Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Torch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A torch is a stick with combustible material at one end, which is ignited and used as a light source. Torches have been used throughout history, and are still used in processions, symbolic and religious events, and in juggling entertainment. In some countries "torch" in modern usage is the term for a battery-operated portable light.

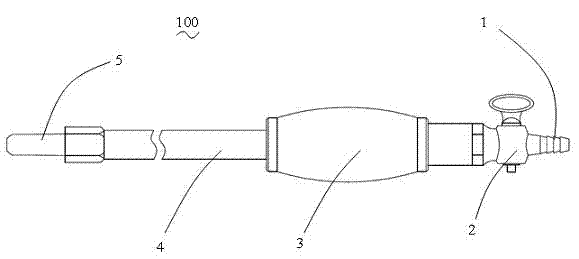

Self-power-generating handheld torch

InactiveCN102080769ASimple structureReduce frictionLighting device with mechanical drivePoint-like light sourceTorchKinetic energy

The invention discloses a self-power-generating handheld torch, comprising a light emitter, a light focusing bowl, an electric storage device and a power generating device, wherein the power generating device consists of a permanent magnet and coils tightly wound; the permanent magnet is slidably placed in the coils; the periphery of the permanent is connected with the inner walls of the coils by means of a plurality of symmetric elastic belts; and the permanent magnet is suspended in the coils. The self-power-generating handheld torch provided by the technical scheme of the invention has the advantages that the structure is simple; simpleness, convenience and practicability are ensured; and the friction of a power generating device can be reduced, kinetic energy is increased, and the power generating efficiency is greatly improved.

Owner:THE FIRST AFFILIATED MIDDLE SCHOOL OF EAST CHINA NORMAL UNIV

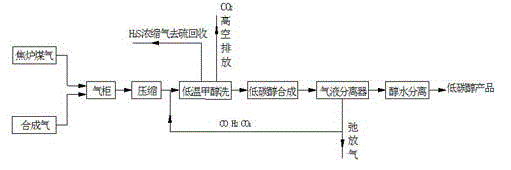

Technology for preparing low-carbon alcohol from syngas and coke oven gas

ActiveCN105130749AImprove thermal stabilityGood chemical stabilityOrganic compound preparationChemical industryLiquid productGas phase

Owner:SEDIN ENG

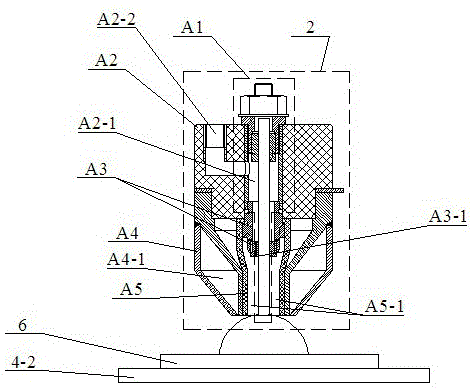

Ground torch system

PendingCN111928279AReasonable locationAvoid insufficient combustionIncinerator apparatusCombustorCombustible gas

Owner:SHANGHAI QIYAO THERMAL ENERGY ENG CO LTD +1

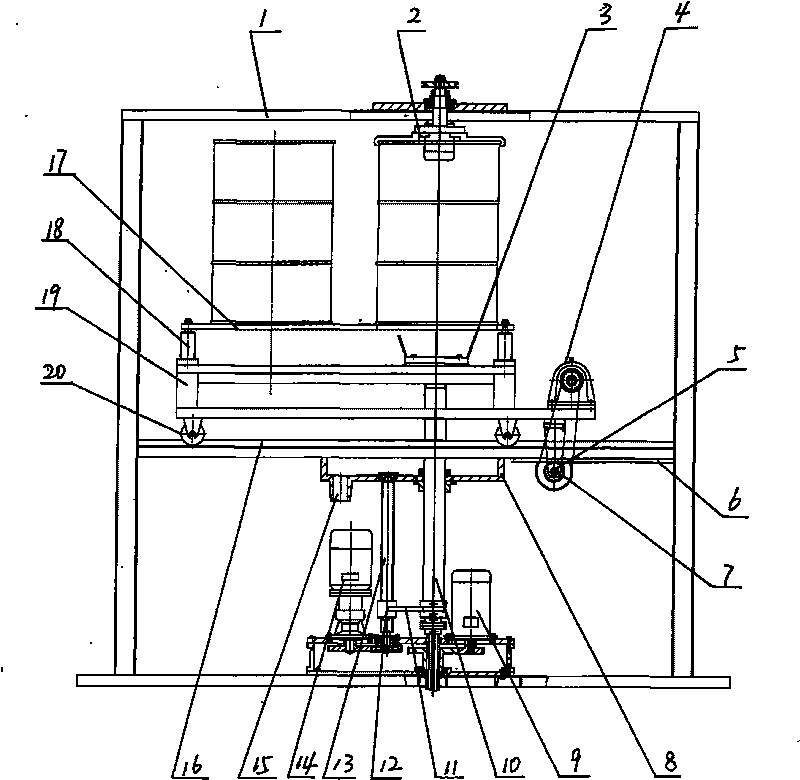

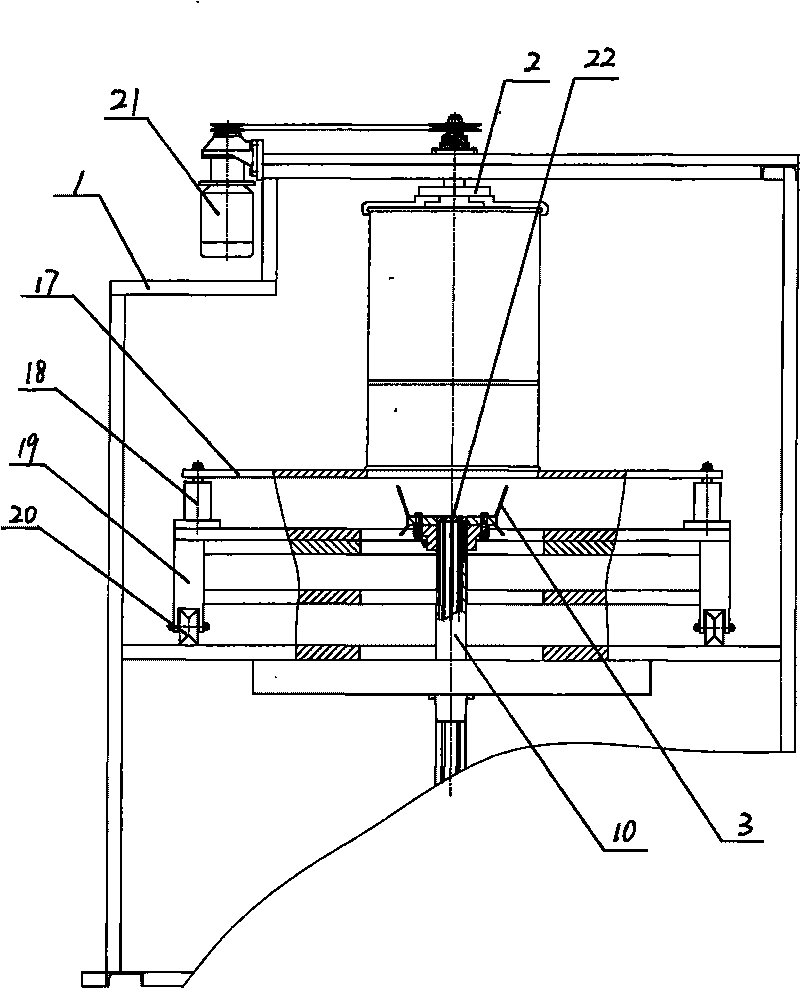

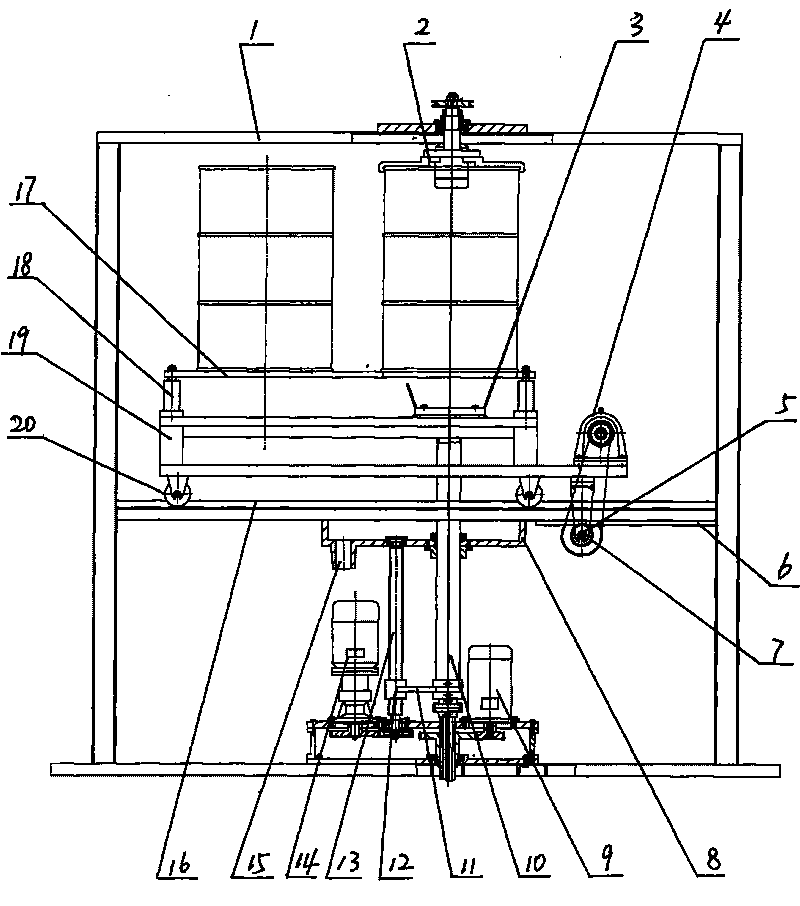

Processing system for renovating inner wall of vertical steel drum

Owner:CHAXI CYLINDER MFG FACTORY HANGU DISTRICT TIANJIN

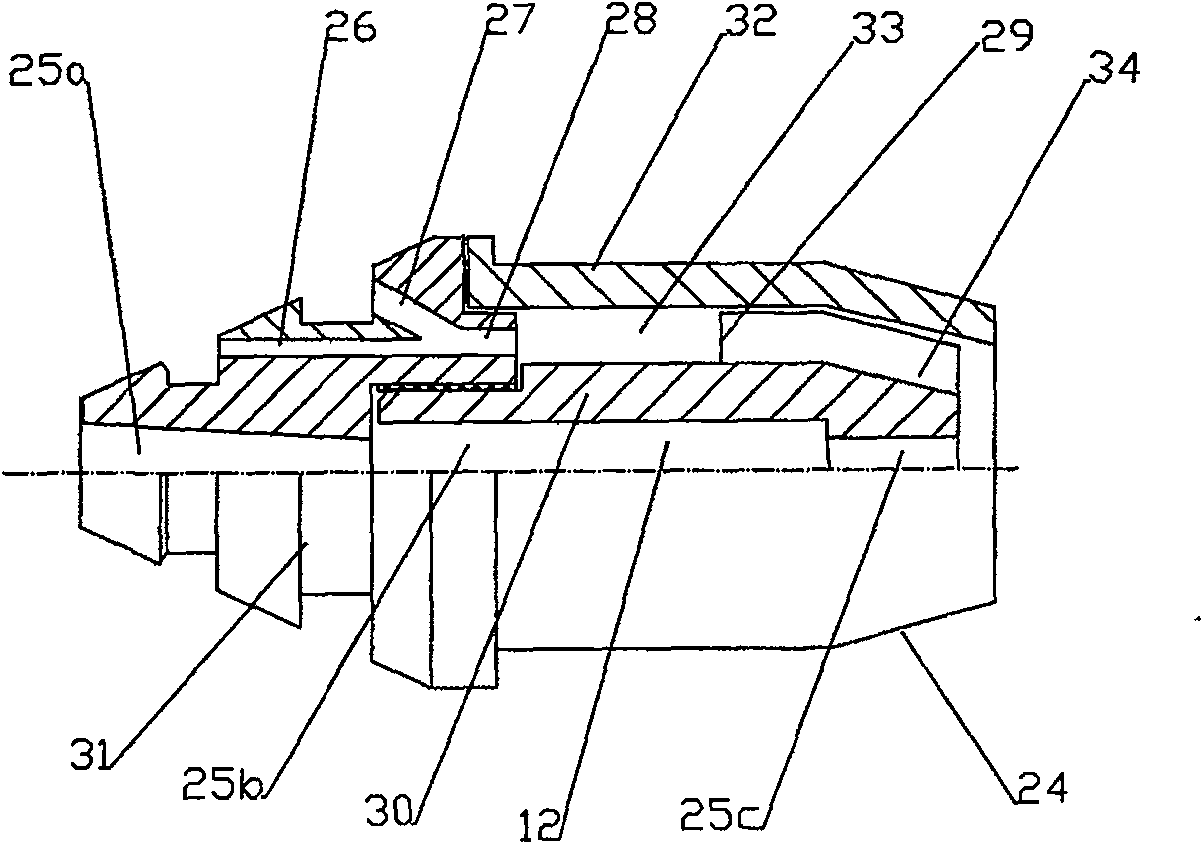

Torch component of plastic rolling machine

Owner:海门市知舟工业设计有限公司

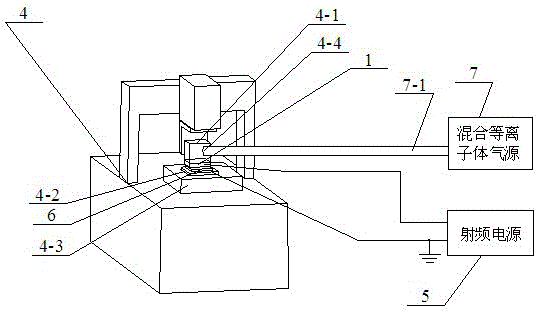

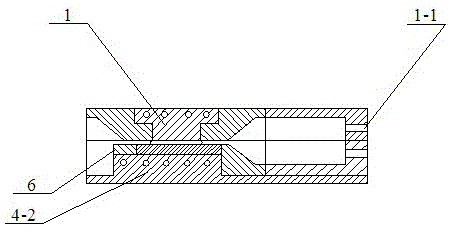

Atmospheric Plasma NC Machining Method of Freeform Surface Optical Parts

ActiveCN103273180BEfficient and precise shapingAvoid damagePlasma welding apparatusNumerical controlFree form

Owner:HARBIN INST OF TECH

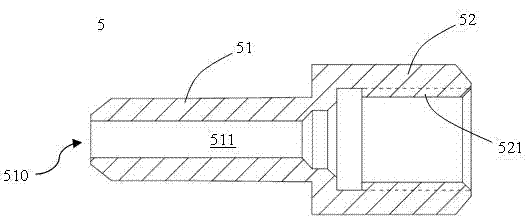

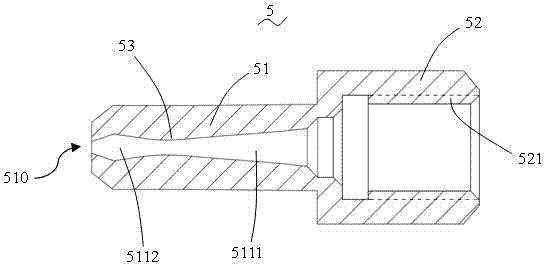

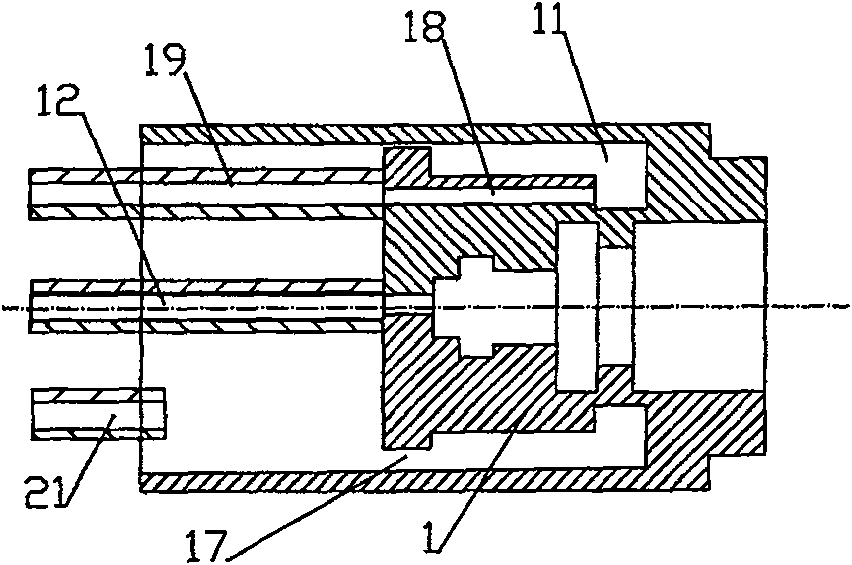

Feeding mechanism for producing optical fiber prefabricated rod

The invention relates to a feeding mechanism for producing an optical fiber prefabricated rod. The feeding mechanism is positioned on a rack; the feeding mechanism comprises a lifting mechanism, a transverse moving mechanism and a rotating mechanism; the transverse moving mechanism is arranged on the lifting mechanism; the rotating mechanism is arranged on the transverse moving mechanism; a targetrod is mounted on the rotating mechanism; the rotating mechanism comprises a rotating motor, a rotating bracket, a rotating base and a rotating disc; the rotating bracket is fixed on the transverse moving mechanism; the rotating motor is fixed on the rotating bracket; the rotating base is rotationally arranged on the rotating bracket; the rotating motor is rotationally connected with the rotatingbase; the rotating base is fixed with the rotating disc. By adopting the feeding mechanism for producing the optical fiber prefabricated rod, a material can be uniformly sprayed and deposited on a target rod by using a blowtorch mechanism, torch firing is lifted gradually, and thus uniformity of the optical fiber prefabricated rod can be maintained.

Owner:WUXI KAILING ELECTRONICS CO LTD

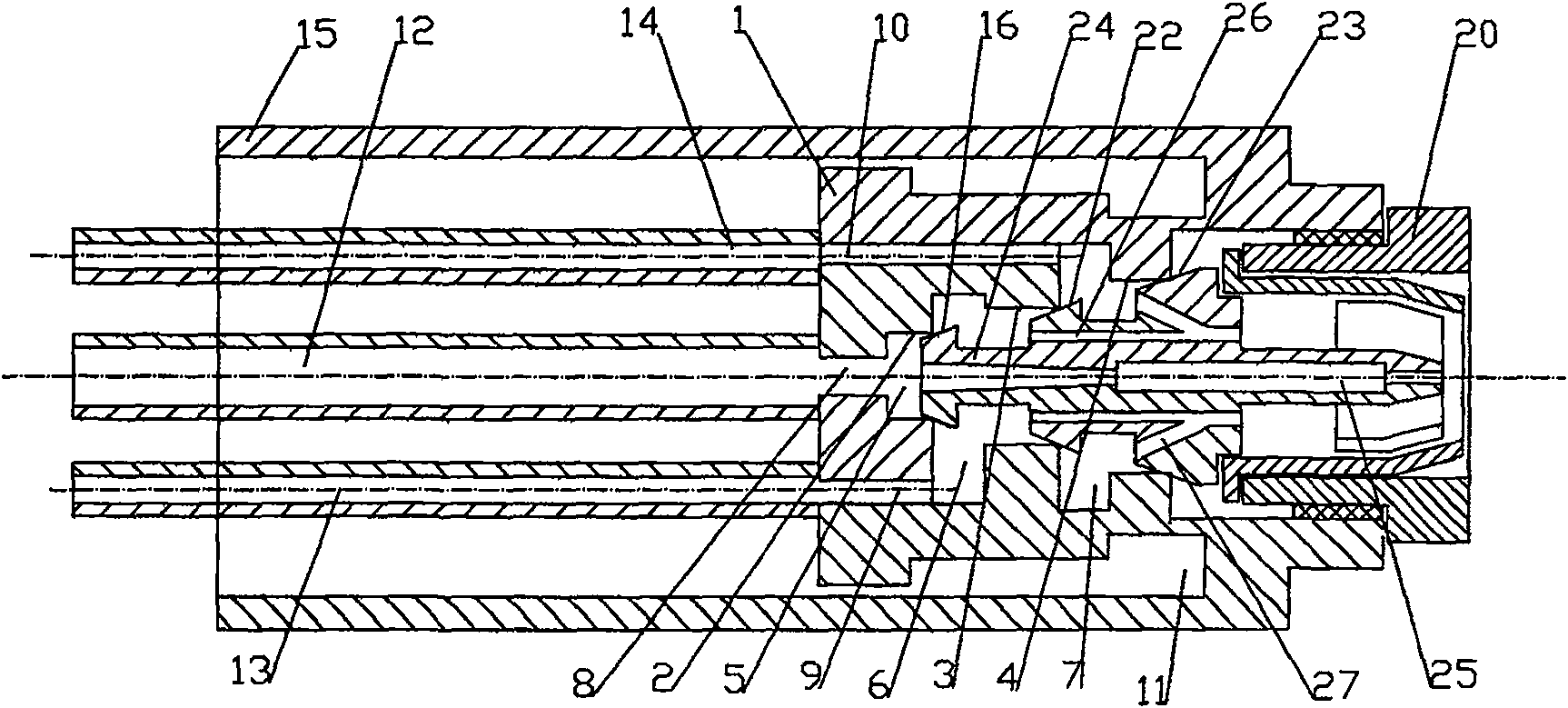

Steel-smelting continuous casting cutting torch

InactiveCN100561048CImprove cooling effectAvoid deformationGaseous fuel burnerSteelmakingCooling effect

Owner:陈寅明

Gasification flash evaporation system capable of automatically cleaning condenser on line

PendingCN112457888AShort online runtimeRealize online smart workGasification processes detailsCombustible gas productionSyngasBuffer tank

The invention provides a gasification flash evaporation system capable of automatically cleaning a condenser on line. The gasification flash evaporation system comprises a first condenser, a second condenser, a first blowback system, a second blowback system, a gas-liquid separation tank, a blowback buffer tank, a low-pressure flash evaporation tank, a low-pressure circulating water pump, a watercooler and a controller, the gasification flash evaporation system achieves on-line intelligent work, automatic switching, automatic putting into use and automatic cleaning, solves the problems that the flash evaporation condenser is short in on-line operation time, flash steam heat cannot be effectively utilized after the condenser is blocked is reduced, the temperature of high-pressure circulating water is reduced (the temperature of synthesis gas washing water is low), and the problems of low water vapor content at the outlet of the synthesis gas washing tower and high conversion energy consumption are solved; and the problems that after the flash evaporation condenser is blocked, heat moves backwards, the pressure of a cooler is large, and a downstream sulfur recovery device or a torchdevice cannot normally put into use are solved.

Owner:NINGXIA SHENYAO TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap