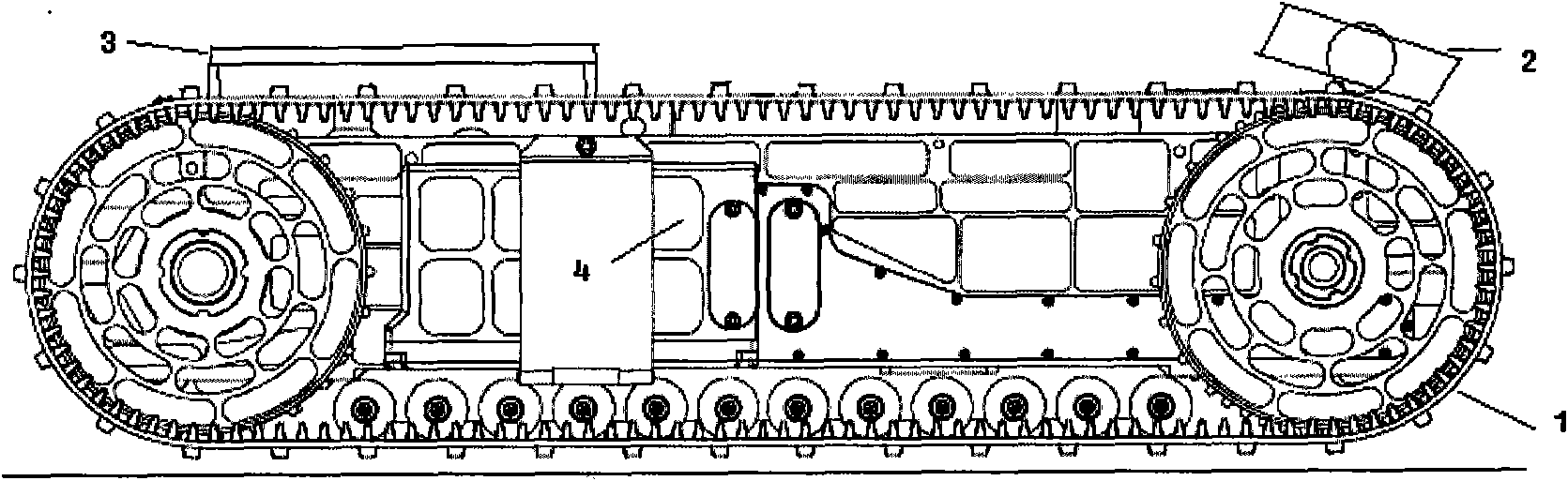

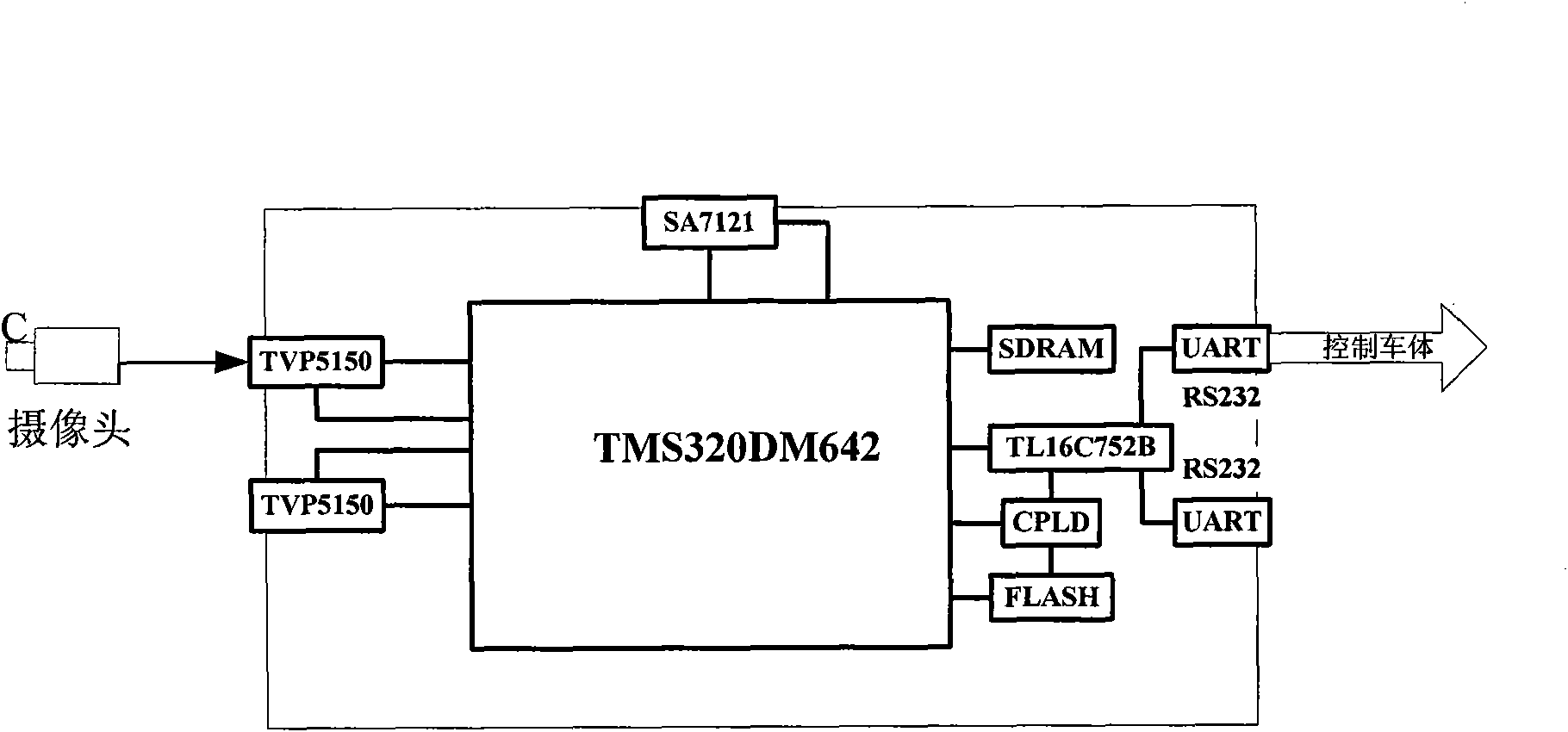

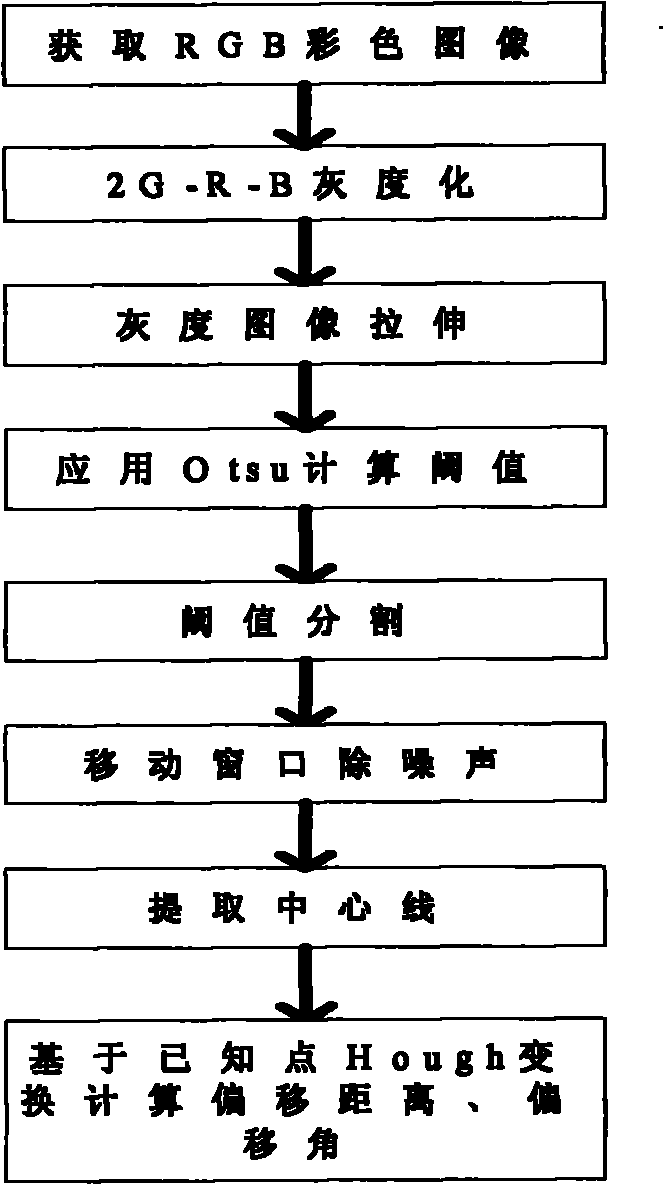

Intelligent navigation control system and method

InactiveCN101976079AImprove environmental adaptabilityImprove work efficiencyInstruments for road network navigationPosition/course control in two dimensionsRobustificationClosed loop

Owner:北京环宇信科技术发展有限公司

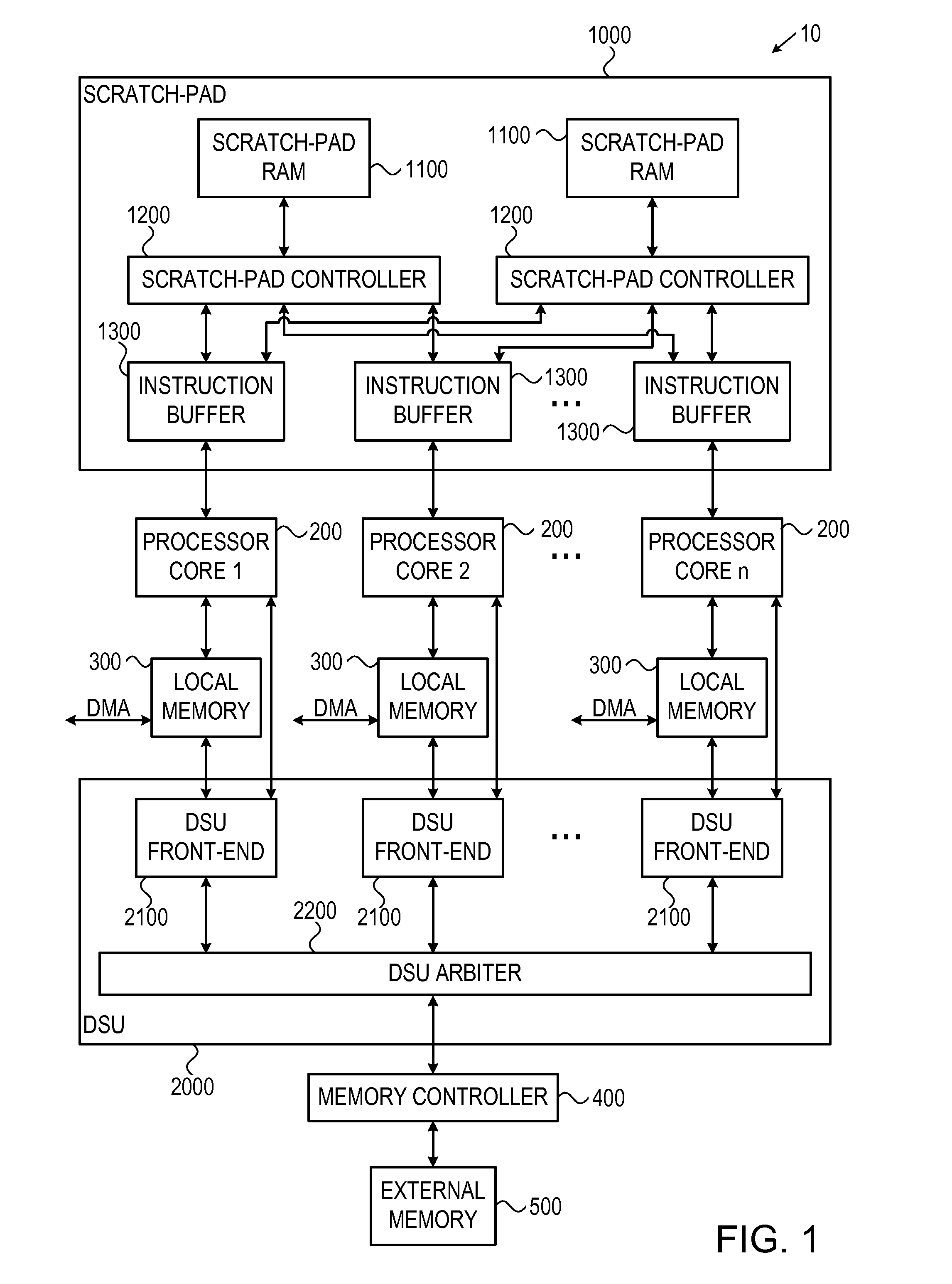

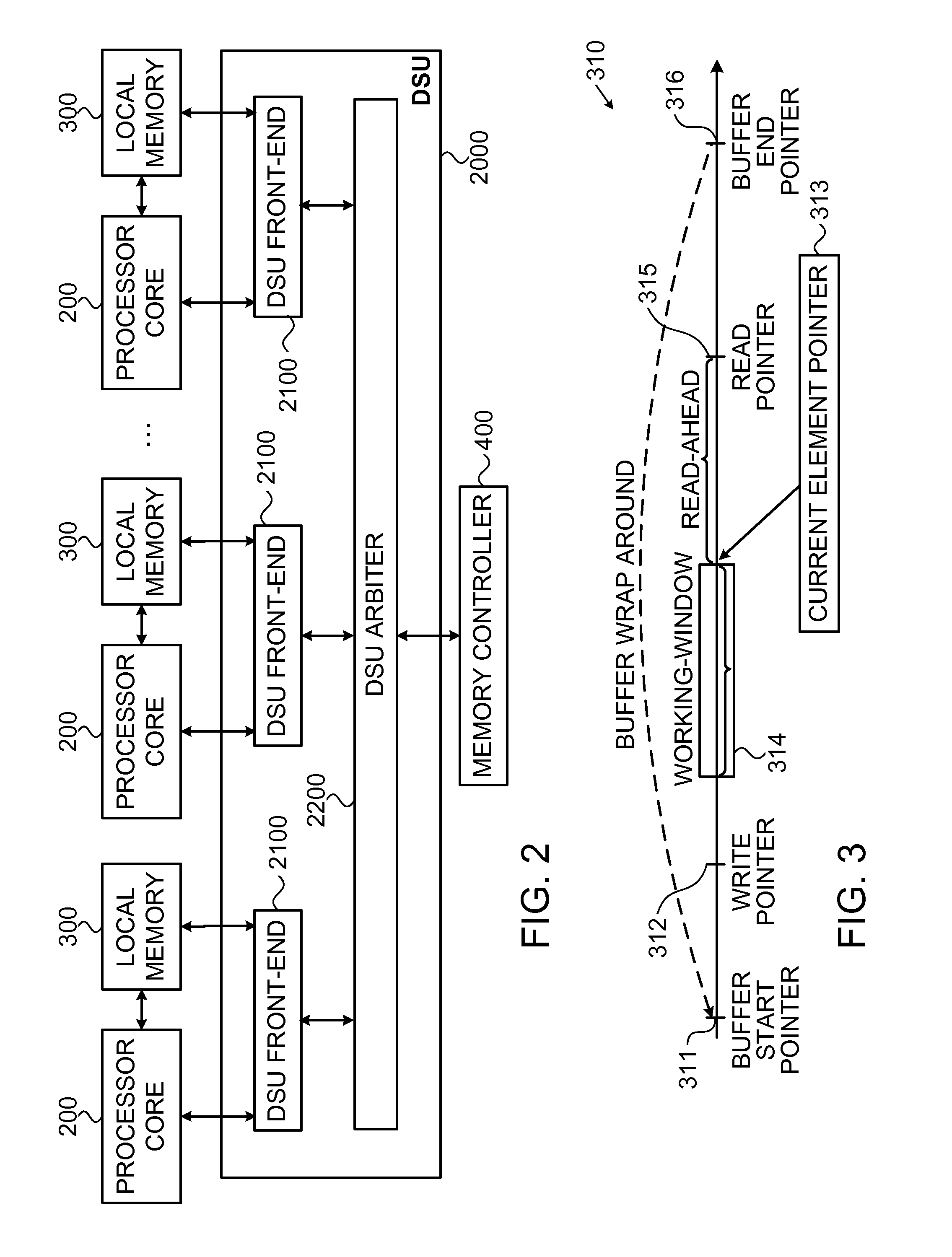

Multiprocessor system-on-a-chip for machine vision algorithms

ActiveUS20120042150A1Program control using stored programsGeneral purpose stored program computerMachine visionData stream

Owner:APPLE INC

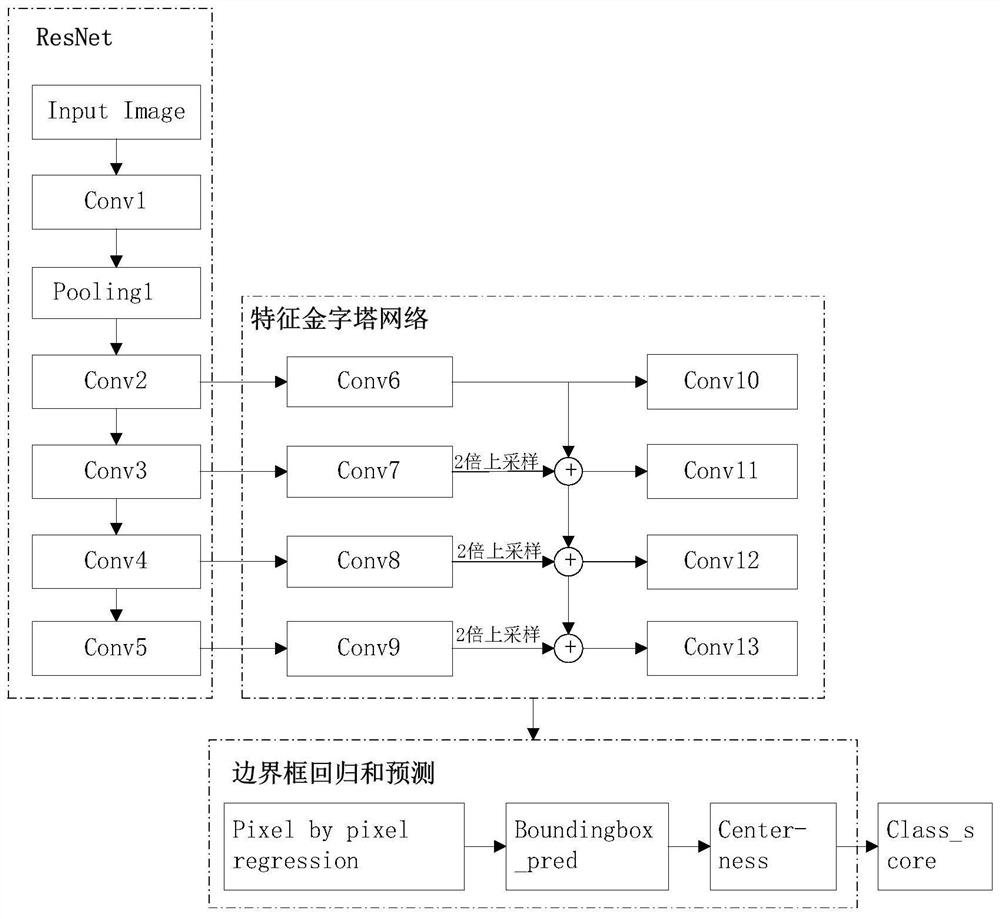

Object recognition and positioning method and device and terminal equipment

ActiveCN111178250AImprove recognition efficiencyImprove accuracyImage enhancementImage analysisPattern recognitionPoint cloud

The invention is suitable for the technical field of machine vision, and provides an object recognition and positioning method and device and terminal equipment. The method comprises the steps: obtaining a two-dimensional image and point cloud data of a to-be-detected region; detecting the two-dimensional image through a pre-trained deep learning model, and identifying a two-dimensional target area and a geometrical shape type corresponding to a target object in the two-dimensional image; mapping the two-dimensional target area to the point cloud data, and determining a first three-dimensionalarea of the target object according to a mapping result; and according to the geometrical shape type and the first three-dimensional area, determining a second three-dimensional area of the target object and positioning the target object. According to the embodiment of the invention, the 3D object recognition and positioning efficiency and accuracy can be improved.

Owner:SHENZHEN YUEJIANG TECH CO LTD

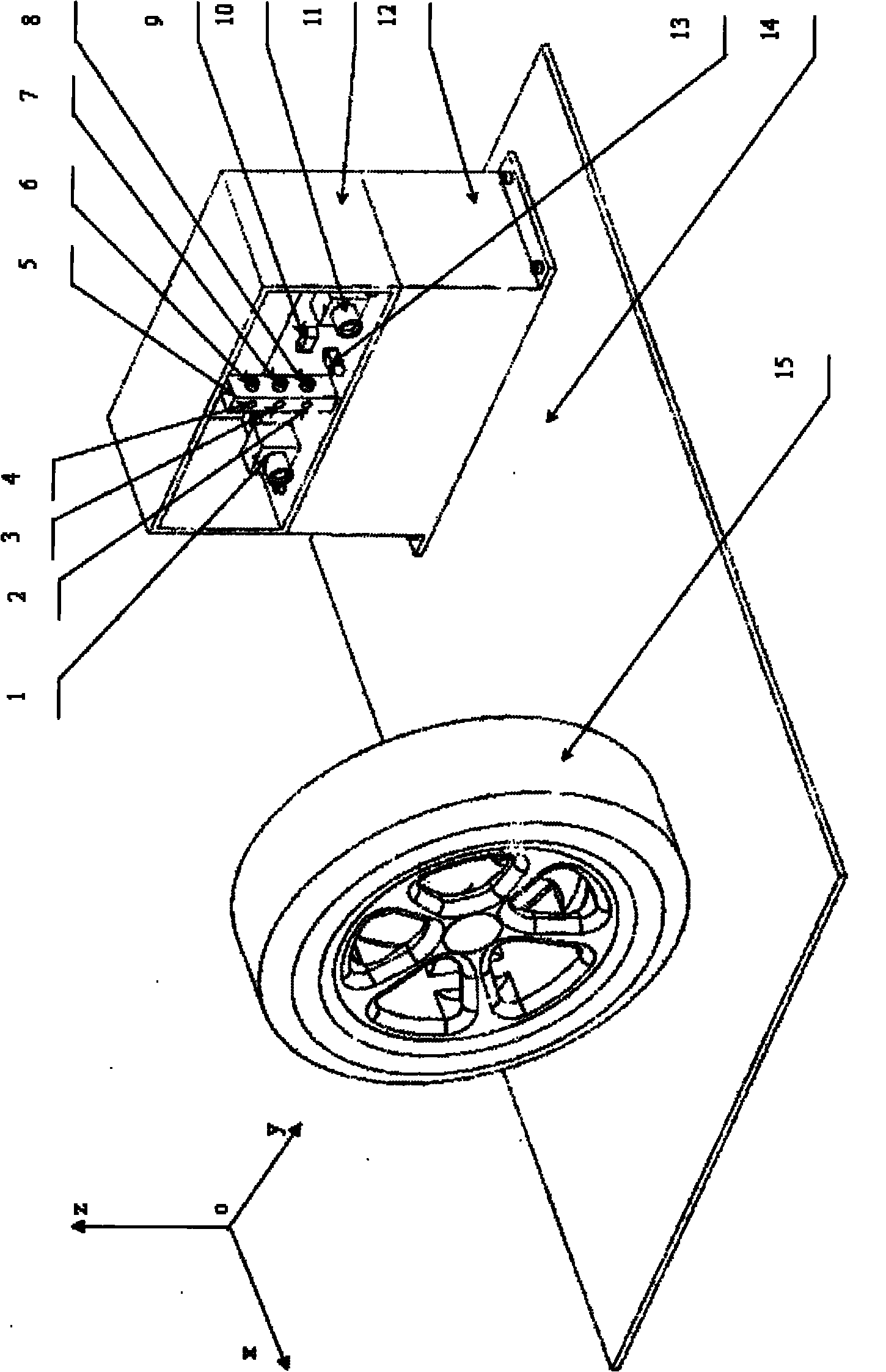

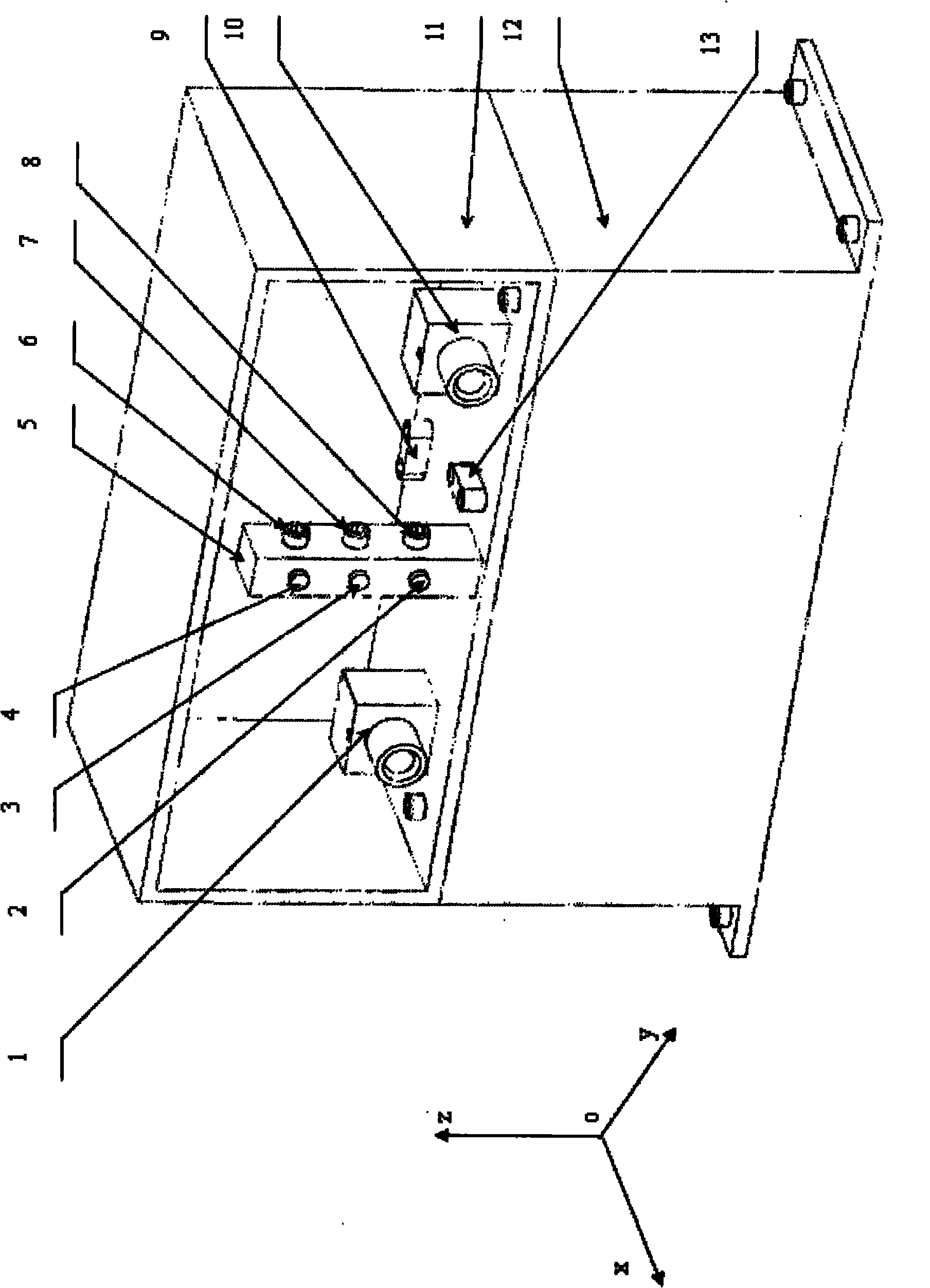

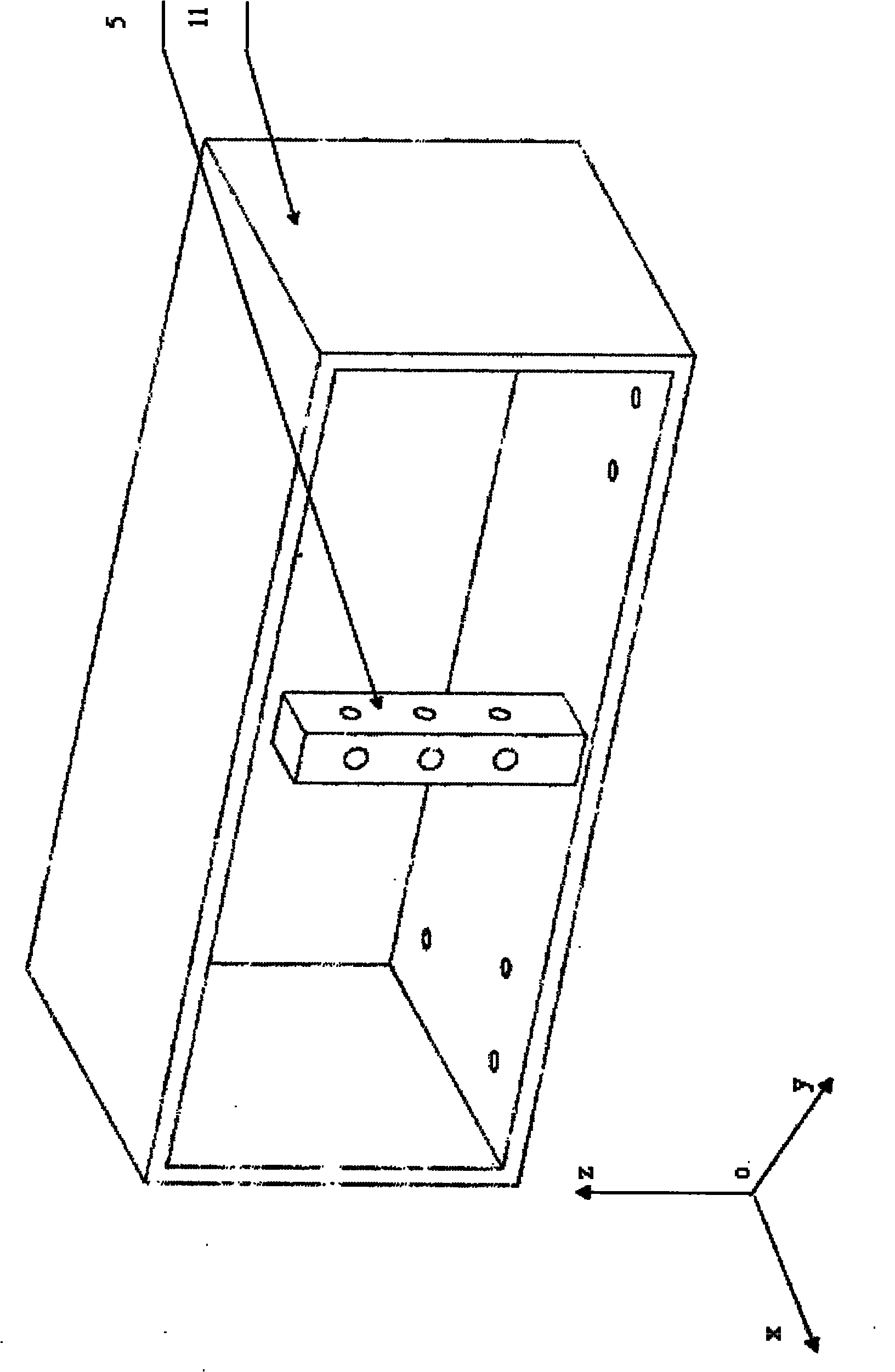

Machine vision-based spatial position detection system for automobile wheel planes and rims

InactiveCN102042806AImprove detection efficiencyImprove detection accuracyUsing optical meansVehicle wheel testingMachine visionVisual perception

Owner:JILIN UNIV

Visual data processing system for fruit external appearance quality online detection technology

InactiveCN1663697ASolve the problem of original signal acquisitionHigh speedImage enhancementCharacter and pattern recognitionScreening methodHandling system

Owner:JIANGSU UNIV

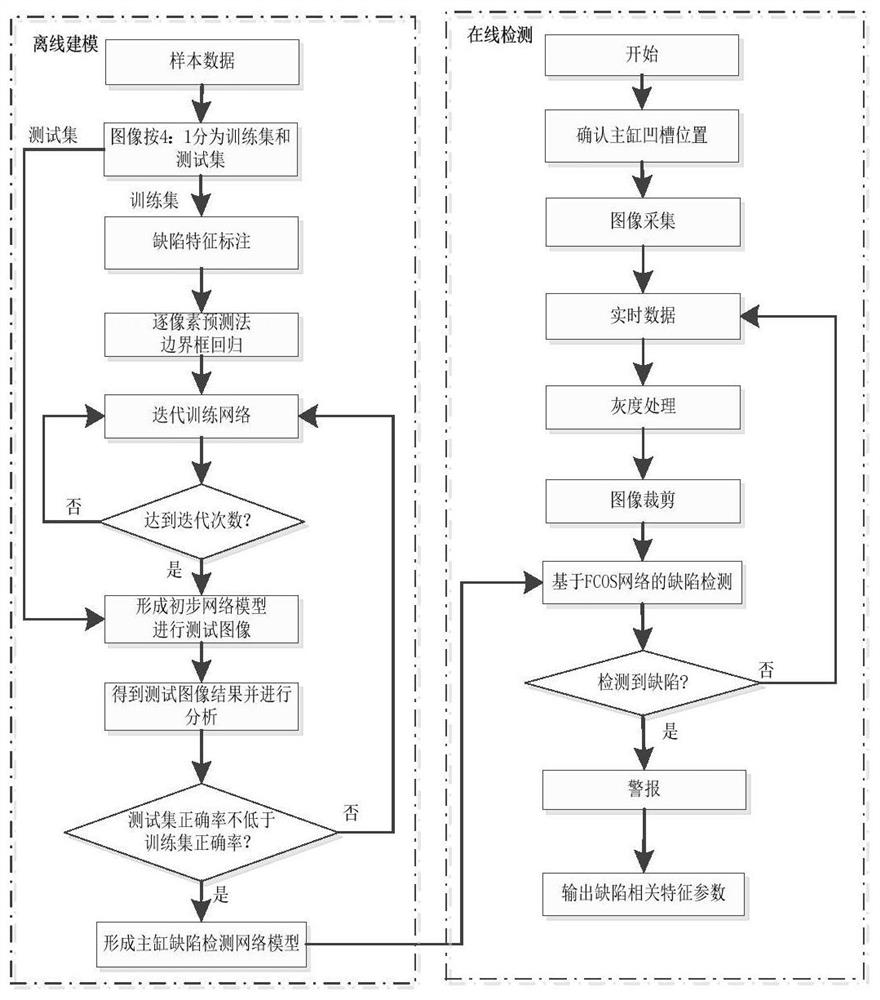

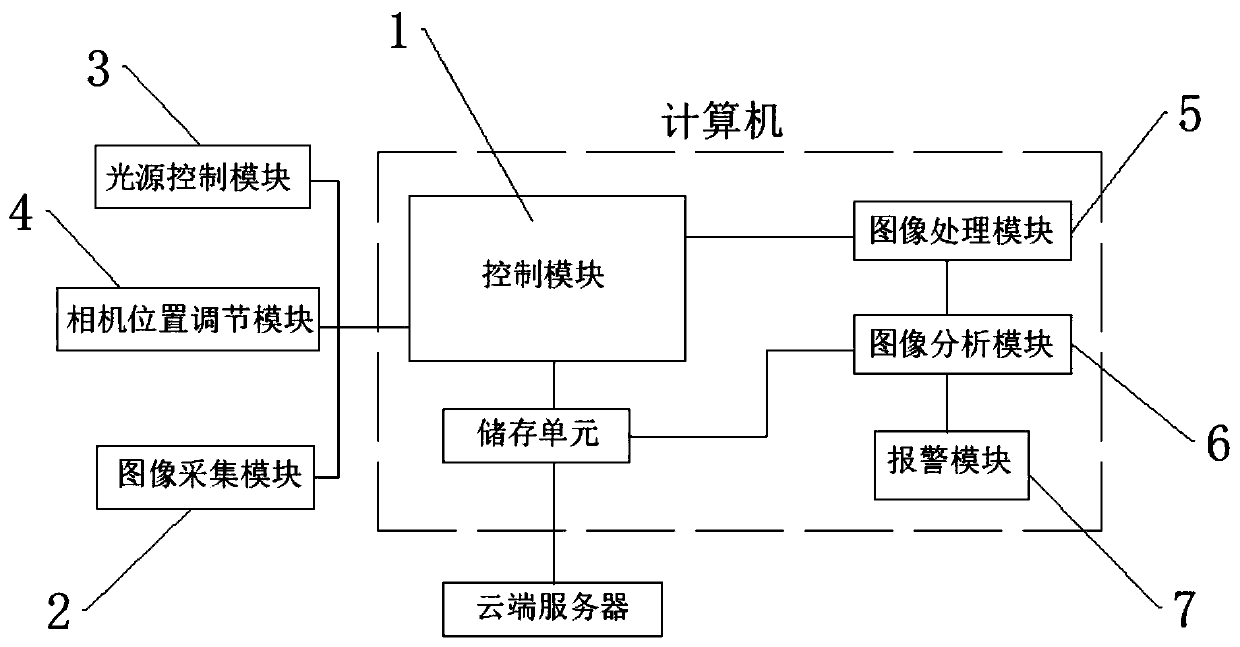

Automobile clutch main cylinder groove surface defect detection method based on deep learning

ActiveCN112419237AEasy to identifyReduce in quantityImage enhancementImage analysisMachine visionAlgorithm

Owner:CHINA JILIANG UNIV

Product packaging defect detection and identification method based on machine vision

The invention discloses a product packaging defect detection and recognition method based on machine vision. The method comprises steps that firstly, a product packaging processing image without surface defects is extracted; a defect image template feature database is established; feature extraction, detection and identification of the packaging image of the to-be-detected product are carried out;and finally, the unqualified packaged products are blown into the collecting box, and the qualified packaged products are conveyed by the conveying belt to be output. The method is advantaged in thatproblems that in the prior art, the product packaging defect detection error rate is high, and production efficiency is low are solved.

Owner:SHAANXI UNIV OF SCI & TECH

Vehicle-mounted mobile violation snapshoting system based on machine vision

InactiveCN109637153AImprove work efficiencyLiquidityDetection of traffic movementCharacter and pattern recognitionMachine visionComputer module

The invention discloses a vehicle-mounted mobile violation snapshoting system based on machine vision. The system comprises high-definition cameras which are mounted on a law enforcement vehicle and respectively carry out video image acquisition on front and back vehicles. The system further comprises a processing host, a communication module, a vehicle feature database and a power supply module,wherein the power supply module is electrically connected with the high-definition cameras, the processing host and the communication module through wires. The system takes the vehicle as a carrier, can carry out monitoring on vehicles in the moving process, and judges whether a vehicle is modified or not through identifying the vehicle in an image, acquiring feature parameters of the vehicle andthen taking parameters of the same vehicle model in the vehicle feature database. Meanwhile, modification judgment is carried out on a vehicle with a specific license plate number through taking dataof a record database of the vehicle administration department so as to judge whether the modification is registered and recorded or not. The vehicle-mounted mobile violation snapshoting system is strong in mobility and high in work efficiency and effectively avoids false detection.

Owner:HEFEI ZHIXIN AUTOMOTIVE TECH CO LTD

A library seat detection system based on machine vision

InactiveCN109447303AWide detection rangeEconomic savingsReservationsCharacter and pattern recognitionMachine visionResource utilization

The invention discloses a library seat detection system based on machine vision, which relates to the technical field of library seat detection, and is used for solving the problem of seat occupationof a library and improving the utilization efficiency of library resources. The system comprises an image acquisition device, an embedded processing device, a display device and a user interaction terminal, wherein the image acquisition device is one or more cameras mounted in a classroom and is used for acquiring seat image information; the embedded processing device processes the collected imageinformation and user reservation information; the display device is used for displaying the use and reservation conditions of seats in a classroom; and the user interaction terminal is intelligent mobile equipment such as a mobile phone and a notebook computer of a user and is used for displaying seat information of a library and allowing the user to reserve seats. The system can detect and display seat use and reservation conditions in real time, a user can reserve seats anytime and anywhere, the library resource utilization efficiency is greatly improved, and the library management order ismaintained.

Owner:ANHUI UNIV OF SCI & TECH

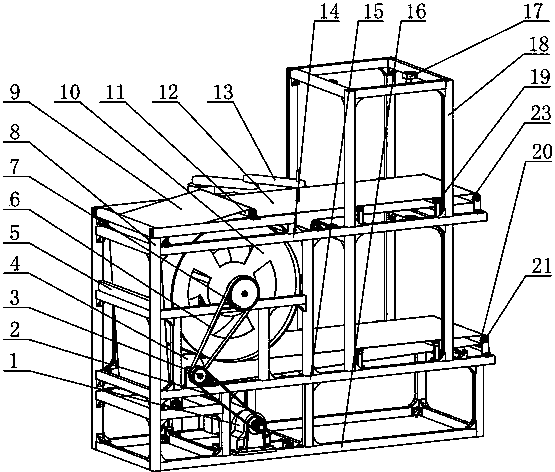

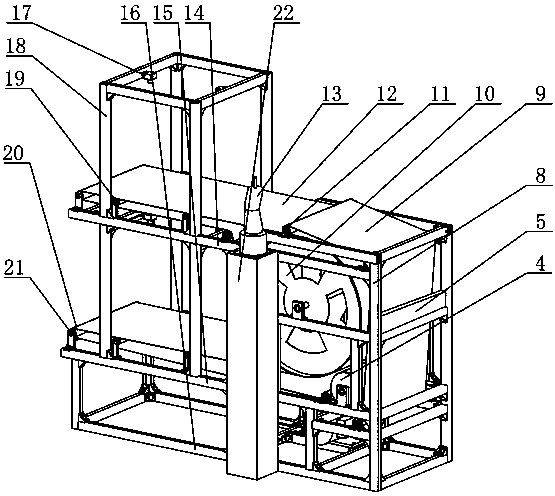

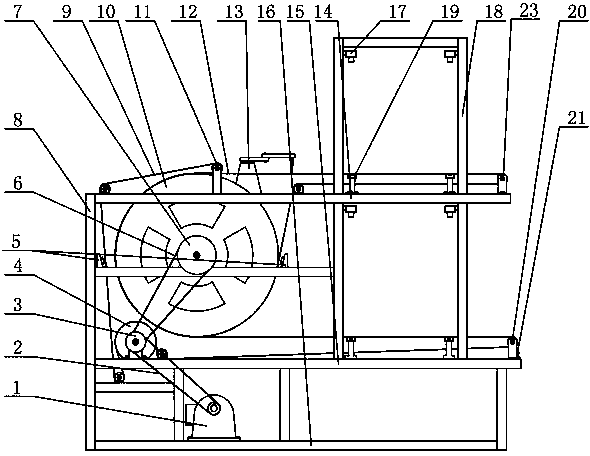

Laser welding system based on machine vision positioning and used for battery box packaging and operating method of laser welding system

InactiveCN107414297AMeet production needsHigh precisionLaser beam welding apparatusMachine visionEngineering

The invention discloses a laser welding system based on machine vision positioning and used for battery box packaging. The laser welding system based on machine vision positioning and used for battery box packaging comprises a conveying mechanism, a clamp, a welding workstation and a control device, wherein a vision detection system and a welding mechanism are arranged in the welding workstation, both the clamp and the welding workstation are arranged on the conveying mechanism, the welding mechanism is arranged behind the vision detection system, and the conveying mechanism and the vision detection system are both connected with the control device. According to the laser welding system based on machine vision positioning and used for battery box packaging, the vision detection system is arranged in the welding workstation, the position of a workpiece is detected through the vision detection system, and then the welding track of the workpiece is corrected according to a detection result, so that the welding precision of the workpiece is greatly improved, the number of defective products is effectively reduced, the yield of machined products is effectively increased, and accordingly the laser welding system can better meet the production requirement of enterprises.

Owner:TONGGAO ADVANCED MFG TECH TAICANG

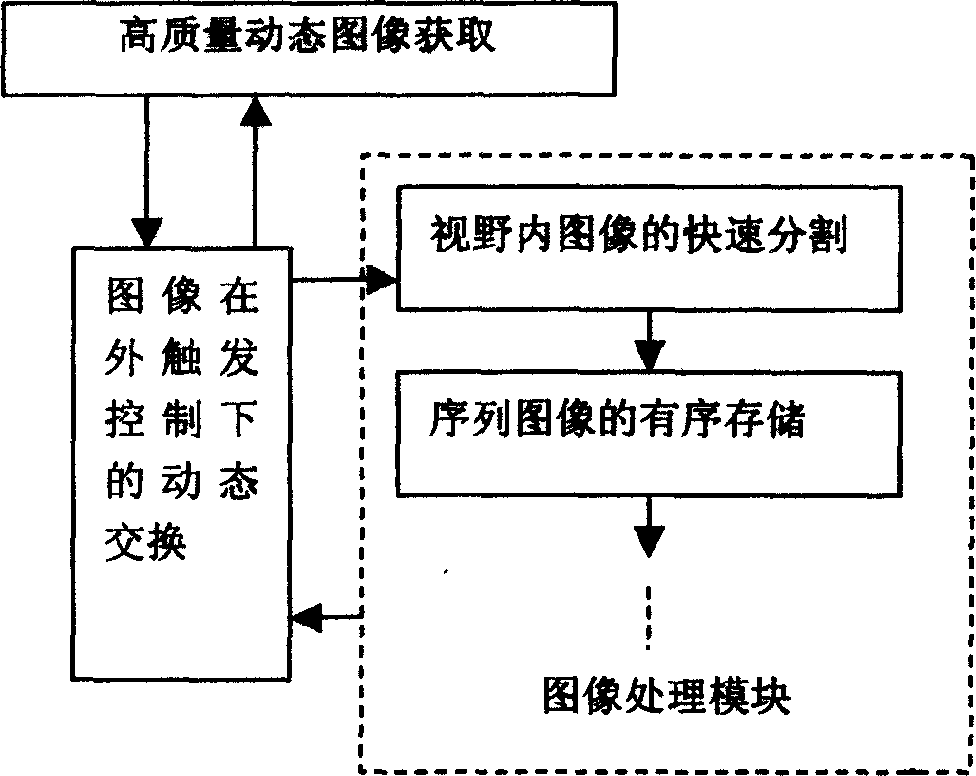

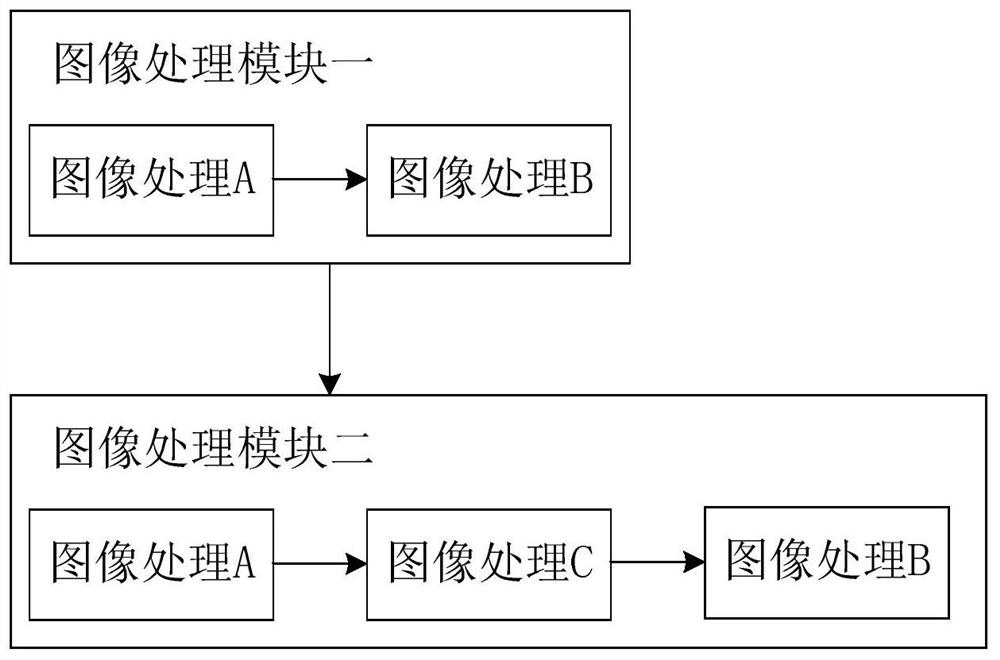

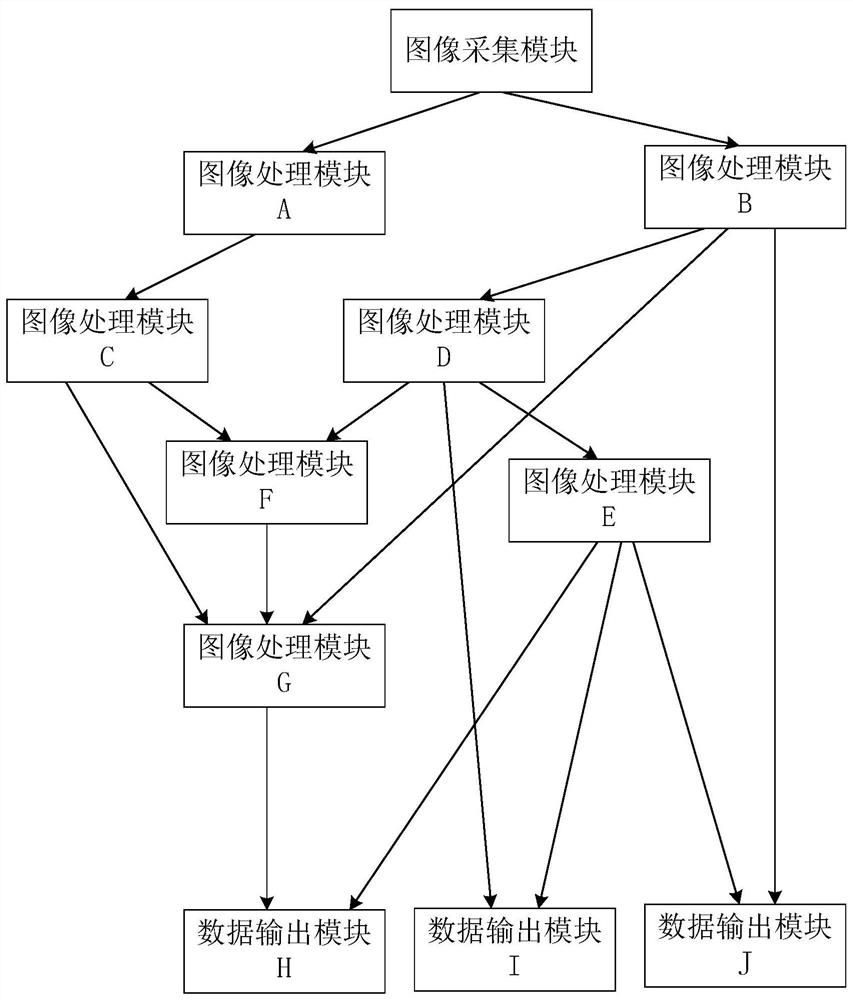

Dynamic configuration method of machine vision software and computer

PendingCN112559074AImprove scalabilityMeet flexibilityCharacter and pattern recognitionProgram loading/initiatingComputer hardwareData stream

Owner:昂视智能(深圳)有限公司

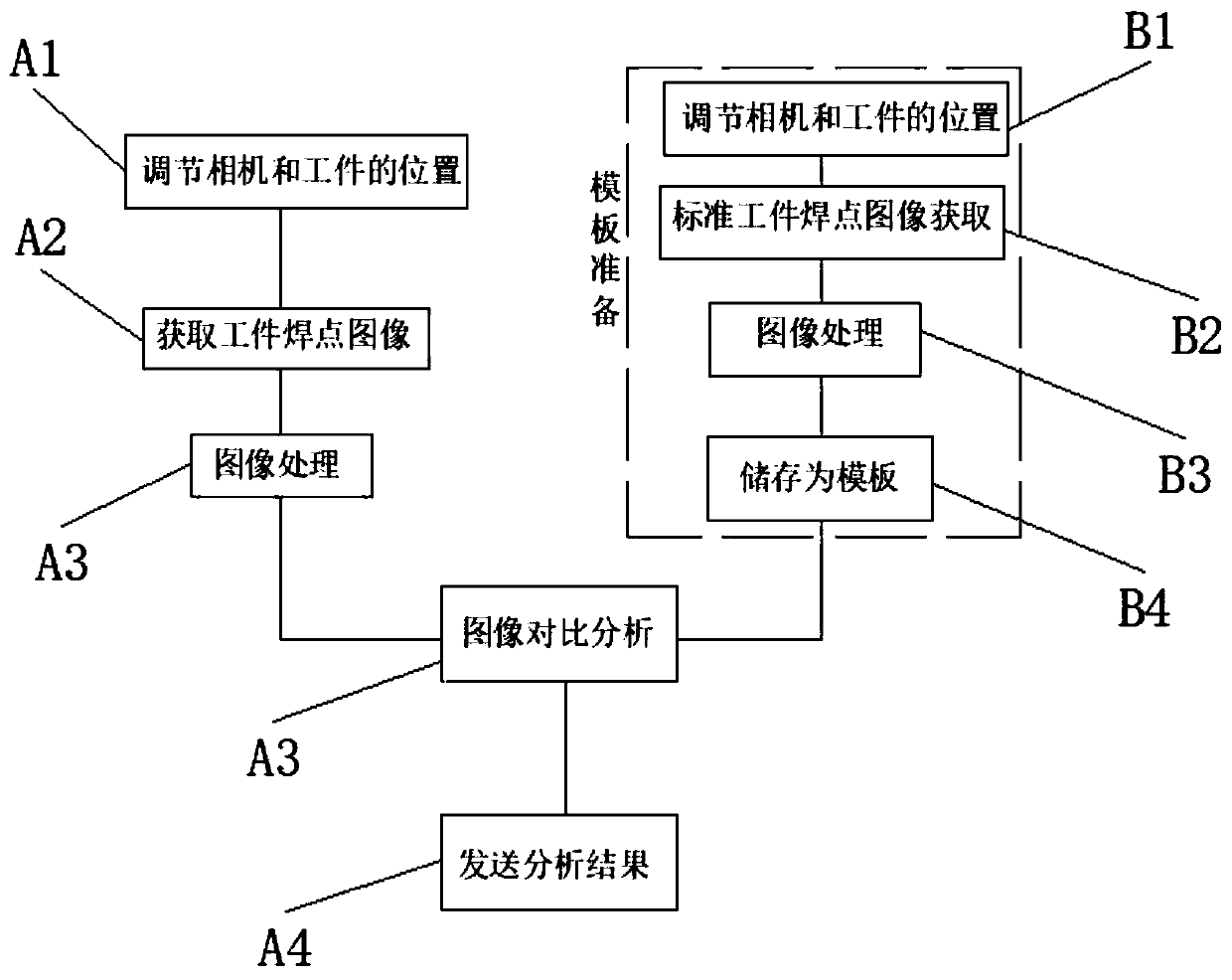

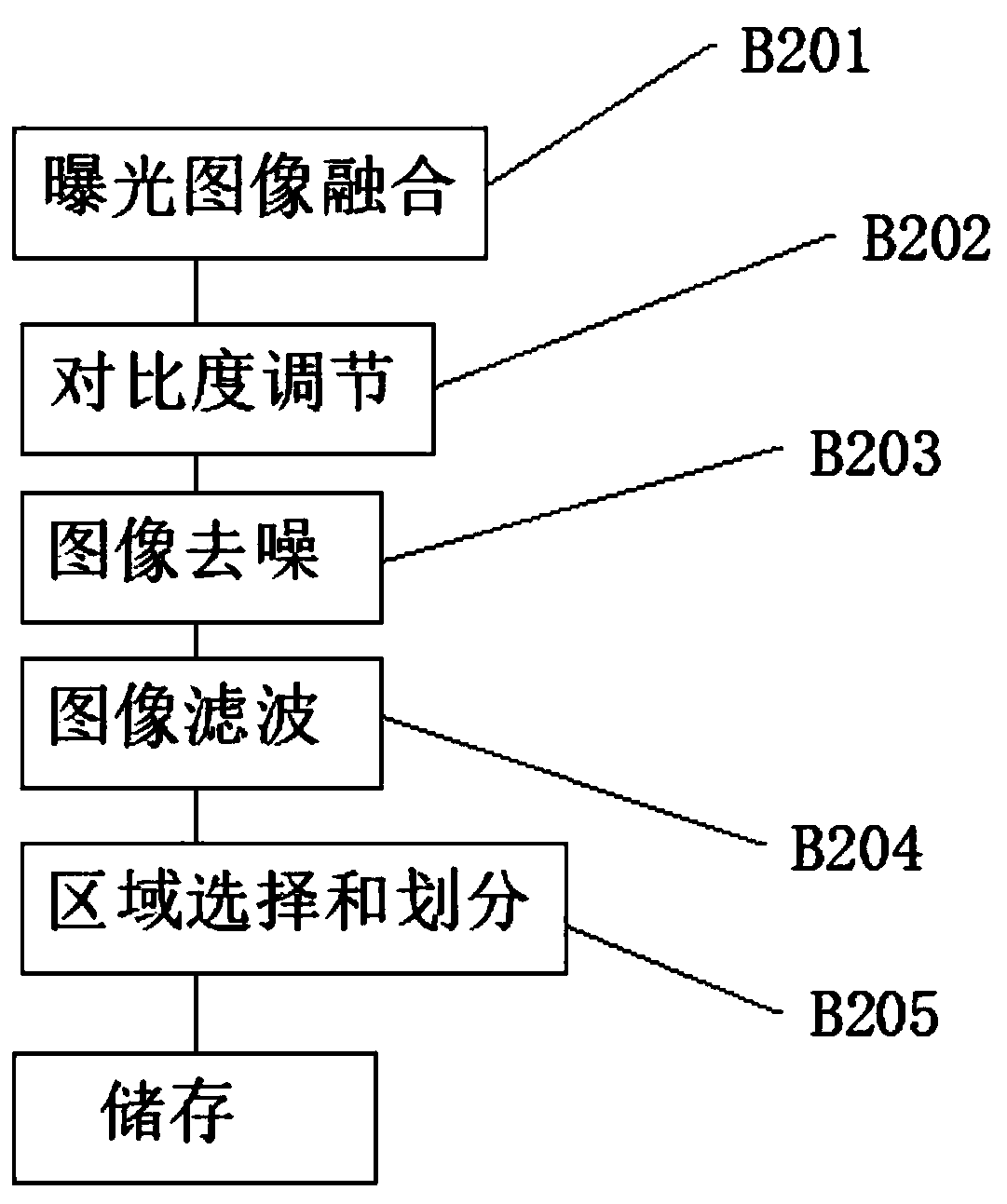

Welding spot appearance detection method based on machine vision

PendingCN111307812AEasy to collectThe analysis result is accurateOptically investigating flaws/contaminationImaging processingMachine vision

Owner:NANCHANG INST OF TECH

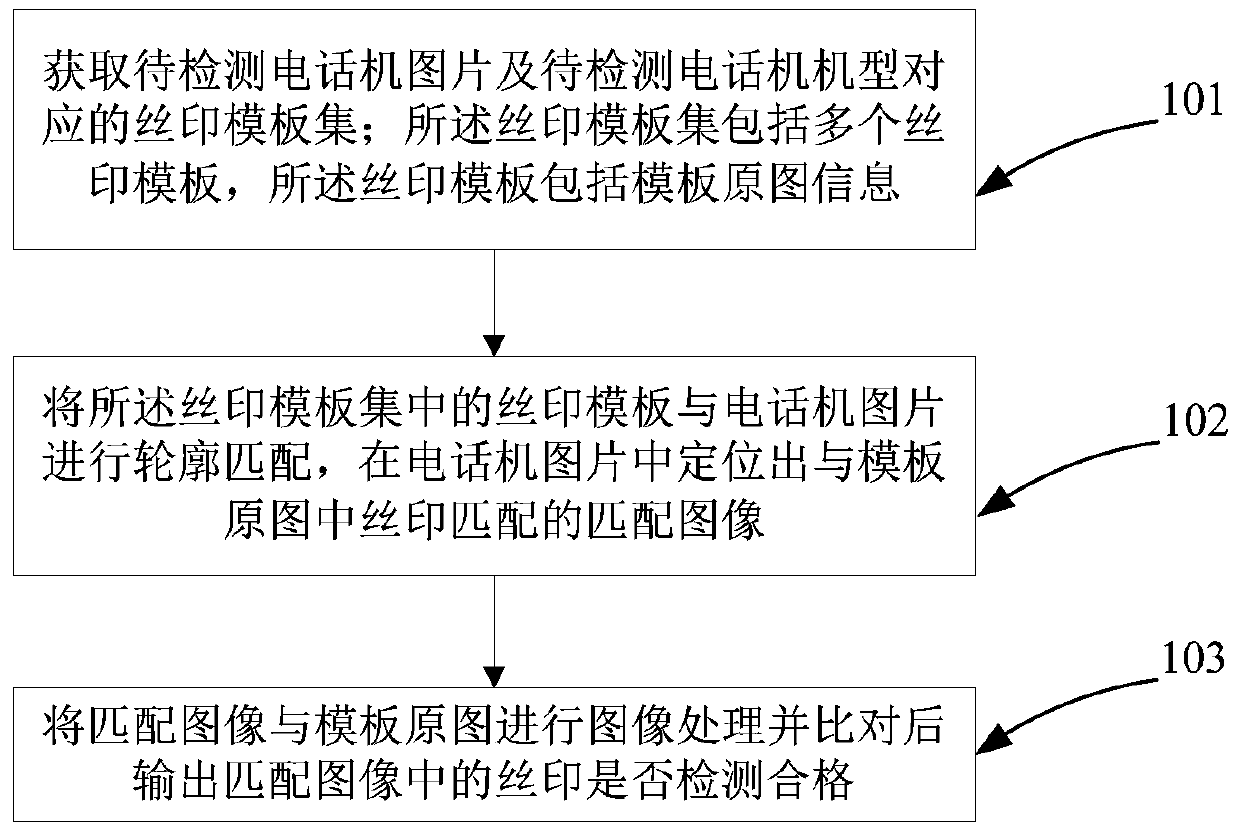

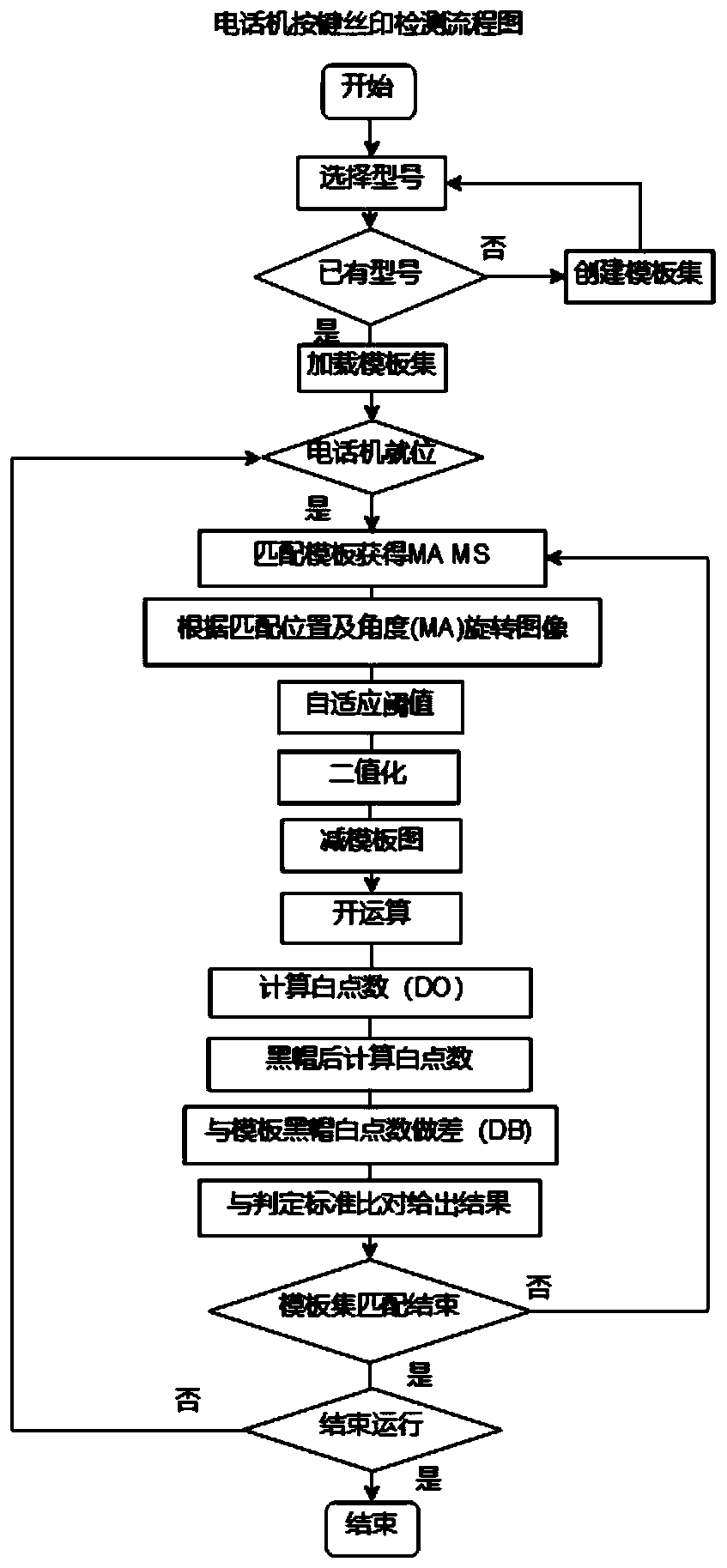

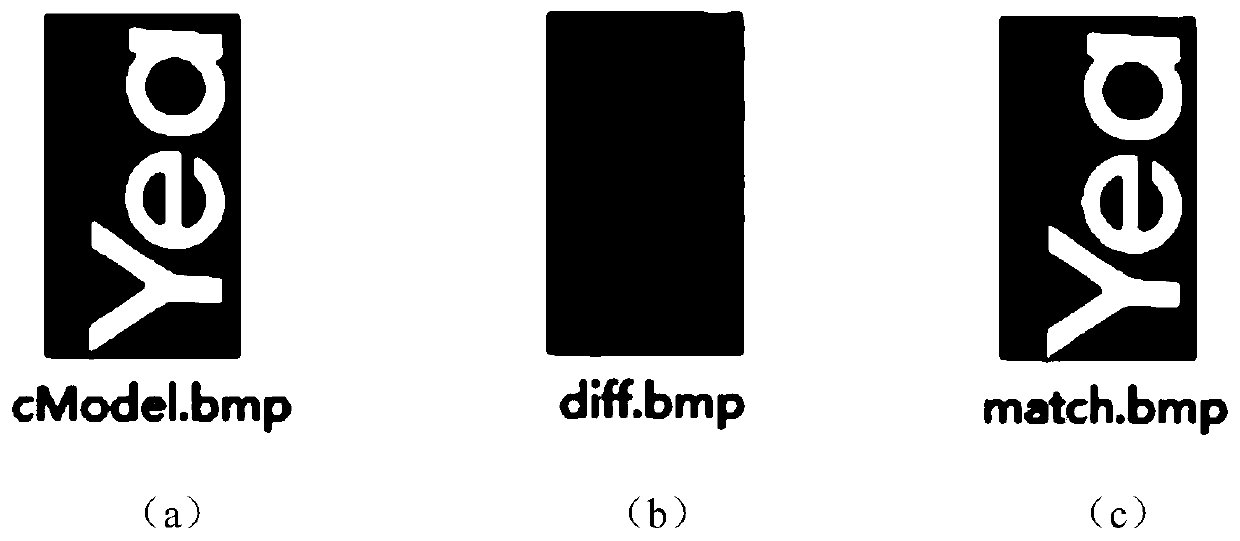

Telephone screen printing quality detection method and system

ActiveCN111028209AImprove screen printing qualityIncrease productivityImage enhancementImage analysisScreen printingContour matching

Owner:NANJING WANLIDA TECH

Machine vision lens with wide working distance and high resolution ratio

The invention discloses a vision lens with a wide working distance and a high resolution ratio. The lens comprises a focusing group GA and a fixing group GB, wherein the focusing group GA and the fixing group GB are arranged in sequence from an objective end to an image surface; the focusing group GA comprises a first lens G1, a second lens G2, a first bonding lens group U1, a second bonding lensgroup U2 and a seventh lens G7; the focal lengths of an optical system, the focusing group GA and the fixing group GB are independently f, fGA and fGB, the combined focal length of the first lens G1,the second lens G2 and the first bonding lens group U is f(G1-G4), and the combined focal length of the second bonding lens group U2 and the seventh lens G7 is f(G5-G7), wherein the above focal lengths independently meet the following relational expression: fGA / f is greater than 1 and less than 1.4, fGB / f is greater than 3 or less than 4, f(G1-G4) / f is greater than 2.0 and less than 2.6, and f(G5-G7) / f is greater than 0.6 and less than 1.0. The lens has the characteristics of high resolution ratio and low distortion and can support the working distance from 0.1m to infinity.

Owner:GUANGDONG AOPUTE TECH CO LTD

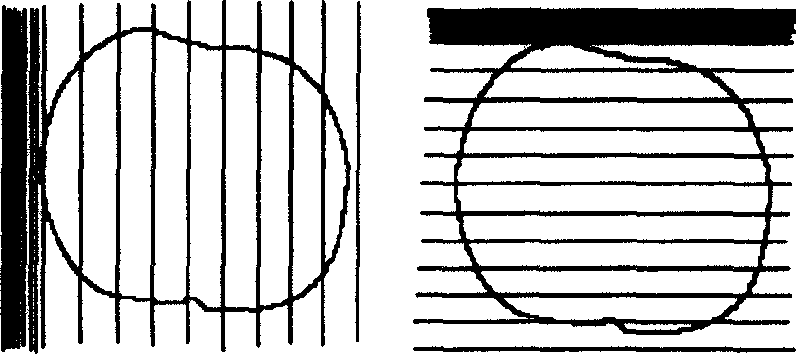

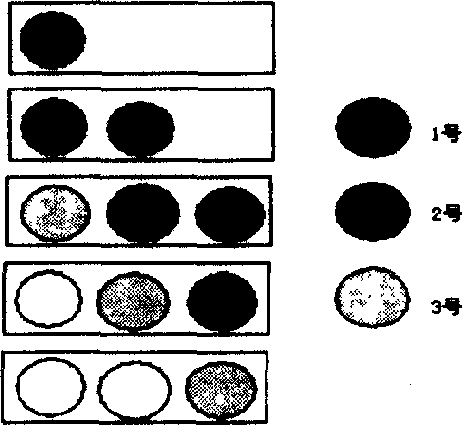

Worm-eaten sunflower seed sorting unit

Owner:JIANGNAN UNIV

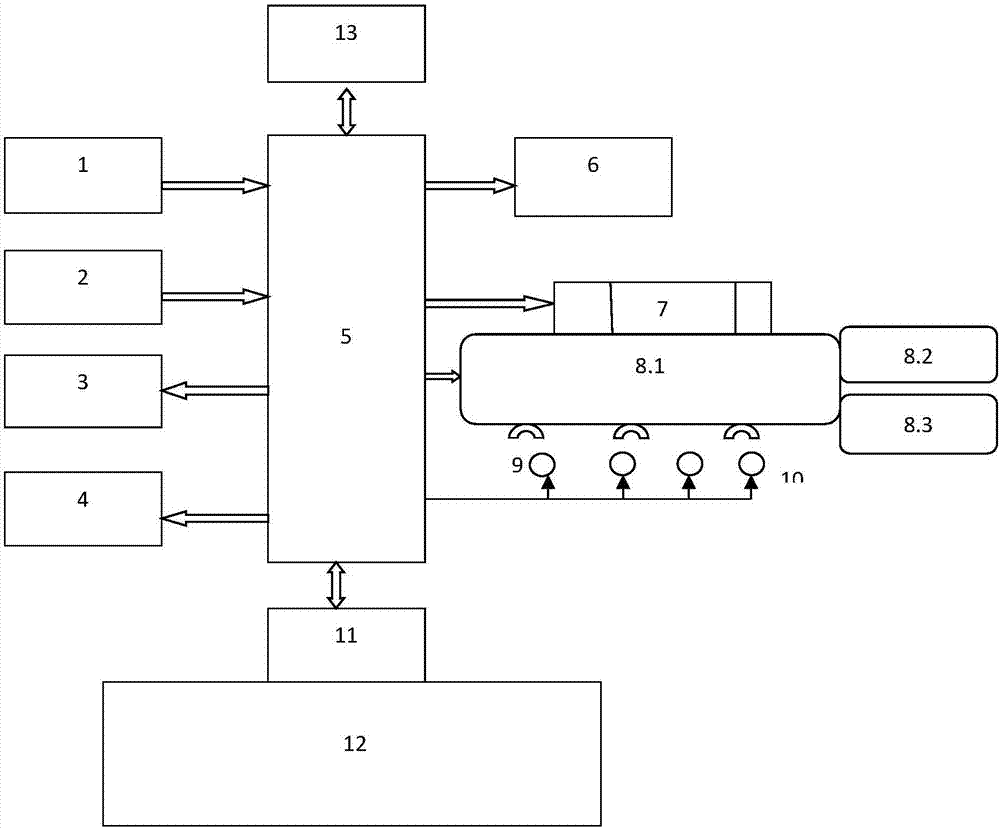

Intelligent production and detection control system for electromagnetic coil and method thereof

ActiveCN107368027AIncrease production capacityEasy to detectProgramme control in sequence/logic controllersElectrical resistance and conductanceMachine vision

Owner:SHANDONG NORMAL UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap