Preparation of solar battery sensitized by utilizing zinc phthalocyanine bisphenol A epoxide derivative

A zinc phthalocyanine bisphenol, solar cell technology, applied in photosensitive devices, circuits, capacitors, etc., can solve problems such as high cost and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below through examples.

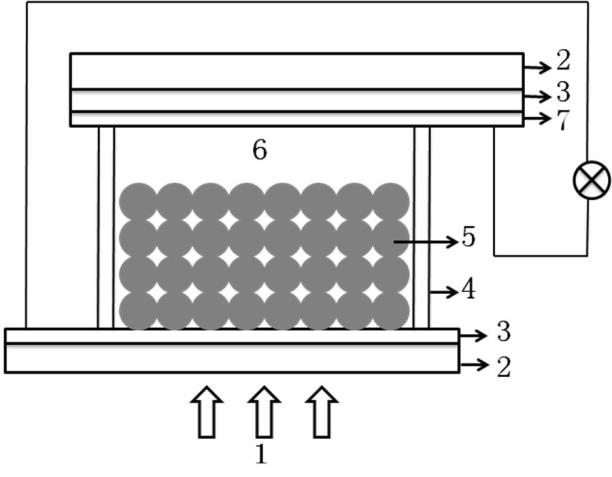

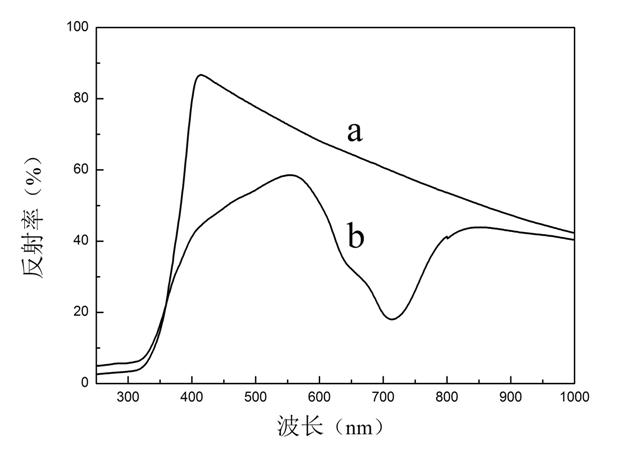

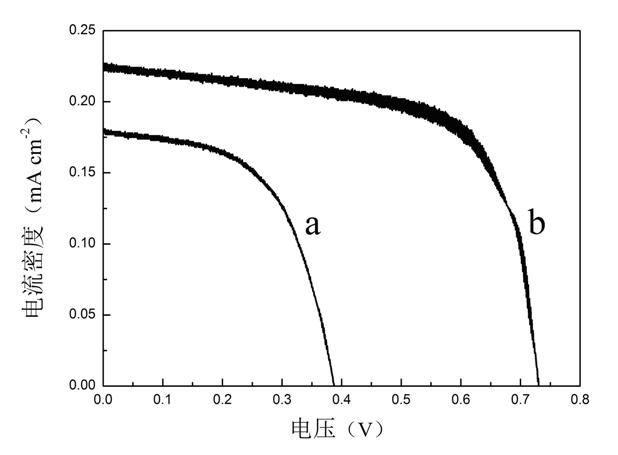

[0025] Example: Preparation and implementation process of dye-sensitized solar cells based on zinc phthalocyanine bisphenol A epoxy derivatives

[0026] (one) Synthesis of zinc phthalocyanine bisphenol A epoxy derivatives:

[0027] A. Preparation of Tetraaminozinc Phthalocyanine

[0028] (a) Preparation of tetranitrozinc phthalocyanine by phthalic anhydride-urea solvent method

[0029] After mixing 2.73 g of zinc acetate tetrahydrate, 9.70 g of tetranitrophthalic anhydride, 27.63 g of urea (the molar ratio is 1:4:40) and 0.21 g of ammonium molybdate tetrahydrate and grinding them evenly with a mortar, they were added to In a 500 ml three-neck flask, add 100 ml of nitrobenzene as a solvent. Stir with an electric mixer, heat to 180°C in an oil bath, condense and reflux, react for 5 hours, cool, filter, and wash the filter cake with methanol until there is no nitrobenzene smell. 1 mol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap