Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Shear strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In engineering, shear strength is the strength of a material or component against the type of yield or structural failure when the material or component fails in shear. A shear load is a force that tends to produce a sliding failure on a material along a plane that is parallel to the direction of the force. When a paper is cut with scissors, the paper fails in shear. In structural and mechanical engineering, the shear strength of a component is important for designing the dimensions and materials to be used for the manufacture or construction of the component (e.g. beams, plates, or bolts).

Multi-purpose strippable acrylate adhesive microporous material and preparation method thereof

ActiveCN102925084AEasy to peelIncrease elasticityFilm/foil adhesivesEster polymer adhesivesPolymer scienceFoaming agent

Owner:HARBIN INST OF TECH

SPS connection method for tungsten and molybdenum dissimilar refractory metals

ActiveCN108262483AEfficient connectionFacilitated DiffusionRoom temperatureUltimate tensile strength

Owner:HEFEI UNIV OF TECH

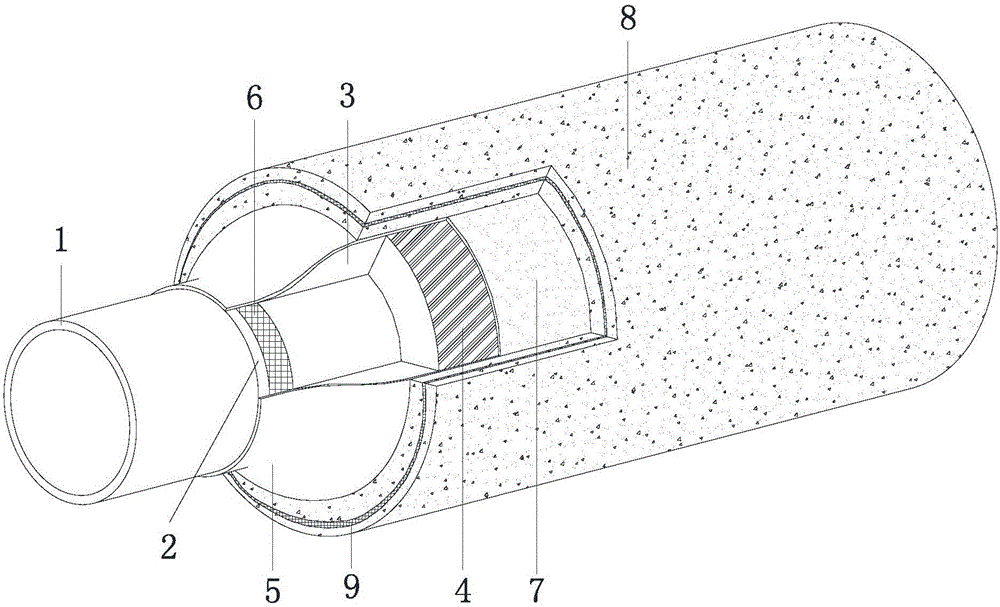

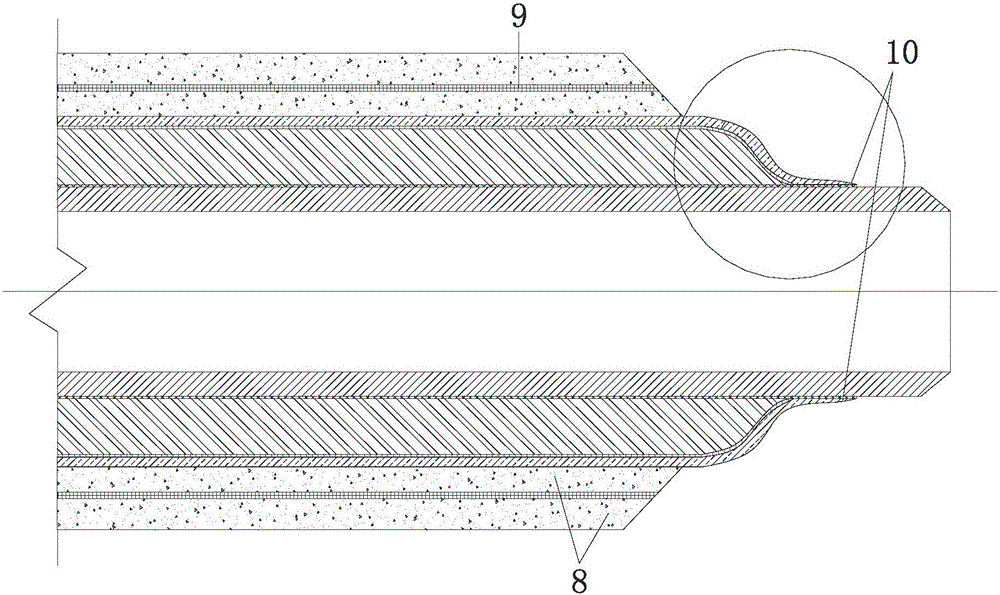

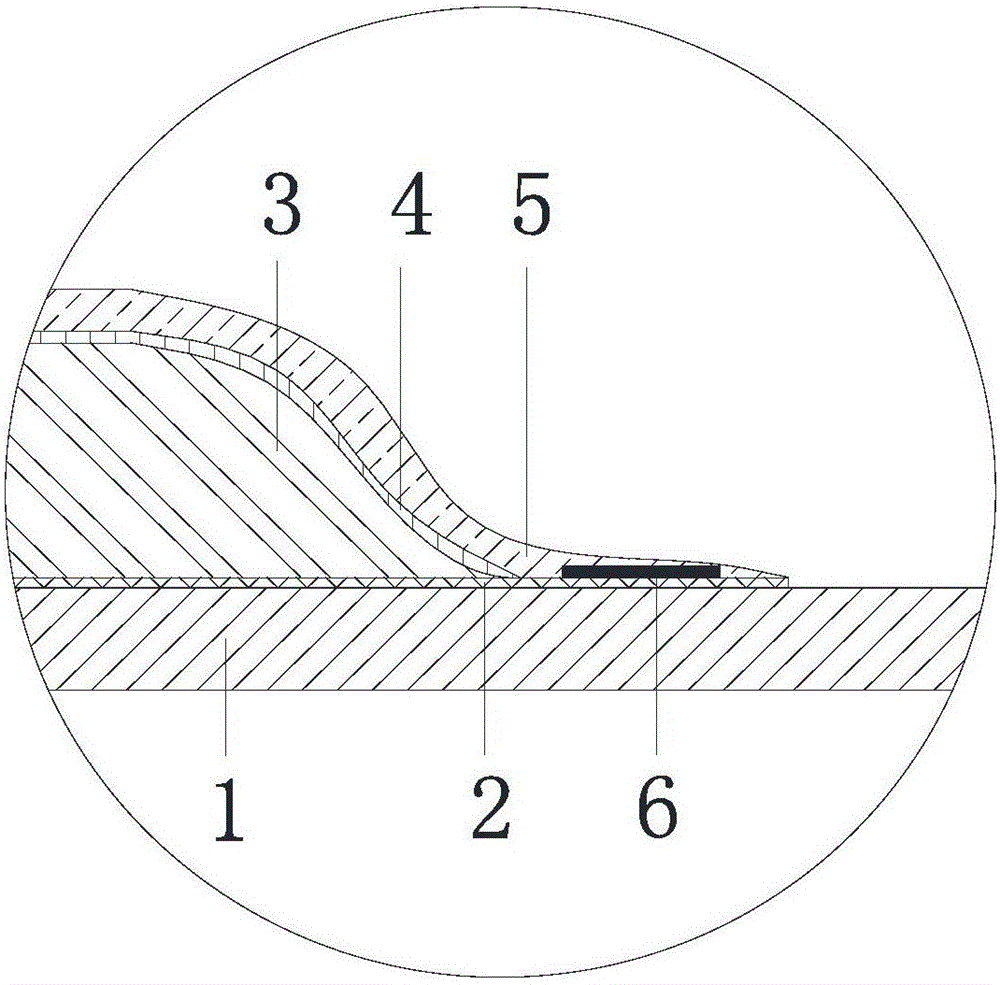

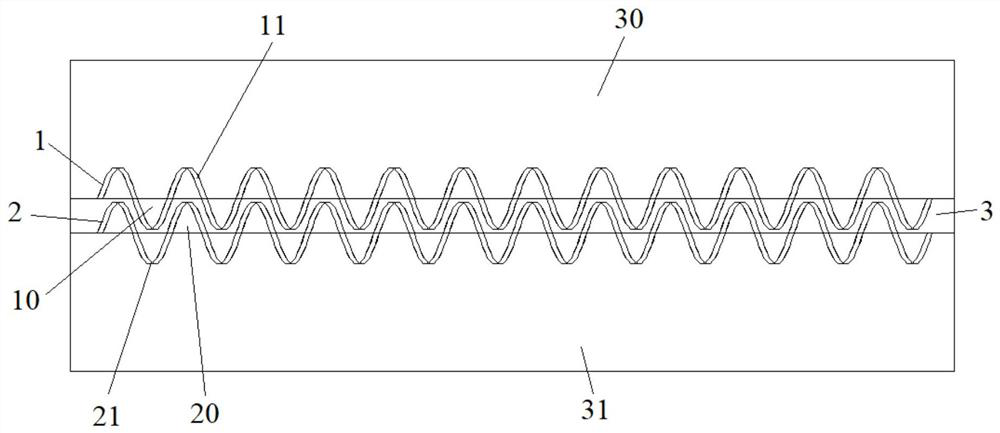

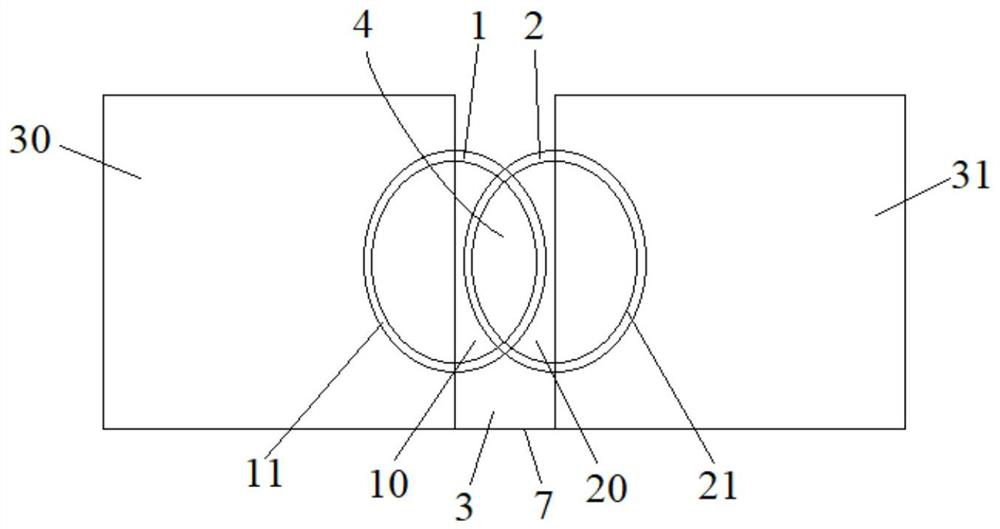

Marine polyurethane spraying prefabricated thermal insulation balance weight pipe and preparation method thereof

InactiveCN105909883AEnsure consistencyAvoid your own flawsThermal insulationPipe protection by thermal insulationPolyolefinAdhesive

Owner:CHINA NAT OFFSHORE OIL CORP +1

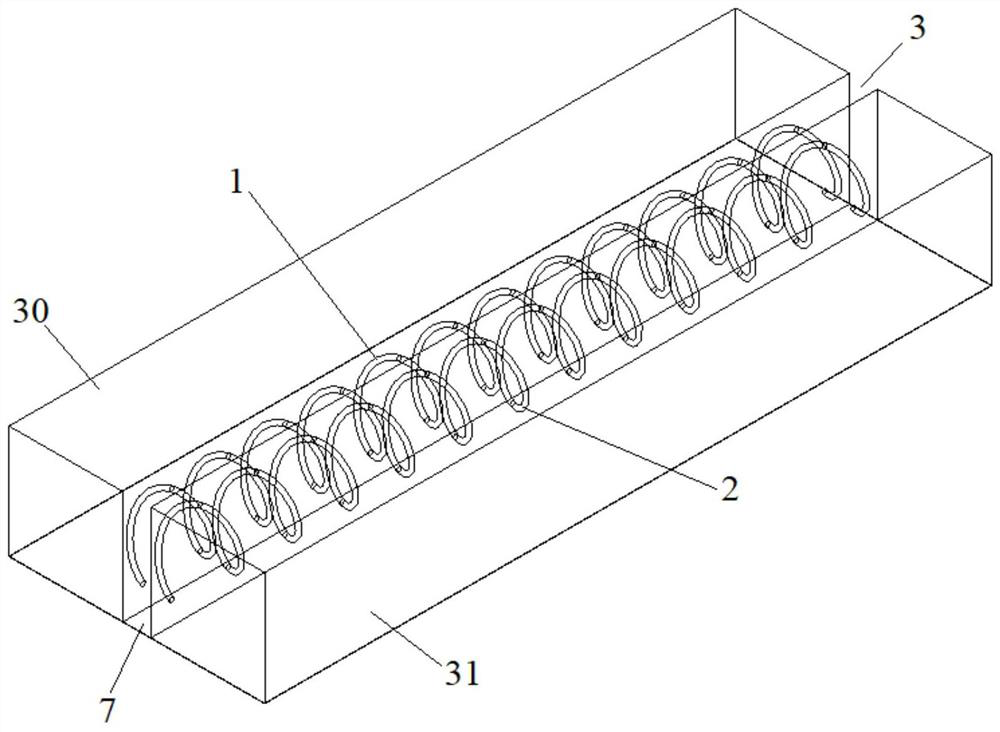

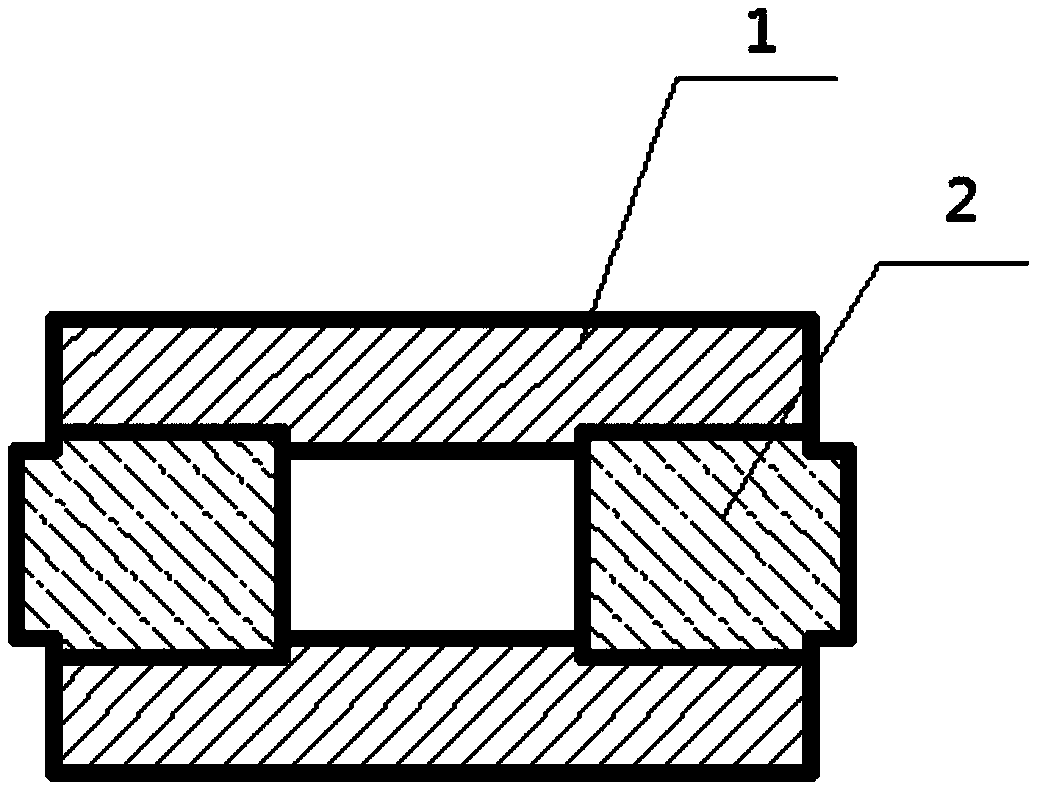

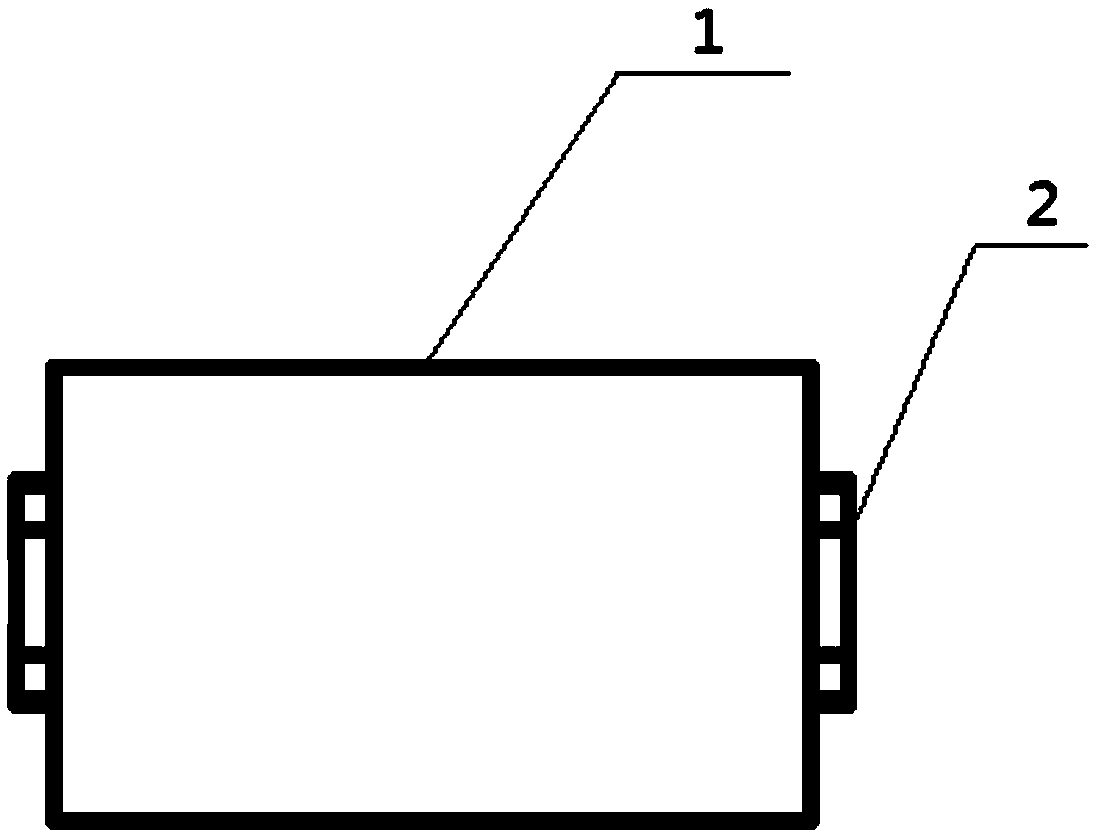

Joint structure, building body and joint structure construction method

ActiveCN113756453AImprove tensile and shear strengthImprove anchor strengthBridge erection/assemblyBuilding reinforcementsUltimate tensile strengthJoint (building)

Owner:CHINA FIRST HIGHWAY ENG +2

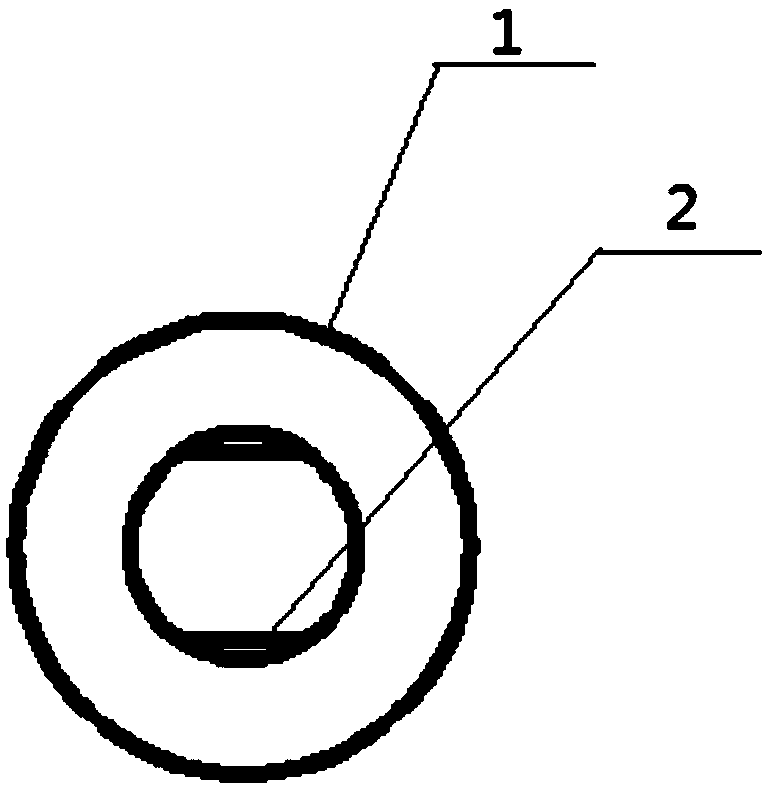

Extrusion processing method of magnesium alloy AZ91D internal threads

ActiveCN109604488ASolve prone to rotten teethSolve the \"slip button\"Thread cutting machinesScrew-threads articlesEmulsionIngot

Owner:HARBIN UNIV OF SCI & TECH +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap