Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7 results about "Continuous feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous Feeding. Continuous feeding is defined as the process whereby waste is fed into a combustion chamber without human assistance while the incinerator is in normal operating conditions with the combustion chamber operative temperature between 850°C and 1,200°C.

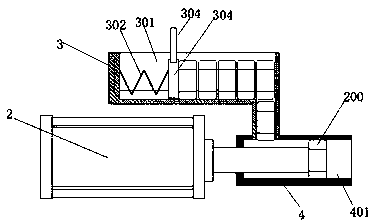

Continuous nut feeding device for automobile part processing

InactiveCN110788607AQuick assemblyRealize continuous assemblyMetal working apparatusIndustrial engineeringHydraulic pressure

Owner:含山县祥瑞运输有限公司

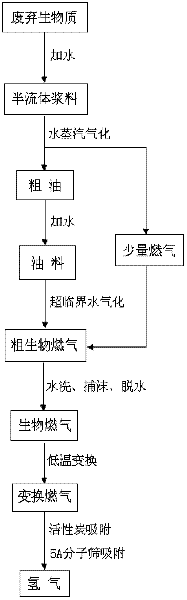

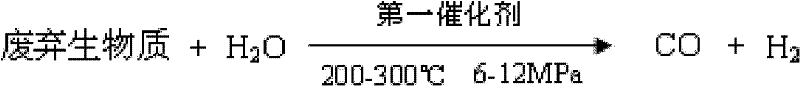

Method for preparing hydrogen by utilizing waste biomass

InactiveCN102653393AReduce pollutionReduce manufacturing costHydrogen separation using solid contactCombustible gas catalytic treatmentRare-earth elementWater vapor

Owner:北京雷恩新材料科技有限公司

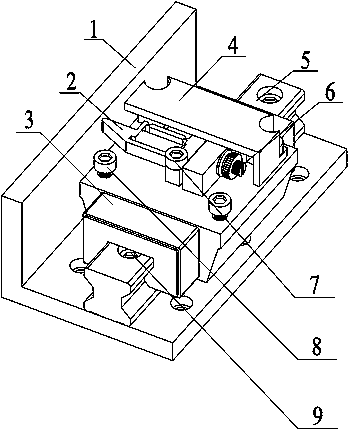

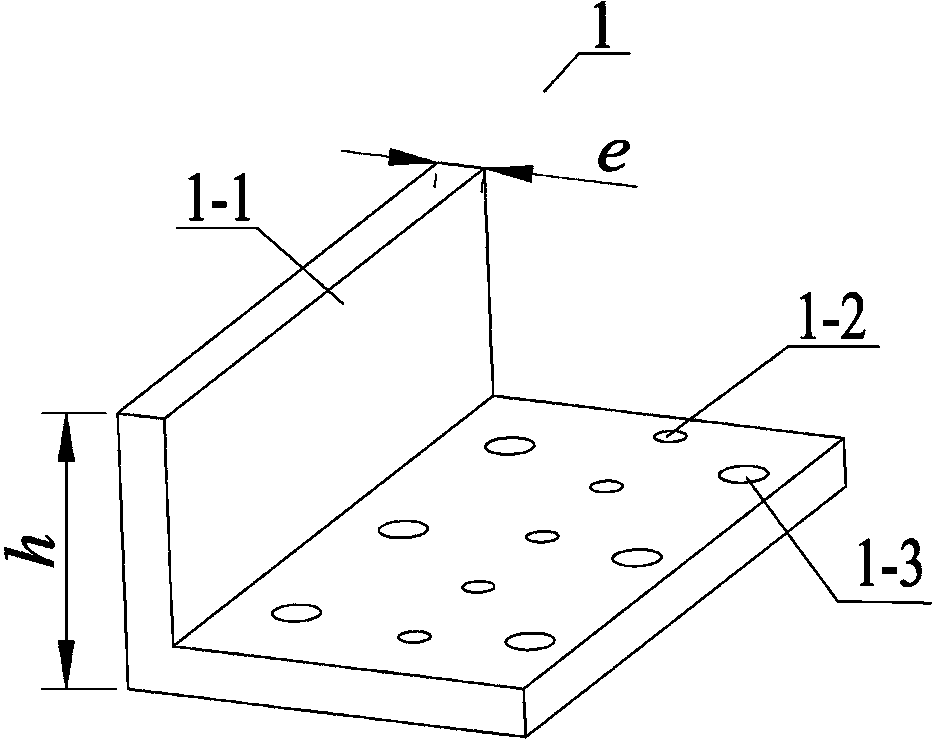

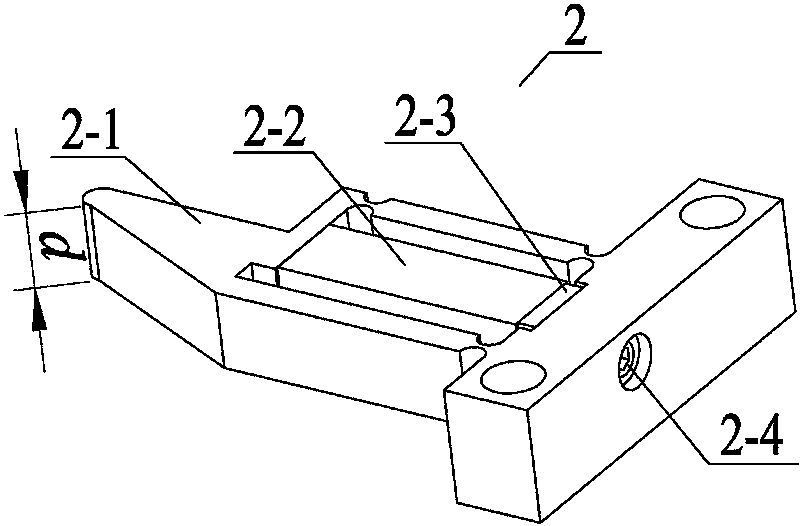

Long-stroke high-precision piezoelectric displacement platform and driving method thereof

ActiveCN108062968AImprove mechanical output characteristicsIncrease the bearing areaInstrument housingMicro nanoEngineering

Owner:CHANGCHUN UNIV OF TECH

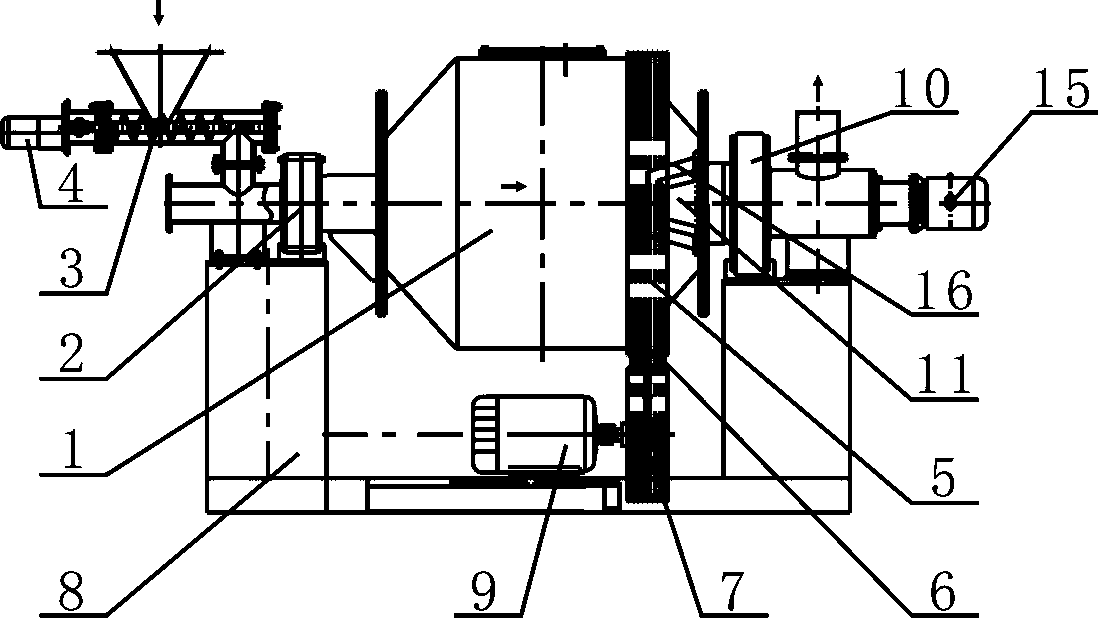

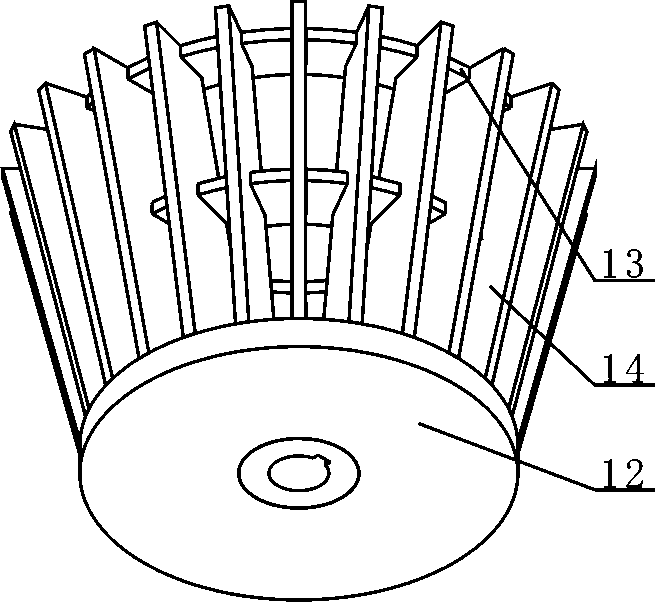

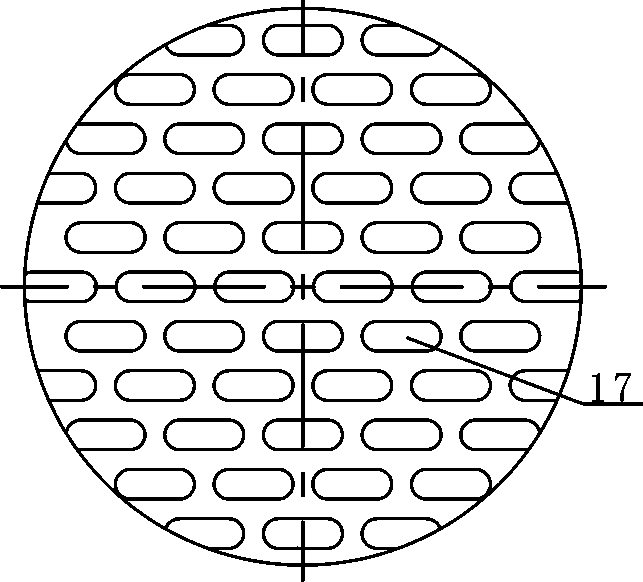

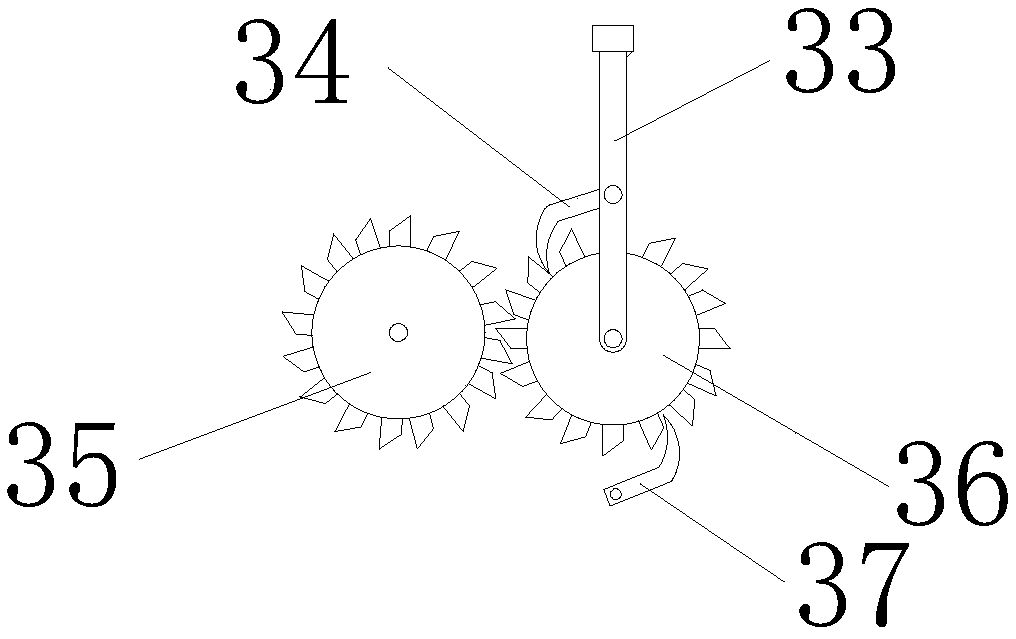

Continuous feeding air separation device

PendingCN108405089AIncrease productionImprove particle size uniformityGrain treatmentsEngineeringAir separation

Owner:LUOYANG SHENGYUAN HIGH TECH MATERIALS

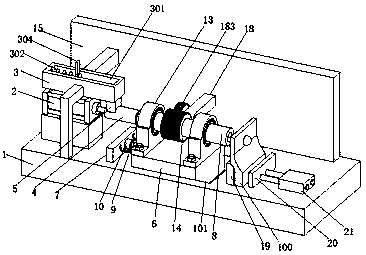

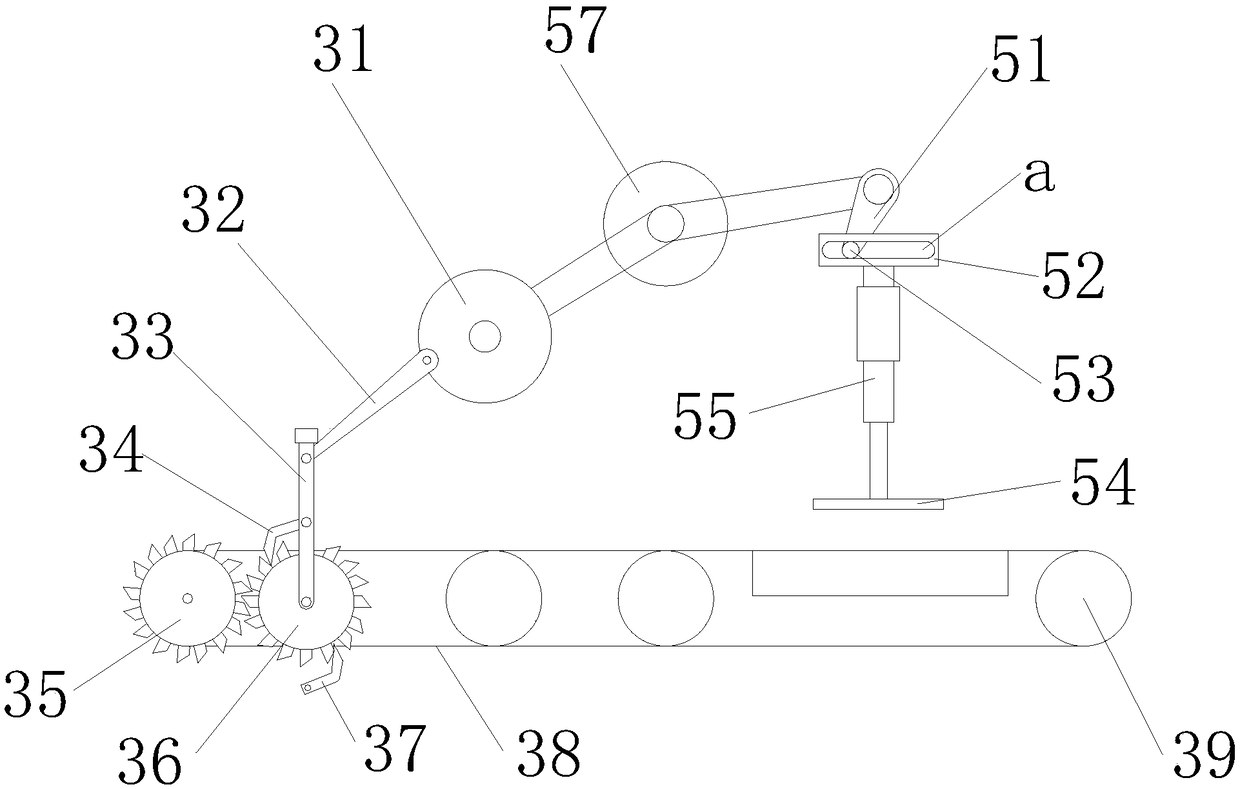

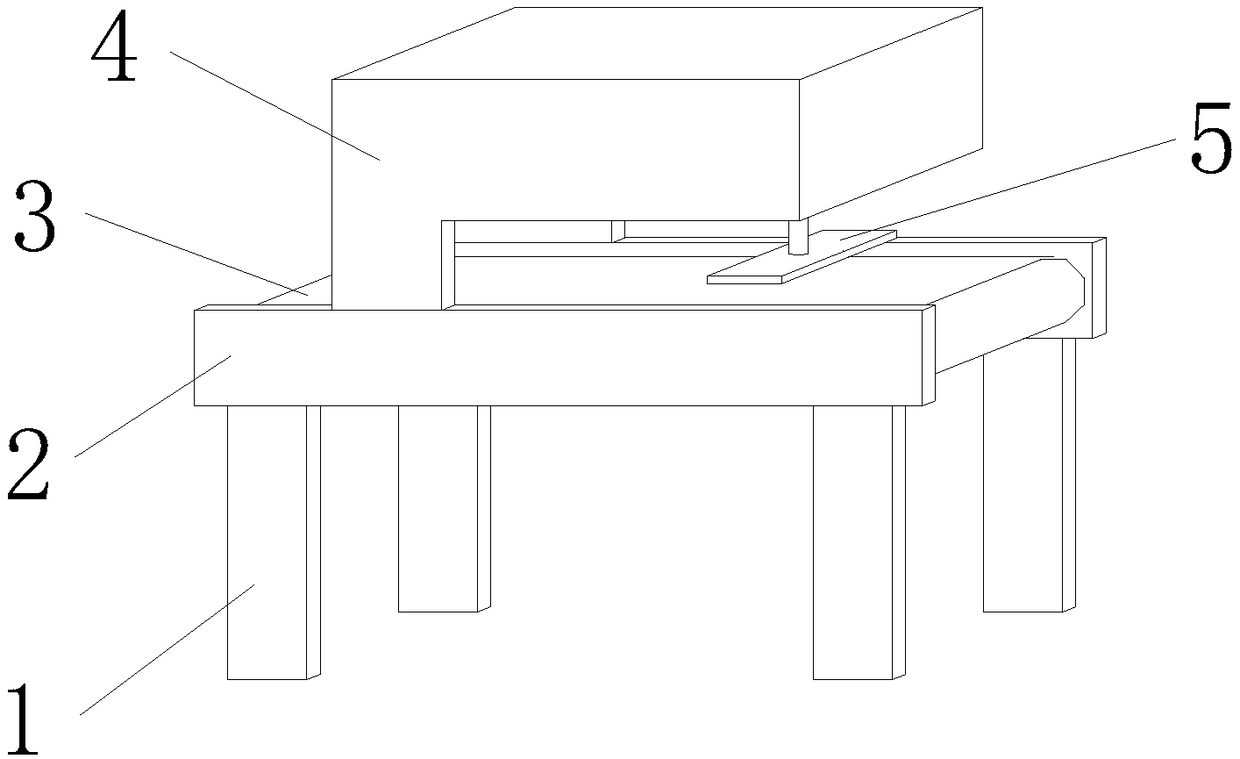

Continuous feeding and stamping apparatus for bottle cap production

InactiveCN109127940AHighly corporatedImprove stamping effectMetal-working feeding devicesClosure capsDrive shaftEngineering

Owner:安徽省潜山县包装制品有限公司

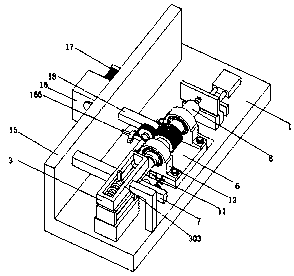

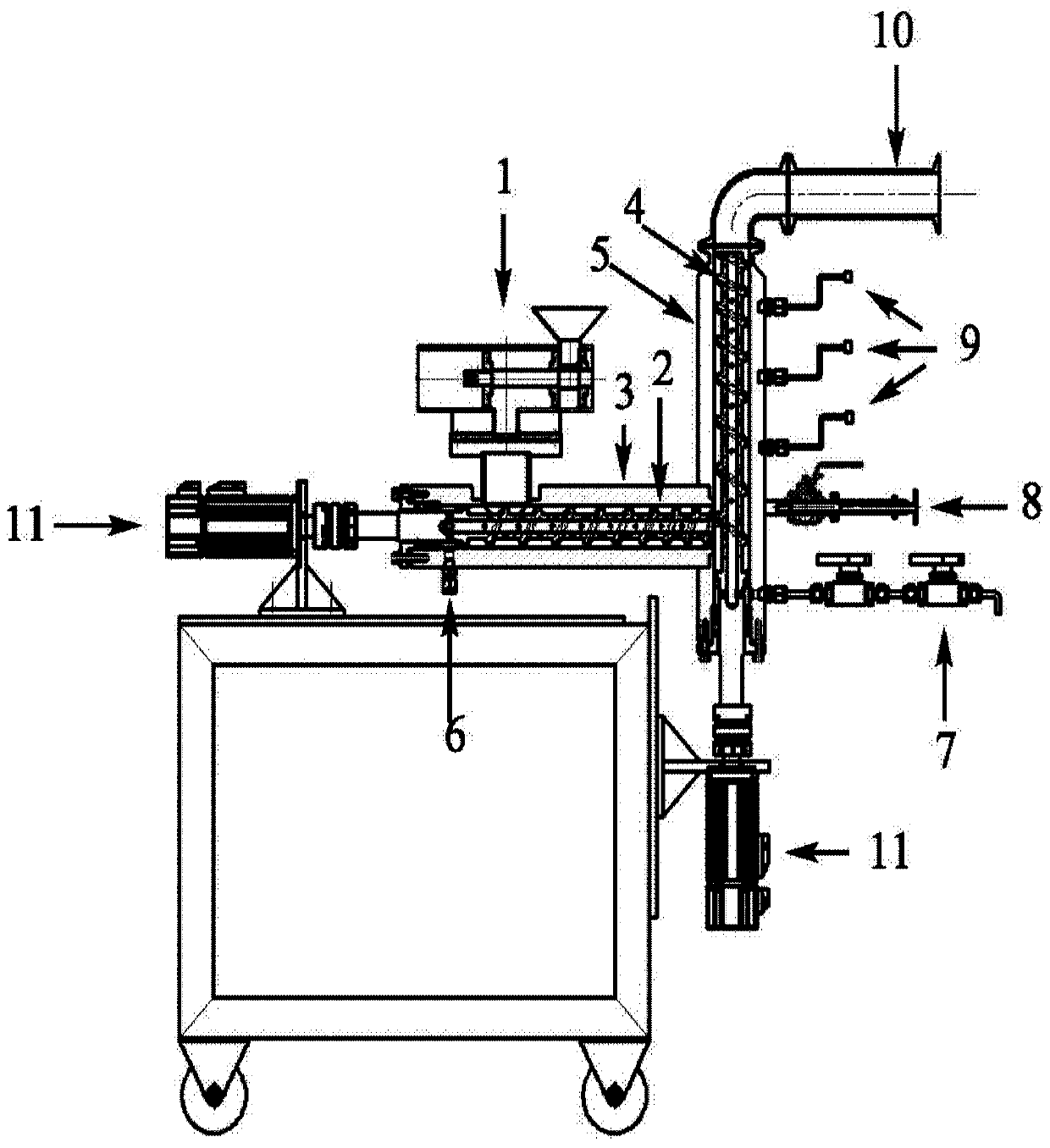

Biomass continuous depolymerization device and method capable of taking materials on line

PendingCN110305677AImprove continuityAchieve disaggregationBiofuelsIndirect heating destructive distillationDepolymerizationProcess engineering

Owner:UNIV OF SCI & TECH OF CHINA

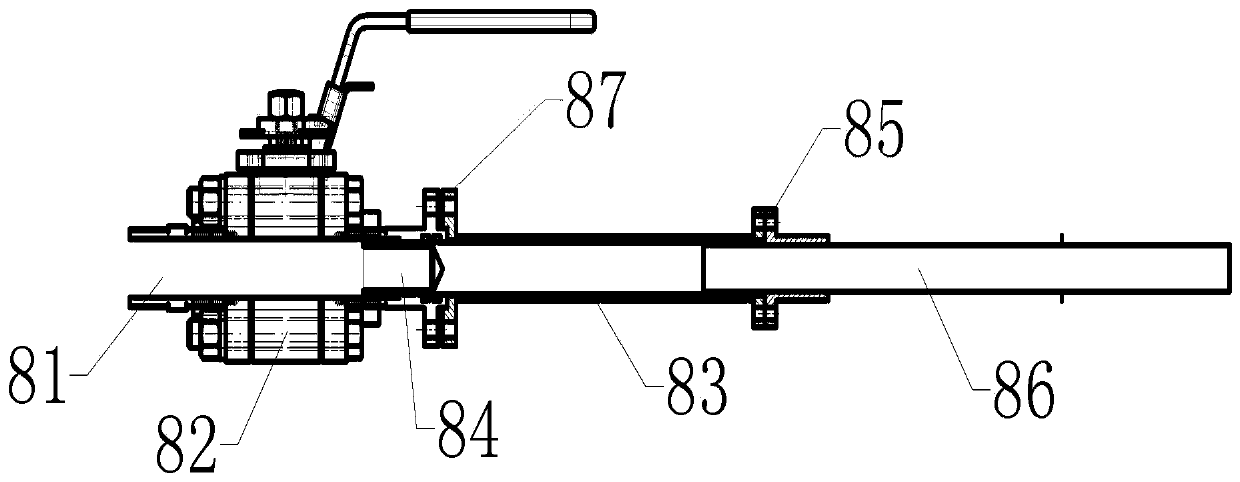

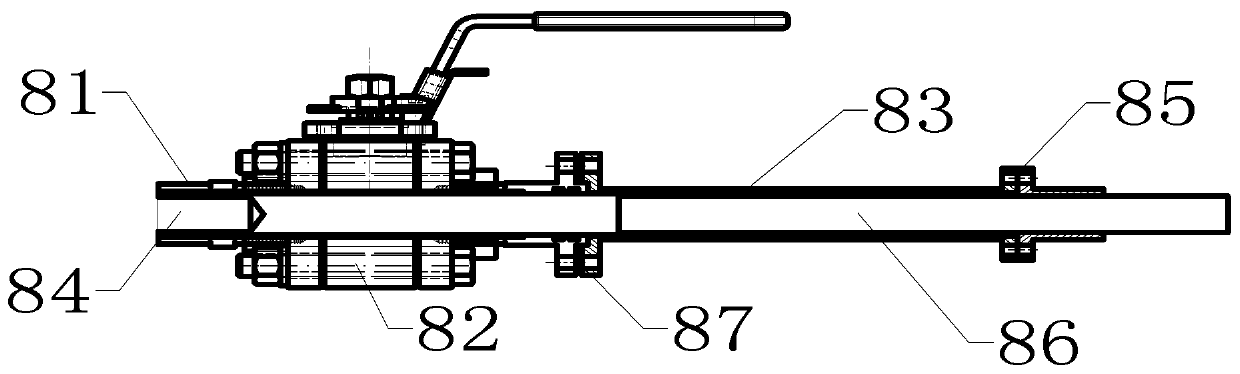

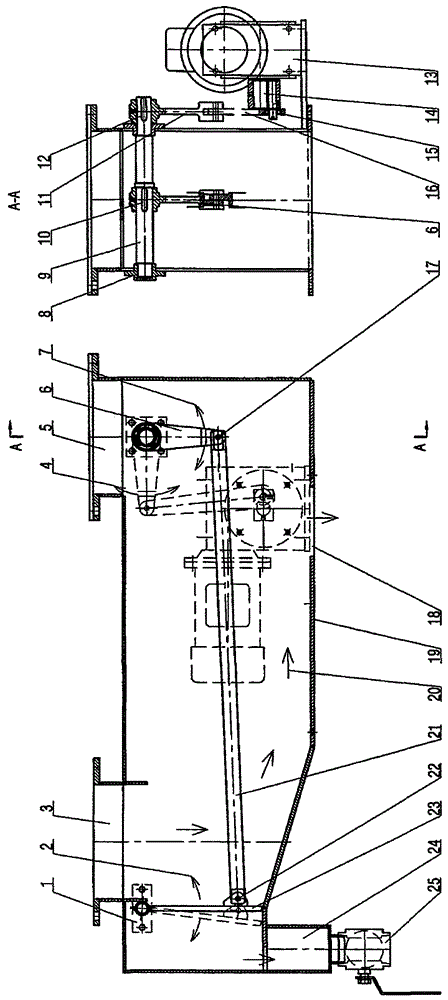

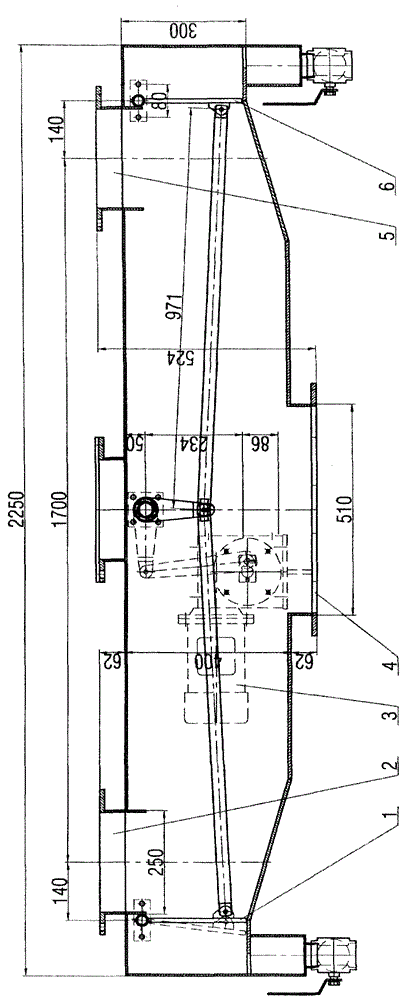

Swing type sealing feeder

InactiveCN104648991AEfficient packagingFeeding volume can be adjustedConveyor partsEngineeringPlain bearing

Owner:焦作市润禾科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap