Bioelectrochemical sensor used for detecting hydrogen peroxide and manufacturing method thereof

A biosensor and bioelectrochemical technology, applied in the field of new bioelectrochemical sensors and their preparation, can solve problems such as disordered enzyme distribution, achieve the effect of improving sensitivity and promoting electron transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Preparation of polypeptide-modified gold electrodes

[0024] Place the gold electrode to be treated in piranha solution (concentrated sulfuric acid: 30% H 2 o 2 = 3:1) for 2 minutes to remove organic matter adsorbed on the surface of the electrode, and rinse thoroughly with ultrapure water. Subsequently, the gold electrodes were polished with fine corundum sandpaper (5000 mesh), and then polished to a mirror surface on the silk containing alumina (grain size: 1 μm, 0.3 μm, 0.05 μm) mortar, respectively. and ultrasonic cleaning in water for 5 minutes. Finally place the electrode in 0.5 M H 2 SO 4 In the 0-1.6 V potential range, the cyclic voltammetry scan was carried out to stability. Dry in a nitrogen atmosphere to obtain a bare gold electrode with a clean surface, which can be used for the modification of the polypeptide matrix. Put the Eppendorf tube containing 70 μL peptide solution (10 μM peptide, 20 mM HEPES and 10 mM TCEP, pH 6.0) upside down on ...

Embodiment 2

[0025] Example 2: Modification of horseradish peroxidase (HRP) on the surface of gold electrodes

[0026] Add 10 μL of the prepared HRP solution dropwise to the surface of the gold electrode that has successfully modified the polypeptide, incubate at room temperature for 3 h, and cover the electrode surface with an Eppendorf tube to prevent the enzyme solution from volatilizing. The modified electrode was washed with ultrapure water to remove weakly adsorbed substances on the surface before use.

Embodiment 3

[0027] Example 3: Acquisition of the electrochemical signal of the working electrode

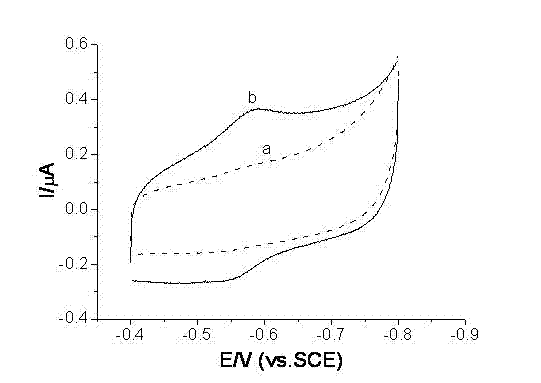

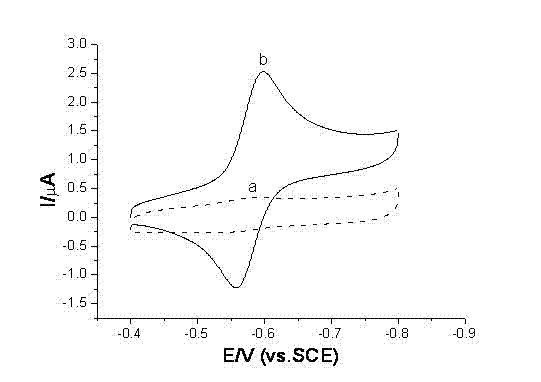

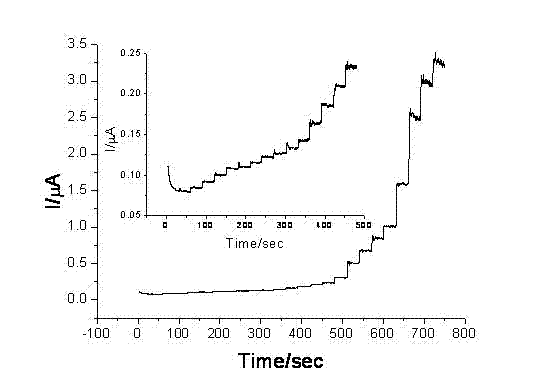

[0028]Due to the poor conductivity of the polypeptide, it has a certain blocking effect on the electron transfer between HRP and the electrode, so the modified electrode cannot obtain the direct electrochemical signal of HRP in 100 mM PBS buffer (pH 7.0). Therefore, we introduced an electron conductor, o-phenylenediamine, into the system. It can act as a bridge for electron transfer between the enzyme and the electrode. Depend on figure 1 It can be seen that the gold electrode modified only with polypeptide did not have any electrochemical response in 100 mM PBS buffer (pH7.0) containing 10 mM o-phenylenediamine, while the gold electrode modified with HRP at the same time showed a pair of Stable, symmetrical redox peaks. at 100 mVs -1 At the scan rate, the reduction peak and oxidation peak potentials were -583 mV and -547 mV, respectively, which were basically consistent with the electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap