Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9 results about "River sand" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tea planting land soil remediation agent and preparation method thereof

Owner:福建小薇金匙科技孵化有限公司

Treatment method of Acer mandshuricum Maxim. seeds for seedling emergence in dormancy-breaking year

InactiveCN107333482AAvoid damageNeat emergenceSeed immunisationSeed coating/dressingSeed dormancyAcer mandshuricum

Owner:HEILONGJIANG ACAD OF SCI INST OF NATURAL RESOURCES

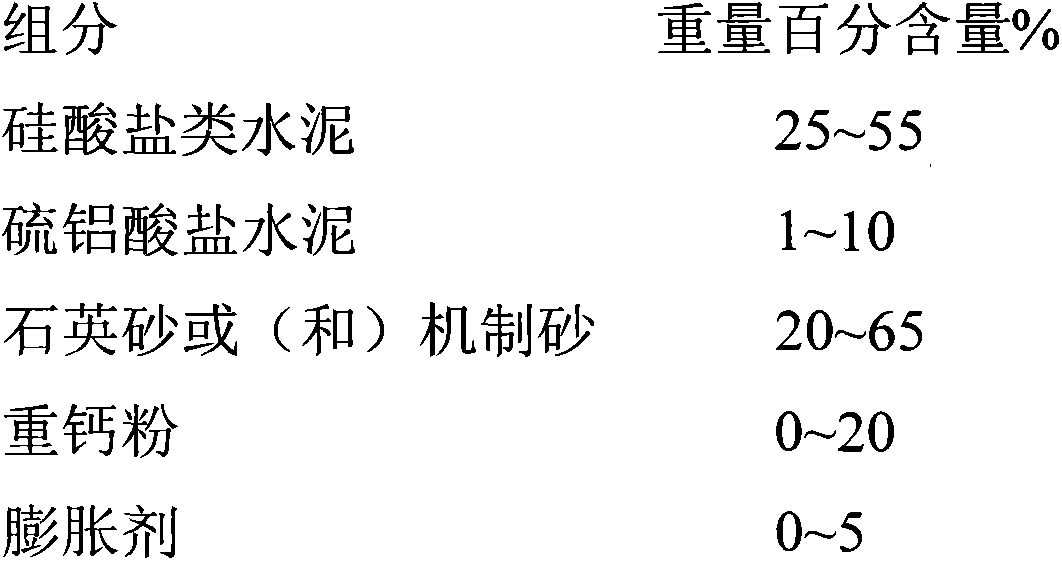

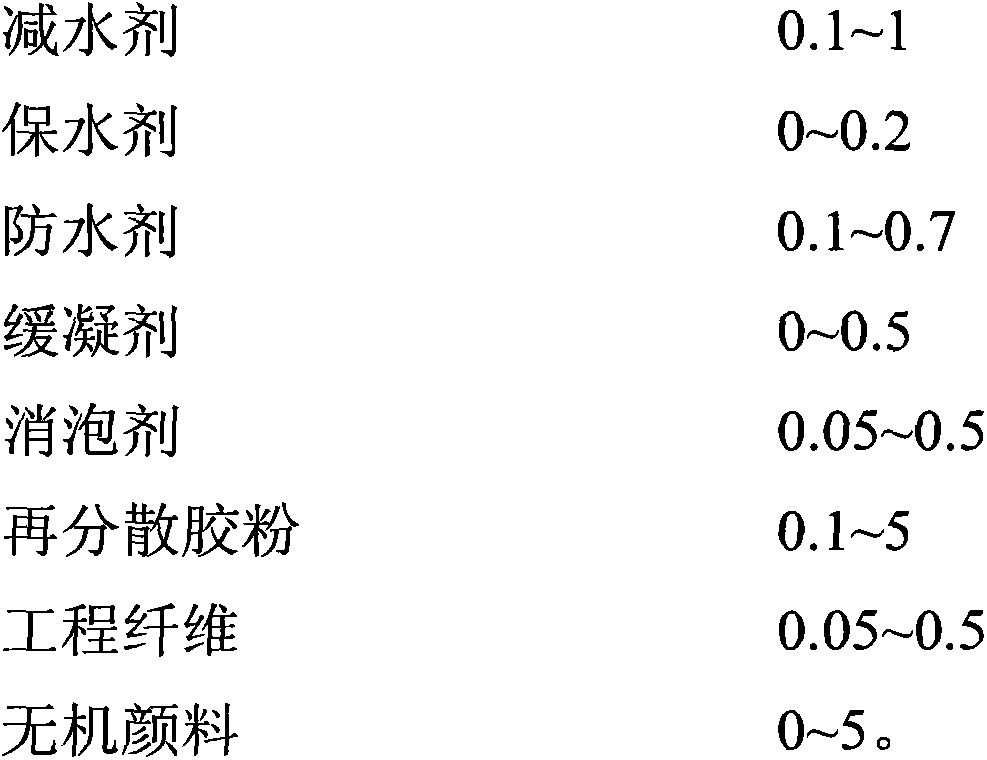

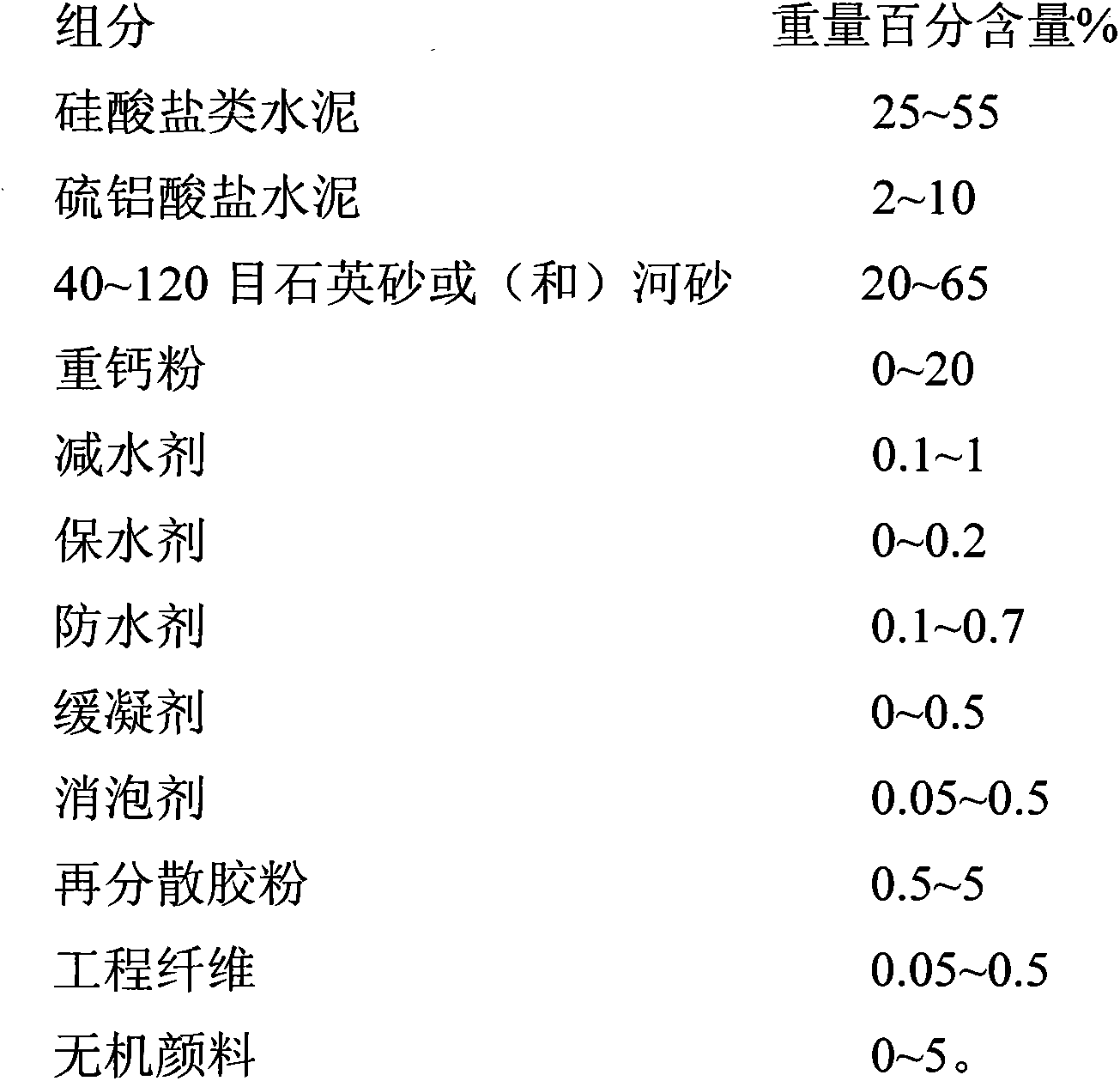

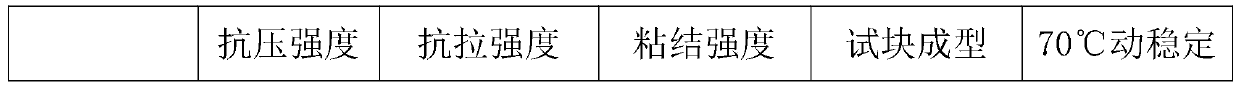

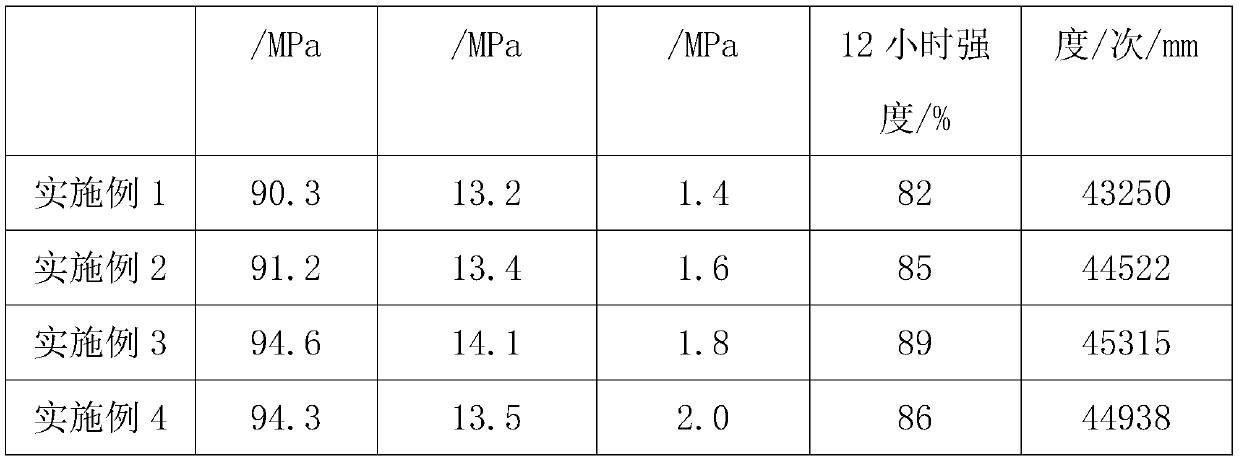

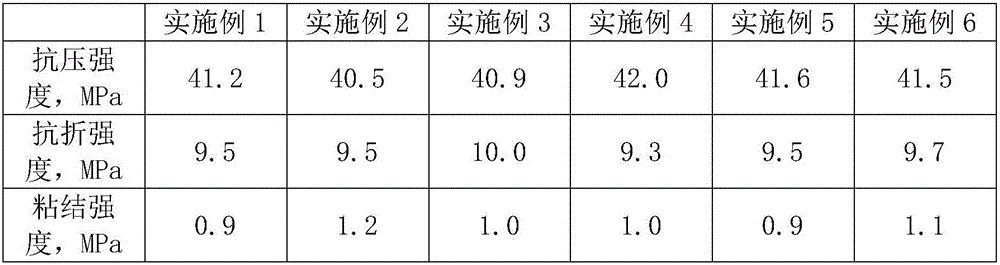

Energy-saving phase-transformation anti-cracking polymer special mortar and preparation method thereof

Owner:绍兴职业技术学院

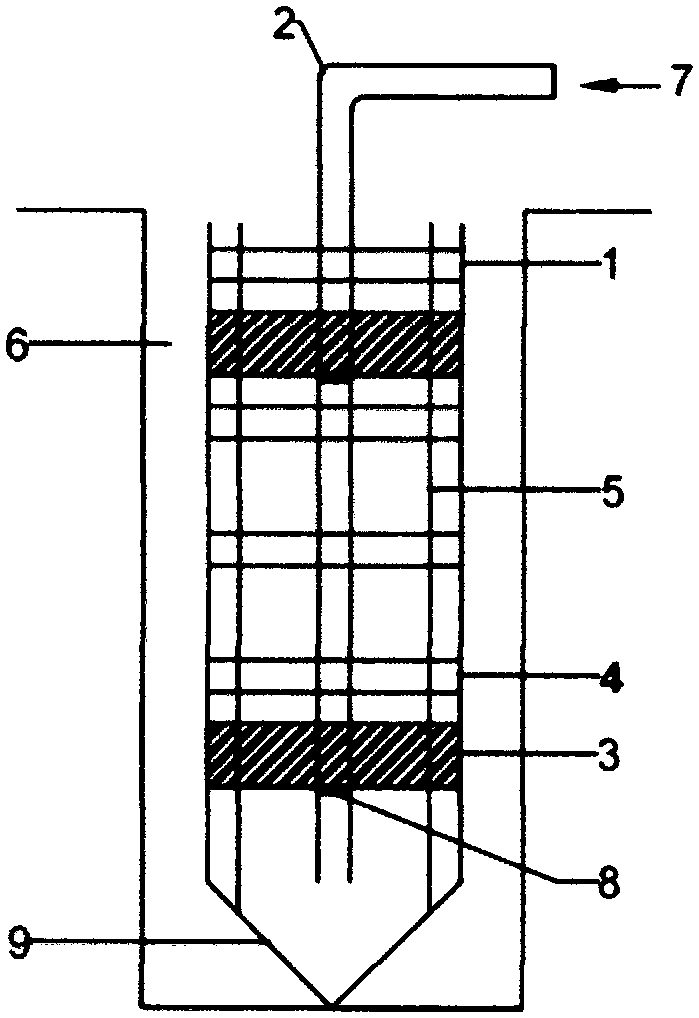

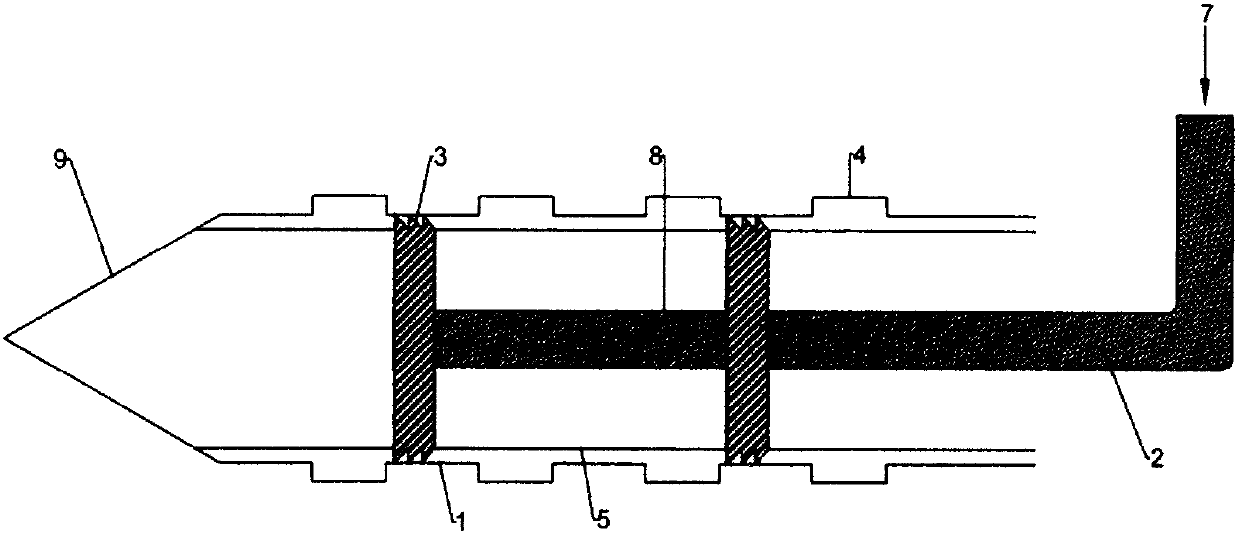

Sleeve valve pipe for reinforcing pit bottom of water-rich pebble bed deep foundation pit and construction process

Owner:CHONGQING UNIV OF EDUCATION

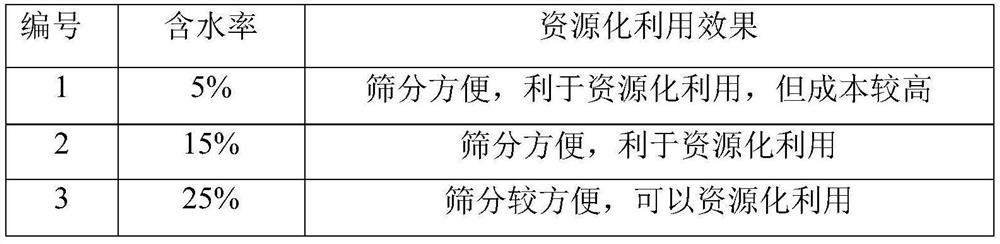

Resource utilization method of dehydrated and desilted bottom mud

ActiveCN113909261ARealize resource utilizationAlleviate shortagesSludge treatment by de-watering/drying/thickeningSolid waste disposalSoil scienceEnvironmental engineering

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

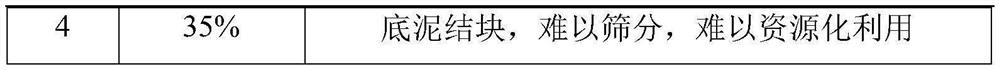

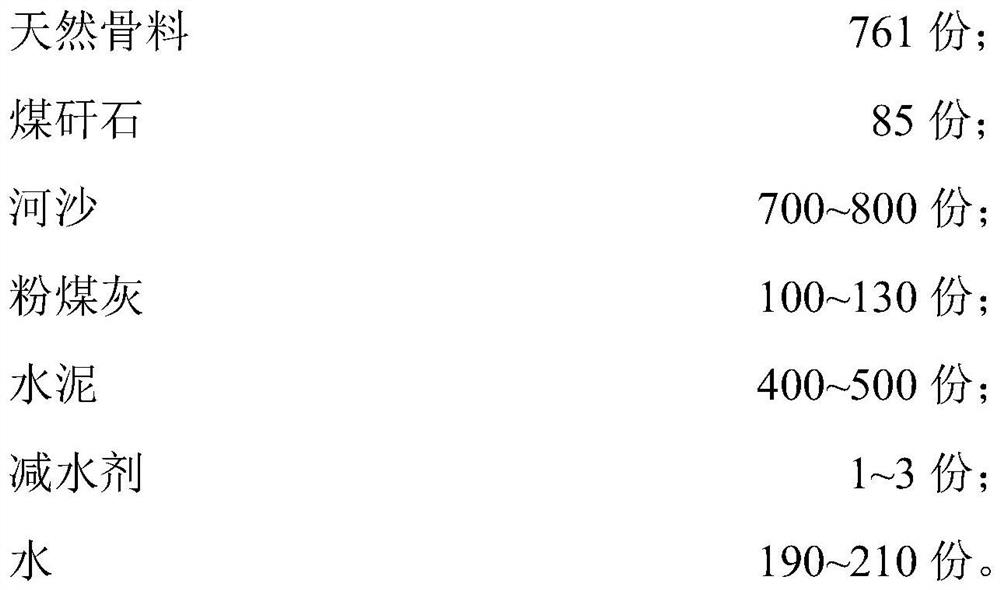

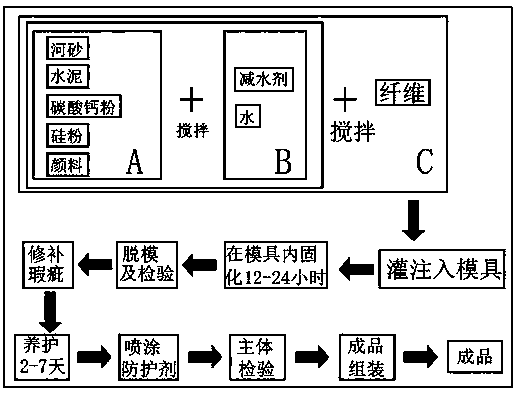

Single-size-fraction coal gangue self-compacting concrete

PendingCN112707700APromote post-hydrationHigh strengthSolid waste managementMining engineeringSorptivity

Owner:张家港市华诚混凝土构件有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap