Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Metal particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A microwave-absorbing corrosion-resistant powder material and a preparation method thereof

InactiveCN108889939AReduce self-healing abilityMaintain electromagnetic propertiesOther chemical processesTransportation and packagingMesoporous silicaMetal particle

The invention discloses a corrosion-resistant powder material capable of absorbing microwave and a preparation method thereof, wherein the powder material is a core-shell structure, the core-shell structure comprises a shell and a core, the shell is a mesoporous silicon dioxide layer, the core is magnetic metal particles, a corrosion inhibitor is filled between the shell and the core, and the particle size of the magnetic metal particles is 0.6 1 micron, is iron carbonyl and nickel carbonyl, or a composite of iron carbonyl and cobalt carbonyl, the weight ratio of iron carbonyl to nickel or cobalt is 8: 1 4: 1. The invention can effectively solve the problems of insufficient microwave absorption and deterioration of corrosion resistance of conventional coatings.

Owner:SHANDONG GEWU NEW MATERIAL TECH CO LTD

Photo-curing conductive adhesive for touch panel

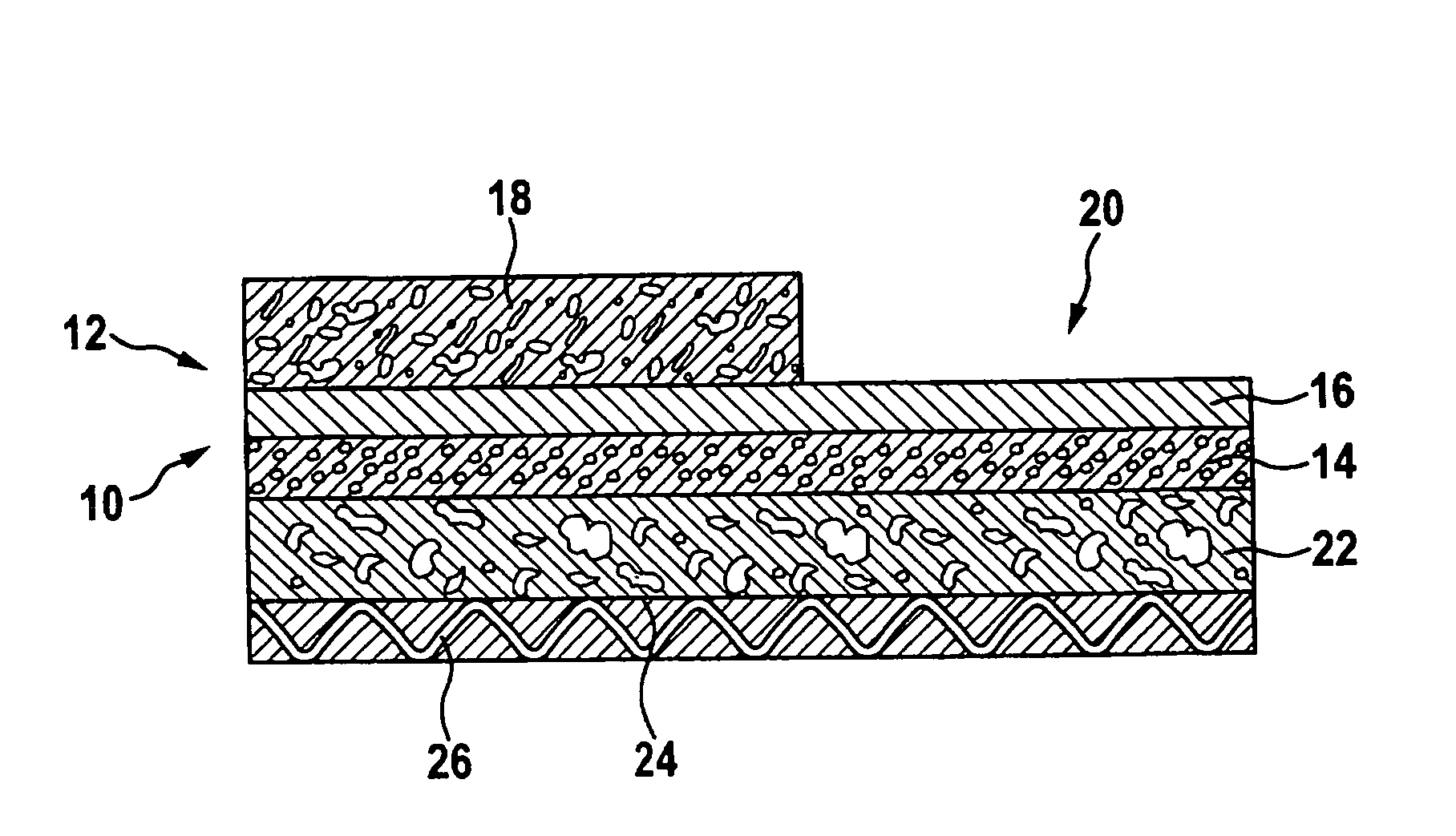

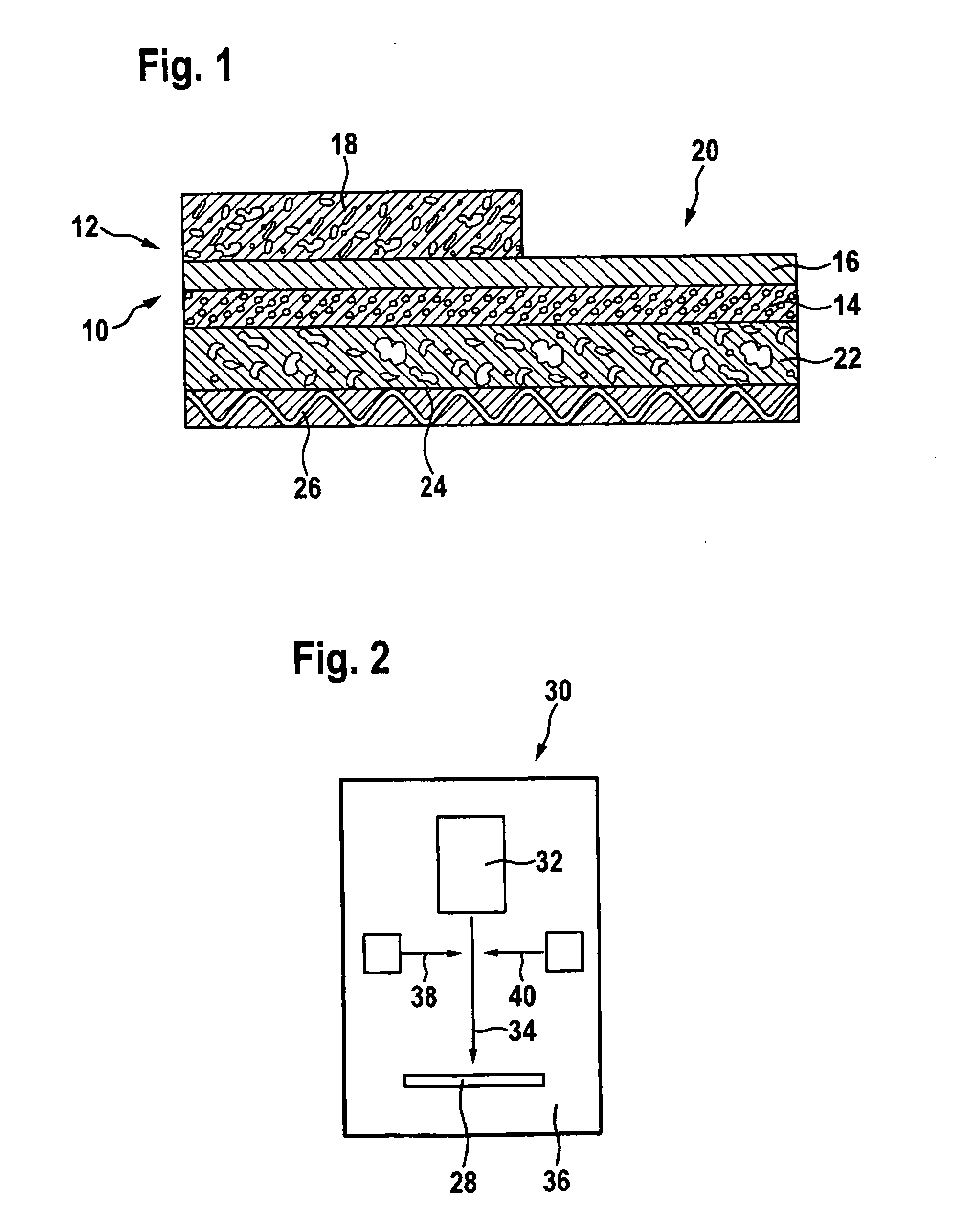

InactiveUS20140284527A1Avoid wasting electricityLow curing temperatureConductive materialEster polymer adhesivesAdhesiveMetal particle

A photo-curing conductive adhesive for a touch panel includes an adhesive in an amount within the range of 20 to 30 wt % and the metal particle composition in an amount within the range of 70 to 80 wt %.

Owner:ETURBOTOUCH TECH

Method of producing a gas-tight solid electrolyte layer and solid electrolyte layer

InactiveUS20100151353A1Improve air tightnessMolten spray coatingFinal product manufactureFuel cellsMetal particle

Owner:DEUTSCHES ZENTRUM FUER LUFT & RAUMFAHRT EV

Method for preparing aluminum particles through rotary cup centrifugal granulation

The invention relates to a method for preparing aluminum particles through rotary cup centrifugal granulation. The aluminum particles are prepared through a granulation device. The device mainly comprises a rotating granulation system used for granulating molten aluminum, an air cooling system used for cooling aluminum drops splashing out during granulation, a metal particle collection structure used for collecting the falling aluminum particles, and an air collection system used for collecting hot air used for cooling the aluminum drops. The method comprises the steps that firstly, heating aluminum ingots, so as to obtain molten aluminum; then, adjusting a driving motor till a rotary cup has the target rotation speed; and pouring molten aluminum into the rotary cup, and starting to carry out granulation to obtain the aluminum particles. According to the method, the porous rotary cup and proper rotation speed are selected, so that the particle size of most of the obtained aluminum particles is guaranteed to be 4 mm to 8 mm as much as possible.

Owner:CHONGQING UNIV

Fabrication method and application method of alumina cement

Owner:LILING XIANGKE WEAR RESISTANT CERAMIC

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap