Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8 results about "Hydrogen sulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen sulfide is the chemical compound with the formula H₂S. It is a colorless chalcogen hydride gas with the characteristic foul odor of rotten eggs. It is very poisonous, corrosive, and flammable.

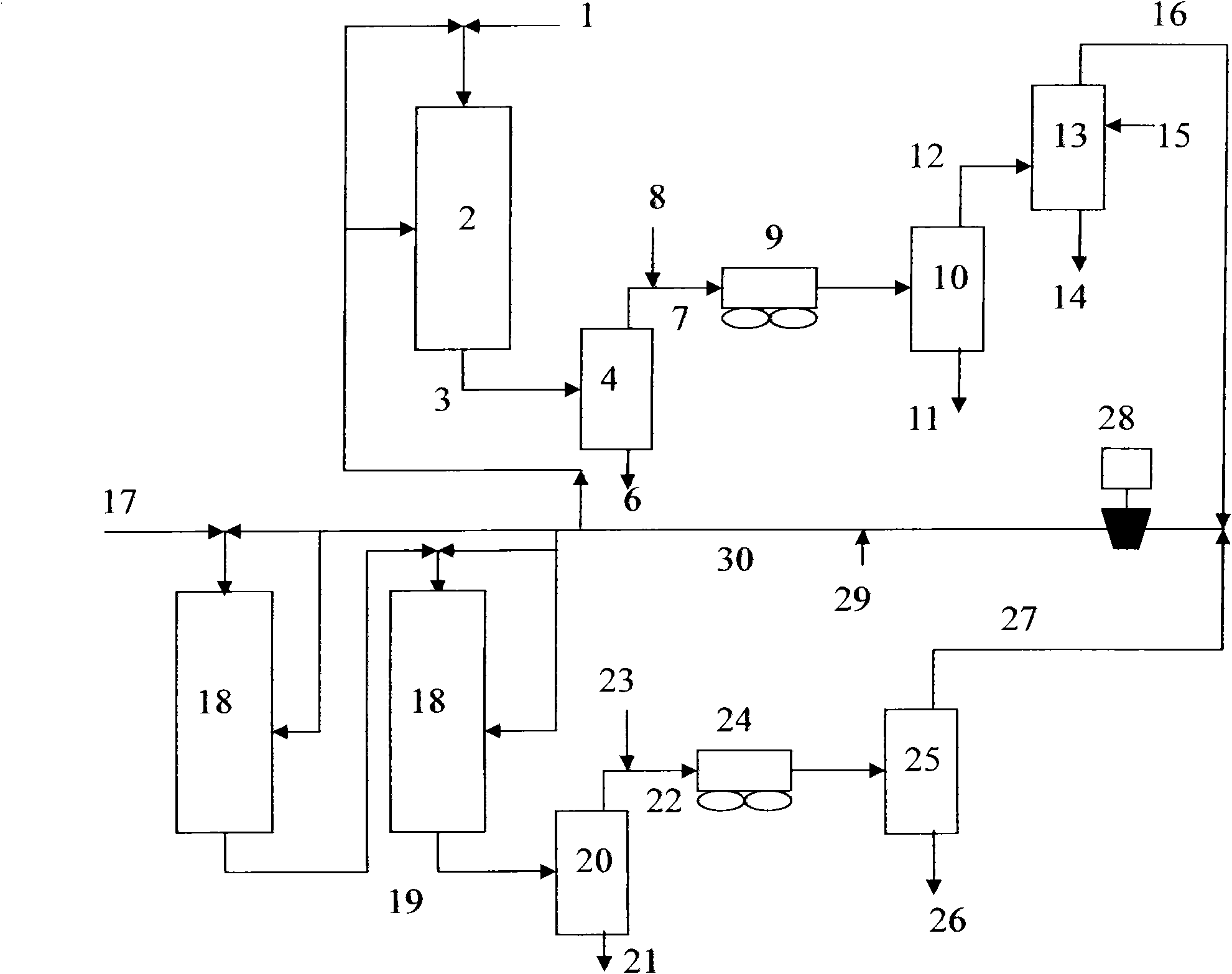

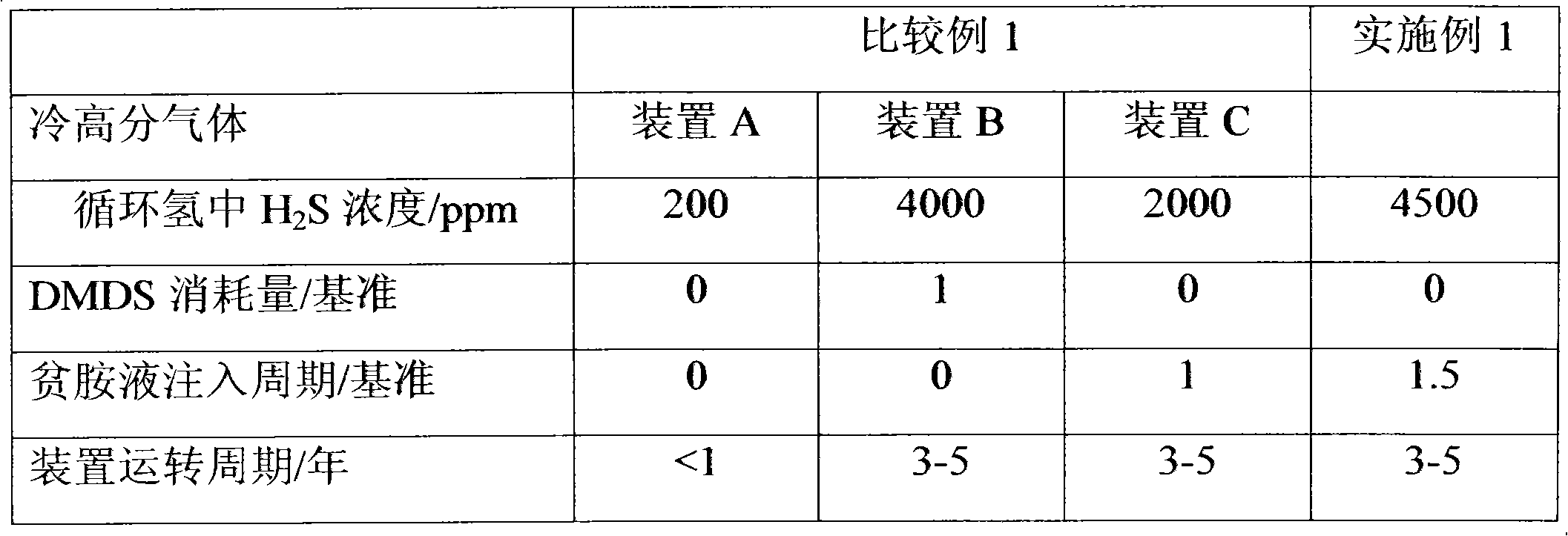

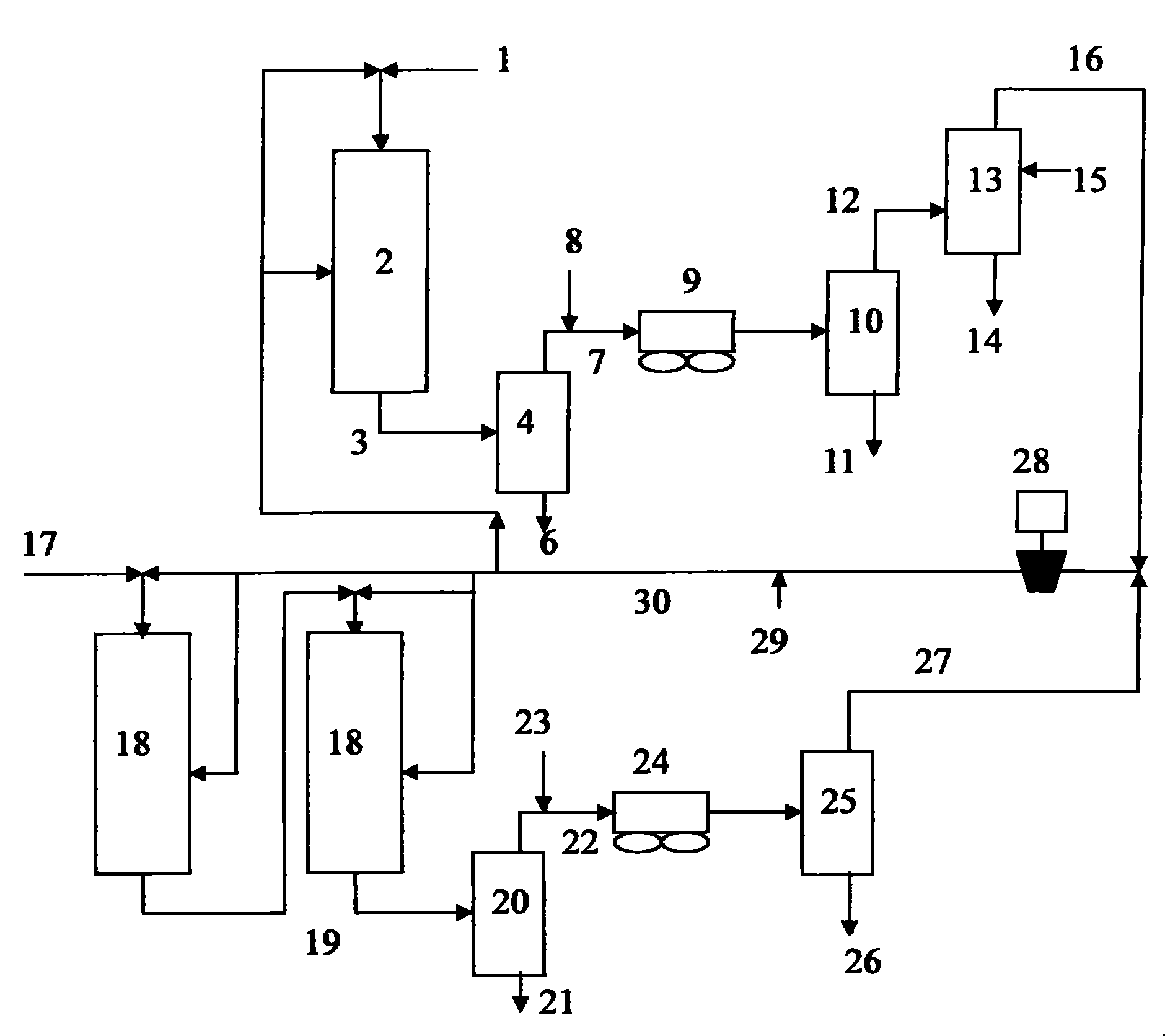

Hydrocracking method for processing low-sulfur raw material

ActiveCN102465014AImprove product qualityIdeal comprehensive processing effectTreatment with hydrotreatment processesHydrogenTotal investment

Owner:CHINA PETROLEUM & CHEM CORP +1

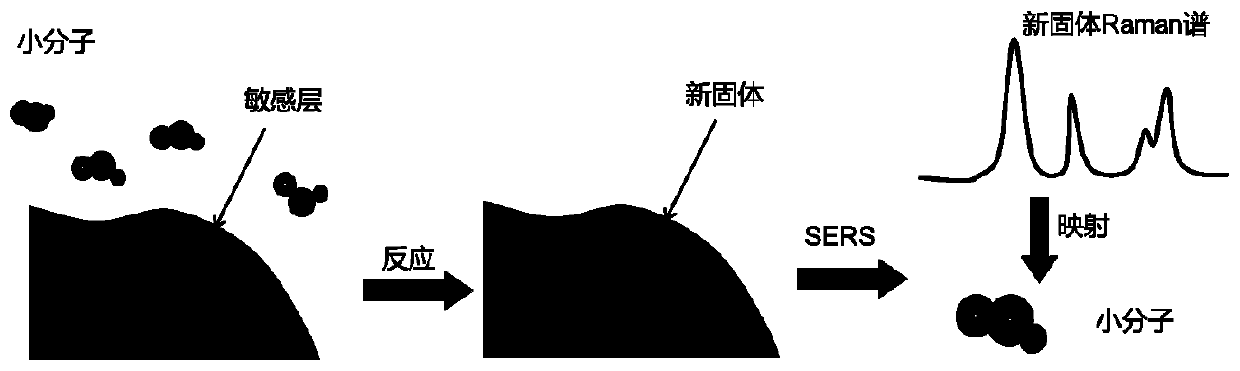

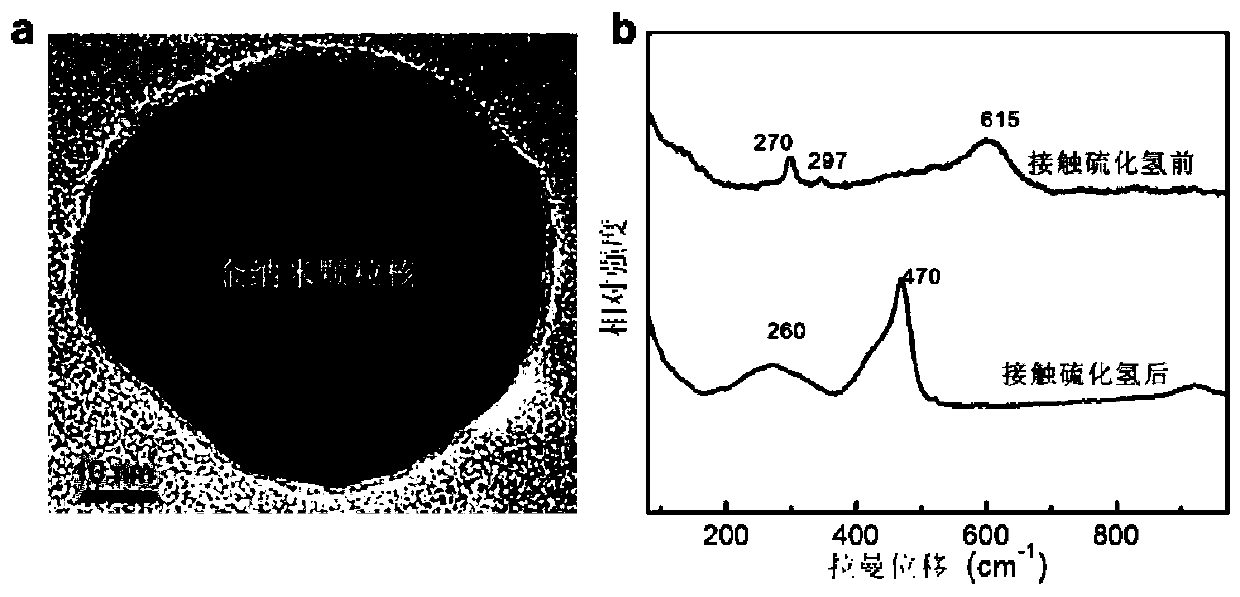

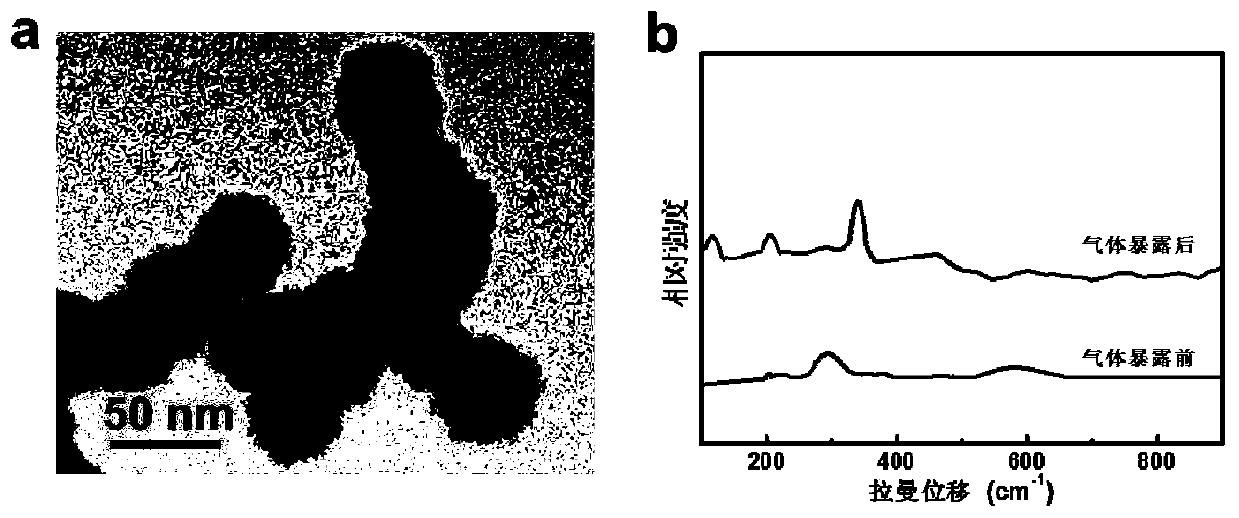

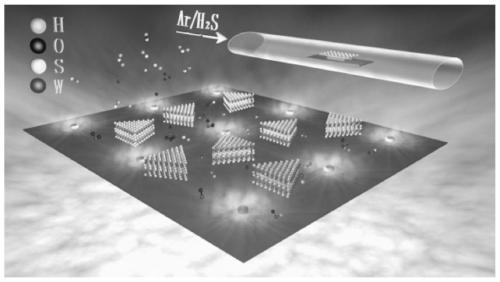

Inorganic sensitive layer based surface enhanced Raman spectrum detection technology and material preparation thereof

ActiveCN110514640AEfficient detectionEasy to makeTransportation and packagingMetal-working apparatusSurface-enhanced Raman spectroscopyThiourea

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

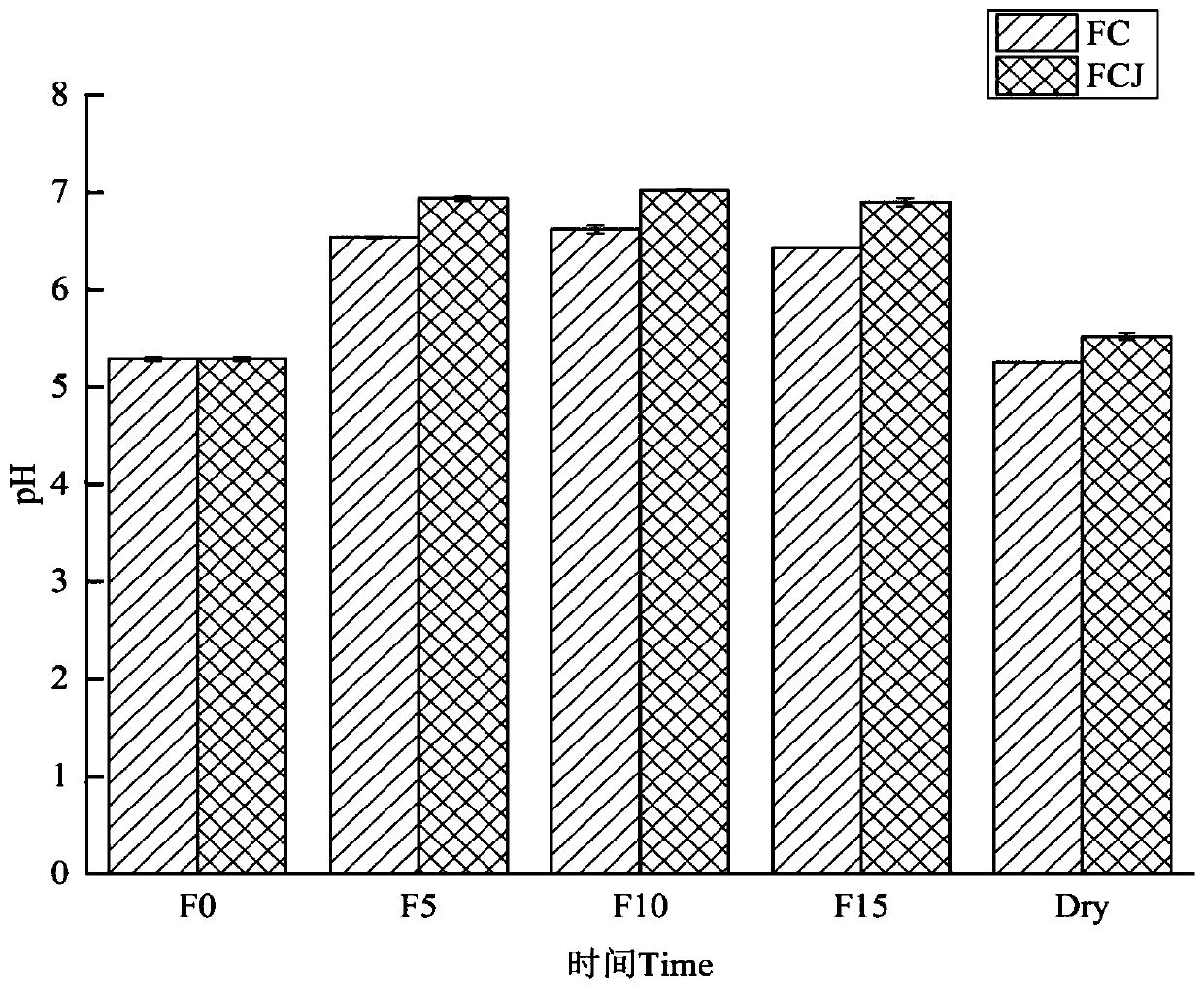

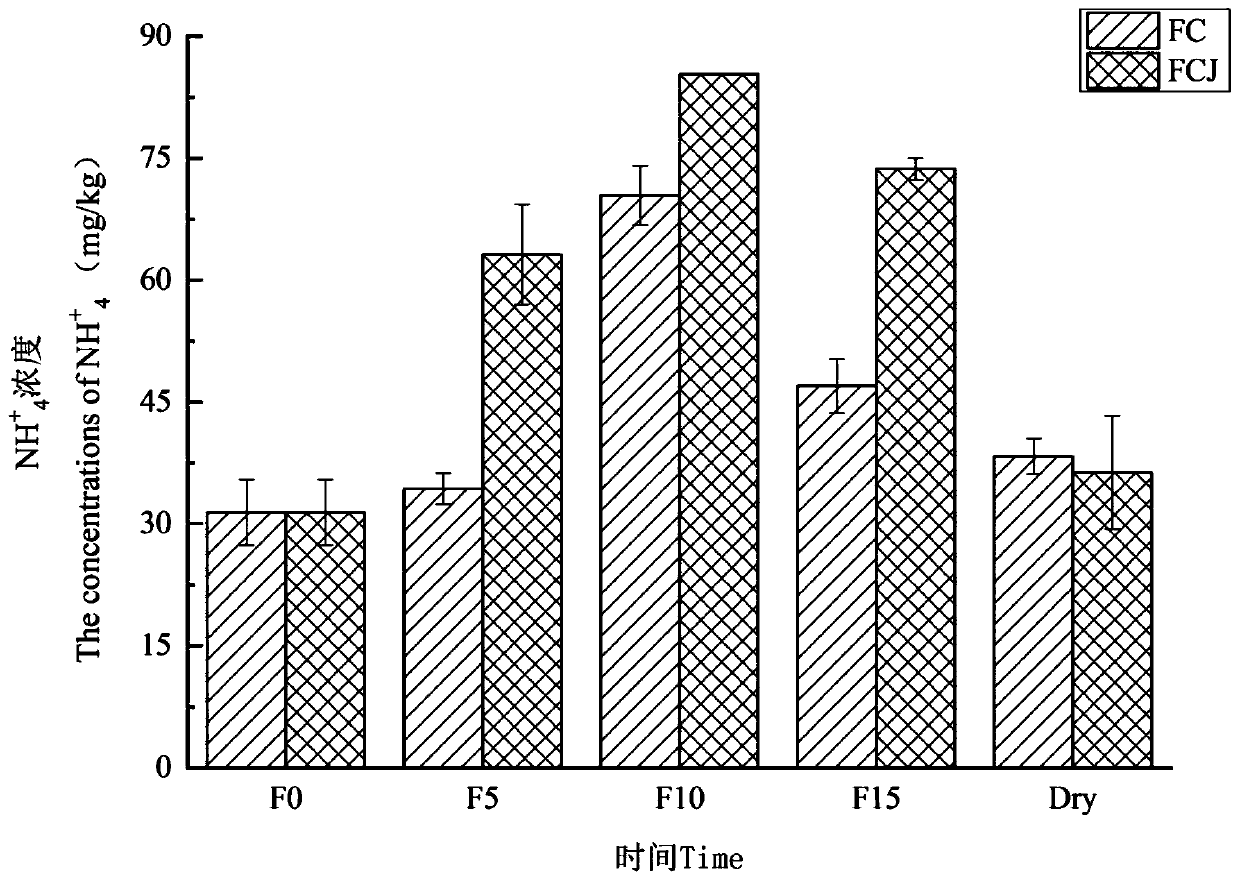

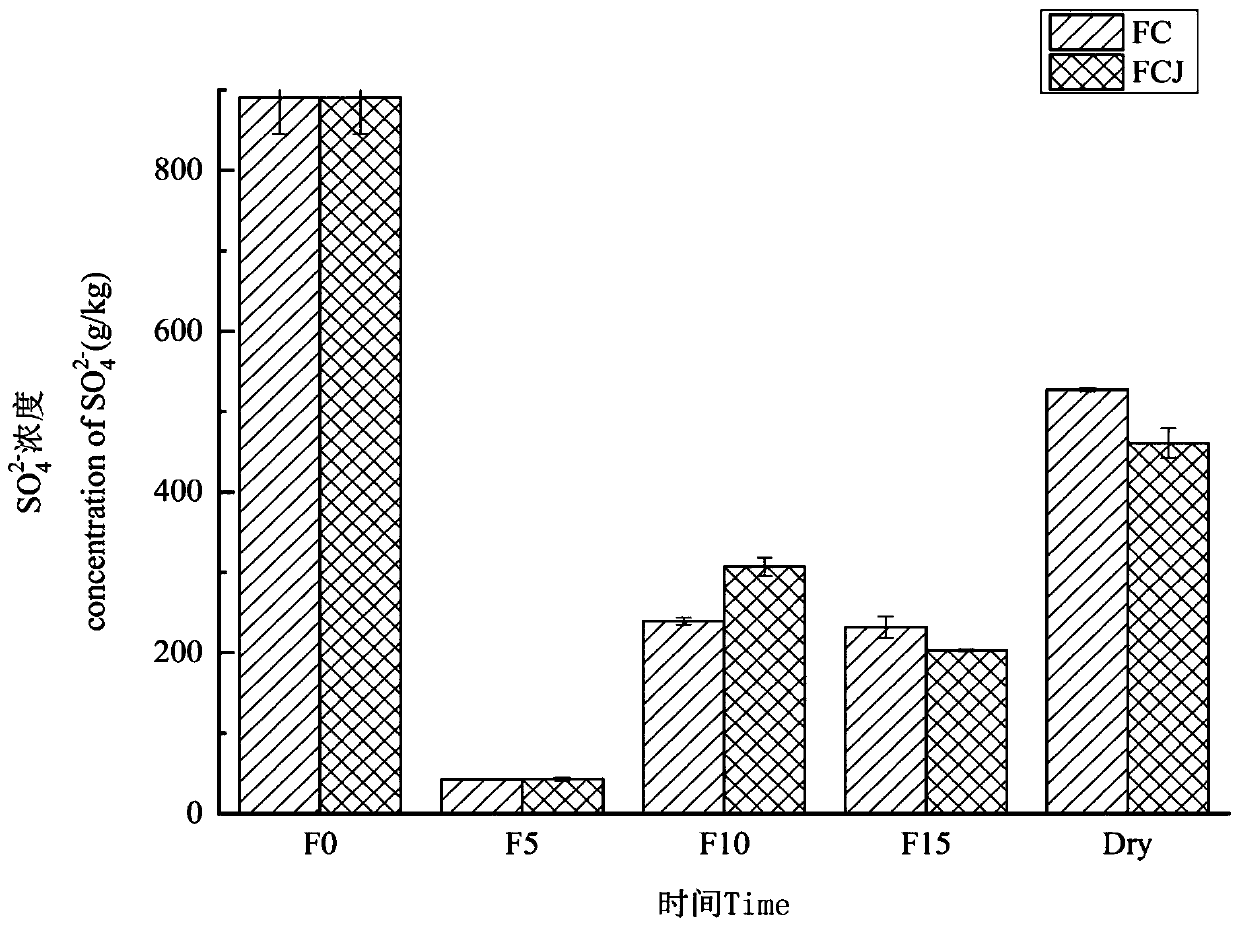

Composition for reductive soil sterilization and application of composition

InactiveCN110178854APromote decompositionIncrease concentrationBiocideAgriculture tools and machinesCelluloseMicrobial agent

Owner:SHENYANG AGRI UNIV

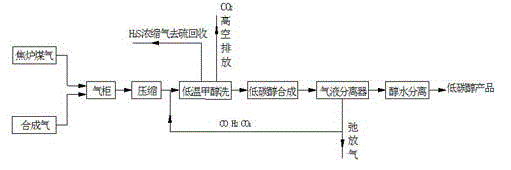

Technology for preparing low-carbon alcohol from syngas and coke oven gas

ActiveCN105130749AImprove thermal stabilityGood chemical stabilityOrganic compound preparationChemical industryLiquid productGas phase

Owner:SEDIN ENG

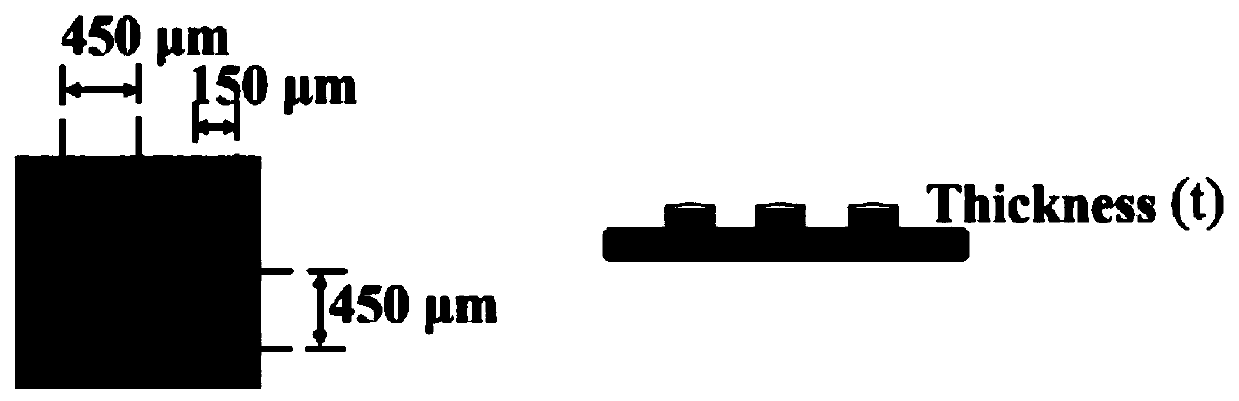

Preparation method of tungsten disulfide single crystal with controllable layer number

ActiveCN111472049AIncrease profitHigh repetition ratePolycrystalline material growthFrom chemically reactive gasesSingle crystalMaterials science

Owner:WENZHOU UNIVERSITY

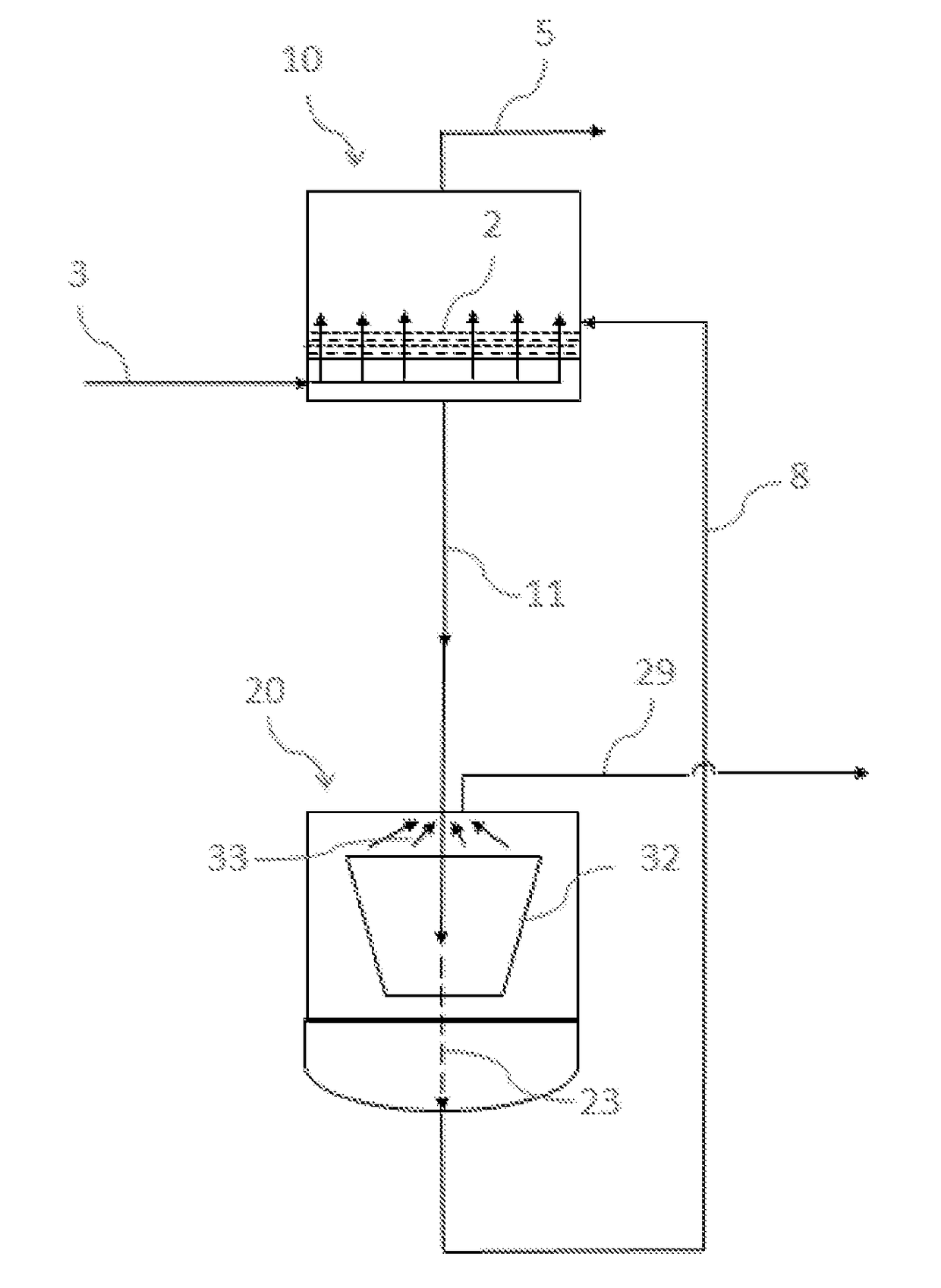

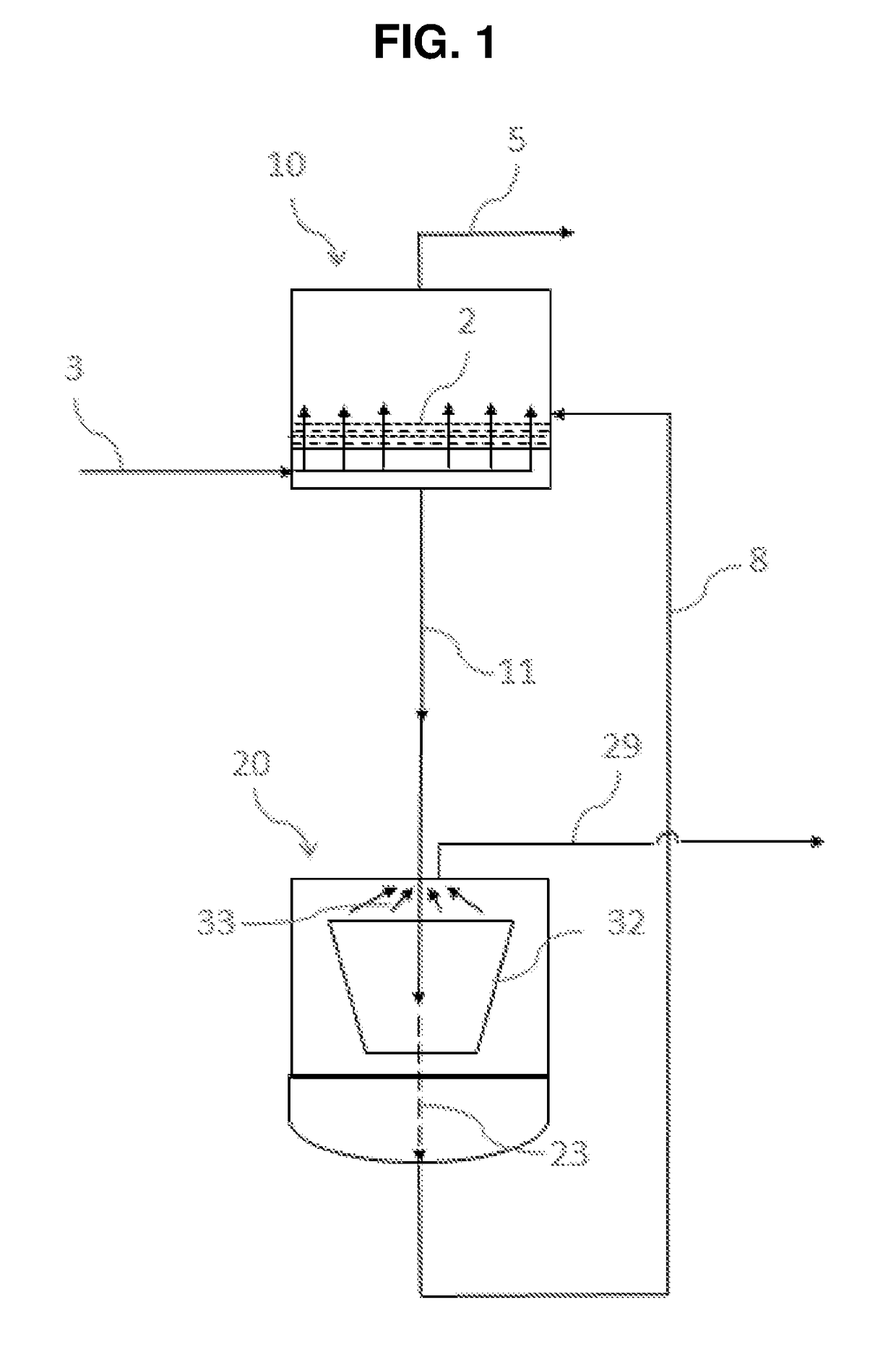

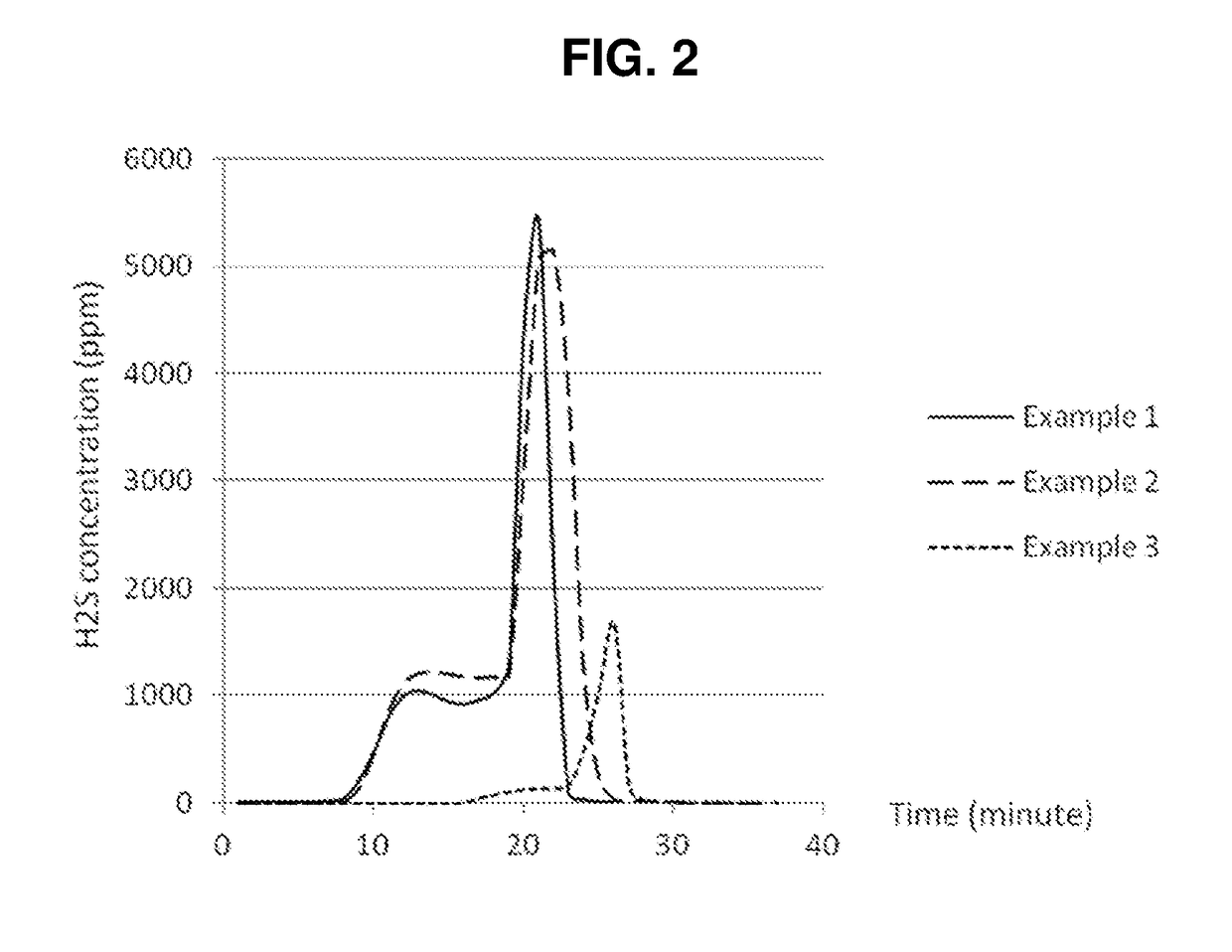

Cross-linked macroporous polymer used for selective removal of hydrogen sulfide from a gas stream

Owner:DOW GLOBAL TECH LLC

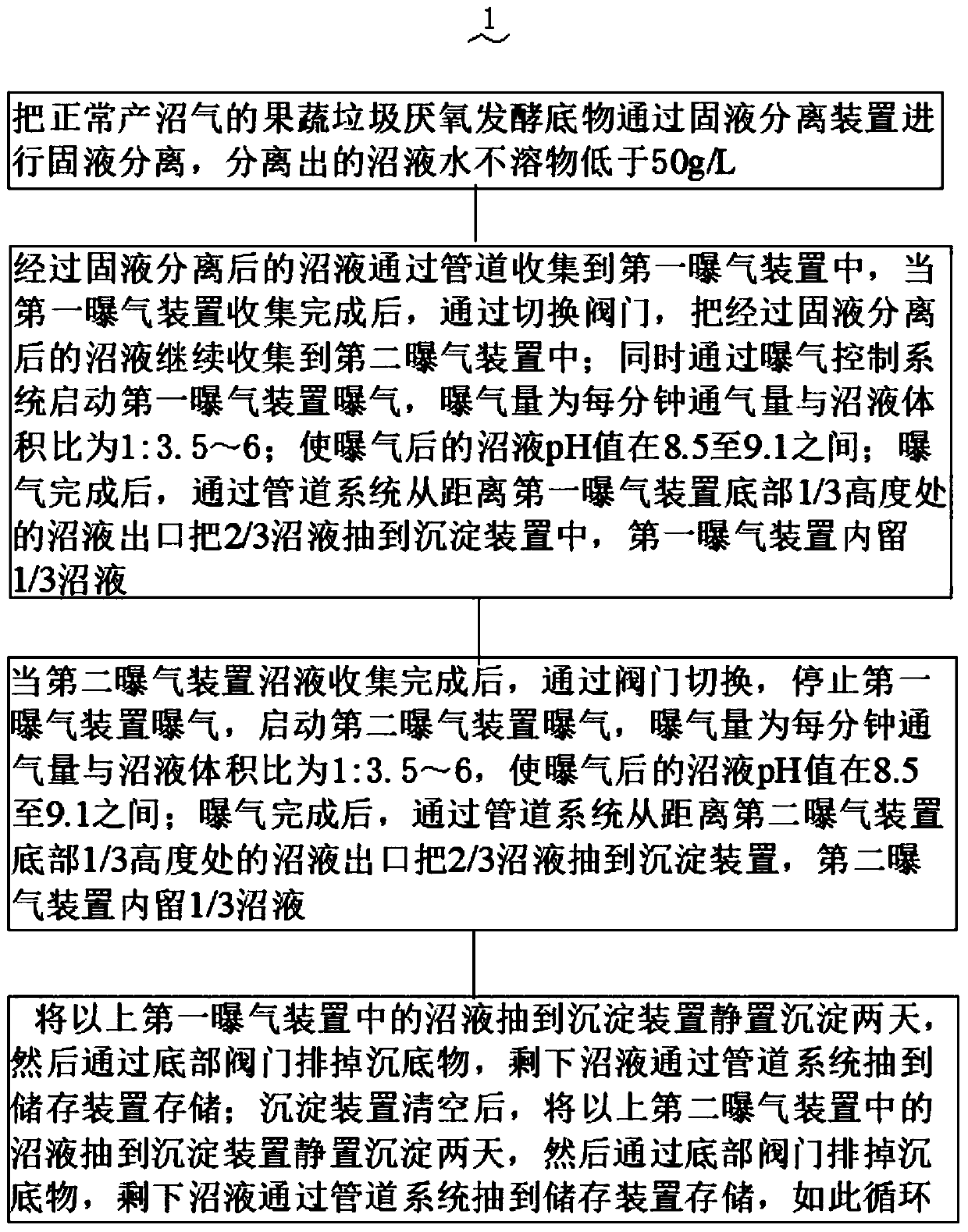

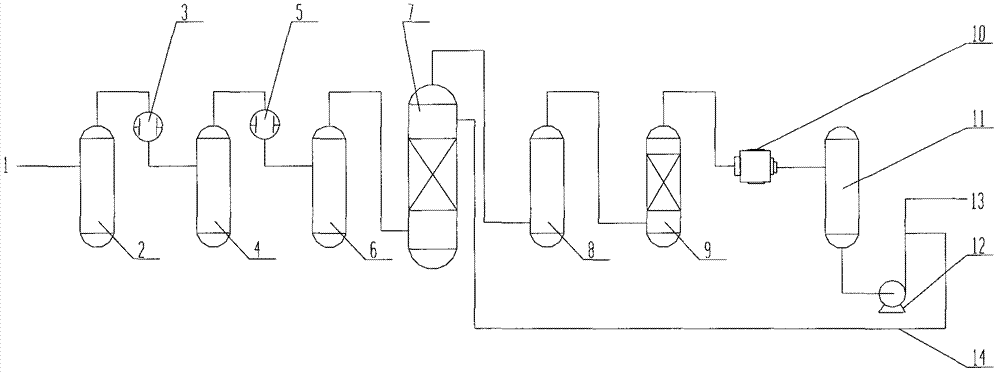

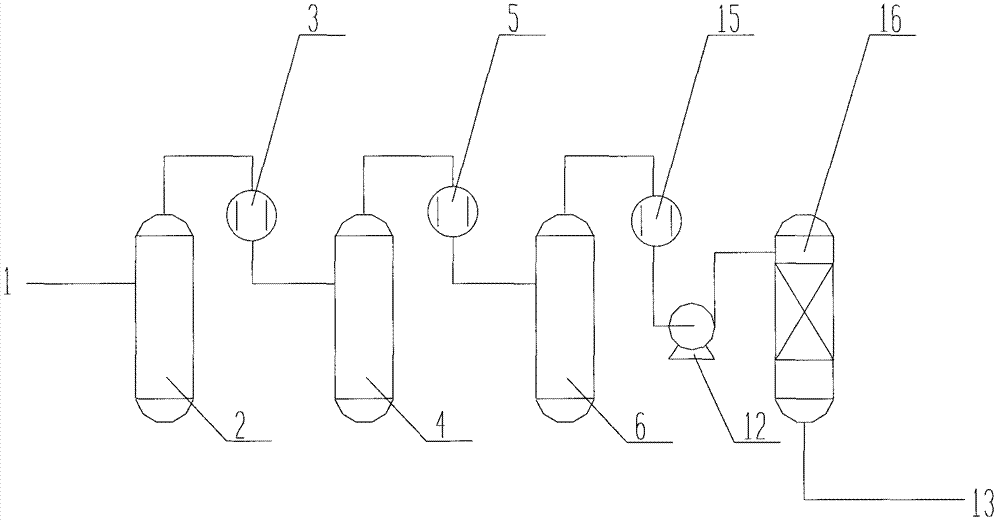

Fruit and vegetable waste anaerobic fermentation substrate efficient treatment method

InactiveCN111333444AImprove processing efficiencyReduce energy consumptionBio-organic fraction processingClimate change adaptationAeration rateSulfur dioxide

Owner:深圳市海吉星环保农业科技有限公司

Liquid ammonia production method

ActiveCN102954669ANo secondary pollutionPromote safe productionSolidificationLiquefactionThree levelAmmonia gas

Owner:CHINA PETROLEUM & CHEM CORP +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap