Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9 results about "Vacuum tube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In electronics, a vacuum tube, an electron tube, or valve (British usage) or, colloquially, a tube (North America), is a device that controls electric current flow in a high vacuum between electrodes to which an electric potential difference has been applied.

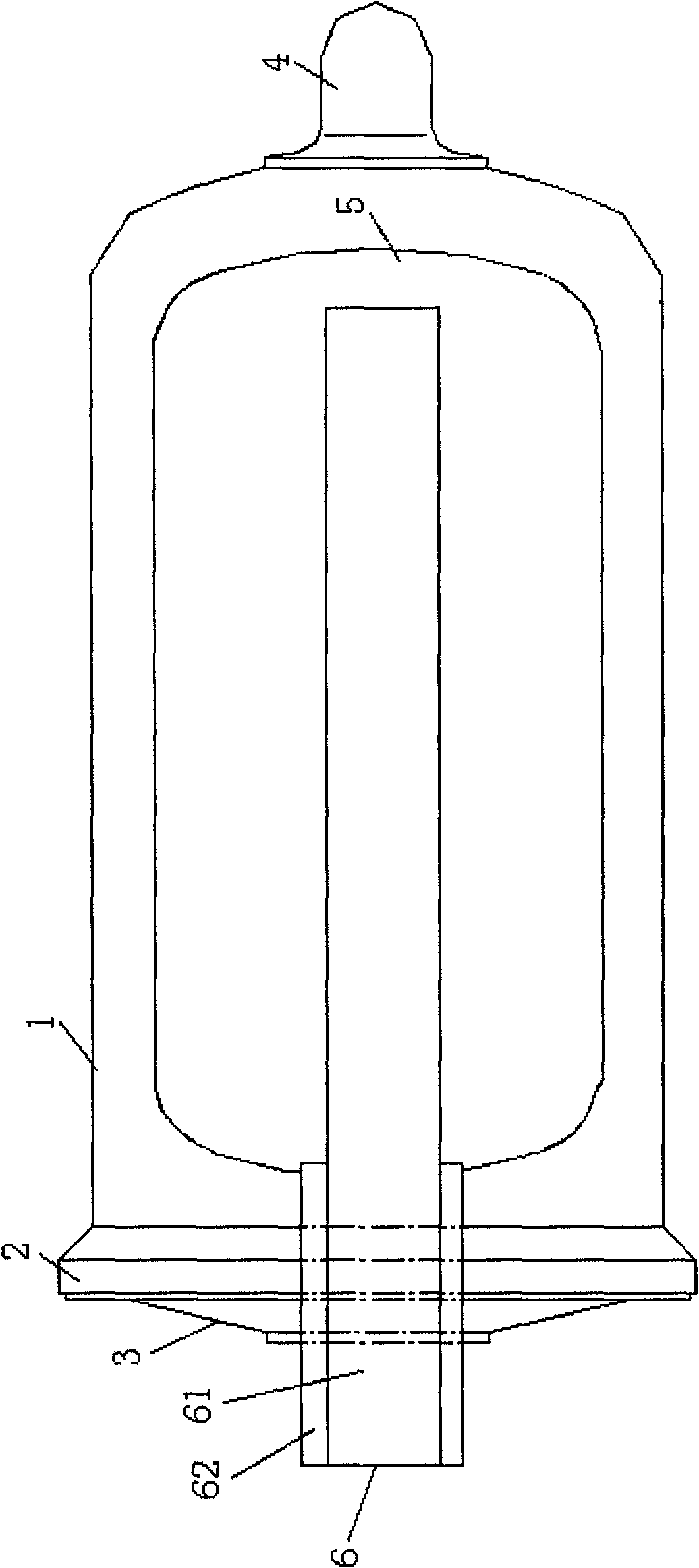

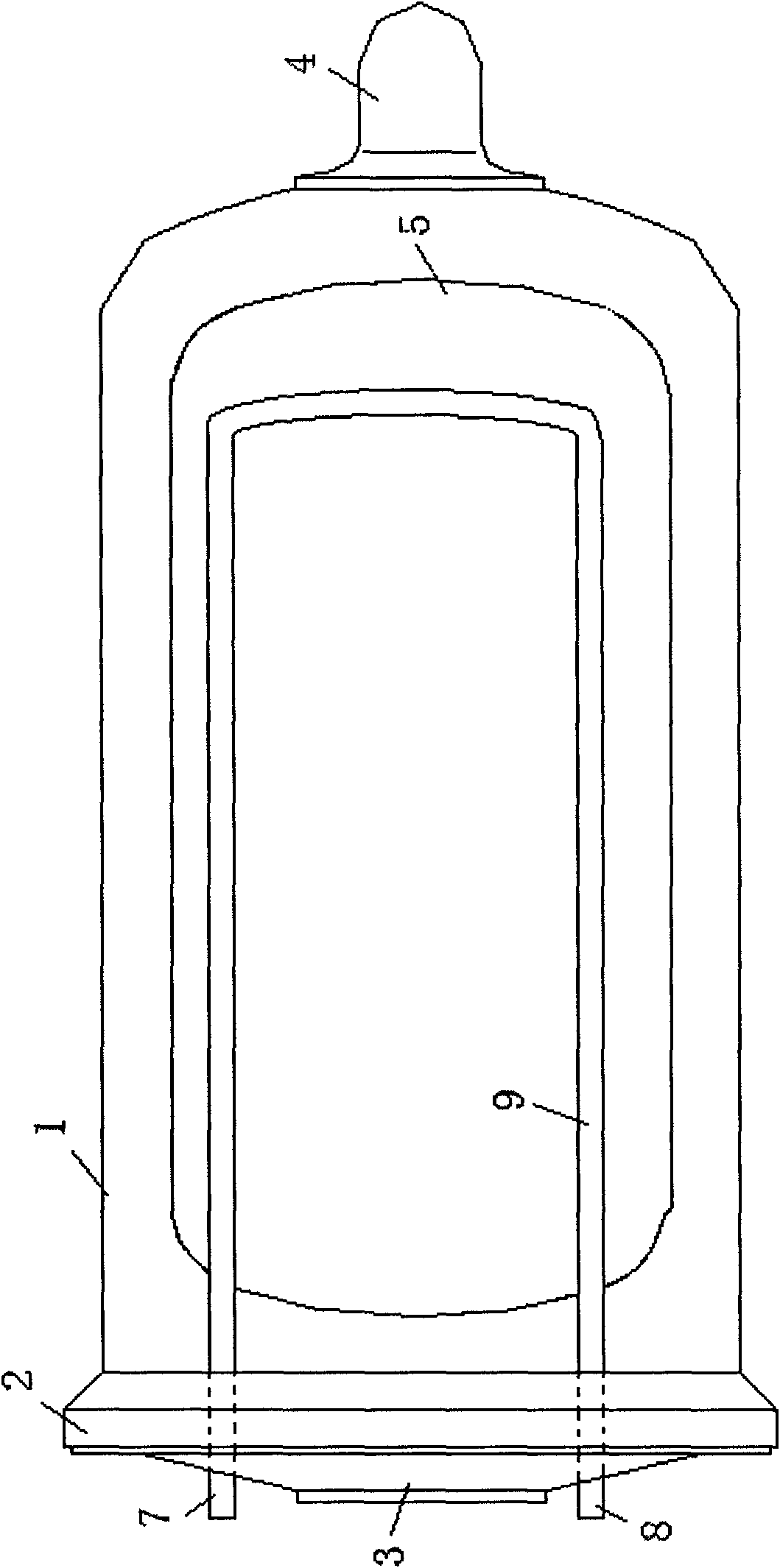

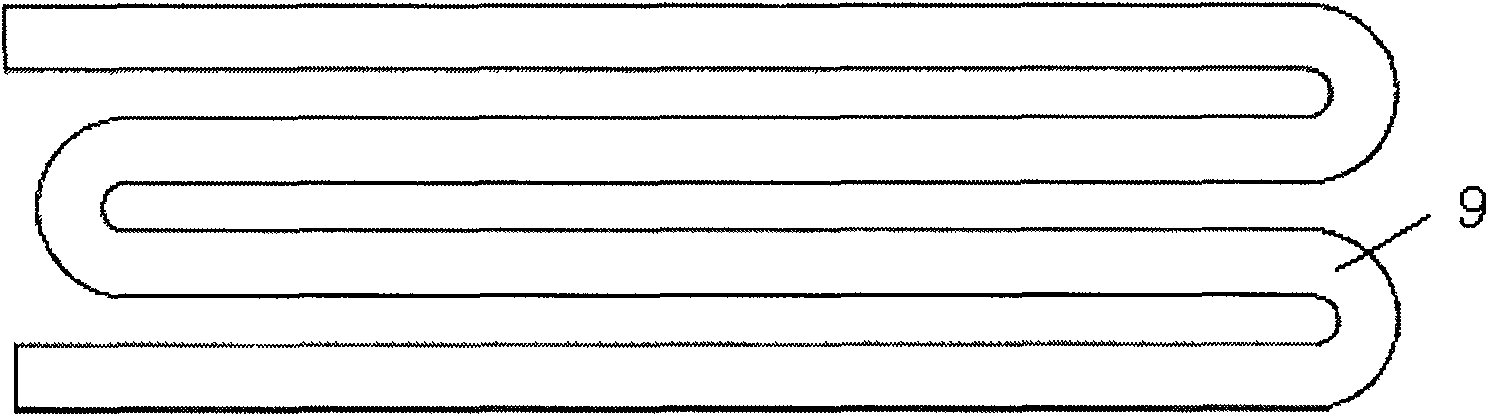

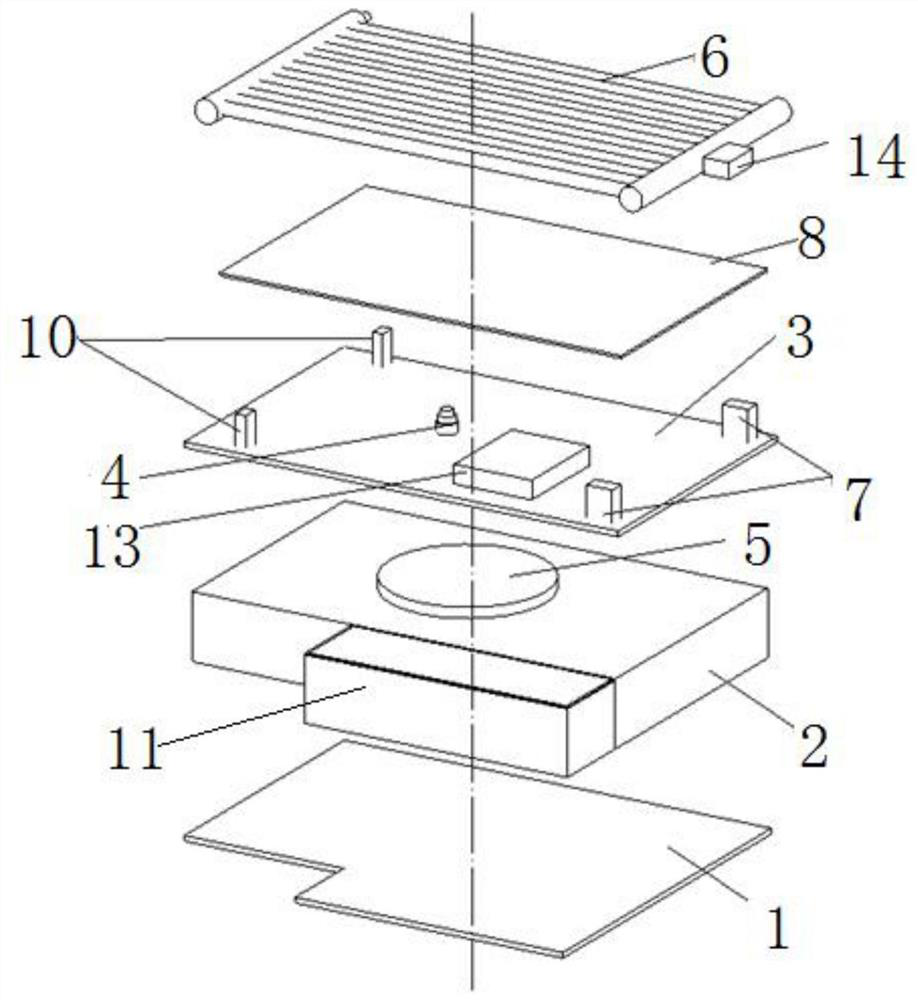

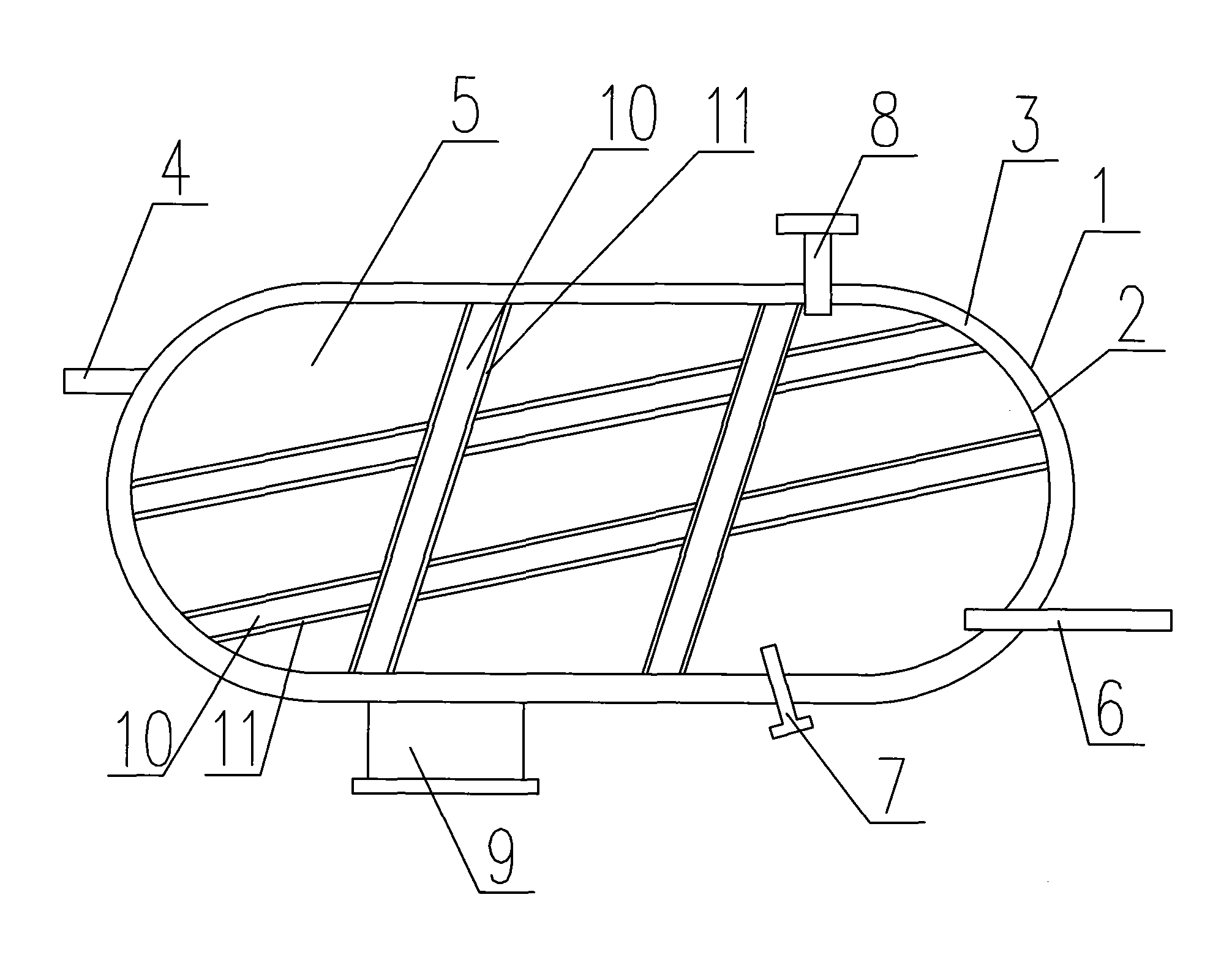

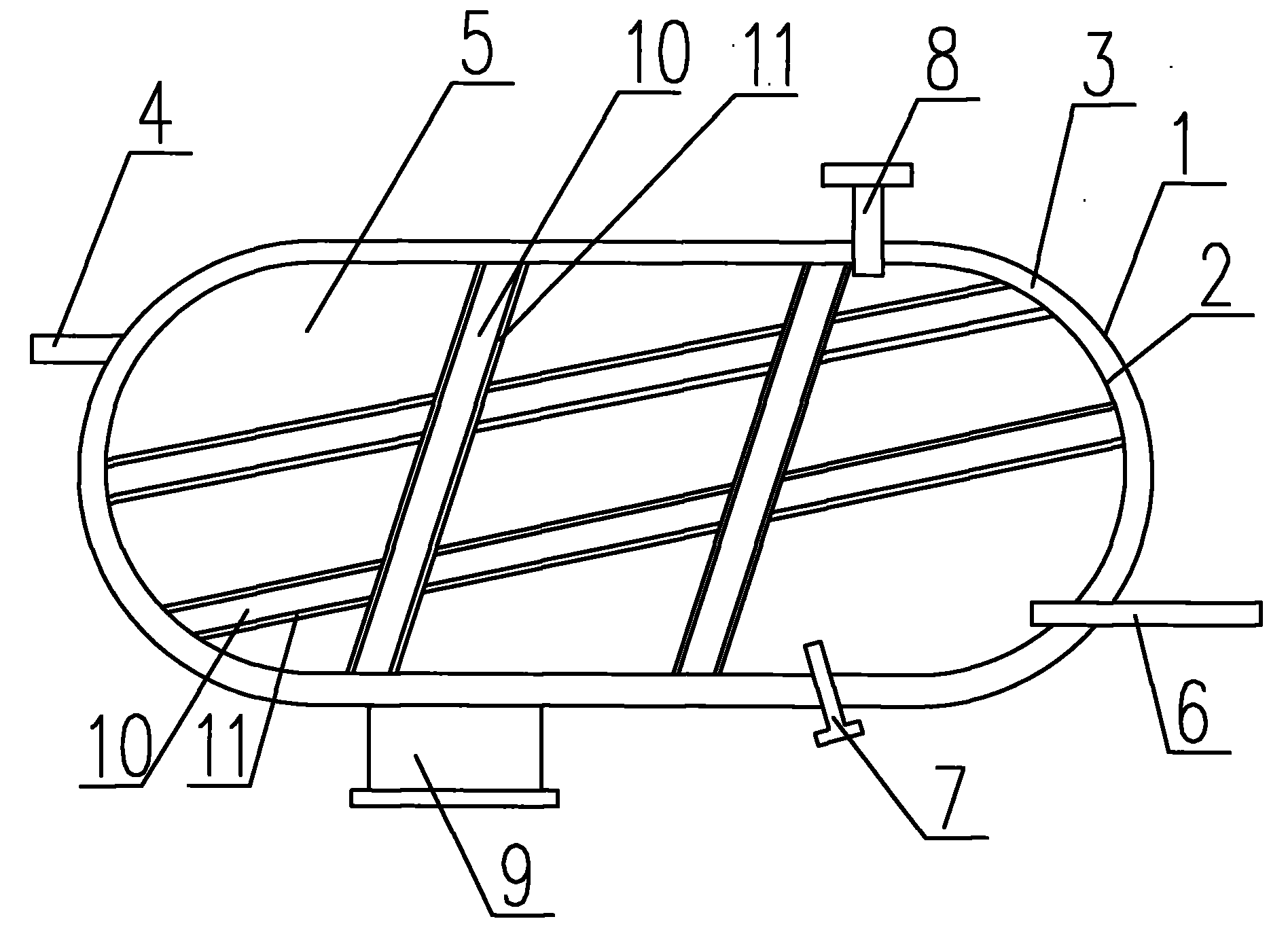

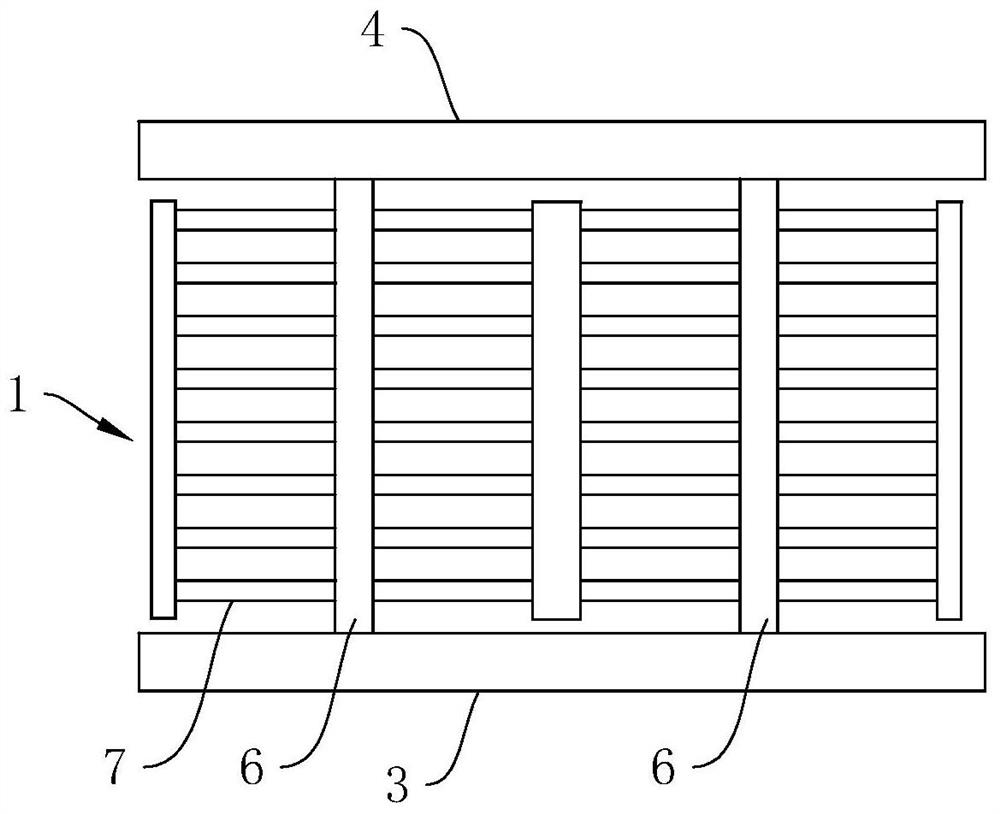

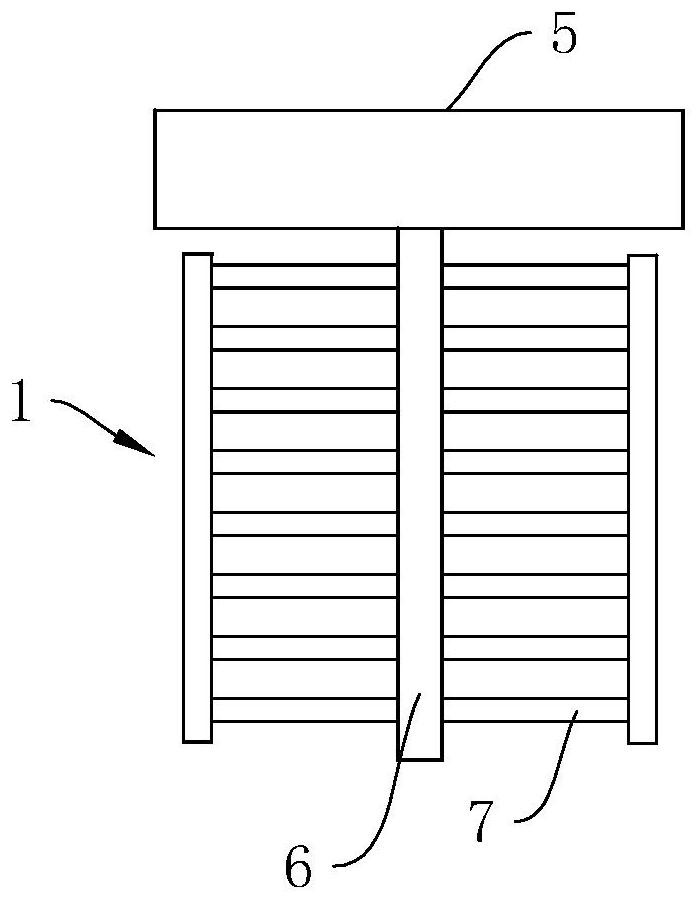

Thermal storage type vacuum tube

InactiveCN101639296AExtended service lifeIncrease the heat exchange areaHeat storage plantsSolar heat devicesSolar waterMetallic materials

Owner:北京桑达太阳能技术有限公司

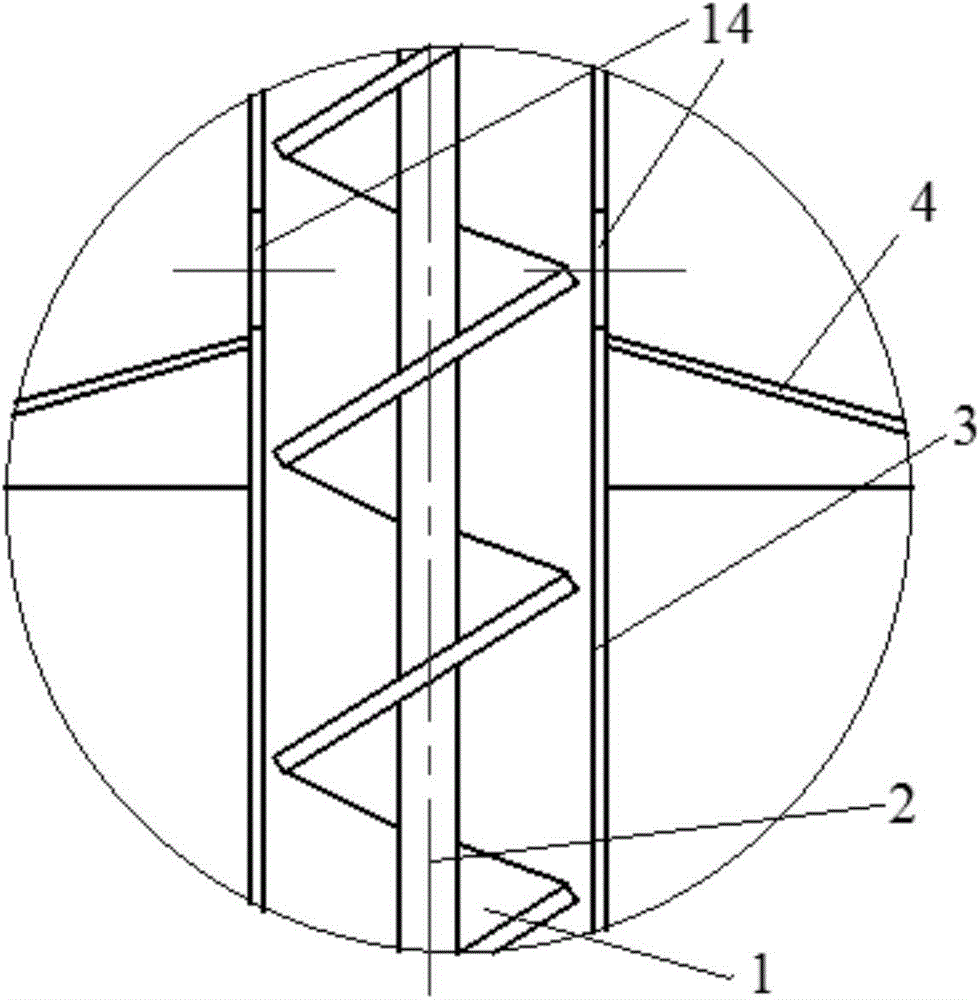

Efficient defoaming solvent-free composite mixing unit cylinder

InactiveCN104941493AGuaranteed defoaming efficiencyQuality assuranceMixersFoam dispersion/preventionVacuum pumpingCoupling

Owner:XIAN UNIV OF TECH

Laminated glass forming device

Owner:黄山市歙县凯旋工贸有限公司

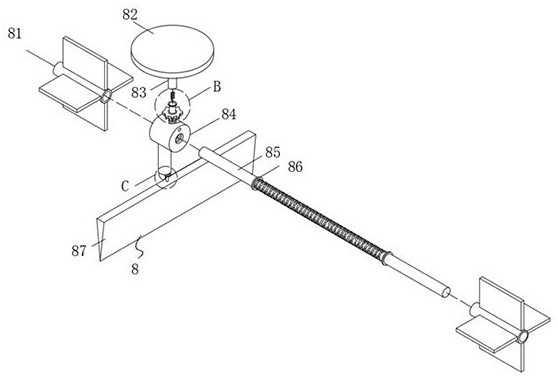

Solar heat collector system utilizing phase change energy storage technology and capable of automatically tracking sunlight

PendingCN111879020AReduced stabilityChange angleSolar heating energyBatteries circuit arrangementsAutomatic controlThermodynamics

Owner:SHENYANG JIANZHU UNIVERSITY

Heat pipe type photovoltaic generating thermal collection assembly

ActiveCN104913520AImprove cooling effectImprove power generation efficiencySolar heating energySolar heat devicesHeat conductingEvaporation

Owner:BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE

Rapid shunting drier for polyester raw material

InactiveCN101928991AWell mixedReduce color differenceMelt spinning methodsFilament-forming treatmentPolyesterEngineering

Owner:张家港保税区炬德化纤有限公司

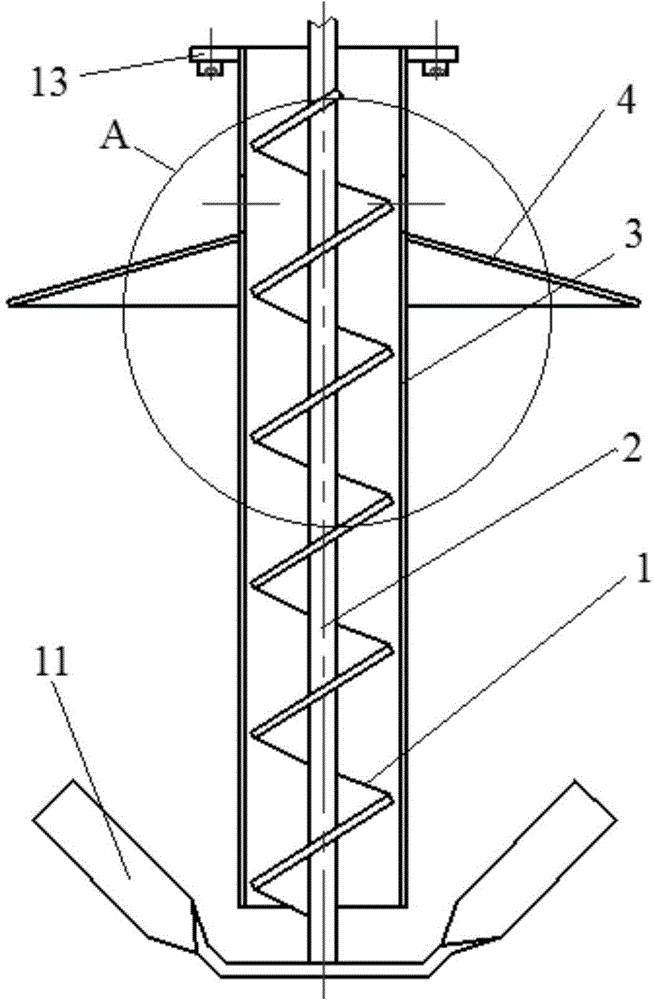

Carbon doping device and carbon doping method for growing semi-insulating gallium arsenide single crystal

ActiveCN113136616AAchieving C deposition amountEasy to controlPolycrystalline material growthFrom frozen solutionsSemiconductor materialsGallium arsenate

The invention discloses a carbon doping device and a carbon doping method for growing semi-insulating gallium arsenide single crystals, and relates to the technical field of semiconductor materials. The device comprises a quartz tube and a PBN crucible set, the PBN crucible set is arranged in the quartz tube, and sealing chucks are installed at the two ends of the quartz tube; pipelines are respectively arranged at two ends of the quartz tube, namely an inflation pipeline and an exhaust pipeline; a third on-off valve is arranged on the gas filling pipeline, two branch gas pipelines which are connected in parallel are arranged on the upstream of the gas filling pipeline and are respectively called an oxygen filling pipeline and a carbon filling pipeline, the oxygen filling pipeline is connected with an oxygen source, and the carbon filling pipeline is connected with a carbon gas source, wherein the on-off of the oxygen source or the carbon gas source is controlled through the valves; the downstream of the exhaust pipeline is provided with two branch air pipelines which are connected in parallel and are respectively called a deflation pipeline and a vacuumizing pipeline, the deflation pipeline is provided with a valve, and the vacuumizing pipeline is connected with a vacuumizing device. According to the invention, an oxygenating baking process and a C deposition process can be respectively implemented, and the two processes are sequentially carried out on the same equipment, so that the equipment is simplified, and the heat energy loss is reduced.

Owner:ITE SEMICON MATERIAL CO LTD

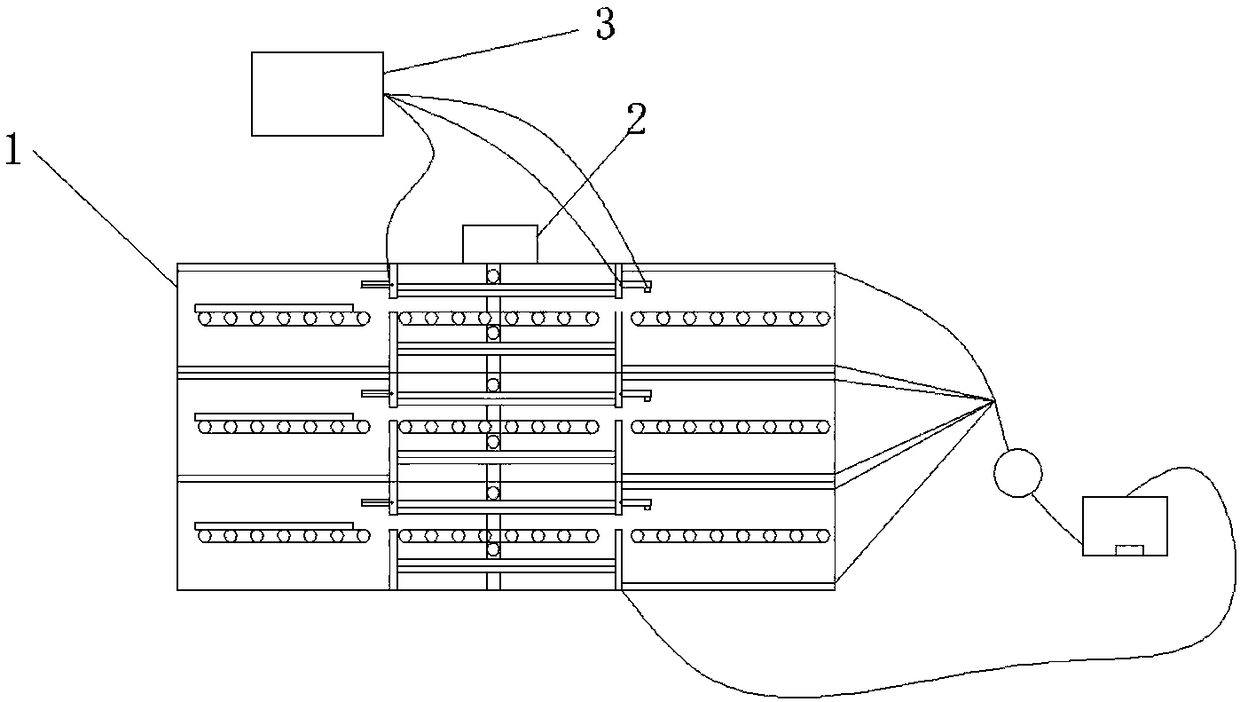

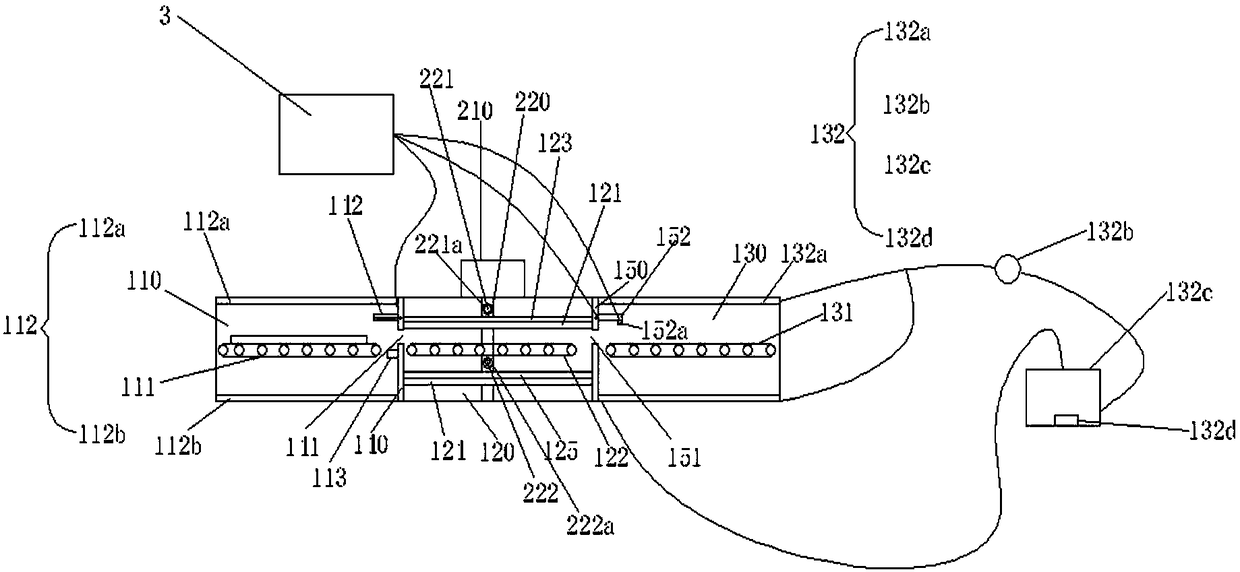

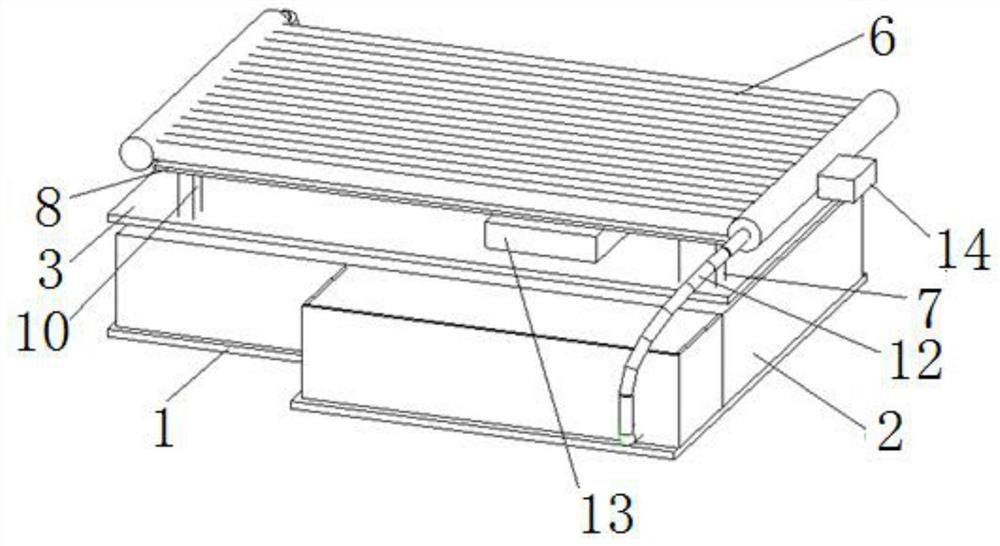

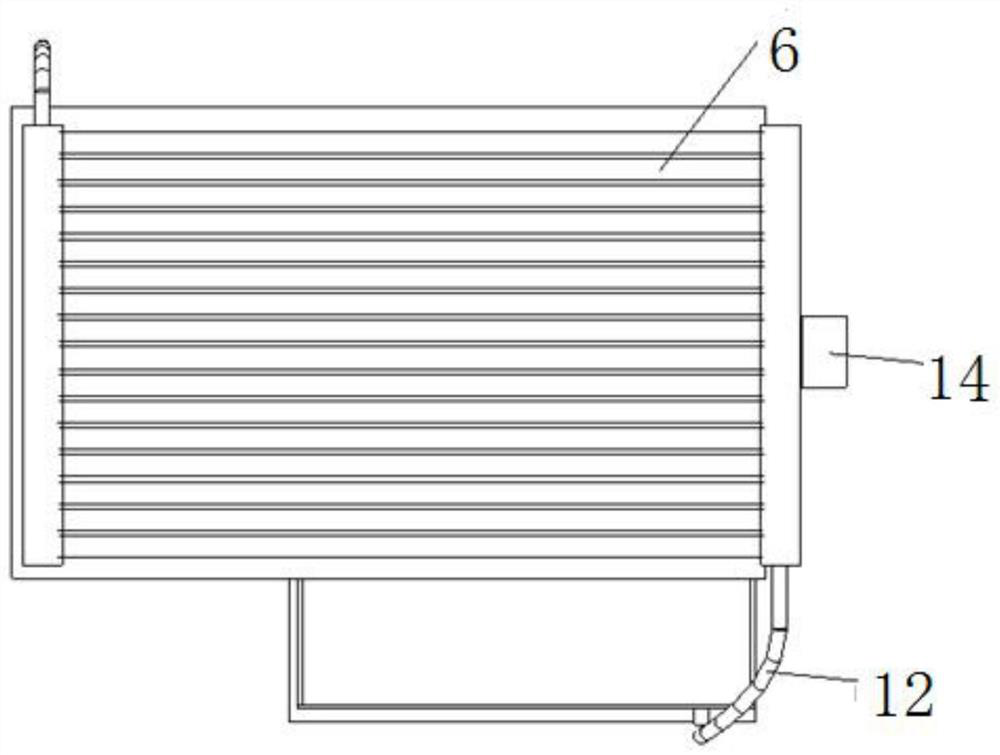

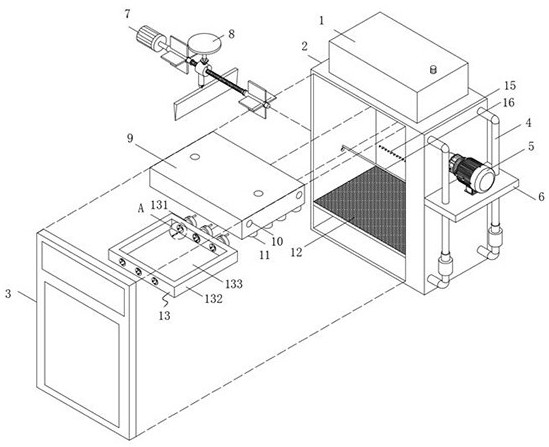

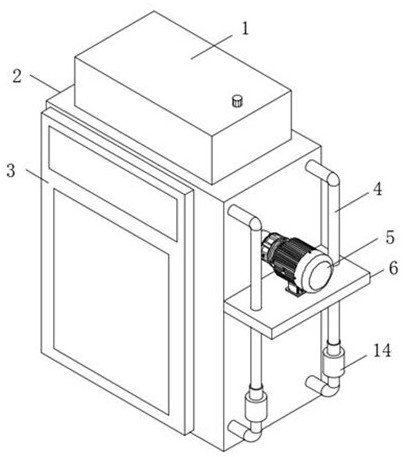

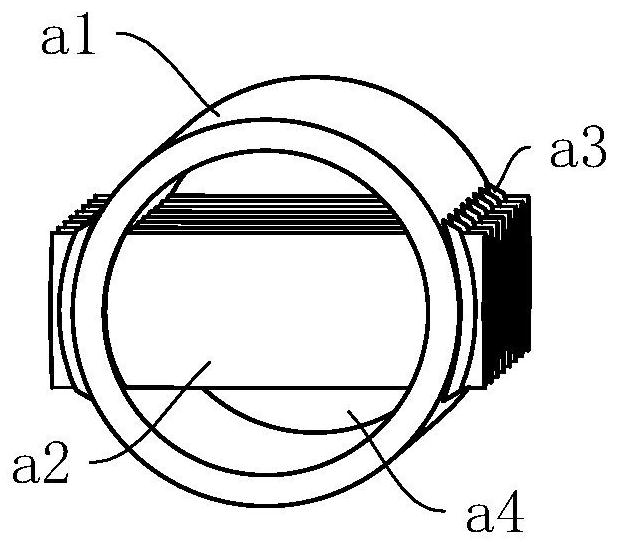

Solar vacuum tube uniform coating equipment

ActiveCN114247597AImprove stack adhesionUniform coatingPretreated surfacesCoatingsElectric machineryEngineering

Owner:LINYI RUIGUANG NEW ENERGY TECH

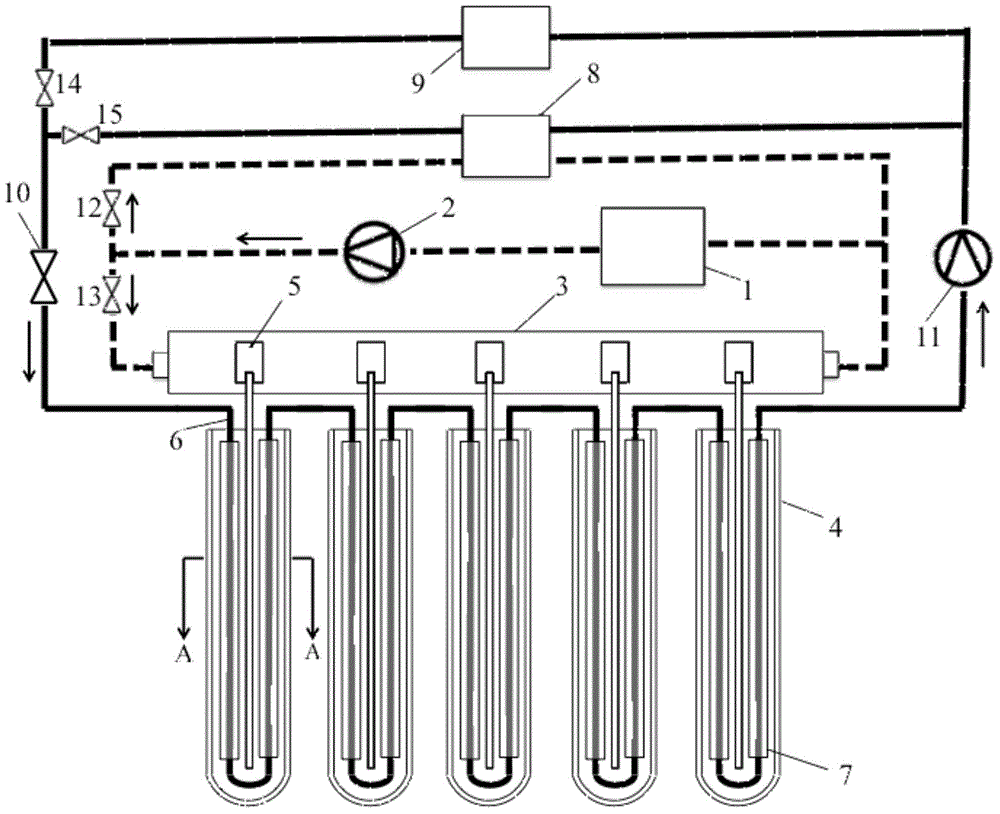

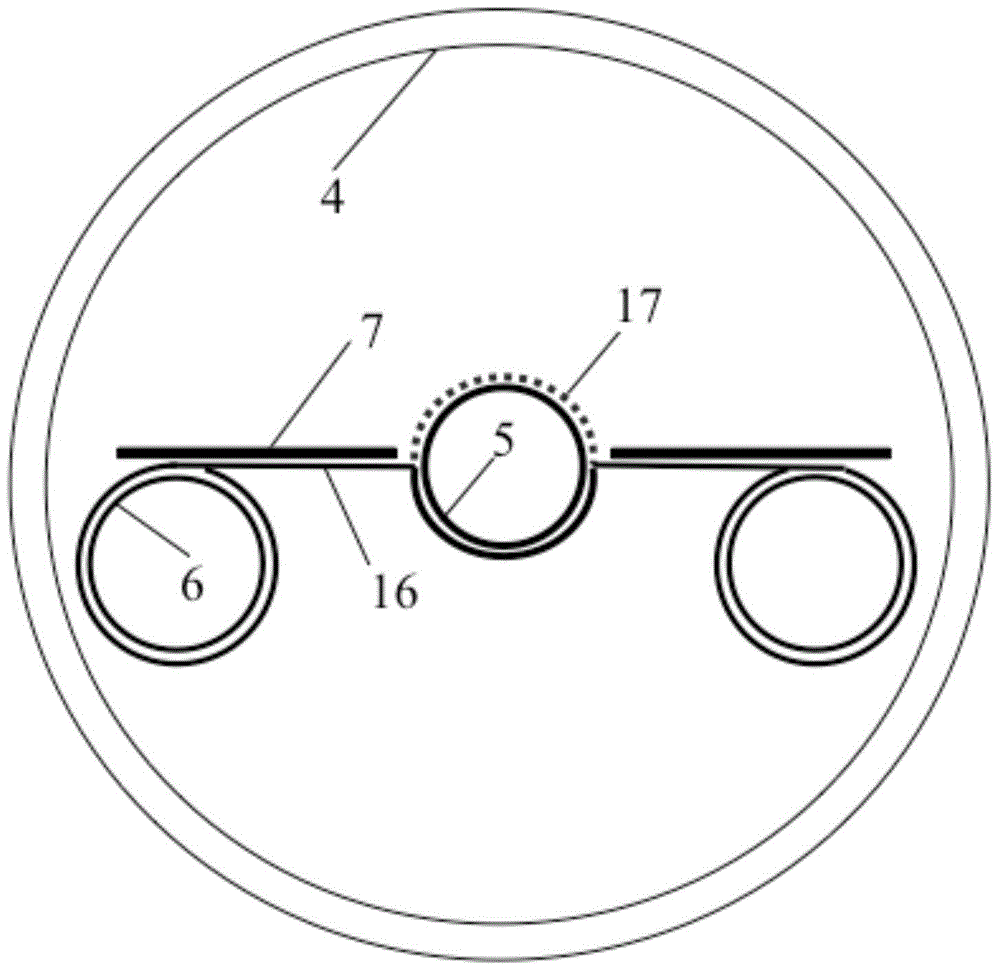

Superconducting heat pipe solar water heating system

PendingCN113251673AEnsuring light-to-heat conversion efficiencyIncrease usageSolar heating energySolar heat collectors with working fluidsThermodynamicsHeat transmission

Owner:山东阳光博士太阳能工程有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap