Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "High-speed steel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-speed steel (HSS or HS) is a subset of tool steels, commonly used as cutting tool material. It is often used in power-saw blades and drill bits. It is superior to the older high-carbon steel tools used extensively through the 1940s in that it can withstand higher temperatures without losing its temper (hardness). This property allows HSS to cut faster than high carbon steel, hence the name high-speed steel. At room temperature, in their generally recommended heat treatment, HSS grades generally display high hardness (above Rockwell hardness 60) and abrasion resistance (generally linked to tungsten and vanadium content often used in HSS) compared with common carbon and tool steels.

Centrifugal high-carbon, high-boron and high-speed steel composite roller shell and fabrication method of combined roller of composite roller shell

Owner:JIANGSU GONGCHANG ROLL

Manufacture method of slip sheet of air conditioner compressor

InactiveCN102251166AImprove the lubrication effectImprove wear resistanceFoundry mouldsSolid state diffusion coatingCarbideSlip sheet

Owner:乐金电子(秦皇岛)有限公司 +1

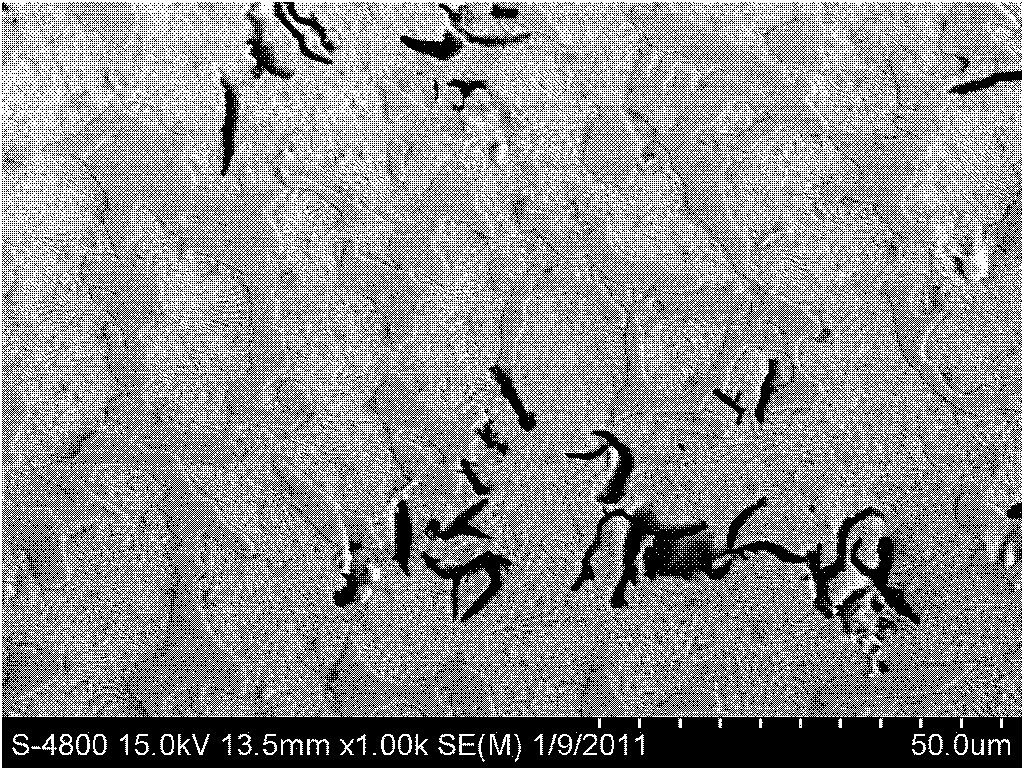

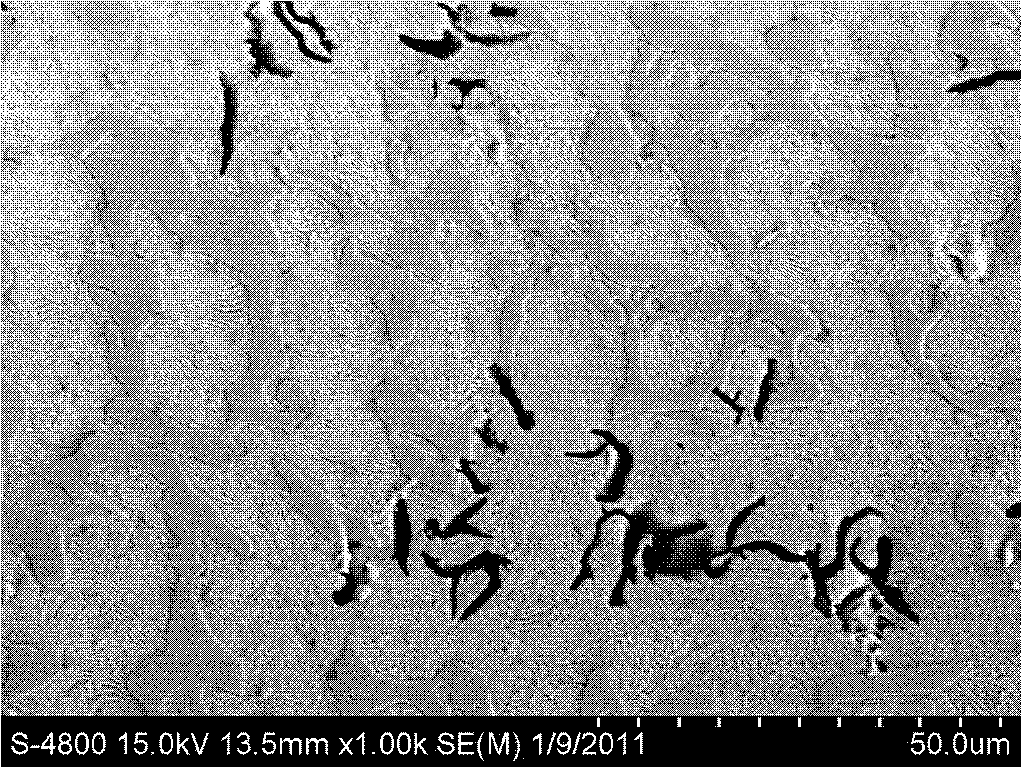

Boron-containing semi-high speed steel cold roller and manufacturing method thereof

InactiveCN101407891AReduce manufacturing costReduce the amount addedProcess efficiency improvementElectric furnaceIngotMolten steel

The invention relates to a boron-containing semi high-speed steel cold roller and a manufacturing method thereof and belongs to the field of steel rolling technology. The existing cold rollers have the problems of poor wear-resistance, high production cost and the like. The invention obtains the boron-containing semi high-speed steel cold roller by pouring the molten steel with the compositions of the following weight percentages of 0.30 to 0.45 of C, 3.8 to 4.2 of Cr, 0.2 to 0.6 of Si, 0.2 to 0.6 of Mn, 0.5 to 0.8 of Mo, 0.2 to 0.4 of Ni, 0.3 to 0.6 of Cu, 0.6 to 1.0 of B, 0.3 to 0.7 of V, 0.6 to 0.8 of Ti, 0.1 to 0.3 of Nb, 0.03 to 0.10 of N, 0.25 to 0.45 of Al, less than 0.03 of S, less than 0.04 of P and the residual quantity of Fe into an outer layer of the cold roller and adopting ductile cast iron as a core part or directly pouring the molten steel into ingots. The roller has the advantages of high hardness and intensity, good toughness and wear-resistance, simple production process, low cost, etc.

Owner:BEIJING UNIV OF TECH

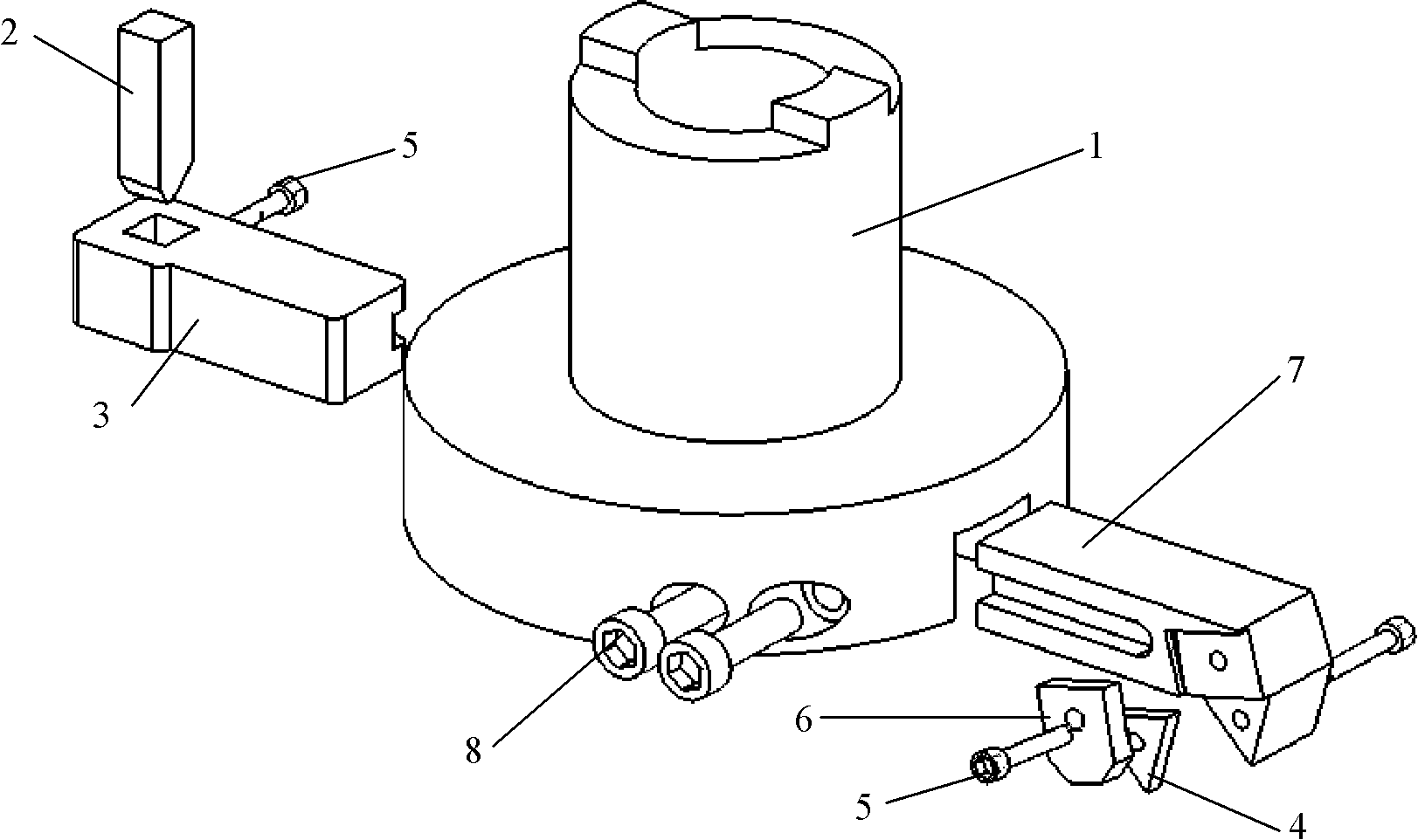

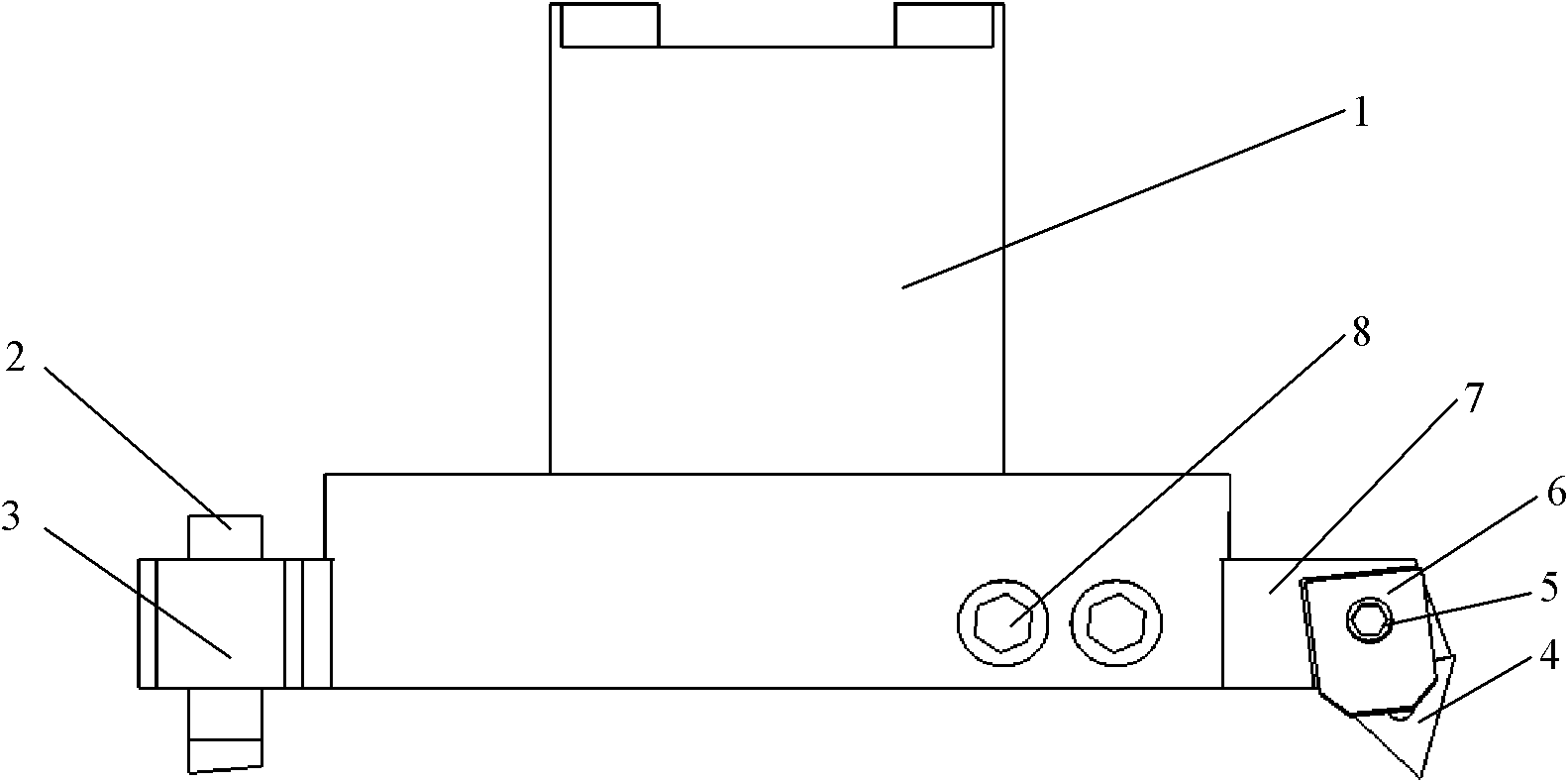

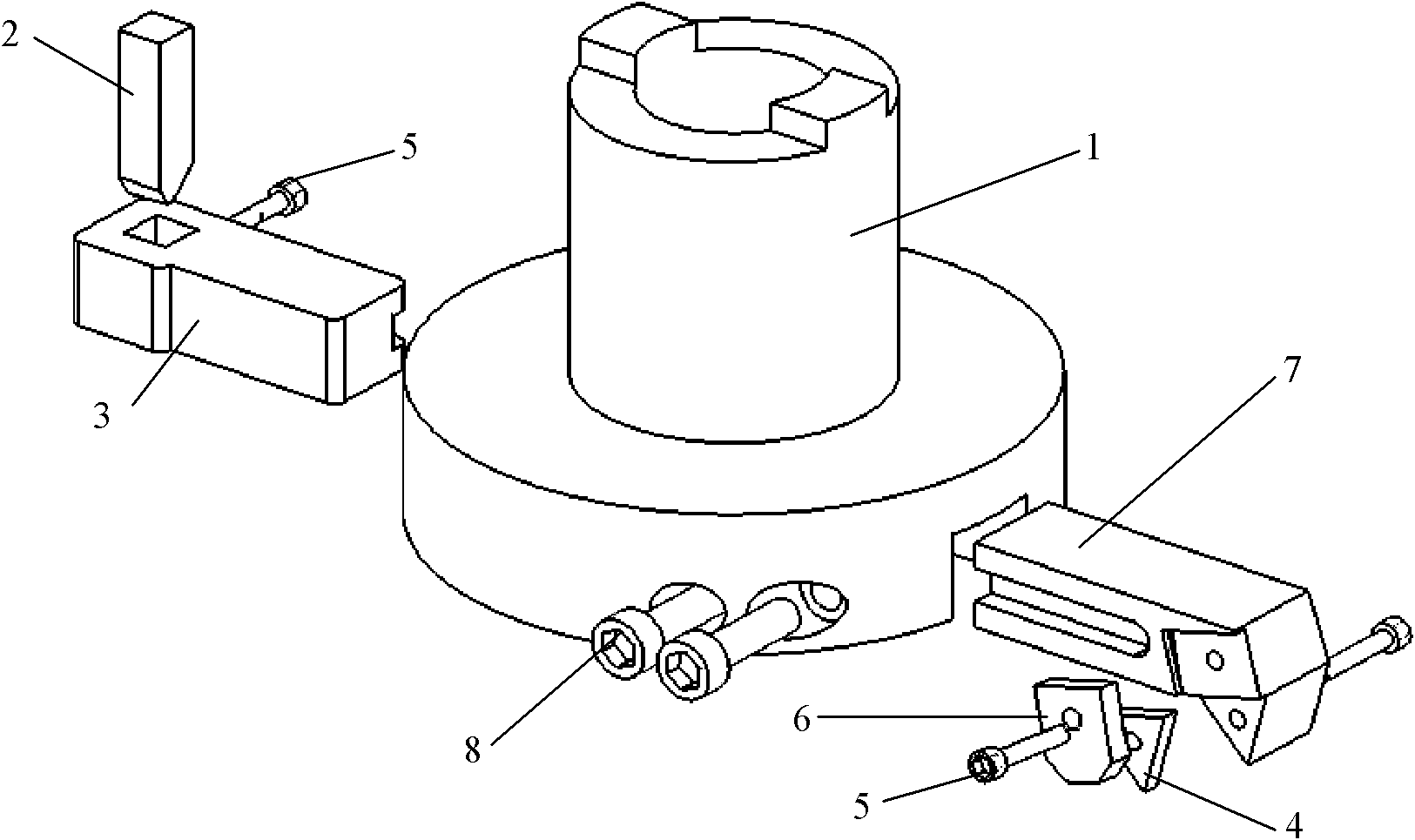

Combined type milling cutter for machining flat surface of aluminum alloy

ActiveCN101934398AControllable diameterImprove processing efficiencyMilling cuttersSurface finishMilling cutter

Owner:NO 8357 RES INST OF THE THIRD ACADEMY OF CHINA AEROSPACE SCI & IND

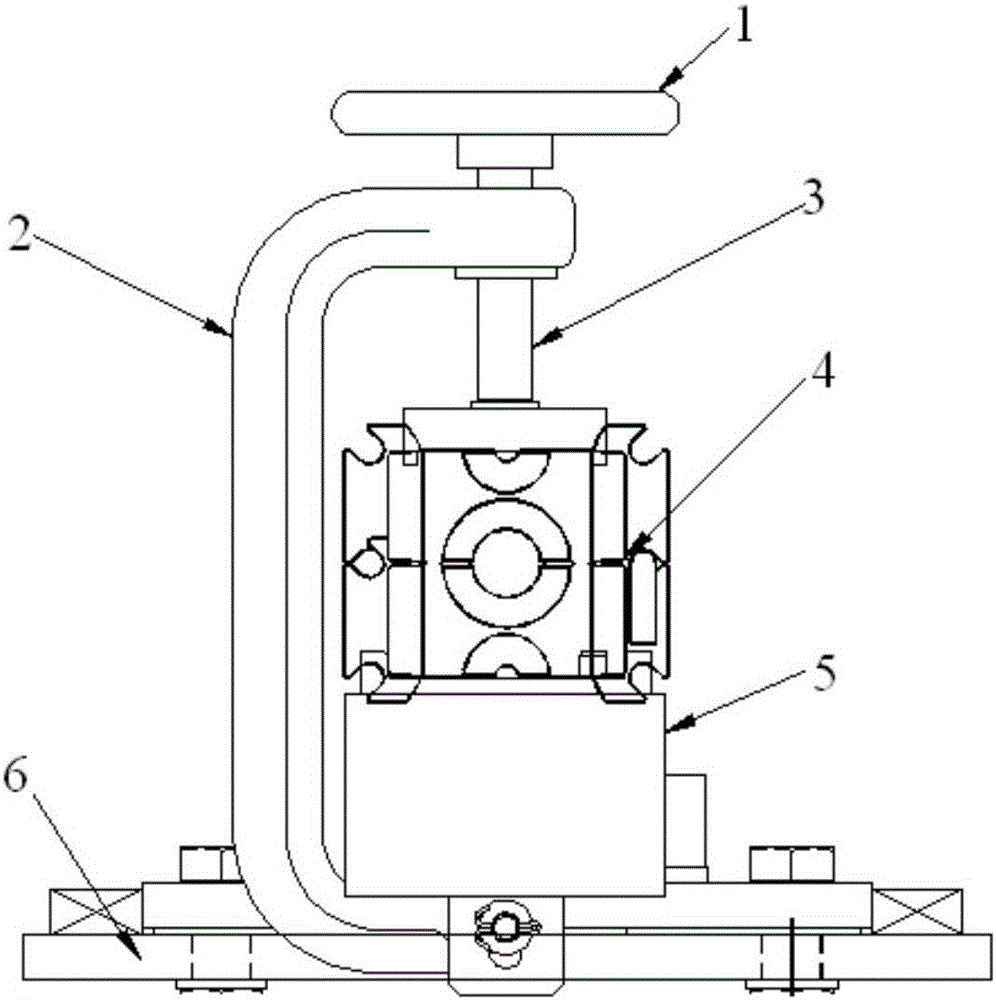

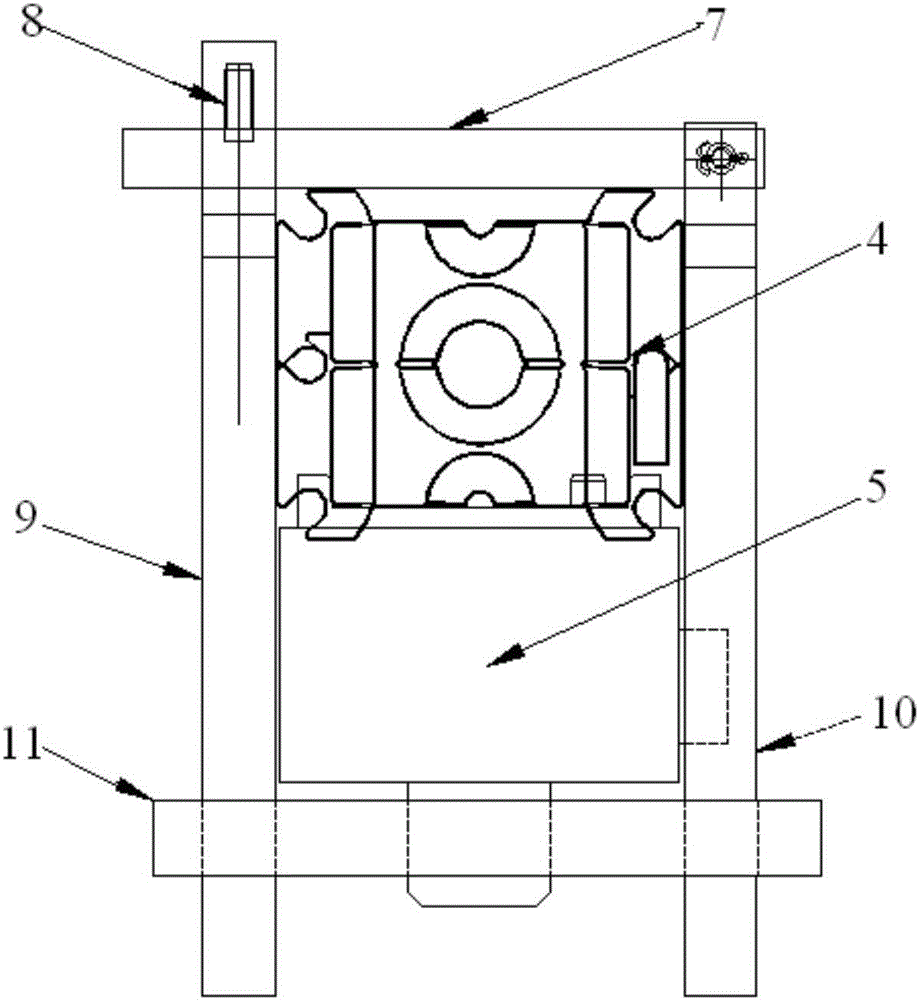

Fixing device for double-sided running groove of high-speed steel rolling production line

InactiveCN106180206APrevent looseningAvoid misalignmentRolling safety devicesMetal rolling arrangementsProduction lineManufacturing technology

Owner:WUHU XINXING DUCTILE IRON PIPES

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap