Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13 results about "Bogie" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bogie (/ˈboʊɡi/ BOH-ghee) (in some senses called a truck in North American English) is a chassis or framework that carries a wheelset, attached to a vehicle—a modular subassembly of wheels and axles. Bogies take various forms in various modes of transport. A bogie may remain normally attached (as on many railroad cars and semi-trailers) or be quickly detachable (as the dolly in a road train or in railway bogie exchange); it may contain a suspension within it (as most rail and trucking bogies do), or be solid and in turn be suspended (as most bogies of tracked vehicles are); it may be mounted on a swivel, as traditionally on a railway carriage or locomotive, additionally jointed and sprung (as in the landing gear of an airliner), or held in place by other means (centreless bogies).

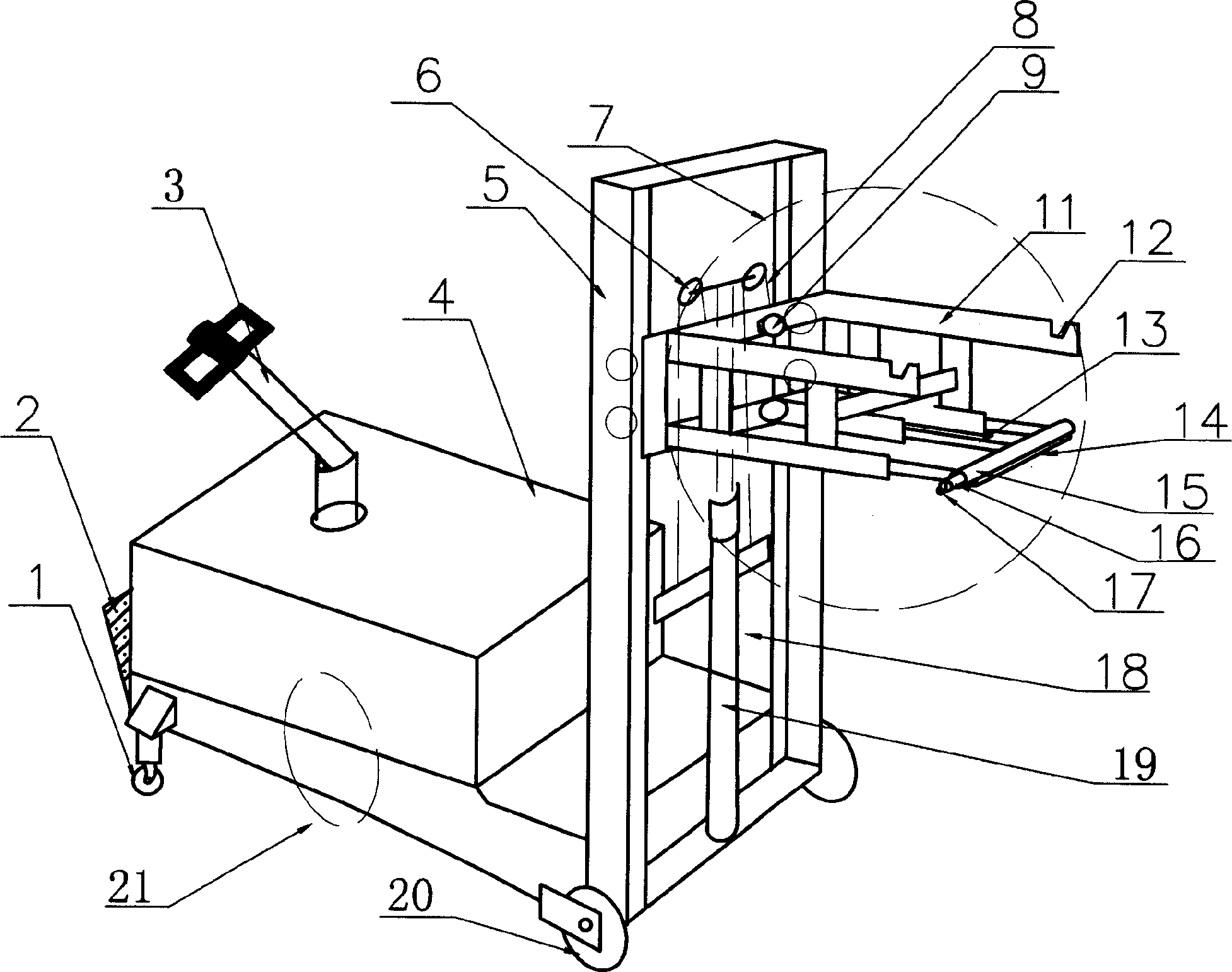

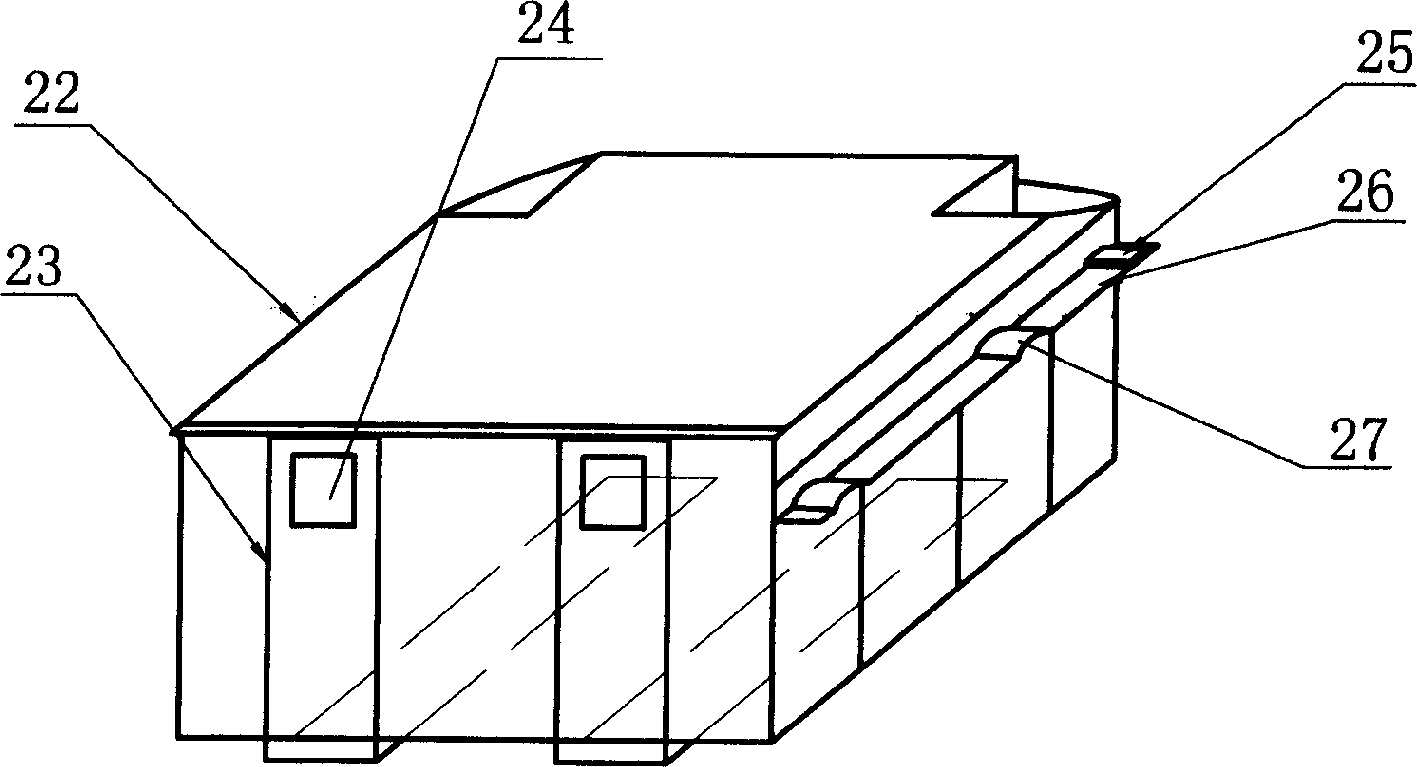

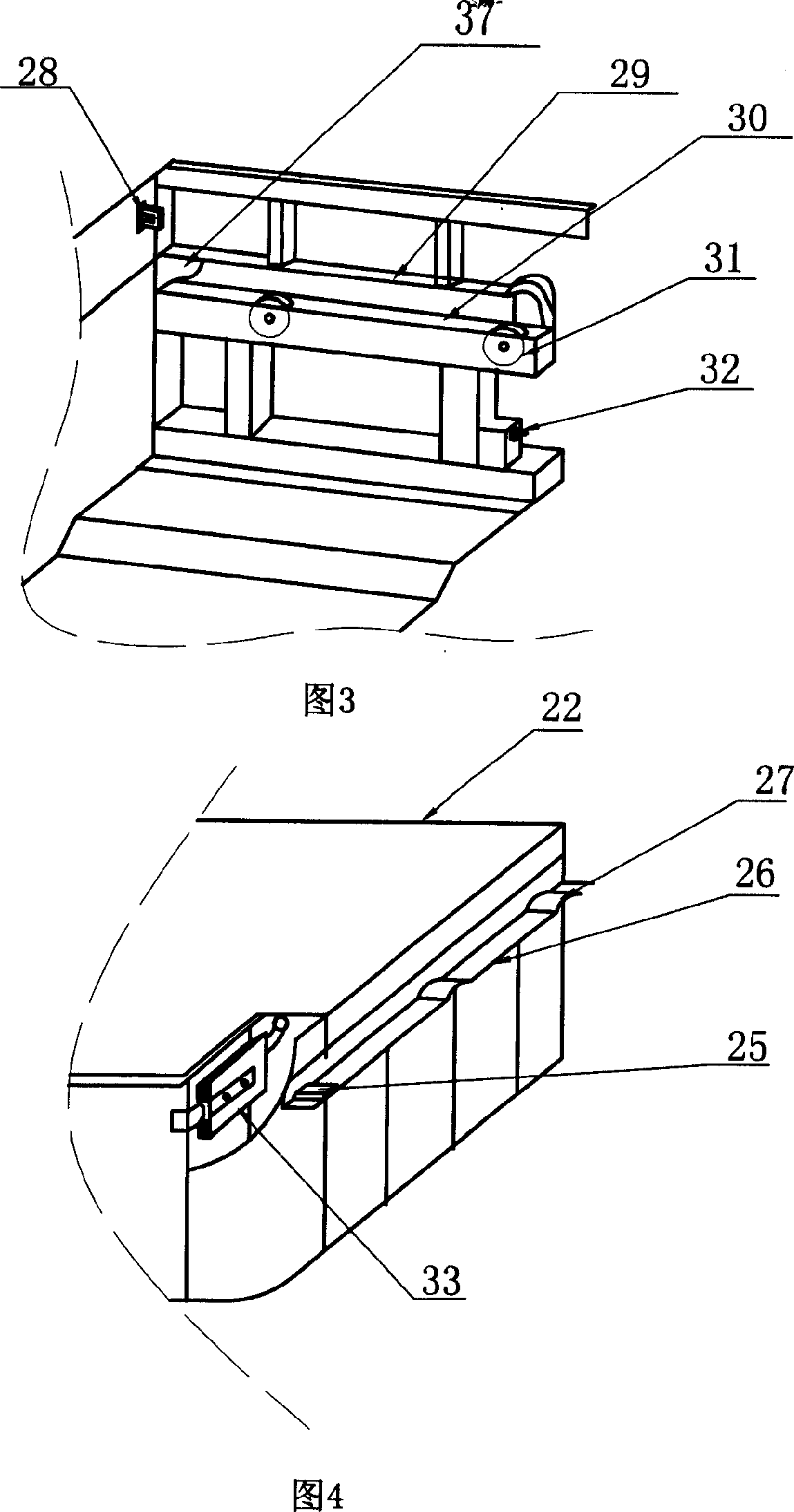

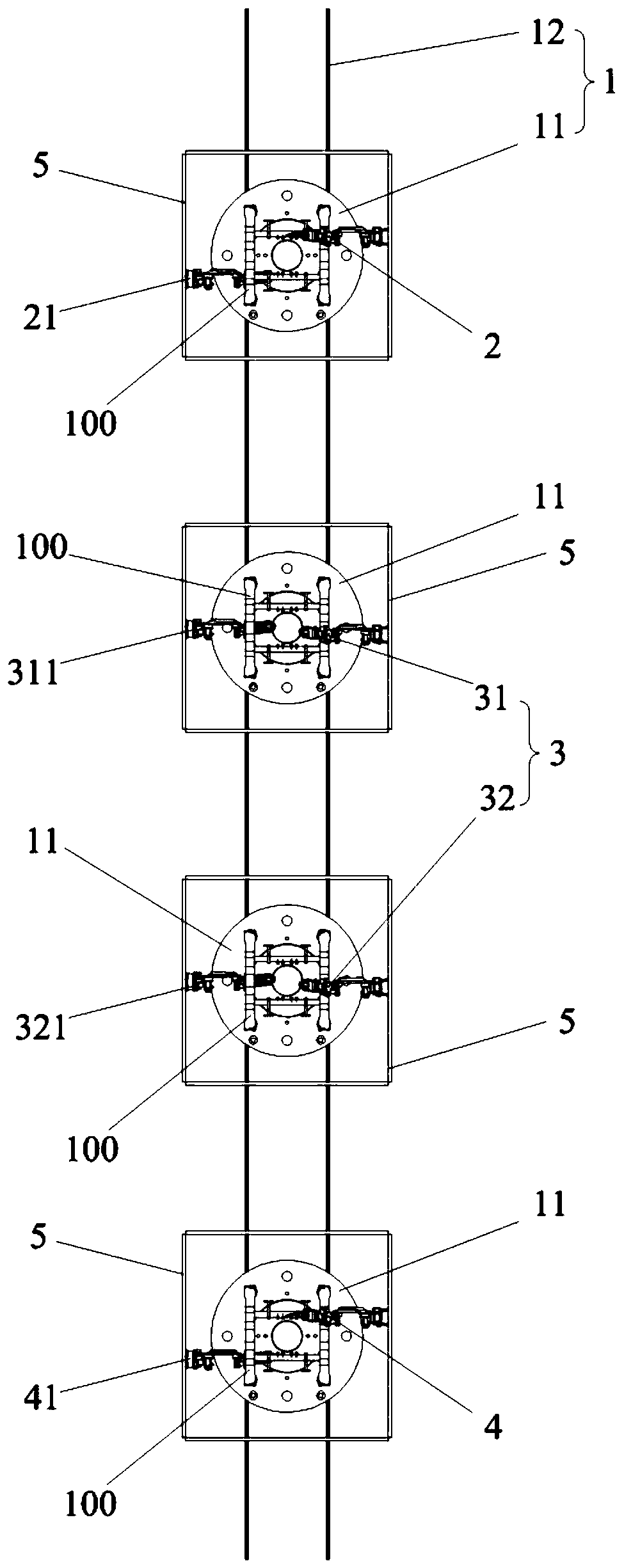

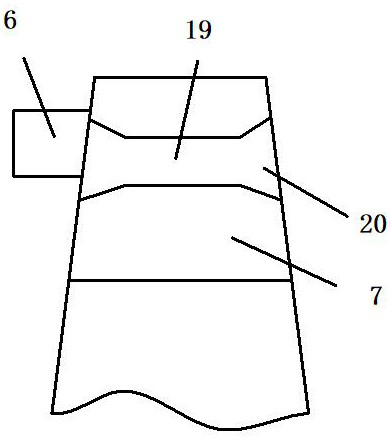

Electric car battery set unloading vehicle, and its track type battery holder and built-in type battery holder

InactiveCN1789048AEasy loading and unloadingImprove convenienceElectric propulsion mountingElectric vehicle charging technologyBogieElectrical battery

Owner:万向电动汽车有限公司

Method for melting purification of magnesia by using waste magnesium product

InactiveCN101837996ADoes not affect normal useQuality is not affectedChemical industryMagnesiaCompression moldingTunnel kiln

Owner:DASHIQIAO WEIMING FURNACE MATERIAL

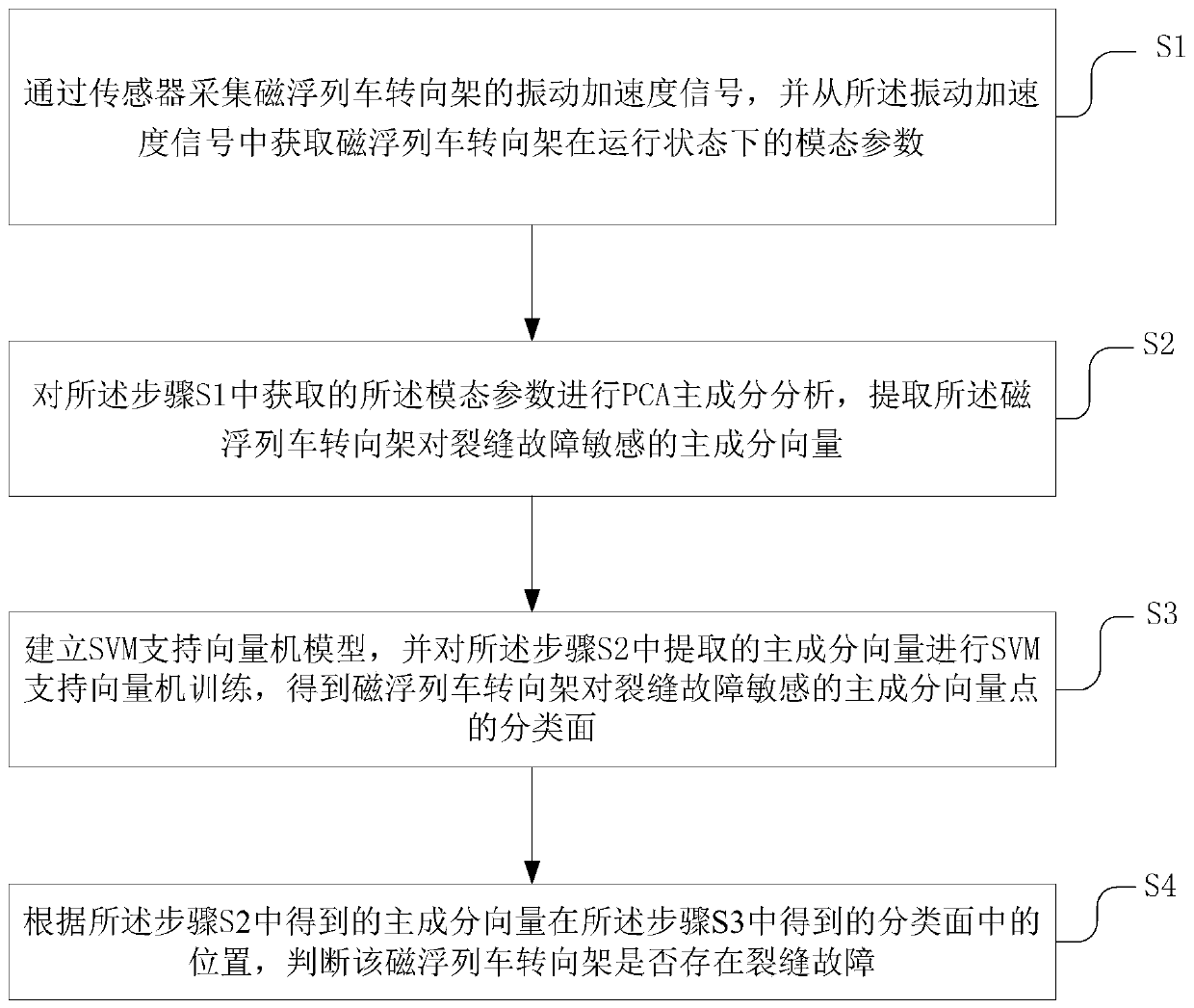

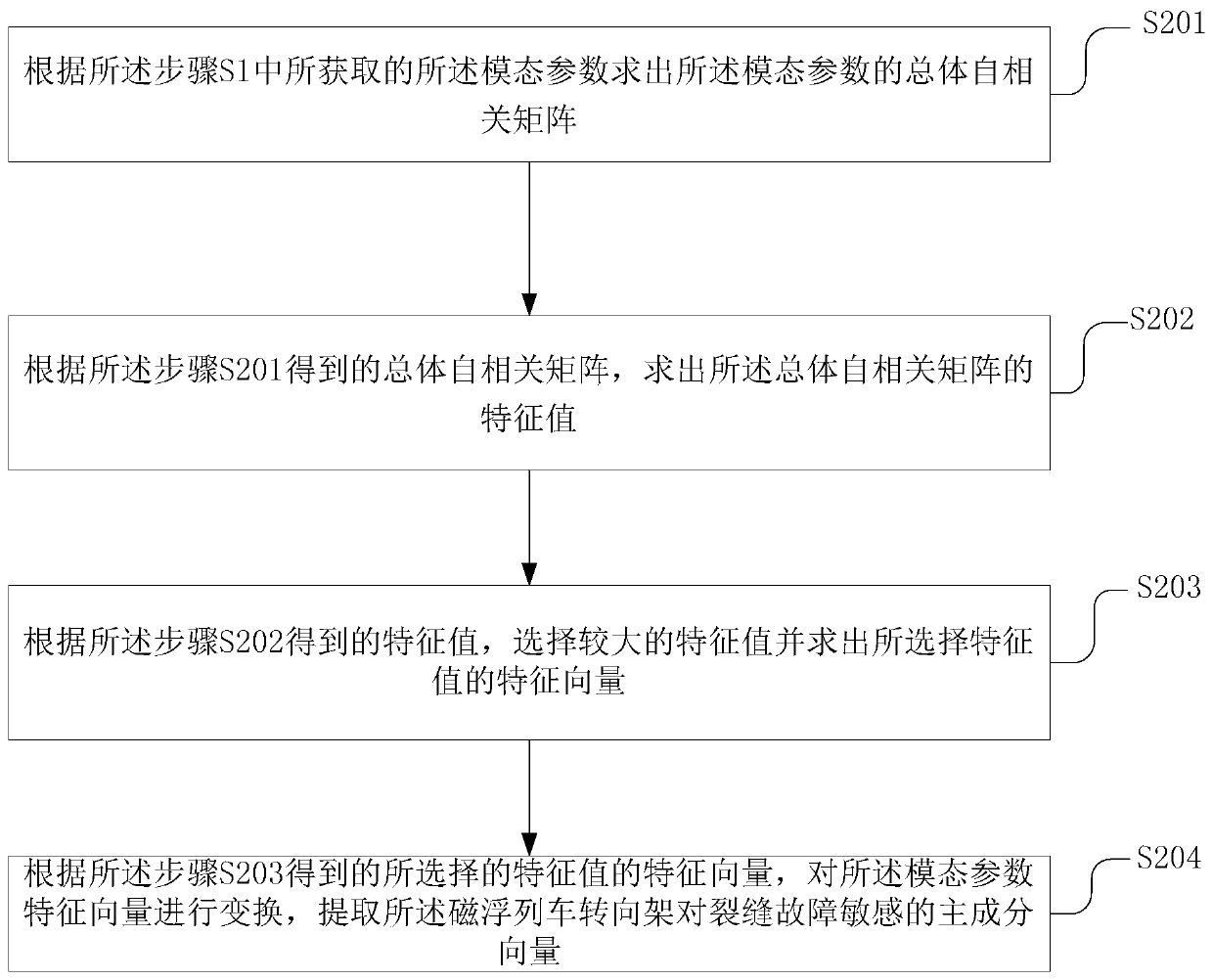

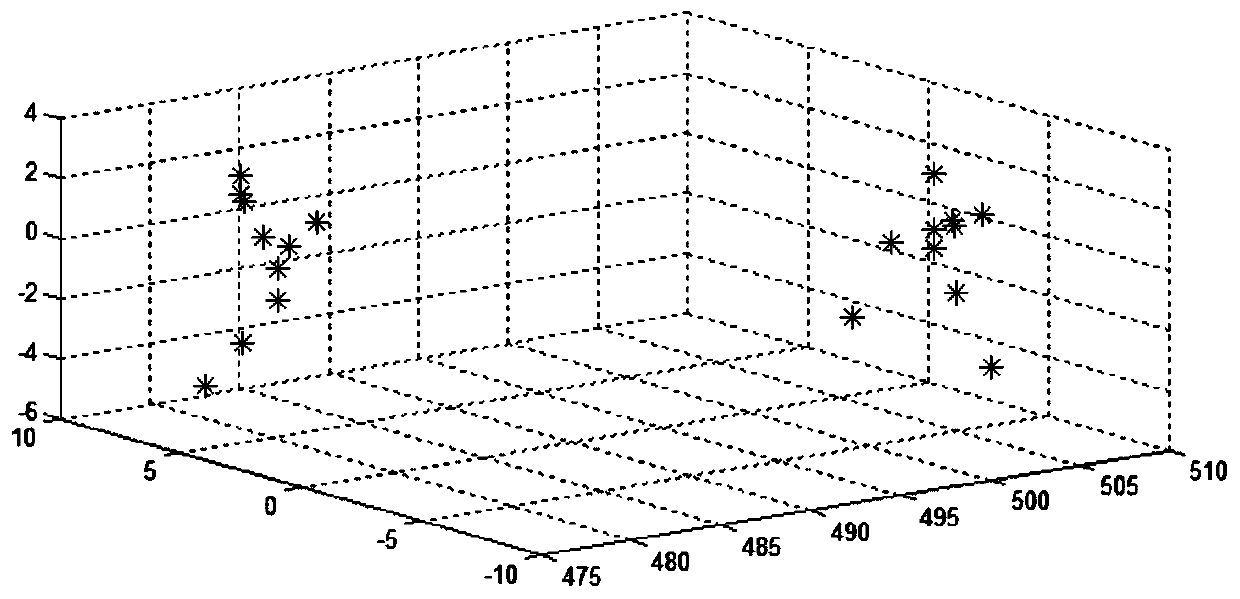

Method for detecting crack fault of bogie of maglev train

ActiveCN109781442AImprove securityEfficient and accurate detectionProcessing detected response signalCharacter and pattern recognitionBogieSupport vector machine

Owner:NAT UNIV OF DEFENSE TECH

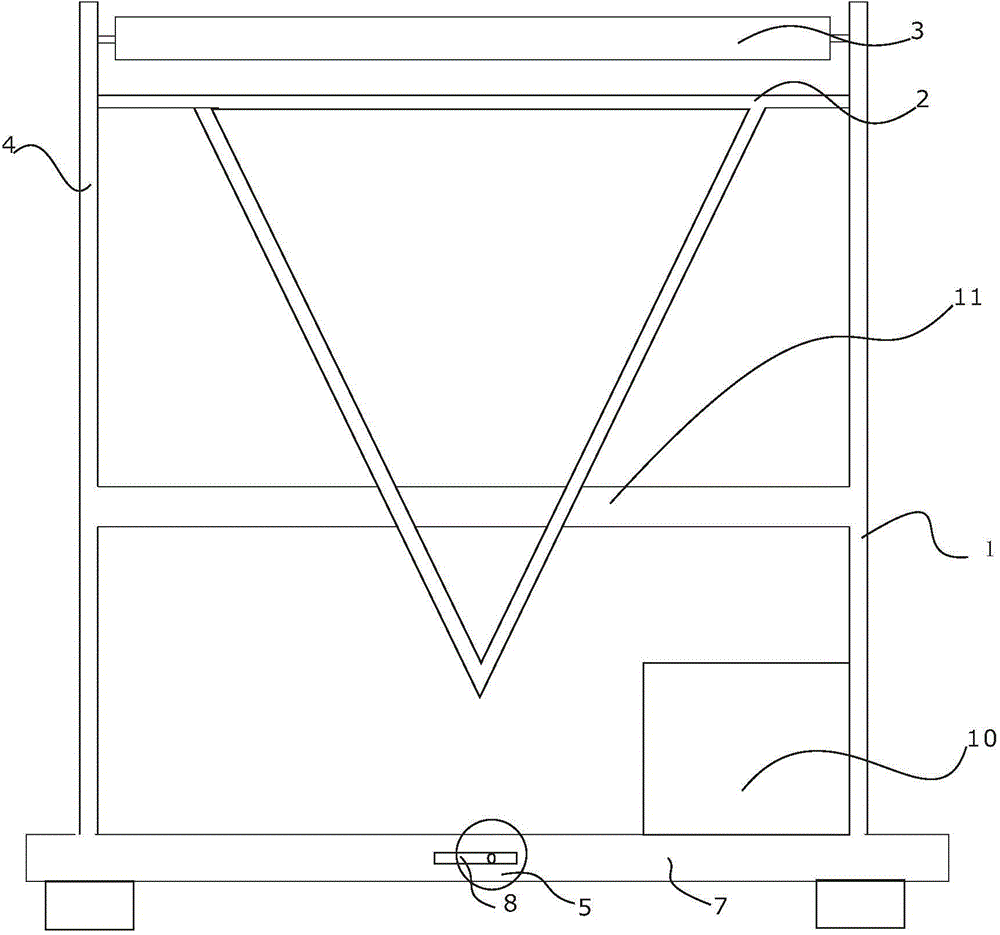

Bullet train bogie framework cleaning equipment

PendingCN111451206AEasy to cleanImprove cleaning efficiencyDrying gas arrangementsCleaning using toolsBogieStain

Owner:BEIJING RAILWAY INST OF MECHANICAL & ELECTRICAL ENG

Steering bending frame for plastic package

Owner:TIANJIN HUI JIN PACKAGING PROD CO LTD

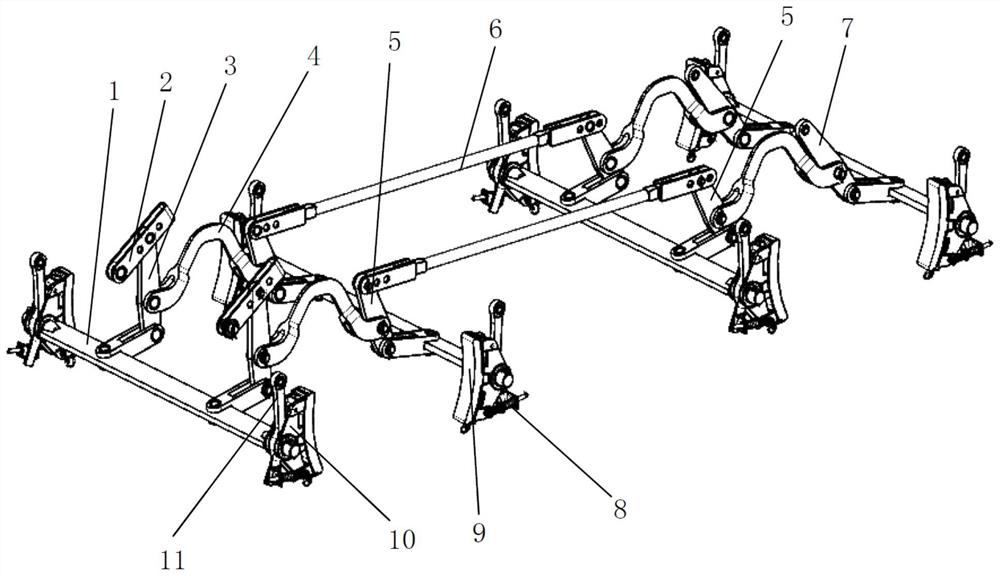

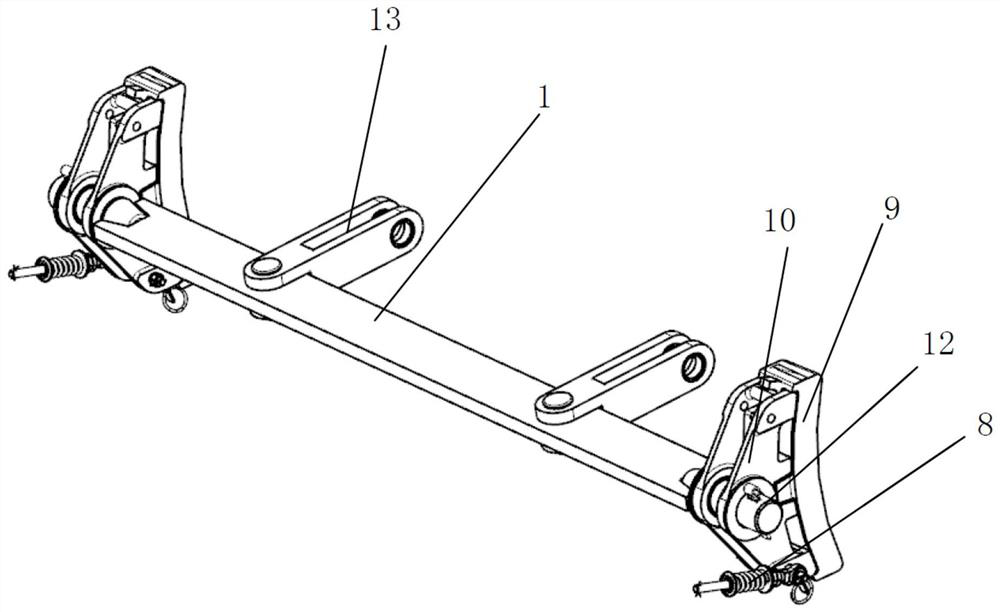

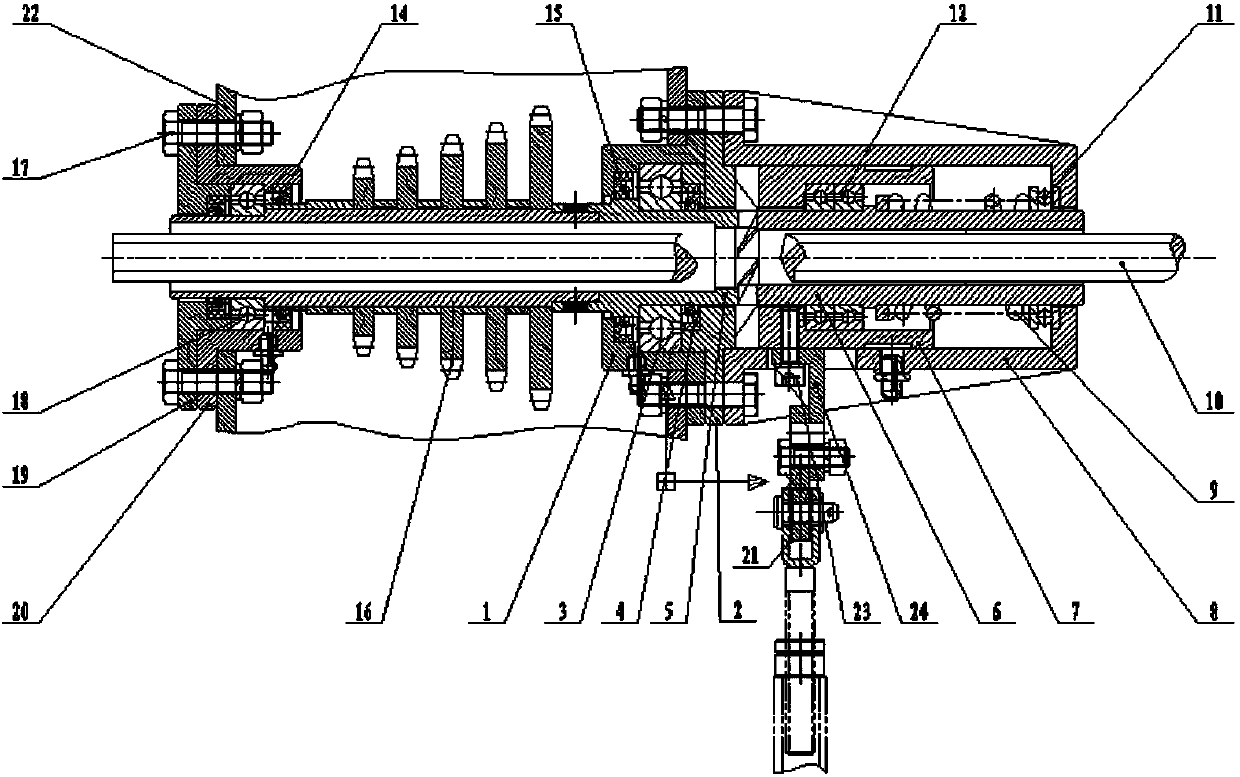

Three-axis welding self-guiding radial bogie foundation brake device

PendingCN112046539AMake full and reasonable use of structural spaceReasonable use of structural space positionRail brake actuationBrake arrangement with braking memberBogieBrake

Owner:CHENGDU TECHCAL UNIV

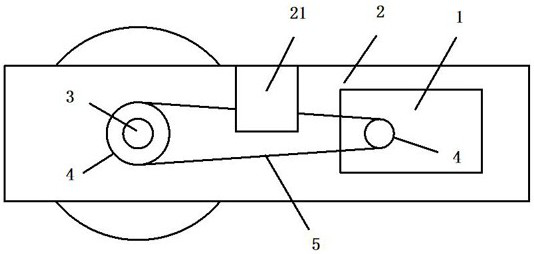

Magnetic power device

The present invention relates to a magnetic power device. It contains said device divided in upper and lower two layers U-shaped slope, bogie set with cuboid permanent magnet, top level with level laid permanent magnet, permanent magnet capable of generating push force to permanent magnet on bogie. Said lower layer slope is set with level laid cuboid permanent magnet whose upper part is S pole and lower surface is N pole, valve set between lower layer slope high-point and bogie movement starting point, permanent magnet capable of generating push force to bogie, bogie opening the valve in moving to lower layer slope high-point, continue sliding to high-point, at the same time valve fell back, bogie using valve as channel from high-point falling to bogie movement starting point of upper layer slope.

Owner:杨飞鹏

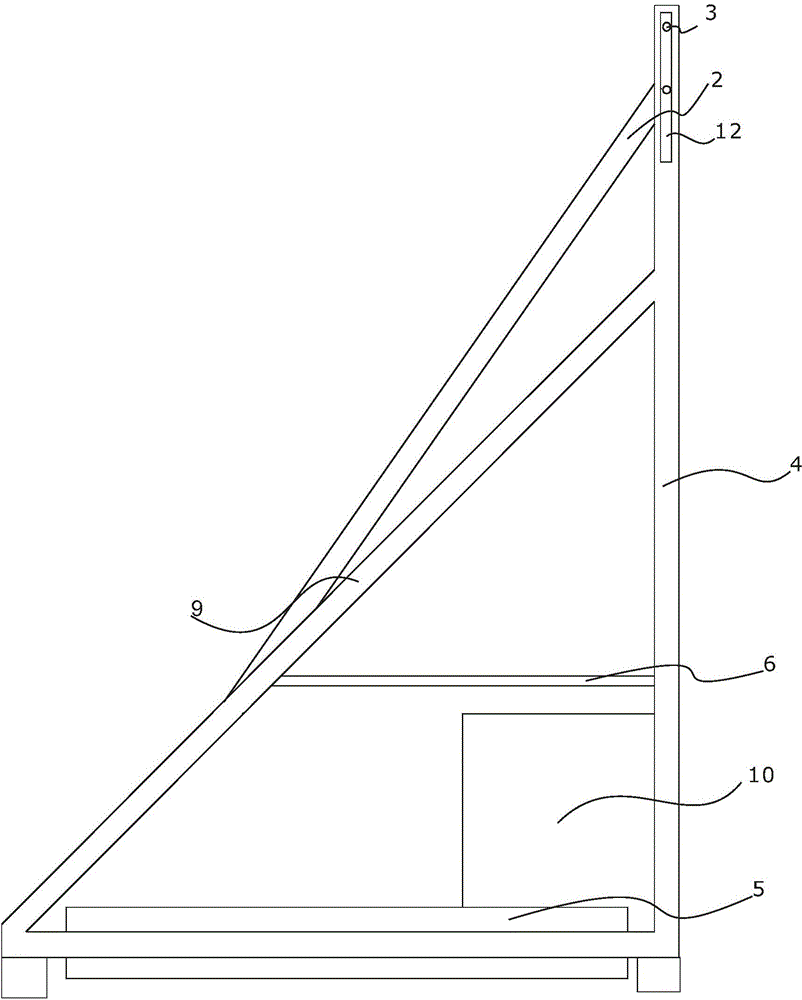

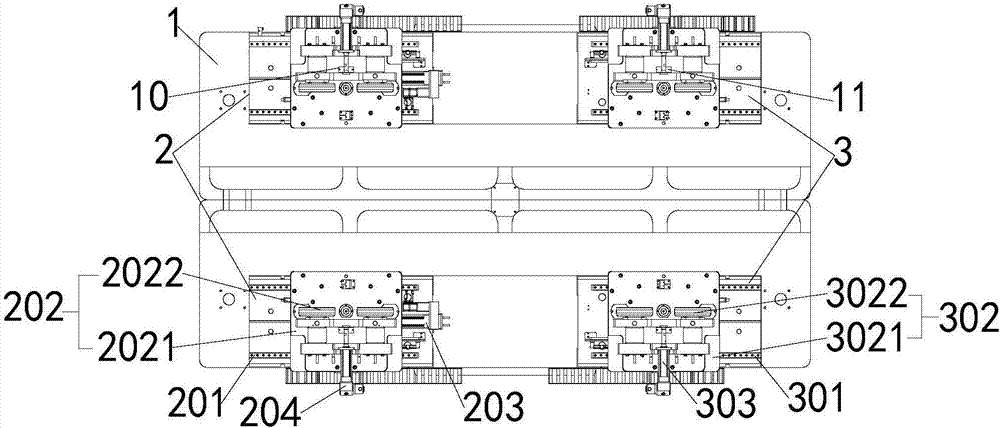

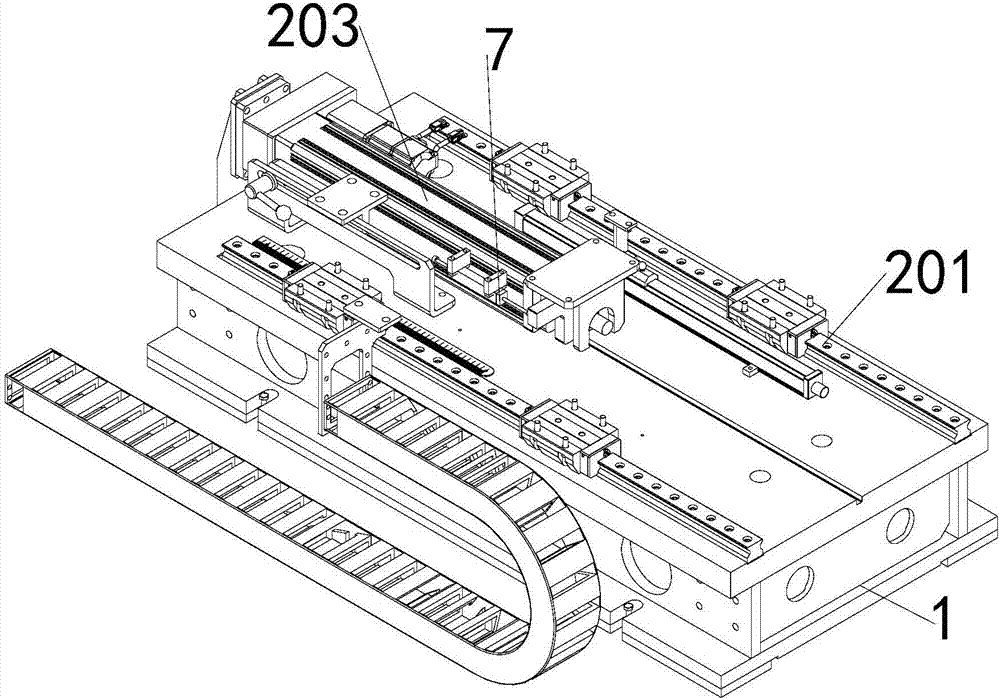

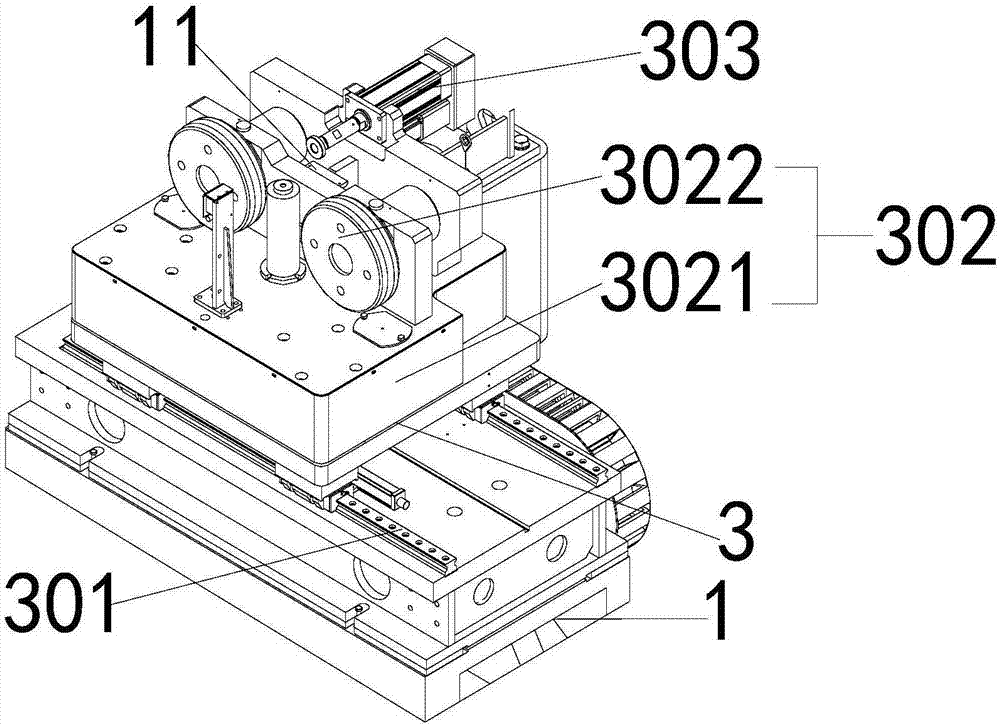

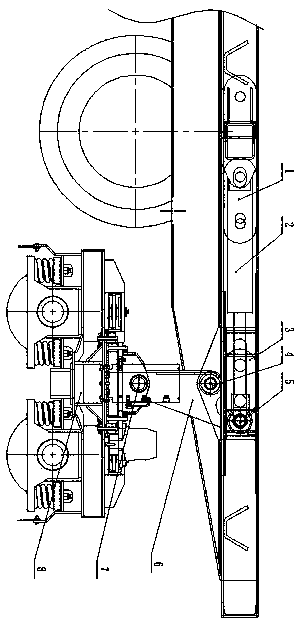

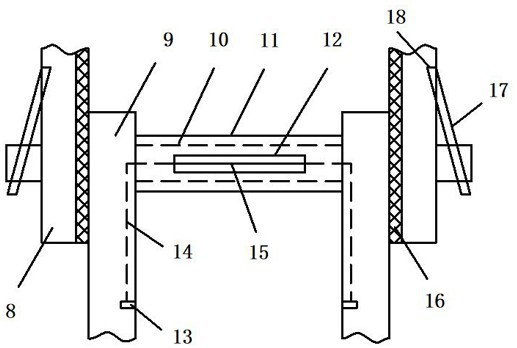

Weighing test device and bogie test system

InactiveCN107132062ARealize automatic reclosingRealize automatic adjustmentRailway vehicle testingSpecial purpose weighing apparatusBogieEngineering

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST +1

Rail dual-purpose fire truck railway running system lifting mechanism and lifting method

PendingCN109130734AReduce stressReduce shockFire rescueRail and road vehiclesBogieHydraulic cylinder

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

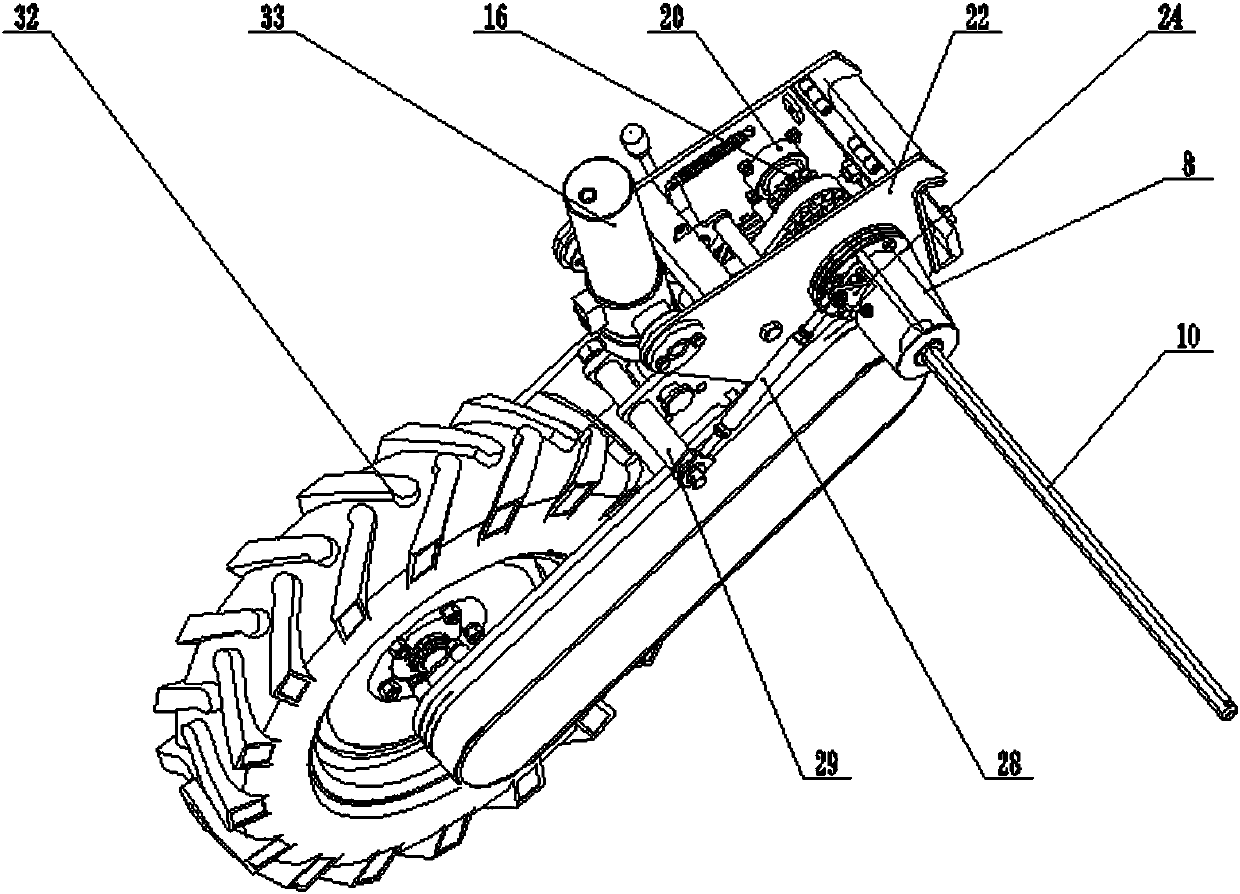

Main transmission clutch of non-tillage precise sowing machine

PendingCN107830078ACompact structureEasy to installFluid actuated clutchesBogieAgricultural engineering

Owner:瓦房店明运农机装备有限公司

Train shaft end generator

ActiveCN111706649AAdjustable tensionAchieve initial positioningGearingPortable liftingBogieGear wheel

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

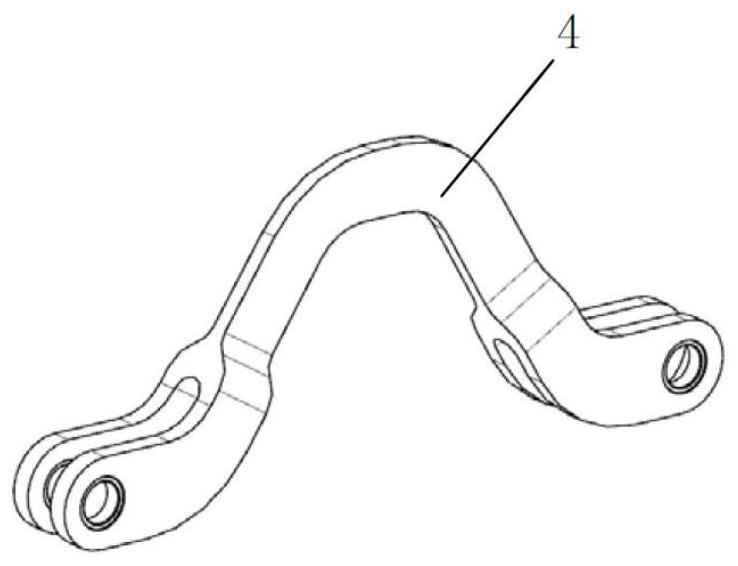

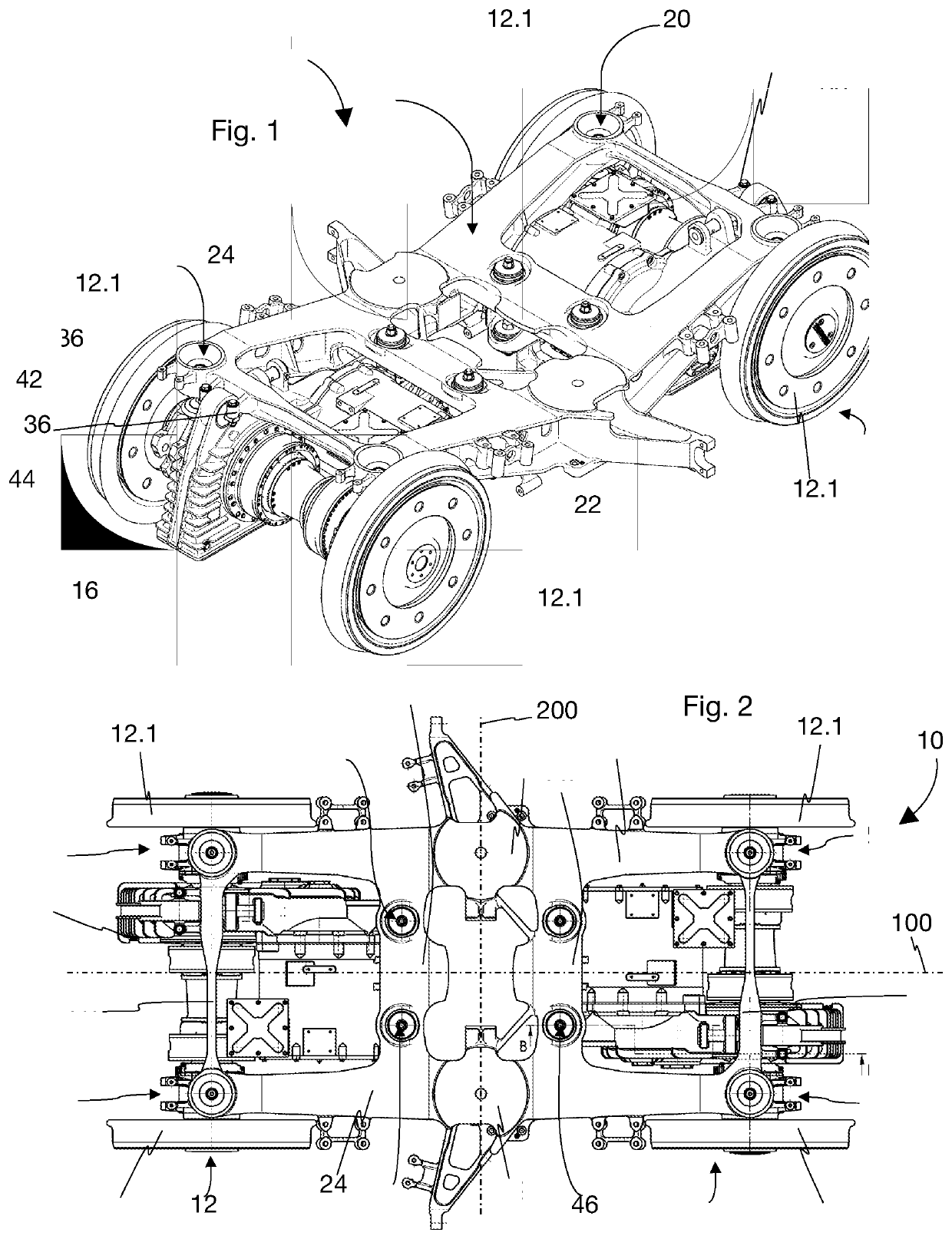

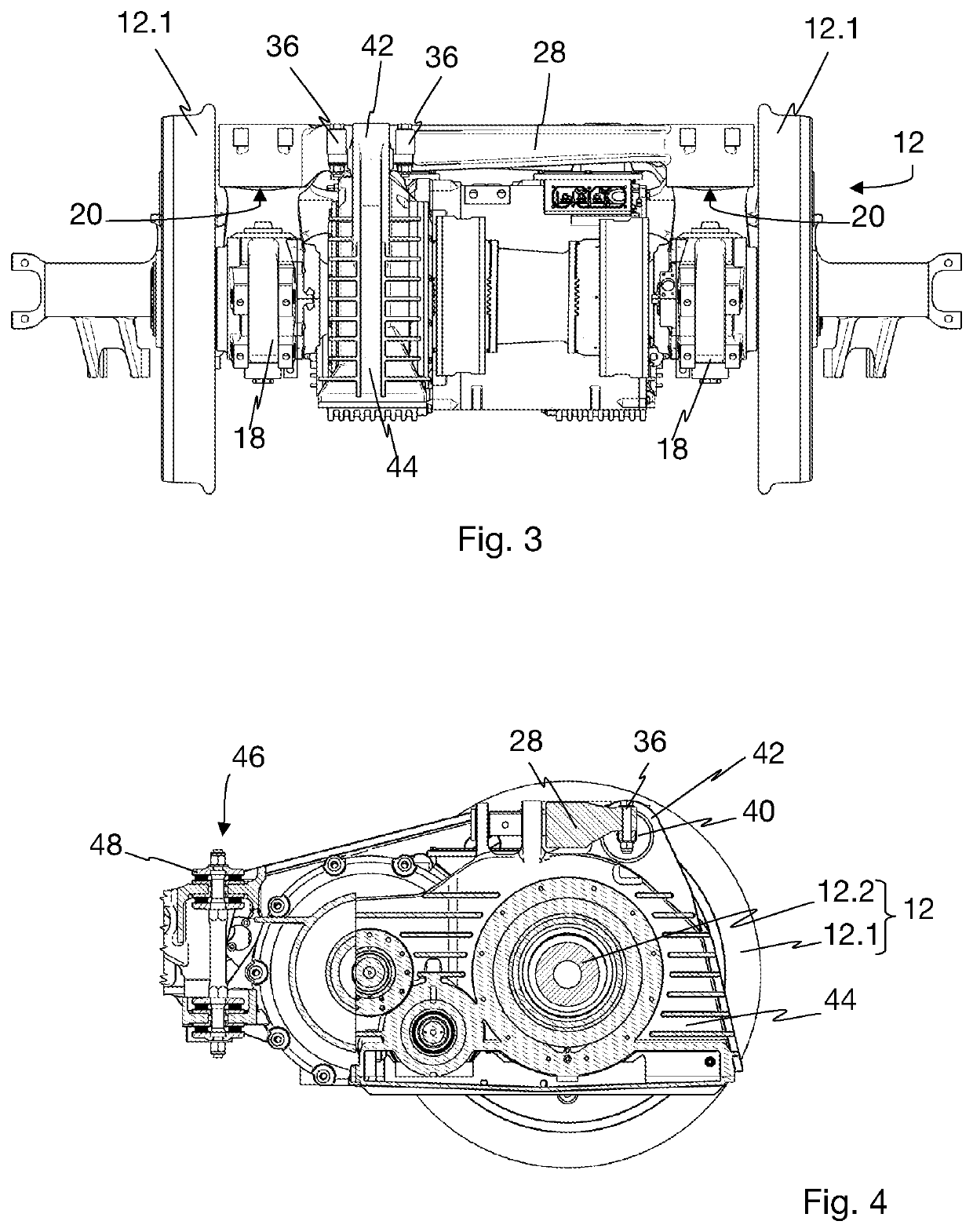

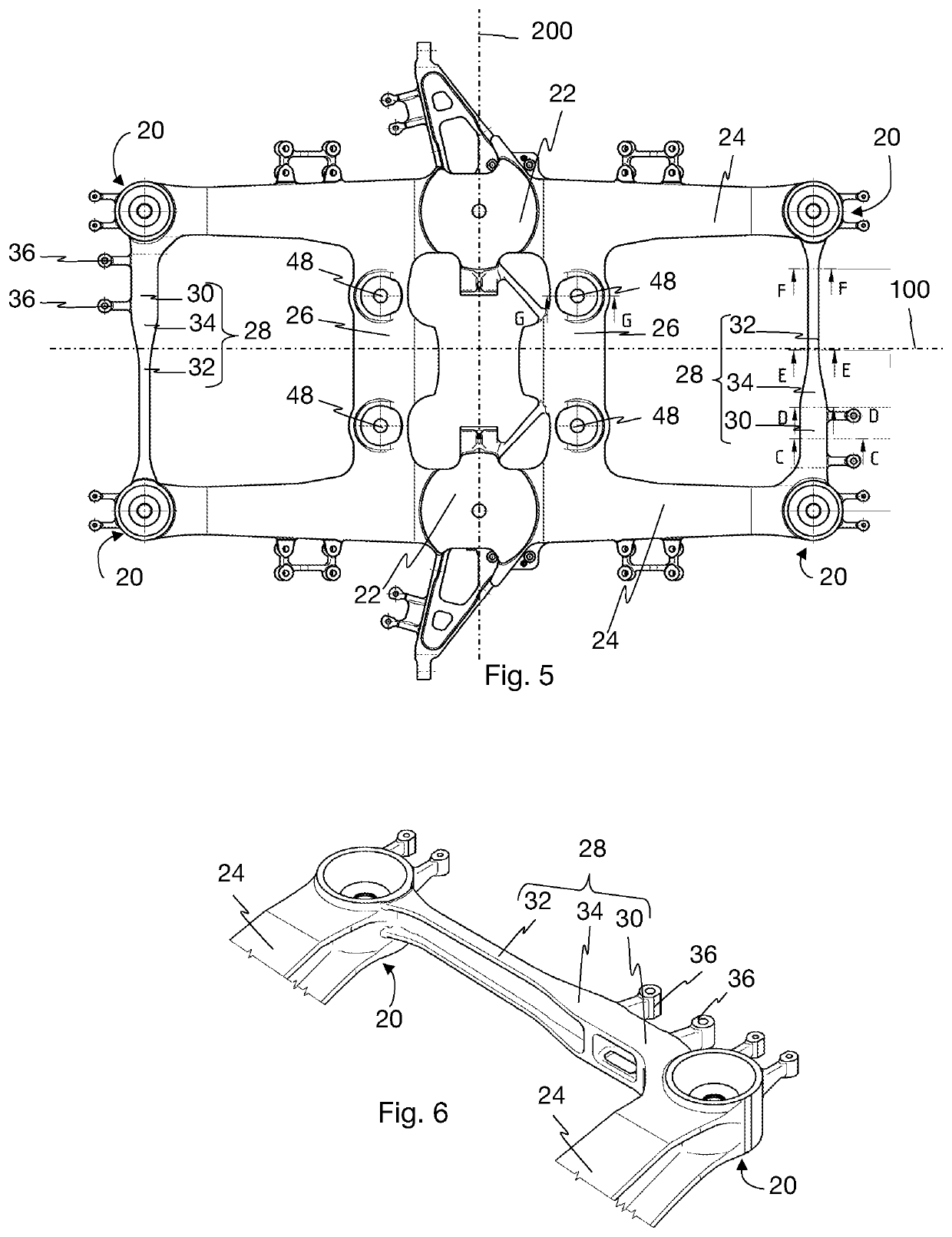

Bogie Frame With Asymmetrical Support Beam and Bogie of a Rail Vehicle

Owner:BOMBARDIER TRANSPORTATION GMBH

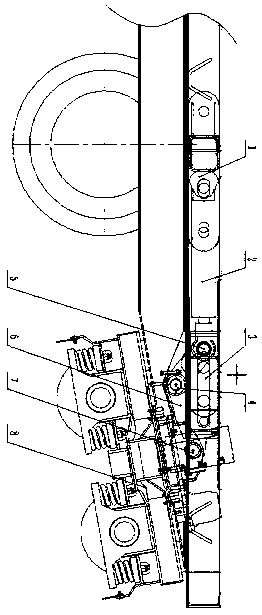

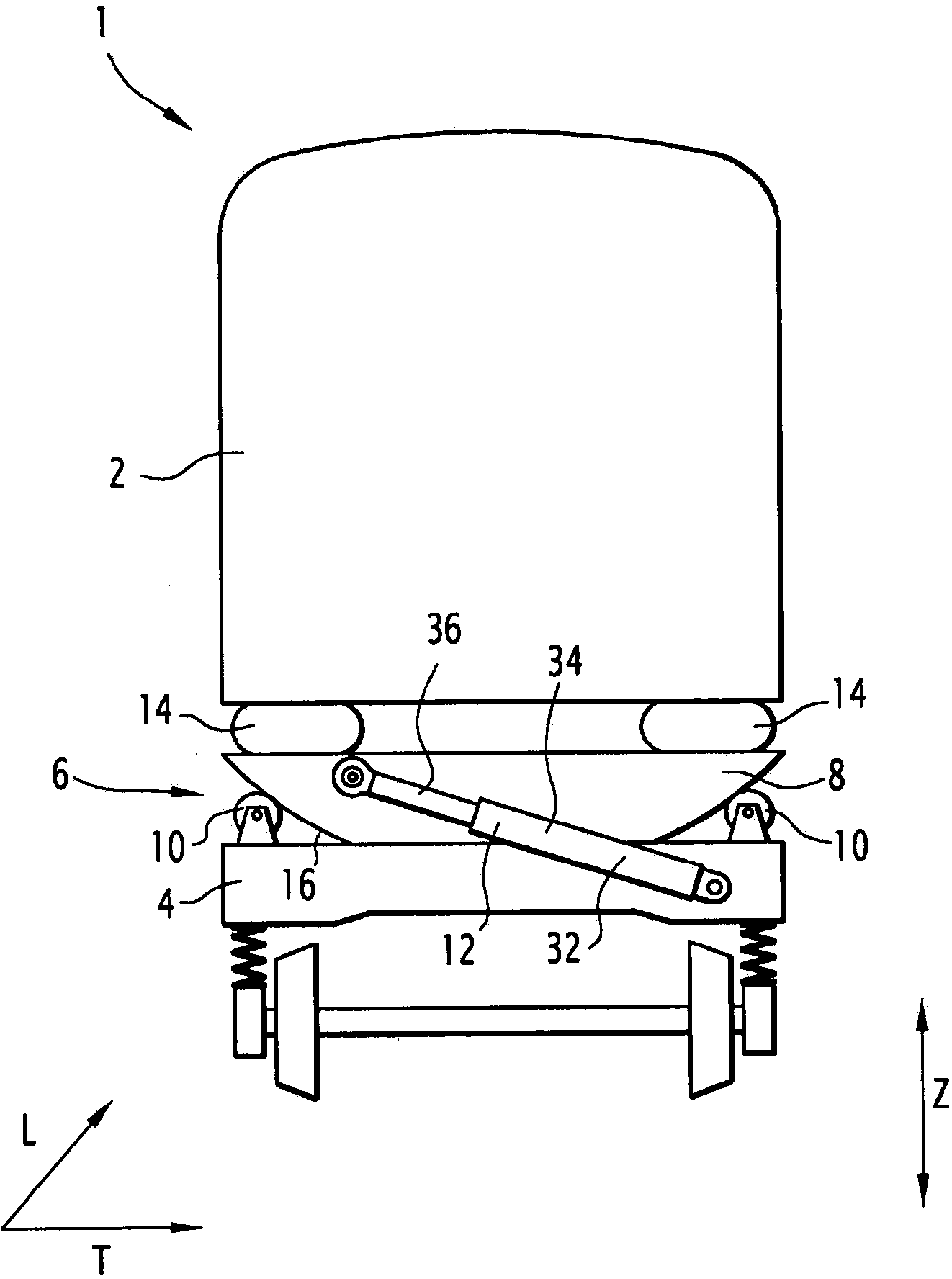

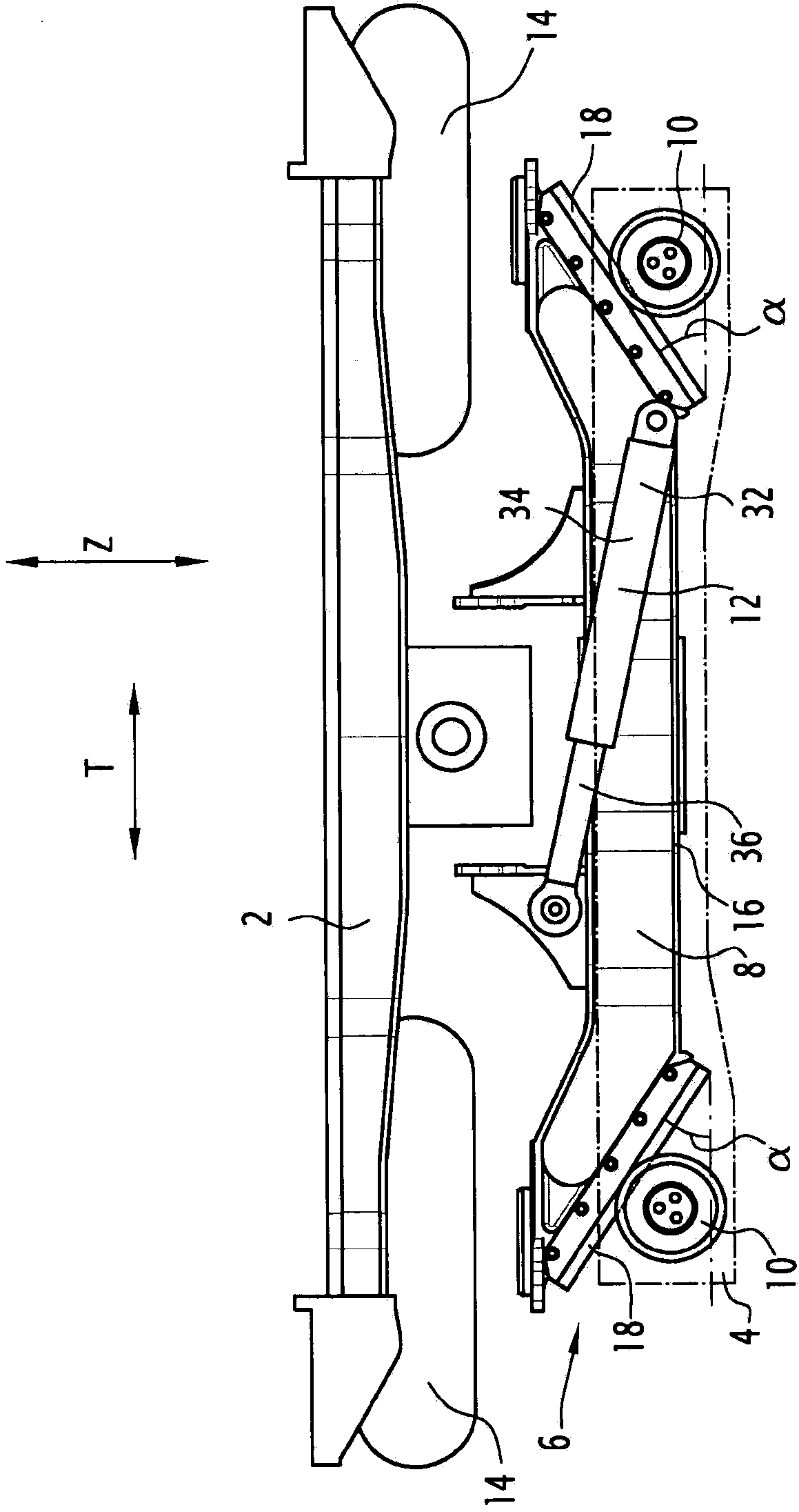

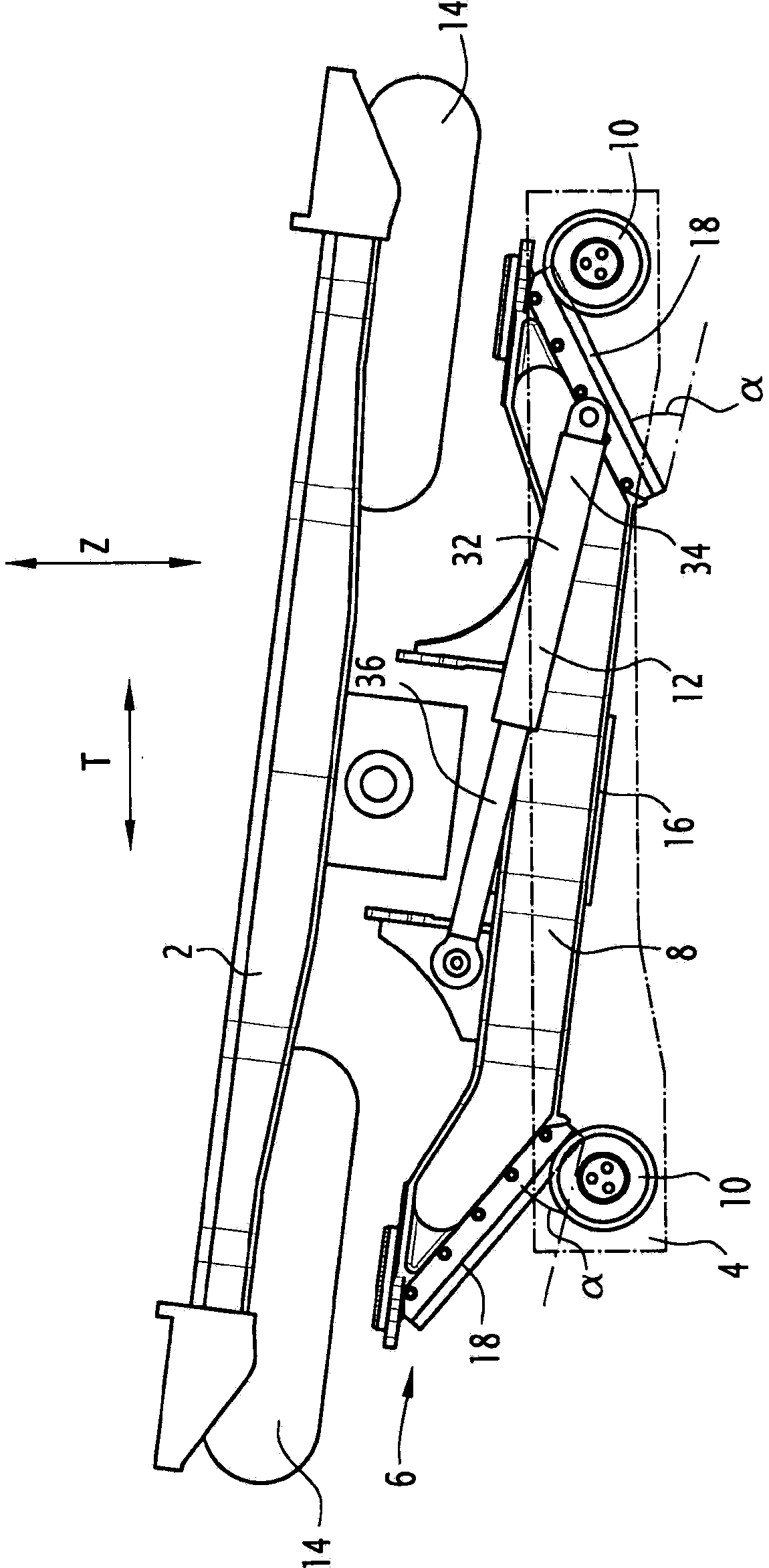

Pendulation device capable of bearing transverse and longitudinal forces

Owner:ALSTOM TRANSPORT SA

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap